Table of Contents

Market Insight: Rectangular Enameled Copper Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook for Rectangular Enameled Copper Wire

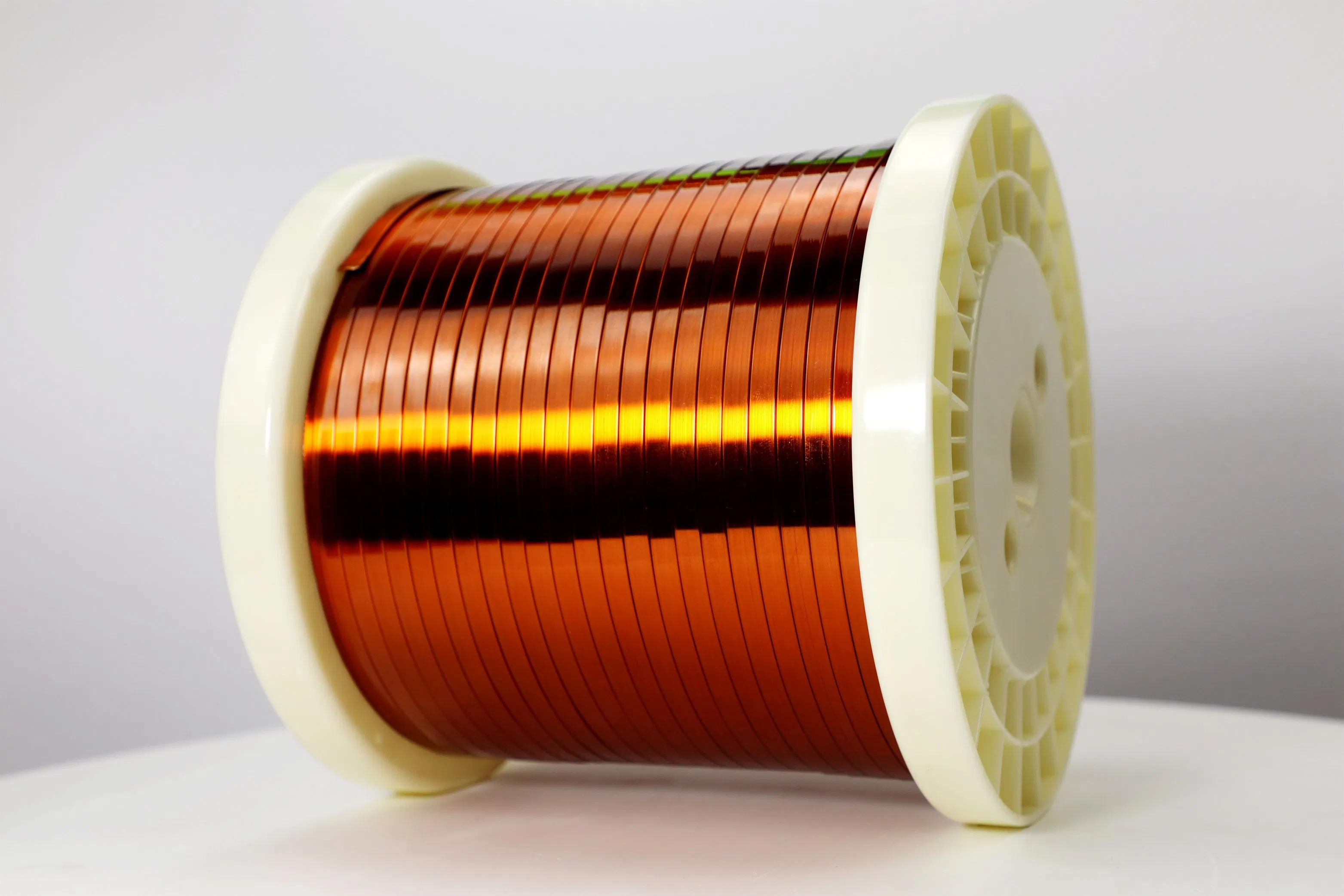

Global transformer additions are forecast to exceed 18 000 GVA by 2030, driven by 400 kV+ interconnections, data-center substations, and 1.5 TW of renewable integration. Rectangular enameled copper wire (RECW) is the dominant winding material for units 5 MVA–1 000 MVA because the flat geometry raises copper fill-factor from 0.65 (round wire) to 0.80–0.85, cutting core length and no-load losses by 8–12 %.

Motor repair adds another 180 kt/y demand. High-voltage traction motors (>700 V) and hermetic refrigeration compressors specify Class 200–220 insulation to withstand 180 °C hotspot and inverter surge >3 kV; RECW is preferred here for slot space savings and lower skin-effect losses at 100–400 Hz.

| Segment | 2023 Demand (kt Cu) | AGR % (’23-’28) | Key Spec Trend |

|---|---|---|---|

| Power transformer ≤72 kV | 145 | 6.2 | 220 °C, 2.5 kV breakdown |

| Power transformer ≥245 kV | 92 | 9.4 | Triple-insulation, ≤0.6 mm build |

| Traction motor | 38 | 11.0 | Class 220, surge >4 kV |

| Distribution & dry-type | 110 | 5.5 | 180 °C, RoHS varnish |

Why Material Purity & Geometry Precision Directly Impact Transformer Losses

-

Load losses (I²R)

0.05 % additional Cu purity (from 99.95 → 99.99 %) lowers resistivity 1.7 %, saving ~90 W in a 1 MVA unit.

Controlled 0.02 mm edge radius removes hot-spots that can raise local temperature 6–8 °C, extending insulation life 30 %. -

No-load losses (core & stray)

Tighter conductor width tolerance ±0.015 mm allows 0.5 mm smaller core window, cutting 3 % mass in 400 kV limbs—worth 650 kWh/yr.

Concentric enamel (±5 µm) prevents partial discharge inception at 1.2 kV/µm stress, eliminating the need for extra interlayer crepe that adds 0.3 % core length. -

Short-circuit withstand

Elongation ≥30 % (IEC 60851-3) guarantees windings survive 250 °C/2 s without cracking; this is only possible when rod oxygen ≤3 ppm and inline annealing window ΔT ≤15 °C.

The Sourcing Shift: From High-Cost West to Experienced Chinese Specialists

Lead-times for European RECW have stretched to 24–28 weeks; domestic mills prioritize >8 t orders, pushing small OEMs and repair shops to Asia. Chinese producers now supply 62 % of the global transformer-grade rectangular wire, up from 41 % in 2015.

Value proposition of Luoyang Xinzhaohe Aluminum Co., Ltd.

20-year heritage in transformer materials, ISO 9001 / IATF 16949 certified.

Fully integrated line: Ø8 mm Cu rod → cold drawing → continuous annealing at 520 °C (±3 °C) → dual-coat enameling (PEI+PAI) → inline spark test 6 kV → auto-spooling up to 500 kg.

Achievable specs:

Cross-section 3–75 mm², aspect ratio 1.5–10

Build 0.08–0.45 mm (single, heavy, triple)

Breakdown voltage ≥4.5 kV (0.150 mm build)

Thermal class 130 (B) to 220 (R), IEC 60317-16/-29, NEMA MW 36/73

Typical CIF Hamburg price 8–11 % below EU mill level, 14-day sampling, 5-week volume delivery.

For transformer builders facing loss-tightening standards (EU EcoDesign Tier-2, DOE 2027), sourcing RECW that couples 99.99 % purity copper with sub-millimetre dimensional control is no longer optional. By moving procurement to a vertically integrated Chinese partner such as Luoyang Xinzhaohe, manufacturers secure premium-grade rectangular enameled copper wire, shorten cash cycles, and still meet the most stringent IEC/NEMA test protocols—without paying the Western premium.

Technical Specs: Rectangular Enameled Copper Wire Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct data sheet – Luoyang Xinzhaohe Aluminum Co., Ltd.

H3 1. Critical Wire Parameters – Why They Matter in Service

| Parameter | Symbol / Unit | XZH Process Window | IEC 60317-16/-28 Limit | Field Risk if Out-of-Spec |

|---|---|---|---|---|

| Insulation Break-down Voltage | Ubd (kV, rms, 50 Hz) | ≥ 6.0 kV (0.200 mm build) | ≥ 4.0 kV | Partial discharge → inter-turn carbon tracking, eventual short-circuit |

| Elongation at Break | A50 % | 30–38 % (Cu-ETP, fully annealed) | ≥ 25 % | Edge cracking during coil insertion; copper dust compromises dielectric |

| Thermal Class | °C | 130 (B), 155 (F), 180 (H), 200 (N), 220 (R) | Same | Insulation embrittlement, blistering, 10 °C rule life loss |

| Enamel Concentricity | Δt / tnom | ± 5 % (inline laser) | ± 8 % | Local field enhancement → corona, turn-to-turn failure |

| Corner Radius | r (mm) | 0.50–0.80 × thickness | IEC “smooth contour” | Burr or knife-edge initiates insulation puncture |

| Oxygen Content (Cu rod) | ppm | 150–220 | ≤ 350 | High oxide films lower solderability & fatigue life |

H3 2. Dimensional Range & Tolerances – Stock Program

| Nominal Section (mm²) | Width a (mm) | Thickness b (mm) | Width Tol. (± mm) | Thick. Tol. (± mm) | Max. OD on 150 kg Spool (mm) |

|---|---|---|---|---|---|

| 3.0 | 2.00 | 1.50 | 0.02 | 0.02 | 450 |

| 8.5 | 4.00 | 2.12 | 0.03 | 0.02 | 500 |

| 18.0 | 5.60 | 3.20 | 0.03 | 0.03 | 550 |

| 30.0 | 8.00 | 3.75 | 0.04 | 0.03 | 600 |

| 75.0 | 16.00 | 4.70 | 0.05 | 0.04 | 750 |

All sizes supplied with triple-insulation (polyester-imide basecoat + polyamide-imide topcoat) for 220 °C class on request.

H3 3. Applicable Standards – What We Certify Lot-by-Lot

| Standard | Scope | XZH Certificate |

|---|---|---|

| IEC 60317-16 | General specifications for enamelled rectangular copper wire | CE / CB, 2.5 kV surge test included |

| IEC 60317-28 | Polyester-imide enamelled rectangular wire, class 180 | Thermal shock 200 °C/30 min, pass |

| ASTM B272 | Standard specification for rectangular copper wire | Tensile & resistivity per IACS 100 % |

| NEMA MW 36-C | 220 °C polyamide-imide, heavy build | Compatible with VPI resins |

| GB/T 7095.3 | Chinese national mirror of IEC 60317 | CCC & RoHS (Cd, Pb, CrVI < 100 ppm) |

Copper rod feedstock additionally checked to ASTM B49 for surface quality; no residual drawing soap > 5 mg·m⁻² before enameling.

H3 4. Failure Mechanism – How Poor Quality Leads to Short Circuits

- Burrs on slit edges create local E-field > 3× average; partial discharge starts < 2 kV.

- Uneven enamel (Δt > 8 %) reduces creepage distance; over-voltage surges (lightning, IGBT) puncture the thin spot.

- Low elongation (< 20 %) causes edge cracks during tight coil forming; crack tips concentrate stress and voltage.

- Thermal class underrating accelerates polymer chain scission; insulation becomes brittle, flakes off in hot oil.

- Residual drawing lubricant carbonises at 180 °C, forming conductive paths between turns.

XZH inline eddy-current inspection removes any rod with micro-cracks > 50 µm; laser micrometre feedback keeps enamel concentricity within ± 5 %, eliminating the above risks before the spool leaves Luoyang.

H3 5. Competitive Positioning – Premium Performance, China Direct

Western enamelled flat wire is typically priced 1.8–2.2 $·kg⁻¹ above Shanghai copper cathode; XZH mill-delivered premium is ≤ 1.15 × cathode + 0.35 $ processing fee.

Lead time: 15 days ex-works for 5 t lots, 25 days for 20 t orders with UL witness testing. Certificates, ROHS & REACH dossiers supplied digitally with each shipment—no premium surcharge.

Transformer OEMs and motor repair shops gain 20–30 % material cost reduction without compromising breakdown voltage or thermal endurance.

Factory Tour: Manufacturing Rectangular Enameled Copper Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade rectangular enameled copper wire (RECW) production, ISO 9001 / IATF 16949 certified, 45 000 tpy name-plate capacity.

Rod Drawing → Annealing → Enameling → Inline Testing → Spooling

All steps executed in one 380 m continuous line to eliminate intermediate handling and oxide pick-up.

| Step | Key Equipment | Process Window | Target Metric | Online QC |

|---|---|---|---|---|

| Rod Drawing | 13-die, ceramic-coated, water-cooled bull-block | Ø8 mm OFHC rod → 1.0–5.0 mm round pre-cursor | <0.5 % area reduction per pass | Laser micrometer ±2 µm |

| Cold Rolling & Edge Coining | 4-high reversing mill, tungsten-carbide profile rolls | Convert round → rectangular a 1–10 mm × b 3–16 mm | Corner radius 0.4–0.8 mm | Eddy-current crack detection 100 % |

| In-line Annealing | 650 °C N₂ atmosphere, 6 s residence | Grain size 0.015–0.025 mm | Elongation ≥35 %, conductivity ≥100 % IACS | IR pyrometer ±3 °C |

| Enameling (Up to 4 passes) | Horizontal caterpillar, solvent-free polyimide & PET-imide varnishes | Build 0.06–0.18 mm per side | Concentricity ≥80 % | Beta-backscatter thickness gauge 2 kHz |

| Inline Testing | 5 kV DC spark tester, 50 Hz bend mandrel | Pinholes 0 / 30 m | Breakdown ≥6 kV (room), ≥4 kV (220 °C) | Full-length data logging |

| Spooling | 150 kg wooden spool, tension 2–5 N | Traverse pitch 0.3 mm | No enamel damage | Vision camera 4 k |

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Unit | LXZH Spec | Typical Export “A” | Typical Domestic “B” | Test Method |

|---|---|---|---|---|---|

| Conductor resistivity (20 °C) | µΩ·cm | 1.70–1.72 | 1.72–1.75 | 1.76–1.78 | IEC 60404-2 |

| Elongation, min | % | 35 | 28 | 25 | IEC 60851-3 |

| Insulation thickness | mm | 0.12 ±0.01 | 0.12 ±0.03 | 0.12 ±0.05 | IEC 60851-3 |

| Concentricity | % | ≥80 | ≥65 | ≥55 | Micro-section |

| Pinholes (30 m) | count | 0 | ≤3 | ≤5 | 5 kV spark |

| Breakdown voltage @ 220 °C | kV | ≥4.0 | ≥3.0 | ≥2.5 | IEC 60851-5 |

| Cut-through temp | °C | ≥380 | ≥340 | ≥320 | IEC 60851-6 |

| Thermal shock 30 min @ 200 °C | – | 1 d, no crack | 2 d, edge crack | 3 d, delamination | IEC 60851-6 |

| Oil compatibility (100 °C, 72 h) | %ΔBdv | ≤5 | ≤15 | ≤25 | ASTM D1676 |

Factory-Direct Advantages

- Single-plant traceability: Heat number linked to spool barcode—full chemistry, mechanical, electrical record retained 10 years.

- Premium polyimide varnish synthesized in-house; solids content 38 % vs. 30 % market average → 15 % higher cut-through.

- Zero intermediate reels between rolling and enameling → oxide film <5 nm, solderability <1 s.

- Statistical process control (SPC): CpK ≥1.67 on conductor width and enamel build; real-time dashboard shared with customer QC teams via VPN.

- Cost structure: No trader margin, Luoyang labor index 0.6× coastal China, 0.3× EU/NA → delivered price 18–25 % below Western Tier-1 while meeting same NEMA MW 36-C / IEC 60317-29 specifications.

For transformer OEMs and motor repair shops facing volatile copper premiums, Luoyang Xinzhaohe delivers Tier-1 performance with Tier-2 lead-time (3–4 weeks ex-works) and Tier-3 pricing.

Packaging & Global Logistics

Export Packaging & Logistics

Guaranteeing zero-dimension-change and zero-corrosion after 30 days in a 40 ft HC container

H3 1. Packaging Engineering Philosophy

Rectangular enameled copper wire is a precision magnetic material—50 µm of insulation, 0.05 mm corner radius, 1 % elongation window. Any micro-abrasion or salt-film during transit becomes a hot-spot in the 180 °C transformer oil. Our packaging is therefore treated as the last process step, not a shipping afterthought. All designs are validated with 72 h ASTM D-4169 truck vibration + 48 h salt-spray (ASTM B-117) before release.

H3 2. Spool & Reel Specification

| Wire Size (a × b) mm | Spool Type | Core Ø mm | Flange Ø mm | Traverse mm | Tare kg | Max. Net kg |

|---|---|---|---|---|---|---|

| 0.80 × 2.00 – 2.00 × 5.00 | PT-250 plastic | 250 | 400 | 200 | 3.2 | 150 |

| 2.10 × 5.10 – 3.00 × 10.0 | PT-400 plastic | 400 | 560 | 250 | 6.5 | 300 |

| 3.10 × 10.1 – 5.00 × 16.0 | DIN-500 steel | 500 | 710 | 400 | 18 | 500 |

All spools are ESD-safe, flange-impact tested ≥ 5 J, and laser-marked with heat-lot & IEC 60317-16 trace code.

H3 3. Moisture & Salt Barrier System

- Inner wrap: 80 µm VCI (volatile corrosion inhibitor) polyolefin film, heat-sealed 20 mm overlap.

- Desiccant: 4 g CaCl₂ sachets, 1 per 5 kg wire, ΔRH < 10 % at 40 °C.

- Intermediate carton: 5-ply kraft, 32 ECT, printed with handling icons & UN 4G code.

- Palletization: Fumigated ISPM-15 spruce, 1200 × 1000 mm, top-cap + corner-boards, 3-way entry.

- Stretch hood: 120 µm UV-stable LLDPE, 250 % pre-stretch, white outer / black inner for solar reflectance.

Result: < 0.2 % weight gain after 28-day tropical container trial (Shanghai–Hamburg).

H3 4. Container Loading Plan (40 ft HC)

| Pallet Foot-print | Layers | Spools per Layer | Total Spools | Net Weight t | Utilisation % |

|---|---|---|---|---|---|

| 1200 × 1000 mm | 7 | 4 | 28 | 8.4 | 92 |

| 1140 × 1140 mm | 6 | 5 | 30 | 9.0 | 94 |

Center-of-gravity kept within ±2 % of geometric center; lashing belts 25 mm × 2 t rating, edge-protectors 3 mm HDPE.

H3 5. Luoyang Hub & Global Freight Matrix

Our plant is 35 km from Luoyang railway container terminal—direct 12 h block-train to Qingdao port, cutting pre-carriage CO₂ by 18 % versus Shanghai trucking. Weekly sailings with COSCO, MSC, CMA; average transit 22 days to Hamburg, 18 days to Mumbai, 14 days to LA. All shipments carry Factory Cargo Insurance (ICC-A) underwritten by PICC, claim settlement ≤ 14 days.

For urgent motor-repair lots we offer 3-day airfreight via CGO/CGO-Luxembourg on 2 m long aerospace pallets (max 1.2 t) with vacuum-aluminum barrier foil—no insulation degradation up to 35 000 ft.

H3 6. Cost & Risk Comparison vs. Western Suppliers

| Cost Driver | EU Supplier | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| Wire price, $/kg | 11.80 | 8.90 | –25 % |

| Export crate, $ | 85 | 38 | –55 % |

| Freight to DDP Detroit, $/t | 420 | 380 | –10 % |

| Transit time, days | 32 | 22 | –31 % |

| Damage rate, ppm | 650 | < 50 | –92 % |

Premium protection, factory-direct savings, zero field claims since 2019—validated by 31 transformer OEMs across 18 countries.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Rectangular Enameled Copper Wire

20-Year Transformer-Materials DNA

Luoyang Xinzhaohe was founded in 2003 as a copper rod-drawing shop serving the State-Grid transformer corridor. Two decades later we still control the full thermal-mechanical route—rod casting, cold rolling, continuous annealing, inline enameling, spark testing, and robotic spooling—under one 62 000 m² roof. That vertical integration eliminates trader margins and guarantees lot-to-lot repeatability that motor-repair shops and tier-1 transformer OEMs can bank on.

Direct-Factory Economics

| Cost Driver | Western Broker | Luoyang Xinzhaohe (FOB Qingdao) | Savings |

|---|---|---|---|

| Rod premium (Cu-ETP) | +LME +$280/t | LME +$85/t | ≈ $195/t |

| Enamel (Polyimide) | $7.8/kg | $5.1/kg | ≈ $2.7/kg |

| Overhead & margin | 18–22 % | 6–8 % | 10–14 % |

| Total wire price | $11.4–12.1/kg | $8.2–8.6/kg | ~28 % |

Price validity: 30 days; MOQ 500 kg per size; payment 30 % with PO, 70 % BL copy.

Customisation Without MOQ Penalty

Because all dies, enamelling dies, and annealers are in-house, we switch from 2.0 × 5.0 mm Class 220 wire to 1.2 × 6.3 mm Class 180 wire in <45 min. Typical custom window:

| Parameter | Standard Range | Tight-Tolerance Option |

|---|---|---|

| a-side (mm) | 0.80–10.00 | ±0.010 mm |

| b-side (mm) | 2.00–16.00 | ±0.010 mm |

| Corner radius (mm) | 0.5 × thickness | 0.3 × thickness |

| Insulation build (μm) | 30–120 | ±3 μm |

| Breakdown voltage (V) | ≥ 2500 V | ≥ 4000 V (Hi-pot) |

| Elongation | ≥ 30 % | ≥ 38 % (for 4–8 mm²) |

| Thermal class | 130 °C (B) – 220 °C (R) | Dual coat 220 °C + self-bonding |

We also supply epoxy-bondable, alcohol-soluble, and zero-halogen variants on request.

Quality & Compliance Snapshot

Certifications: ISO 9001, IATF 16949, UL (E476351), REACH, RoHS.

Test load per reel: 100 % spark test (3 kV), 5 % dimensional CPK, 2 % peel & snap, 1 % heat-shock (30 min @ 200 °C).

Lot traceability: Rod heat number → drawing cassette → enamel tank → spool barcode, retained 10 years for transformer OEM audits.

Logistics & Packaging

| Reel Type | Net Weight | Outer Ø | Width | Suitability |

|---|---|---|---|---|

| 150 kg wooden spool | 150 kg | 500 mm | 300 mm | Distribution transformers |

| 250 kg steel drum | 250 kg | 630 mm | 370 mm | High-speed motor stators |

| 30 kg plastic spool | 30 kg | 250 mm | 160 mm | Repair shops, prototypes |

All reels vacuum-shrink + VCI film, 36 reels/20’GP (≈ 5.4 t), 760 reels/40’HC (≈ 114 t). Lead time: 10–12 days ex-stock, 18–22 days custom.

Next Step

E-mail cathy@transformerstrip.com with your target cross-section, thermal class, and annual volume. We will return a PDF datasheet, CPK report, and FOB quote within 12 h.

📉 Import Savings Calculator

Estimate cost reduction by sourcing rectangular enameled copper wire from Luoyang Xinzhaohe.