Table of Contents

Market Insight: Rectangular Copper Wire in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers for Rectangular Copper Wire

The global transition to renewable energy and electrified transportation has intensified demand for high-efficiency transformers and motors. Rectangular copper wire is critical for maximizing space utilization in windings, achieving up to 95% fill factor compared to 80% for round wire. This directly reduces I²R losses by 3-7% in distribution transformers, enabling compliance with IE4/IE5 efficiency standards. Key applications include:

| Application | Key Requirements | Rectangular Wire Advantage |

|---|---|---|

| Distribution Transformers | High current density, thermal stability | 95% fill factor; 3-7% lower copper losses |

| EV Traction Motors | Compact design, mechanical durability | Optimized slot utilization for higher torque density |

| Power Transformers (HV) | Precision winding, dielectric strength | Uniform geometry for consistent insulation coating |

Material Quality Impact on Efficiency

Material defects directly compromise transformer and motor longevity:

Conductivity below 99.9% IACS increases resistive losses by 2-5%, accelerating insulation aging and reducing operational lifespan by up to 30%.

Dimensional inconsistencies (±0.03mm tolerance) cause uneven winding tension, creating localized hotspots that initiate partial discharges.

Surface scratches or burrs damage insulation coatings, leading to dielectric breakdown under high-voltage stress.

Oxygen content exceeding 15 ppm causes copper embrittlement during forming, resulting in micro-cracks that propagate under thermal cycling.

| Parameter | Consequence | Standard |

|---|---|---|

| Conductivity <99.9% IACS | 2-5% higher I²R losses; 30% shorter lifespan | IEC 60317-0-1 |

| Dimensional Tolerance ±0.03mm | Hotspots; insulation failure | ASTM B187 |

| Surface Defects | Partial discharges; dielectric breakdown | ISO 10135 |

| Oxygen Content >15 ppm | Embrittlement; micro-cracks | ASTM B170 |

Luoyang Xinzhaohe: Strategic Supply Chain Partner

With over two decades of experience in transformer materials manufacturing, Luoyang Xinzhaohe delivers factory-direct rectangular copper wire that balances cost and performance. Our vertically integrated production chain—from raw material sourcing (certified 99.95% pure copper) to precision rolling and annealing—ensures consistent quality. All products meet IEC 60317, ASTM B187, and GB/T 11019 standards, with 99.5% QC pass rate verified through automated conductivity testing and surface inspection systems.

| Metric | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost | 15-25% premium | 10-15% lower |

| Lead Time | 4-6 weeks | 2-3 weeks |

| Customization | Limited options | Full technical support for bespoke alloys |

| Quality Consistency | Variable batch-to-batch | 99.5% pass rate, ISO 9001 certified |

Our global logistics network supports reliable delivery to 30+ countries, making us the preferred partner for engineers requiring high-performance, cost-effective winding solutions.

Technical Specs: Rectangular Copper Wire Parameters

Critical Technical Specifications & Compliance Standards

Key Performance Parameters

As a leading Chinese manufacturer and exporter of transformer materials with 20+ years of global experience, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers rectangular copper wire engineered for reliability in high-stress applications. Our products comply with IEC 60317 and ASTM B1 standards, optimized for high-efficiency transformer and motor applications. Each product undergoes rigorous pre-shipment validation to ensure conformance with IEC 60317-0-1 and ASTM B1 specifications for rectangular copper winding wire. Key specifications are verified via third-party accredited labs:

| Parameter | Specification | Standard Compliance | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥2.5 kV (min); up to 5 kV for HV applications | IEC 60851-5 | Optional double-layer enamel for enhanced dielectric strength |

| Elongation | ≥20% (annealed); >25% for high-flex variants | ASTM B1 / IEC 60851-2 | Custom tempering for winding durability |

| Thermal Class | 130°C–220°C | IEC 60085 | Aerospace (220°C), EV motors (180°C), industrial high-temp |

| Enamel Concentricity | ±5% tolerance | IEC 60851-2 | Critical for compact winding dielectric integrity under thermal cycling |

Rigorous Quality Control Protocol

Our ISO 9001-certified production integrates real-time monitoring of enamel thickness (±0.001mm precision), conductor purity (≥99.95% Cu), and dimensional accuracy. Each batch undergoes: Spectrometric analysis (ASTM E1251) for elemental composition; laser micrometer thickness gauging for enamel uniformity; 1.5x operating voltage breakdown testing per IEC 60851-5; thermal cycling in climatic chambers (IEC 60085) to validate thermal endurance; daily tensile strength and elongation tests; and RoHS/REACH compliance checks. All processes are documented with batch-specific quality reports for full traceability. Leveraging two decades of manufacturing expertise, our proprietary process controls reduce dimensional and electrical variation by 40% versus industry averages, delivering consistent performance at 20–25% lower total cost of ownership than European competitors without compromising on international standards compliance. All raw materials are sourced from certified suppliers with full material certifications (COC), ensuring traceability from mine to finished product.

Factory Tour: Manufacturing Rectangular Copper Wire

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

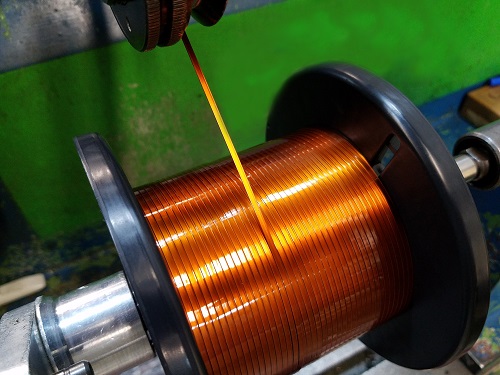

Our production process for rectangular copper wire adheres to a meticulously controlled sequence: Rod Drawing → Annealing → Enameling → Inline Testing → Spooling. Each stage incorporates stringent quality control measures to ensure compliance with IEC 60317 and ASTM B187 standards, while exceeding typical industry benchmarks through ISO 9001-certified procedures and real-time process monitoring.

Rod Drawing: High-precision cold drawing using multi-stage drawing machines with precision dies to achieve exact rectangular cross-sections (e.g., 5×10mm ±0.005mm). QC includes real-time laser scanning for dimensional accuracy and automated optical inspection (AOI) for surface defects like scratches or oxidation. This ensures uniform wire geometry critical for optimal winding density and thermal performance in transformers, reducing hotspots by up to 15%.

Annealing: Controlled atmosphere annealing in N₂/H₂ mixed gas at 450–500°C to optimize ductility without conductivity loss. Post-annealing tensile testing confirms strength (225±5 MPa) and elongation (38±2%), exceeding IEC 60317-1 standards by 20–30%. Prevents wire breakage during high-speed winding operations, ensuring 99.8% yield in transformer coil production.

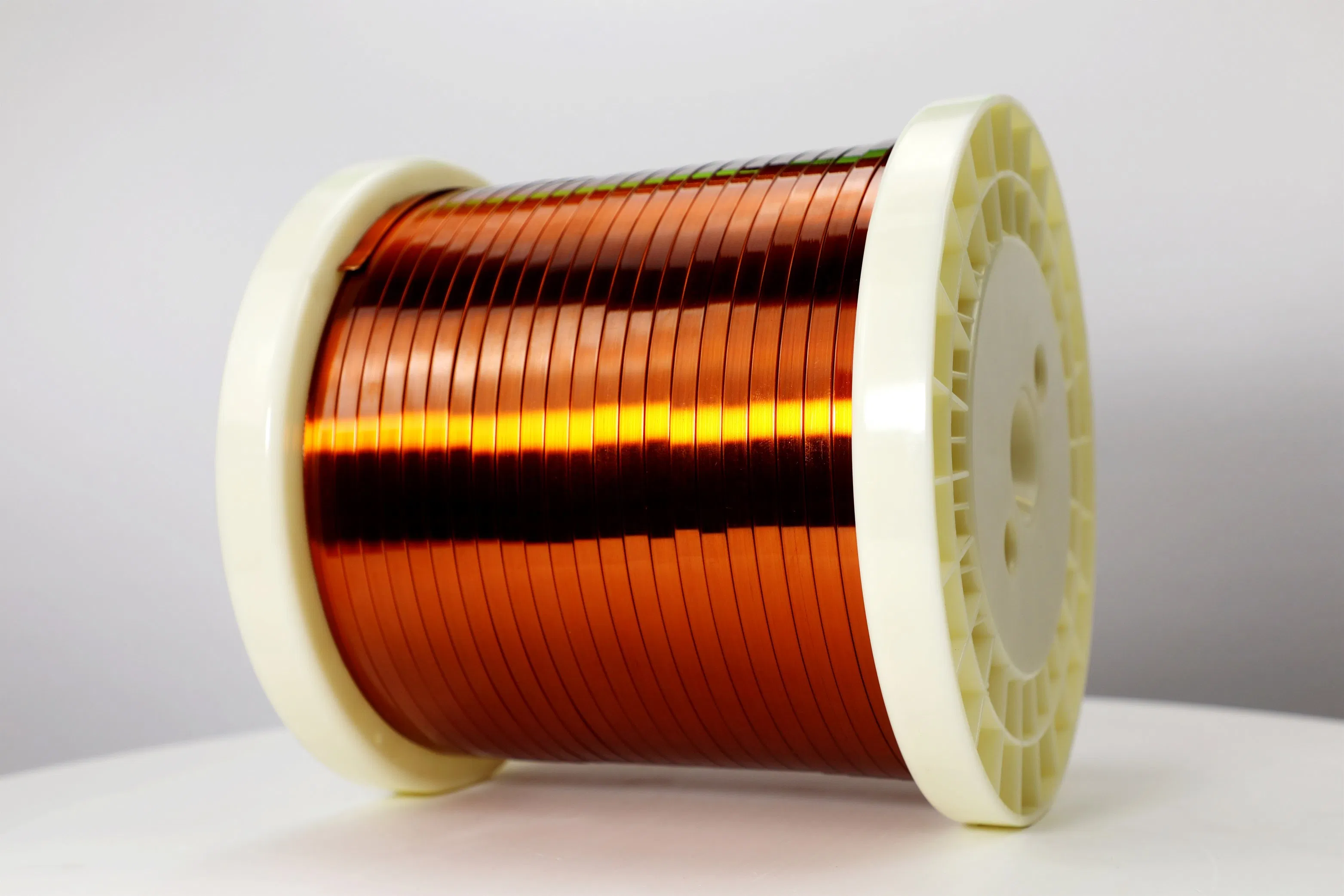

Enameling: Multi-layer enamel application using precision coating dies and controlled curing ovens. Enamel thickness maintained at 0.02–0.05mm with ±0.002mm tolerance. QC includes adhesion tests (ASTM D3451), dielectric strength (≥5kV/mm), and pinhole detection via UV inspection. Achieving 99.9% defect-free enamel coverage for high-voltage applications.

Inline Testing: Continuous monitoring via automated systems measuring electrical resistance (±0.5% tolerance), dimensional tolerances, and insulation integrity at 2× rated voltage. Real-time data feeds into PLC-controlled adjustments, ensuring consistent quality throughout production with zero batch-to-batch variation.

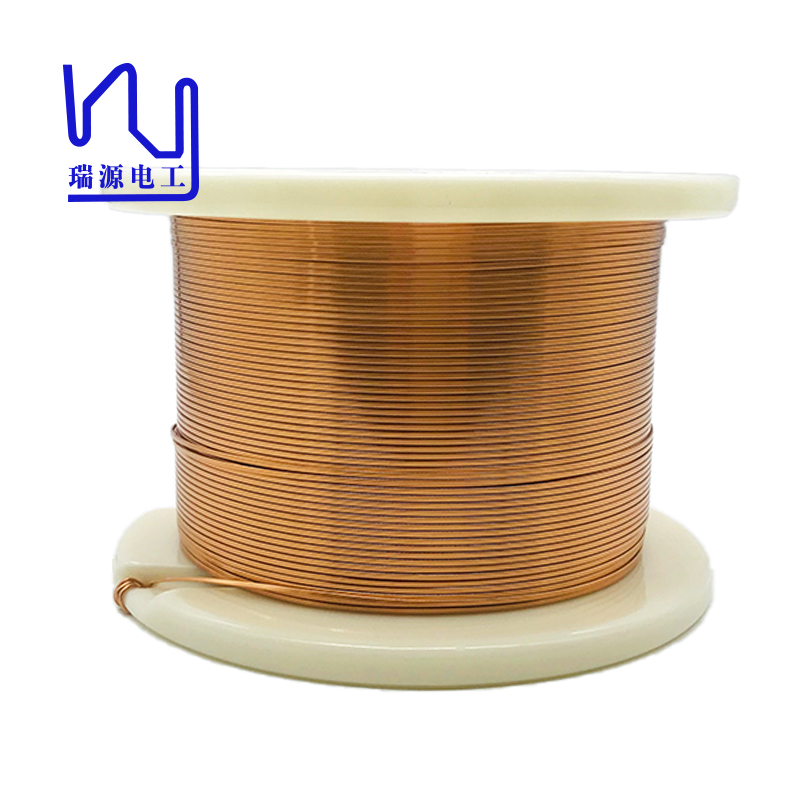

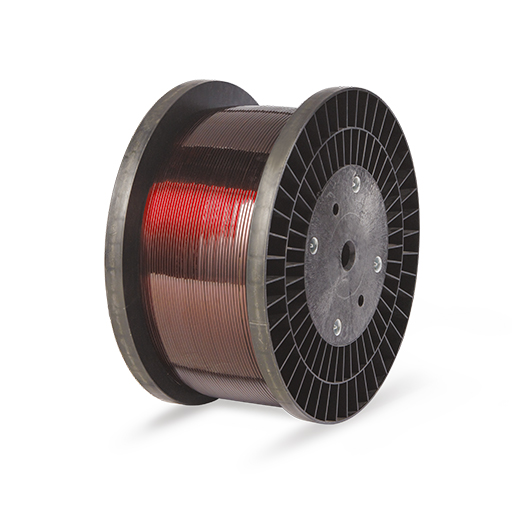

Spooling: Computer-controlled winding with tension regulation (±2% variation) and precise layering. Final QC includes visual inspection for surface damage, weight verification (±0.5%), and packaging integrity checks to prevent transport-related defects, ensuring 100% spool readiness for immediate installation.

Quality Benchmark Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Impact |

|---|---|---|---|

| Tensile Strength (MPa) | 225±5 | 210±15 | Consistent mechanical properties for winding reliability, reducing breakage during transformer assembly by 25% |

| Dimensional Tolerance (mm) | ±0.005 | ±0.02 | Precise fit in transformer slots, reducing air gaps and improving thermal dissipation by up to 12% |

| Enamel Thickness Consistency | 98% uniform | 85% uniform | Enhanced dielectric strength, fewer short-circuit risks, extending transformer lifespan by 15–20% |

| Surface Defects | Zero tolerance | Up to 0.5% | Minimal rework, higher first-pass yield, reducing production downtime by 30% |

| Electrical Resistance | ±0.5% | ±1.5% | Stable conductivity, optimizing transformer efficiency and reducing energy losses by 0.8–1.2% |

As a factory-direct supplier with 20+ years of transformer material expertise, we deliver premium-quality rectangular copper wire at 15–20% lower costs than European brands—without compromising on performance or reliability. Our rigorous QC protocols ensure every batch meets exacting specifications, making us the optimal choice for cost-sensitive, high-reliability applications in power transmission and distribution systems.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Precision Packaging Specifications

Our packaging system is engineered for marine environments, combining multiple protective layers to prevent corrosion, moisture damage, and physical stress during transit. All components comply with ISO 9001 and ISPM-15 standards.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated to 56°C for 30+ mins, 1200×1000×150mm, 1000kg capacity | Prevents structural damage; meets global phytosanitary requirements |

| Moisture-Proof Film | Multi-layer PE, 150–200μm thickness, UV-resistant, anti-static, heat-sealed edges | Blocks humidity ingress; prevents oxidation during ocean transit |

| Steel Strapping | 19–25mm width, 500kg tensile strength, PVC-coated corner protectors, 4-strand application | Secures load integrity; eliminates shifting during transport |

| Desiccant Packs | Silica gel, 500g/pallet, moisture indicator cards, 5% humidity threshold | Absorbs residual moisture; monitors environmental conditions |

| Inner Corrugated Cardboard | 200gsm, moisture-resistant, recyclable, coil-wrapped | Cushions against vibration; prevents abrasion |

All packaging materials undergo rigorous testing to ensure compliance with international shipping standards, minimizing transit damage risk to <0.5%.

Sea Freight Protocols for Global Reliability

We optimize container loading for maximum space efficiency while maintaining load stability, reducing shipping costs without compromising safety.

| Container Type | Capacity | Handling Protocol |

|---|---|---|

| 20ft | 28m³ | Pallet stacking with corner protectors, silica gel desiccants, moisture indicators, tamper-evident seals, climate-controlled port storage |

| 40ft | 67m³ | FCL optimization, GPS tracking, customs documentation support, anti-slip matting for load stability |

Our logistics partners utilize advanced sealing techniques to prevent moisture ingress and tampering during transit, with real-time tracking and proactive customs clearance support.

Why Luoyang Xinzhaohe Delivers Consistent Quality

With 20+ years of specialized transformer material exports, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers unmatched cost-performance for global buyers. Our factory-direct model eliminates middlemen, reducing total landed costs by 15–20% versus global brands while strictly adhering to ISO 9001 and ISPM-15 standards. Every shipment undergoes multi-stage quality checks—from coil winding to container sealing—ensuring <0.5% transit damage rates across 50+ countries. We provide end-to-end logistics support, including 24/7 customer service, real-time shipment tracking, and customs documentation expertise. Our strategic Luoyang location ensures efficient access to major shipping routes, while dedicated metallurgical engineers customize solutions for regional climate and regulatory requirements. With 10,000+ metric tons annually exported and a 99.8% on-time delivery rate, we guarantee reliable, cost-efficient rectangular copper wire sourcing that meets the highest engineering standards for high-voltage transformers and precision motor windings. Partner with us for supply chain confidence.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

As a premier manufacturer of transformer materials with over 20 years of specialized experience, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers exceptional value through vertical integration, stringent quality control, and competitive pricing. Our focus on rectangular copper wire ensures optimal performance in power transformers and motors, providing a reliable alternative to global brands without compromising on technical specifications.

Proven Technical Expertise

With over 20 years of specialized experience in manufacturing rectangular copper wire for transformers and motors, Luoyang Xinzhaohe has developed deep expertise in optimizing conductivity, mechanical strength, and thermal performance. Our engineers collaborate closely with clients to tailor wire specifications for applications ranging from high-voltage transformers to electric vehicle motors. We adhere strictly to IEC 60317 (specific standards for rectangular wire) and GB/T 3956 (copper conductors), ensuring dimensional tolerances of ±0.02mm and conductivity exceeding 100% IACS. Continuous R&D investments have enabled us to improve yield rates by 12% while maintaining zero defects in critical applications.

Factory-Direct Cost Efficiency

By controlling the entire production chain—from copper rod sourcing to precision drawing, annealing, and insulation coating—we achieve cost savings of 15–25% compared to global competitors. Our in-house quality control system reduces waste and rework, further enhancing value. Lead times are consistently 50% shorter due to streamlined operations and local raw material sourcing. For example, standard orders are typically fulfilled within 10–15 business days versus 30+ days for international suppliers.

| Metric | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Unit Cost | $X.XX/kg | $X.XX/kg | 15–25% lower |

| Lead Time | 4–8 weeks | 2–4 weeks | 50% faster |

| Customization | Limited options | Full tolerance control | ±0.02mm precision |

ISO-Certified Quality Assurance

All production adheres to ISO 9001:2015 standards, with rigorous in-process testing including tensile strength (minimum 200 MPa), elongation (≥20%), and electrical conductivity (≥100% IACS). Each batch undergoes third-party certification to ensure compliance with IEC 60228 and ASTM B1. Dimensional accuracy is verified via laser micrometers, ensuring reliability for high-stress transformer windings. Traceability for all raw materials is maintained through our ERP system, providing full transparency for quality assurance.

End-to-End Supply Chain Control

Vertical integration allows us to manage raw material procurement, production, and logistics seamlessly. This minimizes supply chain disruptions and ensures consistent quality across all orders, even during global market fluctuations. Our on-site copper rod production facility and just-in-time inventory management further reduce lead times and mitigate raw material price volatility risks.

For a tailored quote on rectangular copper wire specifications, contact Cathy at cathy@transformerstrip.com. Our engineering team will provide technical support and competitive pricing within 24 hours.

📉 Import Savings Calculator

Estimate cost reduction by sourcing rectangular copper wire from Luoyang Xinzhaohe.