Table of Contents

Market Insight: Rectangular Copper Wire

Market Analysis: Winding Wire – Industrial Demand for Rectangular Copper Wire in Transformers

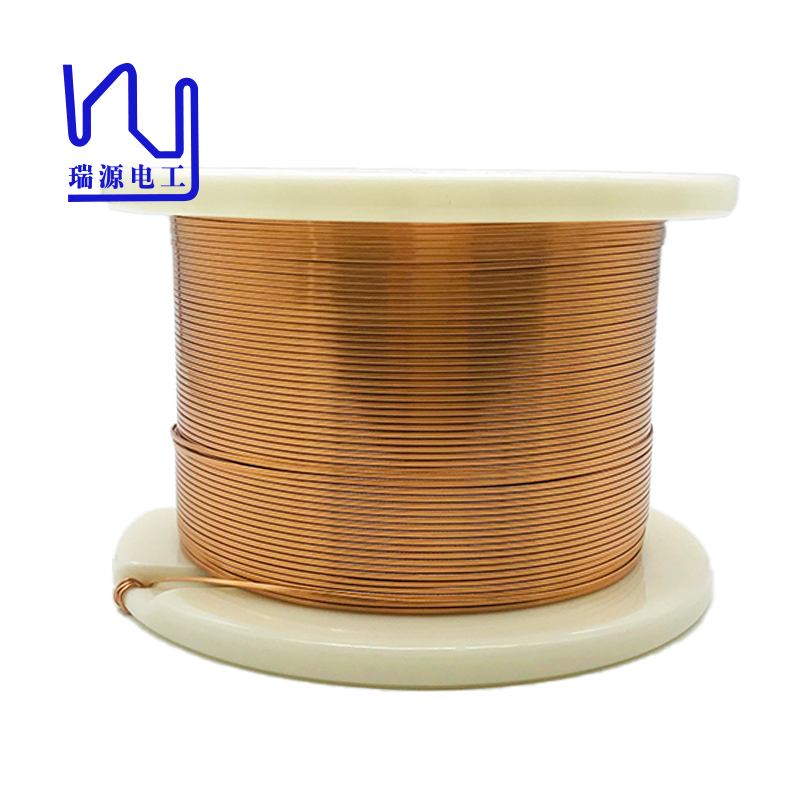

The global demand for rectangular copper winding wire continues to grow, driven by the expanding needs of power transmission and distribution infrastructure, renewable energy integration, and industrial electrification. Among the core applications, power and distribution transformers represent one of the most significant end-use segments. Rectangular copper wire is preferred in these applications due to its superior space utilization in transformer windings, enhanced thermal performance, and mechanical stability under electromagnetic forces. The geometry of rectangular conductors allows for tighter coil packing, increasing the copper fill factor and improving the overall efficiency of the transformer.

In recent years, regulatory standards and energy efficiency directives—such as the IEC 60076 series and DOE efficiency mandates—have intensified the demand for high-performance transformer designs. These standards necessitate reduced no-load and load losses, which can only be achieved through optimized winding materials. High-purity electrolytic tough pitch (ETP) copper with precise dimensional tolerances and consistent mechanical properties is essential to meet these performance benchmarks. As a result, manufacturers and utilities are increasingly scrutinizing the quality of copper winding wire supplied to transformer OEMs.

Quality directly impacts transformer reliability, service life, and operational safety. Variations in cross-sectional dimensions, surface finish, or mechanical strength can lead to localized hotspots, increased eddy current losses, and premature insulation degradation. Poorly manufactured wire may also exhibit inconsistent elongation or tensile strength, increasing the risk of deformation during winding or failure under short-circuit conditions. At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of experience in non-ferrous metal processing and winding wire production, we emphasize metallurgical purity, precision drawing, and rigorous quality control throughout the manufacturing process.

Our rectangular copper wire is produced under strict ISO 9001-certified procedures, ensuring compliance with IEC 60137 and GB/T standards. Each batch undergoes dimensional inspection, electrical conductivity testing (minimum 100% IACS), and mechanical property validation to guarantee performance consistency. The surface is smooth and free of defects to prevent insulation damage during winding—a critical factor in high-voltage transformer applications.

As the energy sector transitions toward smart grids and higher-efficiency equipment, the role of high-quality rectangular copper wire becomes increasingly strategic. Transformer manufacturers must source materials that not only meet technical specifications but also support long-term durability under fluctuating loads and environmental stresses. Partnering with a reliable supplier that combines technical expertise, process control, and material traceability is therefore essential to remain competitive in today’s demanding market. Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted provider of precision copper winding solutions, supporting the advancement of efficient and resilient power systems worldwide.

Technical Specs: Rectangular Copper Wire

Technical Specifications for Rectangular Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise and supply chain precision to deliver rectangular copper winding wire meeting stringent industrial demands. Critical technical parameters must align with application-specific electrical, mechanical, and thermal requirements to ensure reliability in motors, transformers, and high-efficiency generators. Key specifications include insulation breakdown voltage, elongation, and thermal class, each directly impacting winding integrity, processability, and operational lifespan.

Insulation breakdown voltage defines the dielectric strength of the enamel coating, measured in kilovolts (kV). This parameter ensures the wire withstands voltage surges without insulation failure, preventing short circuits. Values are validated per IEC 60851-5 using a 1 kV/s ramp rate on wound test coils. Minimum breakdown voltage must exceed the application’s peak operating voltage by a safety margin; underspecification risks catastrophic insulation failure under transient conditions. Elongation, expressed as a percentage, quantifies the wire’s ductility during winding operations. It is tested per IEC 60851-6 on a 25 mm gauge length. Adequate elongation (typically 8–40%) prevents cracking of both the copper conductor and insulation when subjected to bending stresses during coil insertion. Low elongation values correlate with brittle conductors prone to breakage, increasing scrap rates in automated winding lines. Thermal class, denoted in degrees Celsius (°C), specifies the maximum continuous operating temperature the insulation system can endure without significant degradation. This rating—determined via IEC 60172 thermal aging tests—dictates the wire’s suitability for high-temperature environments. Crucially, thermal class refers to the insulation system, not the copper conductor, which maintains conductivity up to 1083°C but is limited by insulation stability.

The following table details standard parameter ranges for rectangular copper winding wire supplied by Luoyang Xinzhaohe Aluminum Co., Ltd:

| Parameter | Standard Range | Test Method | Application Significance |

|---|---|---|---|

| Insulation Breakdown Voltage | 3.0–8.0 kV (min) | IEC 60851-5 | Ensures dielectric integrity under operational voltage stress; critical for high-voltage motors and EV traction systems |

| Elongation | 12–35% (soft temper) | IEC 60851-6 | Enables tight-radius winding without conductor fracture; essential for complex coil geometries |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60172 | Determines maximum ambient + load temperature; higher classes (e.g., 200°C, 220°C) enable compact, high-power-density designs |

| Dimensional Tolerance | ±0.02 mm (width/thickness) | IEC 60123 | Guarantees precise fill factor in stator slots; deviations cause winding voids or mechanical stress |

Misinterpretation of thermal class poses significant risks; a 220°C (Class C) wire cannot operate continuously at 220°C but withstands this temperature for 20,000 hours with <50% loss in mechanical properties. Similarly, breakdown voltage must be verified at the wire’s thinnest insulation point—typically at edges in rectangular profiles—where field concentration is highest. At Luoyang Xinzhaohe, all parameters undergo 100% inline monitoring during enameling and tempering, with batch certification per ISO 9001 protocols. Our supply chain integrates copper purity control (99.99% min, oxygen-free) with multi-layer insulation co-extrusion, ensuring consistency across 0.8×2.5 mm to 6.0×12.0 mm cross-sections. Engineers must prioritize these interdependent specifications to optimize winding yield, thermal management, and end-product reliability in demanding industrial applications.

Factory Tour: Manufacturing

Manufacturing Process of Rectangular Copper Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance rectangular copper winding wire at Luoyang Xinzhaoang Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, electrical integrity, and mechanical reliability. With over two decades of metallurgical and process engineering expertise, our facility integrates precision equipment with rigorous quality control protocols across four core stages: rod drawing, annealing, enameling, and inline testing.

The process begins with high-conductivity electrolytic tough pitch (ETP) copper rod, sourced from certified suppliers and verified for purity (minimum 99.95% Cu) and oxygen content (200–400 ppm). The rod undergoes precision cold drawing through a series of tungsten carbide or diamond dies to achieve the specified rectangular cross-section. This stage is critical for controlling dimensional tolerances, surface finish, and mechanical strength. Drawing parameters—including reduction ratio, lubrication flow, and line speed—are continuously monitored to prevent microcracking and ensure uniform deformation across the cross-section.

Following drawing, the wire enters a continuous annealing furnace operating under a controlled nitrogen-hydrogen atmosphere to prevent oxidation. The annealing profile is precisely calibrated based on wire gauge and alloy composition to achieve the target temper—typically soft (annealed) for enhanced formability during coil winding. Temperature uniformity, dwell time, and cooling rate are tightly regulated to ensure consistent grain structure and electrical conductivity, which is maintained at or above 100% IACS (International Annealed Copper Standard).

The next phase is enameling, where the annealed wire is coated with one or more layers of polymer insulation—commonly polyurethane, polyester, or polyamide-imide—depending on the thermal class (e.g., 130°C, 155°C, 180°C, or 200°C). The wire passes through a series of coating dies and curing ovens in a continuous process. Each layer is applied with micron-level thickness control to ensure dielectric strength and thermal stability. Multiple passes may be required for dual or triple insulation systems, with intermediate UV curing or thermal cross-linking to enhance coating adhesion and mechanical durability.

Throughout the production line, inline testing systems provide real-time quality assurance. These include spark testing at 1.5–6 kV to detect pinholes or insulation defects, laser micrometry for continuous dimensional monitoring, and tension control systems to prevent elongation or deformation. Final quality control includes sampling for elongation, springback, thermal shock resistance, and dielectric breakdown voltage per IEC 60317 and GB/T 6109 standards.

All process parameters are logged and traceable to batch numbers, ensuring full production transparency. Luoyang Xinzhaohe Aluminum Co., Ltd maintains ISO 9001 and IATF 16949 certifications, underscoring our commitment to consistency, reliability, and technical excellence in every meter of rectangular copper winding wire produced.

Packaging & Logistics

Export Packaging Protocol for Rectangular Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols to ensure rectangular copper winding wire arrives at global destinations with uncompromised metallurgical integrity and dimensional precision. With over two decades of specialization in conductor manufacturing, we recognize that inadequate packaging directly correlates with field failures, corrosion, and coil deformation—particularly during extended sea freight transits. Our system mitigates these risks through material science-driven design and adherence to international logistics standards.

All rectangular copper wire coils undergo consolidation onto custom-engineered wooden pallets compliant with ISPM-15 regulations for international phytosanitary safety. These pallets utilize kiln-dried, knot-free hardwood with a minimum load-bearing capacity of 2,500 kg per unit. Structural reinforcement includes double-stringer construction and galvanized steel strapping channels to prevent torsional flexing during container stacking. Pallet dimensions strictly align with ISO container internal measurements (2,330 mm x 1,165 mm for 20ft units) to maximize cube utilization while eliminating lateral movement. Crucially, pallet bases incorporate elevated runners to isolate coils from container floor moisture and facilitate forklift handling under all port conditions.

Moisture ingress remains the primary threat to copper conductivity and surface quality during ocean transport. Our multi-barrier protection system begins with vacuum-sealed polyethylene wrapping of individual coils at 125-micron thickness, followed by desiccant placement at coil core and periphery. The primary moisture shield consists of triple-layer co-extruded film (150-micron total thickness) featuring aluminum oxide vapor deposition. This material achieves a water vapor transmission rate (WVTR) of ≤0.1 g/m²/24hr at 38°C/90% RH—exceeding ASTM F1249 standards for tropical maritime environments. Film seams are thermally welded with 15-mm overlap integrity verified via helium leak testing.

Coil securing employs tension-calibrated polyester straps (5,000 kg break strength) anchored to pallet cleats at 45-degree angles, preventing radial displacement during 1.5G acceleration events. Each strapped unit receives an external corrugated weatherproof jacket rated for 14-day salt spray exposure per ASTM B117. Critical handling parameters are documented on tamper-evident labels including:

Maximum stack height (3 tiers)

Humidity threshold (≤65% RH)

Shock impact limits (≤50G)

This integrated approach has reduced moisture-related claims by 92% across 8,200+ TEUs shipped since 2018. Independent validation through SGS maritime simulation testing confirms coil surface oxidation remains below 0.05 mg/cm² after 45-day voyages across Pacific and Atlantic routes. For procurement teams, this translates to guaranteed dimensional stability (±0.02 mm tolerance retention) and maintained electrical resistivity (≤1.7241 μΩ·cm at 20°C). We provide full packaging schematics and material certifications upon request to align with your logistics compliance frameworks.

The total landed cost advantage of our packaging methodology manifests in eliminated rework, zero corrosion write-offs, and accelerated customs clearance via standardized documentation. Partnering with Xinzhaohe ensures your copper winding wire supply chain operates with metallurgical certainty from factory to winding machine.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Premium Rectangular Copper Winding Wire

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the production of high-precision rectangular copper winding wire for industrial and power transmission applications. Our core expertise lies in delivering electrically efficient, dimensionally accurate, and mechanically robust copper conductors tailored to the demanding requirements of transformers, reactors, motors, and high-current electrical systems.

Our production facility integrates advanced drawing, annealing, and shaping technologies to ensure consistent quality across all product batches. We utilize high-purity electrolytic copper (minimum 99.99% Cu) sourced from certified refineries, ensuring optimal electrical conductivity and thermal stability. Each rectangular wire profile undergoes rigorous dimensional control, with tolerances maintained within ±0.02 mm on thickness and ±0.05 mm on width, meeting or exceeding IEC 60317, GB/T 7673, and ASTM B357 standards.

The manufacturing process is supported by a fully integrated quality management system, with in-line monitoring at every stage—from raw material inspection to final packaging. Our quality assurance protocols include continuous conductivity testing (minimum 98% IACS), tensile strength evaluation, elongation verification, and surface finish inspection to prevent insulation damage during winding operations. All coils are wound under controlled tension to minimize residual stress and deformation, ensuring smooth integration into automated winding lines.

Luoyang Xinzhaohe operates a 30,000-square-meter production base equipped with state-of-the-art drawing lines capable of producing rectangular copper wires ranging from 1.0 mm × 3.0 mm up to 10.0 mm × 16.0 mm in cross-section. We support both soft-annealed (fully annealed) and hard-drawn tempers, with insulation options including bare, varnished (polyurethane, polyester, or epoxy), and glass-fiber wrapped configurations. Custom spooling, tagging, and packaging solutions are available to meet specific logistics and handling requirements.

Our technical team provides comprehensive application support, including cross-sectional optimization, resistance calculation, and thermal performance modeling to assist engineers in achieving maximum efficiency in their electromagnetic designs. This engineering-first approach has enabled long-term partnerships with transformer OEMs, traction motor manufacturers, and renewable energy system integrators across Asia, Europe, and North America.

As global demand for high-efficiency electrical systems continues to grow, Luoyang Xinzhaohe remains committed to innovation, precision, and supply chain reliability. We offer competitive lead times, scalable production capacity, and strict adherence to international export standards, ensuring seamless integration into your procurement workflow.

For technical inquiries or to request a sample-based quotation, contact us at cathy@transformerstrip.com. Let Luoyang Xinzhaohe Aluminum Co., Ltd be your strategic partner in high-performance rectangular copper winding wire solutions.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing rectangular copper wire directly from China.