Table of Contents

Market Insight: Rectangular Enameled Copper Wire

Market Analysis: Rectangular Enameled Copper Wire Demand in Transformer Applications

The global transformer sector represents a dominant and rapidly evolving market for rectangular enameled copper wire (RECW), driven by escalating electrical infrastructure investments, renewable energy integration, and electric vehicle (EV) proliferation. Demand is particularly acute for high-efficiency distribution and power transformers, where RECW’s superior space utilization within windings directly translates to enhanced power density and reduced core losses compared to round wire alternatives. This geometric advantage, maximizing copper fill factor within constrained window areas, is critical for meeting stringent international efficiency standards like IE4 and IE5. Concurrently, the surge in EV charging infrastructure and onboard vehicle transformers necessitates RECW capable of handling higher frequencies and thermal stresses, further intensifying specifications. Industrial automation and data center expansion also contribute significantly, demanding reliable, compact magnetics where RECW is indispensable. This confluence of factors positions RECW as a high-growth segment within the broader winding wire market, with sustained demand projected globally.

Quality parameters for RECW in transformer applications are non-negotiable and directly dictate end-product reliability and operational lifespan. The core requirement is exceptional dimensional precision; strict tolerances on width, thickness, and corner radius (typically ±0.02mm or tighter) are essential to ensure uniform winding tension, prevent insulation damage during coil formation, and achieve optimal thermal management within the core window. Deviations cause air gaps, localized hotspots, and reduced thermal conductivity, accelerating insulation degradation. Equally critical is the enamel insulation system’s integrity. It must provide flawless dielectric strength, withstand high-voltage partial discharges inherent in transformer operation, and maintain adhesion under severe thermal cycling (Class 155, 180, 200, or 220 per IEC 60317). Pinholes, thin spots, or poor thermal stability lead to premature inter-turn or layer-to-layer failures. Copper purity is fundamental; minimum 101% IACS conductivity ensures minimal resistive losses, directly impacting transformer efficiency and operating temperature. Contaminants or inconsistent tempering compromise formability and long-term mechanical stability under electromagnetic forces.

The consequences of substandard RECW are severe and costly. Inferior insulation invites electrical breakdown, causing catastrophic transformer failure requiring expensive replacement and unplanned downtime. Dimensional inaccuracies increase manufacturing scrap rates during winding and compromise thermal performance, forcing derating or reducing the transformer’s operational life expectancy. Poor copper quality elevates I²R losses, directly contradicting efficiency mandates and increasing lifetime energy costs. For transformer manufacturers, sourcing RECW from suppliers with rigorous metallurgical process control, certified testing protocols (e.g., ASTM D2307, IEC 60851), and deep application expertise is not merely a procurement decision but a fundamental risk mitigation strategy. At Luoyang Xinzhaohe Aluminum Co., Ltd., our two decades of specialized focus on high-performance winding wire supply chains ensure RECW meets the exacting thermal, electrical, and mechanical demands of modern transformer design, safeguarding asset integrity and operational efficiency for our global industrial partners. Quality here is measured in decades of service, not just initial cost.

Technical Specs: Rectangular Enameled Copper Wire

Technical Specifications for Rectangular Enameled Copper Wire

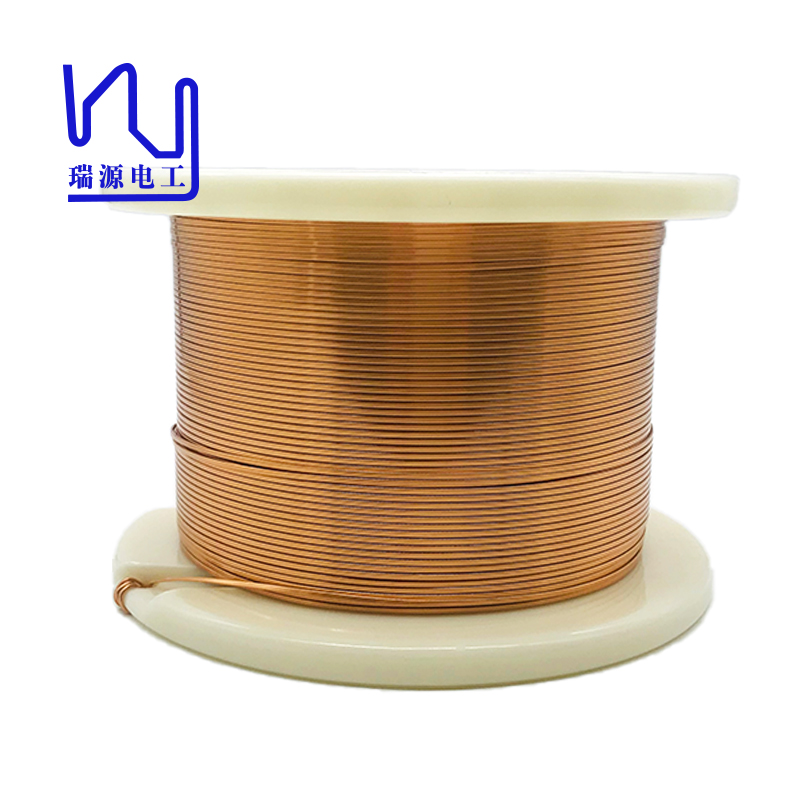

Rectangular enameled copper wire is a precision-engineered winding material designed for high-performance electrical applications, particularly in transformers, motors, generators, and inductors where space efficiency and thermal reliability are critical. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and wire manufacturing expertise, our rectangular enameled copper wire is produced to meet stringent international standards, ensuring consistent electrical, mechanical, and thermal performance.

A key performance indicator for enameled wire insulation is the dielectric breakdown voltage, which reflects the maximum electric field the insulation layer can withstand before electrical failure occurs. Our rectangular enameled copper wire is manufactured with multiple layers of high-purity polymer insulation, typically polyurethane, polyesterimide, or polyamide-imide, depending on the thermal class. The insulation breakdown voltage is tested per IEC 60317 and GB/T 6109 standards, with minimum breakdown values ranging from 3,000 V to over 8,000 V AC, depending on wire dimensions and insulation thickness. This ensures reliable operation in high-voltage windings and prevents inter-turn short circuits under surge conditions.

Elongation, or tensile ductility, is another critical mechanical property, especially during coil winding and shaping processes. Our copper conductors are drawn from high-conductivity electrolytic tough pitch (ETP) copper (Cu ≥ 99.97%) and annealed to achieve optimal softness. The elongation at break is maintained between 15% and 40%, depending on the wire cross-sectional area and temper (typically soft or half-hard). This ensures the wire can withstand bending and forming without cracking the enamel coating or fracturing the core conductor.

Thermal performance is defined by the thermal class rating, which indicates the maximum continuous operating temperature the insulation system can endure over a 20,000-hour service life. Our product line covers thermal classes from 130°C to 220°C, including 155, 180, 200, and 220°C grades. These ratings are achieved through advanced enamel formulations and curing processes, providing long-term thermal stability, resistance to thermal shock, and minimal degradation under thermal cycling.

The following table summarizes the key technical parameters for our standard rectangular enameled copper wire series:

| Parameter | Test Standard | Typical Range / Value |

|---|---|---|

| Conductor Material | GB/T 5231, ASTM B187 | ETP Copper (Cu ≥ 99.97%) |

| Cross-Section (Width × Height) | Custom | 1.60 mm × 4.00 mm to 6.00 mm × 10.00 mm |

| Insulation Material | IEC 60317 | Polyesterimide, Polyamide-imide (PEI-PAI) |

| Thermal Class | IEC 60085 | 130, 155, 180, 200, 220 °C |

| Breakdown Voltage (AC) | GB/T 6109.2 | 3,000 V – 8,500 V (depending on size) |

| Elongation at Break | GB/T 6109.1 | 15% – 40% |

| Resistance to Thermal Shock | GB/T 6109.6 | No cracking at 200–250 °C (depending on class) |

| Adhesion | GB/T 6109.3 | Pass (mandrel winding test) |

These specifications are validated through in-house quality control systems, including continuous monitoring of tensile strength, dimensional accuracy, and insulation continuity. All batches undergo 100% spark testing to ensure defect-free enamel coverage.

Factory Tour: Manufacturing

Manufacturing Process for Rectangular Enameled Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical and winding wire expertise to produce high-reliability rectangular enameled copper wire. Our ISO-certified manufacturing process integrates stringent quality control at every stage, ensuring dimensional precision, electrical integrity, and thermal endurance for demanding motor and transformer applications. The production sequence begins with high-conductivity electrolytic tough pitch (ETP) copper rod, typically 8.0 mm diameter, sourced from certified suppliers meeting IACS 100%+ conductivity standards.

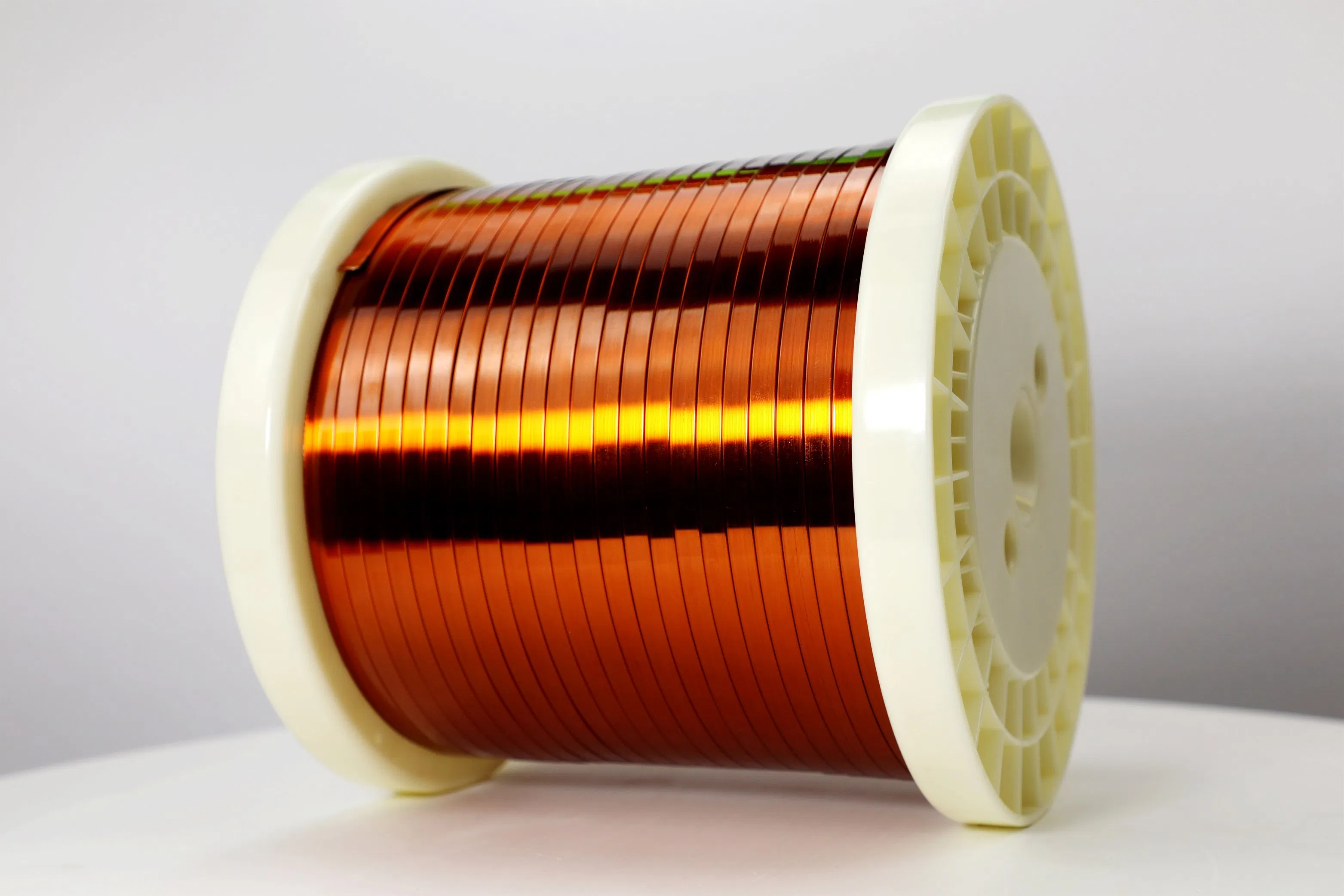

Rod drawing transforms the copper rod into the precise rectangular cross-section required. The rod undergoes progressive reduction through a series of tungsten carbide or diamond dies within a multi-die continuous drawing machine. Critical process parameters include controlled reduction ratio per pass, precise die alignment, and constant lubricant flow to prevent surface defects. Tension control systems maintain uniform elongation, achieving final dimensions within tight tolerances, typically ±0.02 mm on width and thickness. Inline laser micrometers continuously monitor the wire profile, with automatic feedback loops adjusting die positions to maintain cross-sectional geometry. Surface quality is verified via high-resolution optical inspection immediately post-drawing to detect scratches, pits, or irregularities.

The drawn wire then enters a vertical or horizontal continuous annealing furnace. This step is critical for restoring ductility lost during drawing and ensuring the wire meets mandated elongation specifications, usually 10-20% minimum. Annealing occurs in a precisely controlled protective atmosphere, typically a mixture of hydrogen and nitrogen, to prevent oxidation and ensure a clean, oxide-free surface essential for optimal enamel adhesion. Temperature profiles are meticulously calibrated based on wire gauge and speed, with pyrometers monitoring the process in real-time. Post-annealing, conductivity is verified via eddy current testing to confirm restoration to near-theoretical maximum values (≥98% IACS).

Enameling applies the insulating polymer coating through a multi-pass dip-bake process. The wire passes through a precision applicator die immersed in enamel resin, ensuring uniform wet film thickness. Solvent content and viscosity are continuously monitored and adjusted. Each applied layer undergoes immediate curing in high-temperature ovens with precisely controlled temperature zones and residence times to achieve complete polymerization without thermal degradation. Single or double builds are applied depending on the required voltage class, with intermediate cooling between coats. Critical enamel properties like dielectric strength, thermal class (e.g., 180°C, 200°C), and flexibility are governed by resin formulation and cure kinetics.

Comprehensive inline testing occurs throughout the enameling line. A high-voltage spark test (typically 1500-6000 V DC depending on build) detects pinholes or thin spots in the insulation. Tension monitoring ensures mechanical stability during coating. Final quality verification includes destructive testing on production samples: dimensional checks, elongation tests, thermal shock resistance, solderability, and adhesion tests per IEC 60317 standards. Every production reel undergoes 100% spark testing and visual inspection before release, guaranteeing zero-defect delivery for critical electromechanical components. This integrated process control, honed over twenty years, delivers consistent, high-performance enameled wire meeting global industry specifications.

Packaging & Logistics

Export Packaging for Rectangular Enameled Copper Wire – Technical Specification

Luoyang Xinzhaohe Aluminum Co., Ltd. adheres to stringent international export packaging standards for rectangular enameled copper wire to ensure product integrity during long-distance maritime transportation. Given our two decades of experience in the winding wire manufacturing sector, we recognize that effective packaging is not merely logistical—it is a critical component of product performance assurance upon delivery. Our export packaging system is engineered to mitigate environmental exposure, mechanical stress, and contamination risks inherent in sea freight logistics.

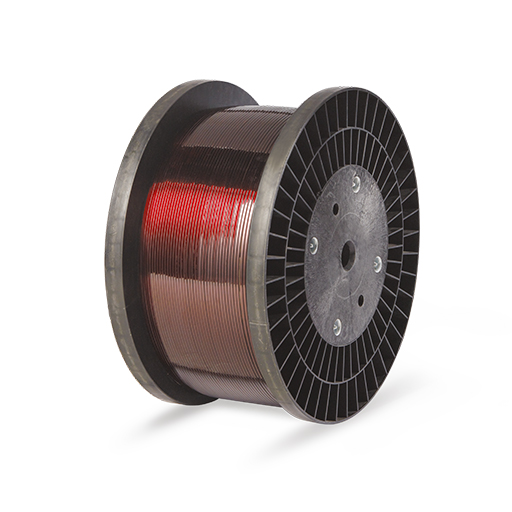

All rectangular enameled copper wire shipments are mounted on high-density wooden pallets constructed from kiln-dried, ISPM-15 certified hardwood. This certification ensures compliance with global phytosanitary regulations, preventing the transmission of wood-borne pests across borders. The wooden base provides structural rigidity, enabling safe stacking and securing within shipping containers. Each pallet is designed to support the total coil weight while maintaining dimensional stability under dynamic load conditions typical during vessel transit, including vibration, acceleration, and lateral shifting.

Coils are wound precisely onto spools made of moisture-resistant composite materials, which are then firmly fixed to the wooden pallet using steel strapping and corner braces. This mechanical immobilization prevents axial or radial movement during transport, minimizing the risk of deformation or insulation damage to the enameled surface. All fastening components are corrosion-resistant to withstand high-humidity environments encountered in maritime shipping lanes.

A multi-layer moisture-proof barrier system is applied to protect against salt-laden air and condensation within containerized cargo holds. The primary protective layer consists of heat-sealed, metallized polyethylene vapor barrier film, which exhibits a water vapor transmission rate (WVTR) of less than 0.5 g/m²/24hr at 38°C and 90% relative humidity. This film fully encapsulates the coil and spool assembly, creating a hermetic seal that prevents moisture ingress. An additional layer of UV-stabilized polyolefin outer wrap provides abrasion resistance and further environmental shielding.

Desiccant packs with a minimum absorption capacity of 120% of their weight in water vapor are placed within the sealed envelope to buffer against internal humidity fluctuations. Relative humidity indicators are affixed inside the packaging to allow for non-invasive monitoring of internal conditions upon receipt.

Labeling is conducted in accordance with international shipping protocols, with each package displaying product specifications, batch numbers, net weight, handling instructions, and orientation arrows. All markings are solvent-resistant and UV-stable to maintain legibility throughout extended transit durations.

This comprehensive packaging methodology has been validated through accelerated climatic testing and real-world shipping trials across major trade routes, including trans-Pacific and Europe-Asia corridors. It reflects our commitment to delivering rectangular enameled copper wire in optimal condition, regardless of destination.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Rectangular Enameled Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and winding wire manufacturing expertise to deliver industry-leading rectangular enameled copper wire solutions. Our technical foundation, built upon rigorous non-ferrous metal processing discipline, ensures exceptional product consistency and performance critical for demanding electromagnetic applications including high-efficiency transformers, traction motors, and industrial generators. We operate as a vertically integrated technical partner, not merely a supplier, providing deep metallurgical insight alongside robust supply chain execution.

Our core strength resides in advanced precision drawing and enameling technology specifically optimized for rectangular profiles. We utilize state-of-the-art continuous annealing systems with precise atmosphere control, ensuring optimal copper grain structure and mechanical properties essential for complex winding geometries without compromising electrical conductivity. The application of multiple enamel layers employs computer-controlled metering dies and advanced infrared curing ovens, guaranteeing uniform coating thickness, exceptional dielectric strength, and superior thermal stability across the entire cross-section. This meticulous process control directly translates to reduced inter-turn faults and extended component lifespan in your final assemblies.

Quality assurance is embedded throughout our production lifecycle. We implement stringent in-process monitoring of critical parameters including dimensional tolerances (width, thickness, corner radius), elongation, thermal shock resistance, and dielectric breakdown voltage per IEC 60317 and customer-specific standards. All batches undergo comprehensive final inspection using calibrated optical measurement systems and high-potential testers. Our metallurgical laboratory conducts regular copper purity verification (minimum 99.97% Cu) and microstructure analysis to validate material integrity. This systematic approach ensures every coil meets the exacting requirements of modern high-density windings.

Key Production Capabilities Summary

| Parameter | Specification Range | Quality Standard Compliance |

|---|---|---|

| Cross-Section Width | 1.00 mm to 10.00 mm | IEC 60317, ASTM B354 |

| Cross-Section Thickness | 0.80 mm to 6.00 mm | Tight Tolerance Control |

| Thermal Class | 155 (F) to 240 (C) | IEC 60851, UL 1446 |

| Enamel System | Polyesterimide, Polyamide-imide | Solvent-Free Options |

| Annual Capacity | 8,000+ Metric Tons | Dedicated Production Lines |

Supply chain resilience is equally paramount. We maintain strategic raw material inventory buffers of high-conductivity electrolytic tough pitch (ETP) copper rod and premium-grade enamels, mitigating market volatility. Our integrated logistics framework utilizes real-time tracking and optimized routing, ensuring on-time delivery performance exceeding 98% globally. We offer flexible packaging configurations, including precision wound reels with customized tension control, minimizing handling damage and maximizing your production line efficiency.

Partner with Luoyang Xinzhaohe to secure a technically proficient, reliable source for mission-critical rectangular enameled copper wire. Our commitment to metallurgical excellence, process precision, and supply chain transparency delivers measurable value through enhanced product reliability and reduced total cost of ownership. Contact our technical sales team to discuss your specific application requirements and receive a detailed capability statement. Initiate your sourcing solution today by emailing Cathy at cathy@transformerstrip.com.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing rectangular enameled copper wire directly from China.