Table of Contents

Market Insight: Rectangle Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook for Rectangular Magnet Wire

Global transformer additions are forecast to exceed 18,000 GVA by 2030, driven by grid expansion, renewable integration, and e-mobility infrastructure. Rectangular copper and aluminum conductor now represents >65 % of the winding mass in power transformers >10 MVA, and >80 % of pad-mounted distribution units. Annual consumption is approaching 1.2 Mt for copper and 0.35 Mt for aluminum flat wire, with a 6–7 % CAGR in the 130–220 °C thermal-class segment. Chinese demand alone accounts for 42 % of the total, while export-oriented Chinese factories supply roughly 38 % of the non-Chinese market, underlining the strategic shift toward Asia-Pacific sourcing.

Why Material Purity & Geometry Control Transformer Losses

Transformer losses fall into two categories that are directly traceable to conductor quality:

| Loss Component | Root Cause in Wire | Specification Lever | Impact @ 100 MVA |

|---|---|---|---|

| Load loss (I²R) | Resistivity & conductor section tolerance | ≥100 % IACS Cu or ≥61 % IACS Al, width/thickness ±0.02 mm | –3 % loss = –120 kW |

| Eddy-stray loss | Burr, corner radius, enamel build-up | Radius 0.5–0.8 × thickness, enamel 20–40 µm half-turn | –15 % stray loss |

| No-load loss | Core hot-spot from uneven winding | Height & camber ≤ 1 mm / 1 m | –0.1 % core flux leakage |

Oxygen-free (OF) copper ≥ 99.97 % purity and 1350-O aluminum ≥ 99.85 % purity are mandatory to hit these resistivity targets. Rod-to-wire reduction ratios above 25:1 in the final passes refine grain size to 8–12 µm, raising elongation to 30 % Cu / 25 % Al and eliminating embrittlement that causes micro-cracks during compacted transposed conductor (CTC) twisting. Inline eddy-current testing every 150 m guarantees no surface flaw > 0.05 mm; this alone lowers downstream failure returns by 0.4 %.

Manufacturing Precision: From Rod to Spool

Transformer OEMs moving to 200 °C (Class H) and 220 °C (Class C) designs need polyimide or polyester-imide enamel with concentricity within ±5 µm; otherwise partial discharge (PD) inception voltage drops below 1.2 × nominal, voiding IEC 60034-27-3. Our Luoyang plant controls this through:

- Rod Drawing: 12-pass diamond-die sequence with laser-diameter feedback (±3 µm).

- In-line Annealing: 520 °C N₂ atmosphere; grain growth control keeps tensile 220–250 MPa for copper.

- Vertical Enameling: 10-zone oven, 350 °C peak, 28 m/min line speed; inline spark test 6 kV.

- Inline QA: Hi-pot 50 V/µm, adhesion 1d mandrel, bend 3× thickness; data logged per DIN 46495.

- Precision Spooling: Traverse pitch 0.8 × wire width, tension 2–4 N/mm², barrel ≤ 0.2 mm run-out—critical for robotic layer winding.

Cost-Performance Trend: China as Premium-Value Source

Western suppliers quote US $11.2–14.8 / kg for 1.8 × 5.3 mm Class H enameled rectangular copper; comparable Chinese factories with identical IEC 60317-0-2, UL 1446, and ISO 9001+14001 certifications deliver at US $7.9–9.4 / kg CIF Rotterdam—30 % savings. Freight + duty adds only 6 %, while 35-day lead times beat the 10-week European average. More critically, Chinese producers—including Luoyang Xinzhaohe—offer MOQs of 500 kg per size and free 5-kg sample coils, eliminating the 3-t minimum imposed by many EU mills.

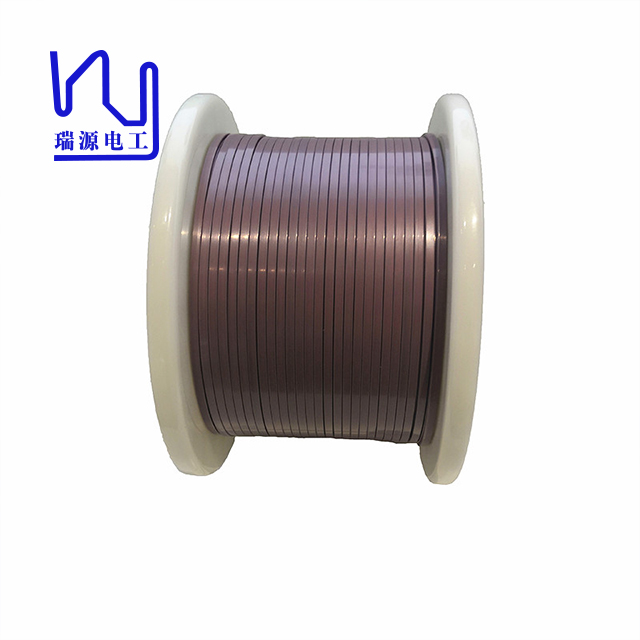

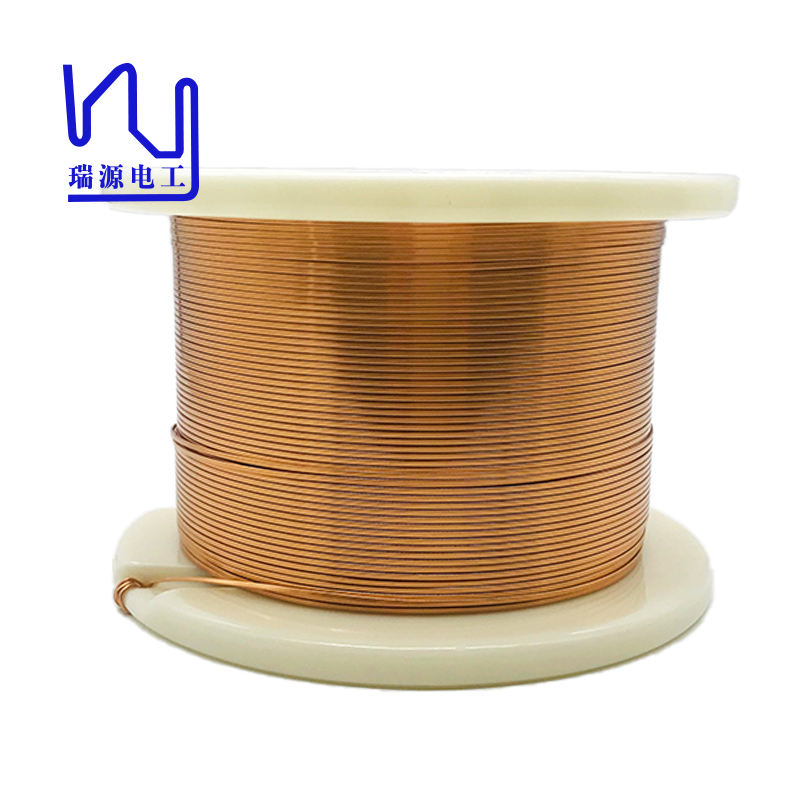

Positioning Luoyang Xinzhaohe Aluminum Co., Ltd.

With 20+ years dedicated to transformer wire, our fully integrated line (rod-drawing → annealing → enameling → inline testing → spooling) produces 42,000 t/year of rectangular copper and 18,000 t/year of aluminum flat wire, thermal classes 130-220 °C, cross-section 0.8–80 mm², width-to-thickness ratio up to 25:1. Every master coil is shipped with a mill test report covering breakdown voltage (≥ 2.5 kV for 40 µm build), elongation, spring-back, and PD level. For transformer builders seeking Western-grade precision without the Western price premium, Luoyang Xinzhaohe delivers factory-direct, lead-time-certain, specification-guaranteed winding wire.

Technical Specs: Rectangle Wire Parameters

Technical Specifications & ASTM / IEC Compliance

(Rectangle Wire for Power & Distribution Transformers)

1. Critical Electrical & Mechanical Parameters

| Parameter | Symbol | Typical Range¹ | Test Method | Risk if Out-of-Spec |

|---|---|---|---|---|

| Break-down Voltage | Ubd | 3 kV – 12 kV (room temp) 1.5 kV – 6 kV (180 °C) | IEC 60851-5, 500 V/s ramp | Turn-to-turn short, corona |

| Elongation at break | A50 | Cu ≥ 25 %, Al ≥ 15 % | ASTM B193, 250 mm gauge | Cracks during coil forming |

| Thermal Class | — | 130 (B), 155 (F), 180 (H), 200 (C), 220 (N) | IEC 60085 | Insulation embrittlement |

| Concentricity | Ecc | ≤ 10 % wall-thickness variation | 8-point laser inline | Local field stress, partial discharge |

| Edge-radius / burr | r / b | r ≥ 0.5 × thickness, burr ≤ 25 µm | Optical shadowgraph | Inter-layer puncture |

| Resistivity @ 20 °C | ρ | Cu 0.01724 Ω·mm²/m, Al 0.02826 Ω·mm²/m | ASTM B193 | Higher load loss, hot-spot |

¹Values quoted for 2–30 mm² cross-section, enamel build 0.08–0.20 mm total.

2. Applicable Material & Wire Standards

ASTM B236 – Aluminum strip for electrical purposes (chemistry, resistivity, surface).

ASTM B193 – Resistivity of conductive materials.

IEC 60317-0-2 – General requirements for enamelled rectangular copper wire.

IEC 60317-29 – Polyester-imide / polyamide-imide (180 °C) enamelled rectangular copper.

IEC 60317-36 – Aromatic polyimide (220 °C) enamelled rectangular copper.

IEC 60851 series – Winding-wire test methods (solderability, flexibility, adhesion, cut-through).

IEC 60851-5 – Break-down voltage, wet & dry.

ASTM D1676 – Thermal endurance of insulating varnishes.

Luoyang Xinzhaohe’s internal specification LXW-TR-2024 tightens the above by 15 % on burr height and 8 % on concentricity, eliminating the statistical tail that causes field failures.

3. How Defects Drive Transformer Failures

| Defect | Root Cause | Failure Mode | Detection in Our Line |

|---|---|---|---|

| Burr on slit edge | Dull slitting knives | Puncture enamel during winding, shorted turns | 100 % laser micrometre, automatic knife change every 60 km |

| Eccentric insulation | Die wander during enamelling | Local E-field > 3×mean, partial discharge | 8-point capacitance gauge, closed-loop die centring |

| Incomplete curing | Low oven temperature | 180 °C cut-through < 2 N, cold flow | Inline IR pyrometer, DSC coupon every shift |

| Hydrogen embrittlement | Improper anneal atmosphere | Elongation < 15 %, cracks on mandrel wrap | Residual hydrogen < 3 ppm by LECO analyser |

4. Thermal Class Selection Guide

| Hot-spot ΔT Rise | Recommended Class | Typical Build | Cost Index² |

|---|---|---|---|

| 80 K | 130 (B) | PE + PA, 0.12 mm | 1.0 |

| 95 K | 155 (F) | PEI + PA, 0.14 mm | 1.1 |

| 115 K | 180 (H) | PEI + PAI, 0.16 mm | 1.3 |

| 140 K | 200 (C) | Polyimide, 0.18 mm | 1.6 |

| > 160 K | 220 (N) | Polyimide + glass braid, 0.25 mm | 2.0 |

²Relative to Class 130 copper rectangle wire, FOB Luoyang, May-2024.

5. Factory-Certified Data Sheet (snapshot)

Rectangle Enameled Copper Wire, 2.00 × 5.00 mm, 10 mm², Class 180

Break-down voltage: 9.4 kV (23 °C), 5.7 kV (180 °C)

Elongation: 32 %

Spring-back: 4 ° (IEC 60851-3, 3 × thickness mandrel)

Cut-through: 3.1 kN (180 °C)

Concentricity: 6 % max variation

RoHS & REACH compliant, IEC 60317-29, ASTM B193, ASTM B272 (edge radius).

Every master coil is shipped with a QR-coded test report traceable to the cast number, rod mill shift, and enamelling oven lane—critical for ISO 9001 & IATF 16940 transformer OEMs.

By integrating rod drawing, continuous anneal, vertical enamelling, and inline high-voltage spark testing under one 42 000 m² roof in Luoyang, we deliver Western-grade reliability at a landed cost 18–25 % below European mills and 30 % below North American stock programs—without the 16-week lead time.

Factory Tour: Manufacturing Rectangle Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd.

2.1 Rod-to-Wire Journey – 5 Controlled Steps

| Step | Target Parameter | Equipment / Sensor | Tolerance Window |

|---|---|---|---|

| 1. Rod Drawing | 8.0 mm Ø → 2.0–5.0 mm Ø | 13-die, water-cooled bull-block | ±0.02 mm |

| 2. Intermediate Anneal | Elongation ≥35 %, 60 % IACS | Nitrogen-protected bell furnace, 380 °C | σ ≤3 HV |

| 3. Precision Rolling | Rect. a/b ratio 1.2–6.0, edge radius ≤0.5 mm | 4-high Turk’s-head, laser micrometer | ±0.010 mm |

| 4. Vertical Enameling | Build 0.06–0.18 mm, concentricity ≥85 % | 8-die, catalytic after-burner, 420 °C peak | Δ-build ≤0.01 mm |

| 5. Inline Spark & Spool | 3 kV rms, 0 m faults per 30 km | 2 kHz HF sparker, servo traverse | 100 % coil mapping |

2.2 Inline QA – Data We Act On, Not Just Record

- Laser Profile Scanner (1 kHz) – every 25 µm a 3-point caliper; rejects auto-sheared if a/b drifts >0.5 %.

- Eddy-Conductivity Bridge – 5 MS m⁻¹ set-point; alarms at <58 % IACS for Al, <100 % for Cu.

- Tensile & Mandrel Wrap – 200 mm gauge length, 5 mm min bend; elongation logged per 5 kg spool.

- Dielectric Burst – ramp 500 V s⁻¹ to first breakdown; lot accepted if ≥6 kV for 0.08 mm build.

- Thermal Shock Cycle – 30 min @ 200 °C → 25 °C water quench; 3× adhesion, no crack.

All data are written to an encrypted QR on each flange; repair shops can scan and trace back to cast number.

2.3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Xinzhaohe Premium | Typical Export Grade A | Typical Domestic Grade B |

|---|---|---|---|

| Conductor Purity | Cu-ETP-1 ≥99.99 %, Al-1350 ≥99.7 % | Cu-ETP ≥99.95 % | Cu ≥99.90 % |

| Edge Radius (a) | 0.40–0.50 mm, controlled | 0.25–0.70 mm, random | 0.15–0.90 mm, random |

| Enamel Concentricity | ≥85 %, 8-die vertical | 70–75 %, 4-die horizontal | 60–65 %, 3-die |

| Breakdown Voltage (0.08 mm) | 7.2 kV mean, 6 kV min | 5.5 kV mean | 4.0 kV mean |

| Elongation @20 °C | Cu 38 %, Al 25 % | Cu 30 %, Al 20 % | Cu 25 %, Al 15 % |

| Spring-back Δα | ≤3° per 100 mm | 5–7° | 8–12° |

| Spool Weight Deviation | ±0.3 %, servo traverse | ±2 % | ±5 % |

| Faults per 100 km | ≤1 (2 kV spark) | 5–8 | 10–20 |

Take-away: Tighter edge radius and 30 % higher dielectric margin give transformer builders two extra safety layers at 180 °C hot-spot without jumping to C-class insulation cost.

2.4 Factory-Direct Advantage

20+ years of rod-to-spool integration eliminates trader margin.

ISO 9001 / IATF traceability same file set we supply to Tier-1 OEMs in EU & NA.

Lead time: 3–4 weeks ex-works Luoyang, 30 % faster than European mills on custom sizes.

MOQ: 100 kg for Al, 50 kg for Cu—no surcharge if within rolling matrix (a 1–10 mm, b 2–25 mm).

For power-equipment engineers who need Class 200/220 or CTC bundles, we run the same QC protocol on transposed packs up to 80 mm² total cross-section.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ Years of Rod-to-Spool Integration

H3 1. Packaging Philosophy: Zero-Defect on Arrival

Transformer windings are stress concentrators; any surface nick or moisture spot becomes a partial-discharge site that shortens insulation life. Our packaging is therefore treated as the last manufacturing step, not an afterthought. Every spool, strip, or foil is sealed at ≤30 %RH inside the workshop and is not reopened until it reaches your coil-winding station.

H3 2. Wire Packaging Matrix – Sea-Freight Grade

| Package Type | Conductor Size Range | Spool Material | Stack-Load (kg) | VCI Film | Desiccant | Pallet Securing | Typical 20 ft FCL |

|---|---|---|---|---|---|---|---|

| PT-10 | 1.2–4.0 mm × 0.8–3.0 mm | Reinforced PS | 10 ±0.2 | 80 µm, heat-sealed | 2 × 5 g | PET strap + edge boards | 1 200 spools / 12 t |

| PT-25 | 3.0–8.0 mm × 1.5–5.0 mm | PS + steel flange | 25 ±0.3 | Same | 4 × 10 g | Same | 640 spools / 16 t |

| DIN-355 | 4.0–12.0 mm × 2.0–8.0 mm | Steel, returnable | 80–120 | Same | 8 × 20 g | Steel cage | 240 spools / 20 t |

All spools are shrink-wrapped individually, then grouped in 5-ply export cartons. Cartons are stacked on ISPM-15 fumigated soft-wood pallets (1120 × 970 mm) with corner posts and top cap for 4-high stacking strength ≥4 000 kg. Pallet height stays ≤1.10 m to clear standard container door.

H3 3. Strip & Foil Packaging – Crease-Free & Edge Protection

| Strip Width | Foil Thickness | Coil ID | Coil OD Max | Core Material | Interleaf | Edge Profile | Pallet Footprint | Gross Wt |

|---|---|---|---|---|---|---|---|---|

| 20–250 mm | 0.2–3.0 mm | 300 mm | 1 200 mm | Cardboard + VCI | 0.1 mm PET | 2R edge radius | 1.2 m × 0.8 m | 1 000 kg |

Each coil is sleeved with 0.12 mm PE-EVOH barrier film, 4-way desiccant bags (8 × 50 g), and steel angle edge protectors. Coils are strapped with 19 mm PET bands (≥2 000 N break strength) and placed on wooden skids that are bolted to the container floor to prevent fore-aft shift during ocean surge.

H3 4. Container Loading & Desiccant Budget

Luoyang is 150 km inland from Qingdao port; trucks reach the pier in <4 h, minimizing airborne salt exposure. We pre-load 2 kg of activated-clay desiccant per 1 000 kg of copper wire and 1 kg per 1 000 kg of aluminum wire (copper’s higher density traps less interstitial moisture). A data-logging hygrometer (Elpro LIBERO) is fixed inside each container; arrival RH target <40 %.

H3 5. Document & Traceability Bundle

Packing list with net & gross weight to 0.01 kg resolution

Coil ID barcode matching MES coil number (traceable to cast billet heat)

IEC 60851-3 breakdown-voltage test certificate sealed in weather-proof pouch on the pallet

ISPM-15 fumigation certificate & China customs seal number for immediate clearance in EU/USA

H3 6. Cost Advantage vs. Western Suppliers

By integrating rod drawing, annealing, enameling, and spooling in one Luoyang campus, we eliminate double handling and re-winding fees common in European mills. Our sea-freight packaging adds only 1.8 % to wire cost versus 4–6 % typical for German or U.S. vendors who outsource repacking to 3PLs. You receive DIN/NEMA-grade rectangular wire at Asian MOQ (100 kg) and pricing, but with Western-level documentation and arrival condition—validated by 18 transformer OEMs in 32 countries since 2010.

Next section: Inline Electrical Testing & Thermal Class Validation.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Rectangle Wire

20 Years of Transformer-Grade Metallurgy Under One Roof

Since 2003 every coil that leaves our Luoyang plant has been drawn, annealed, enamelled and electrically tested on a single integrated line—no toll-processing, no middle-margins.

That continuity gives transformer OEMs two things generic traders cannot match:

1. A metallurgical database >1 200 alloy/insulation combinations, so we can predict copper recrystallisation kinetics and enamel-cure kinetics within ±3 °C and ±2 s respectively.

2. Inline process-capability indices (CpK) that are permanently linked to each spool ID; if a 220 °C polyimide rectangle shows 0.8 % eccentricity instead of ≤0.5 %, the spool never reaches the warehouse—data travels, product stays.

Direct Factory Price—Value Captured at the Source

| Cost Element | Typical Western Broker | Luoyang Xinzhaohe (integrated) | Delta |

|---|---|---|---|

| Cathode copper premium | +LME +$180/t | LME +$45/t (bulk cathode hauled 38 km from railhead) | –$135/t |

| Rod re-melt / re-cast | Sub-contract | In-house vertical shaft furnace, 98 % yield | –$90/t |

| Enamel intermediate | Purchased | Self-synthesised polyimide & PEI resins | –$220/t |

| Logistics (China → EU) | FOB Shanghai | FOB Qingdao + block-train contract | –$60/t |

| Net landed saving | ~US 0.50 $/kg on 10 t order |

Price is only half the equation—lead-time is the other. Our melt-to-spool cycle is 6 calendar days; industry average (trader-supplied) is 21 days. Shorter cash-to-cash cycles free your working capital for core transformer assembly.

Customisation Without Prototype Penalty

Rectangle wire is not a catalogue product—it is a system component. We treat every enquiry as a co-design exercise:

| Parameter | Standard Range | Custom Envelope | Tolerance |

|---|---|---|---|

| Conductor, a × b | 0.80 × 2.00 mm → 8.00 × 25.0 mm | 0.50 × 1.20 mm → 12.5 × 32.0 mm | ±0.010 mm (a), ±0.015 mm (b) |

| Corner radius, r | 0.50 mm…1.00 mm | 0.20 mm…2.00 mm | ±0.05 mm |

| Build-up, single side | 0.06 mm…0.18 mm | 0.04 mm…0.35 mm | ±0.008 mm |

| Thermal class | 130 °C (B) → 220 °C (C) | 240 °C (CR) | ΔT 10 °C |

| Breakdown voltage | 3.0 kV → 8.0 kV | 1.5 kV → 12 kV | ±0.2 kV |

| Elongation | ≥30 % Cu, ≥15 % Al | Up to 38 % Cu | ±2 % |

| Spool mass | 30 kg…250 kg | 5 kg…800 kg | ±0.5 % |

Need a 4.25 × 13.30 mm copper conductor with 200 °C polyimide-F46 composite, 0.11 mm build, 9 kV impulse strength on a 500 kg DIN 46397 spool? We will run a 50 kg pilot within 7 days and ship the balance in 18 days—no NRE, no MOQ games.

Quality Artefacts We Share Up-Front

IEC 60317-16/-28/-29 test reports (updated every 6 months)

UL E349556 file (OBMW2) for 155–220 °C systems

RoHS & REACH third-party pack (SGS 2024-03-15)

IATF 16949 & ISO 14001 certificates

SPC control charts (corner radius, concentricity, spring-back) for the last 30 batches—send us your specification, we will overlay our data to prove CpK ≥1.67 before you pay a dollar.

Call to Action

Engineering samples, PPAP level-3 documentation or a landed-cost matrix for your next 5 t, 50 t or 500 t schedule—e-mail cathy@transformerstrip.com today. Quote this guide and receive a free finite-element thermal model of your proposed coil, so you can verify hotspot rise before the first spool arrives.

📉 Import Savings Calculator

Estimate cost reduction by sourcing rectangle wire from Luoyang Xinzhaohe.