Table of Contents

Market Insight: Pure Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for transformer strip and foil—primarily aluminum and copper—continues to expand in parallel with increasing investments in power infrastructure, renewable energy integration, and industrial electrification. Transformer windings, a core component of both distribution and power transformers, rely heavily on high-purity conductive strip materials to ensure efficient electromagnetic performance and long-term reliability. Aluminum strip, in particular, has gained significant market share due to its favorable conductivity-to-weight ratio, corrosion resistance, and cost-effectiveness compared to copper, especially in medium- and high-voltage distribution transformers.

Industrial demand for pure aluminum strip in transformers is driven by several key sectors. Utilities upgrading aging grid infrastructure are adopting aluminum-wound transformers to reduce transportation and installation costs, given their lighter weight. Renewable energy projects, such as solar and wind farms, require step-up transformers that benefit from aluminum’s scalability and thermal stability. Additionally, industrial OEMs manufacturing dry-type and oil-immersed transformers are increasingly standardizing on high-conductivity aluminum alloys such as 1060, 1070, and 1350, which meet international specifications including ASTM B418 and IEC 60164.

Copper strip remains critical in applications requiring maximum conductivity and compact design, such as high-efficiency distribution transformers and specialty equipment. However, its higher density and cost limit widespread adoption in large-scale deployments. As a result, the market exhibits a strategic balance: copper is preferred in space-constrained or ultra-high-efficiency applications, while aluminum dominates in cost-sensitive, weight-dependent, and large-volume installations.

Material quality is paramount in transformer strip performance. Impurities, inconsistent thickness, poor surface finish, or inadequate mechanical properties can lead to increased eddy current losses, localized heating, and premature insulation breakdown. High-purity aluminum (99.6% min) ensures optimal electrical conductivity, typically ≥61% IACS for 1350 alloy, while precise dimensional control—within ±0.02 mm tolerance—enables tight winding accuracy and uniform dielectric distribution. Surface defects such as scratches, pits, or residual oxides compromise insulation integrity, increasing the risk of partial discharge and dielectric failure under operational stress.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized production experience, we emphasize rigorous process control from billet casting through cold rolling and slitting. Our transformer-grade aluminum strips are manufactured under ISO 9001-certified quality systems, with full traceability, spectrographic analysis, and in-line thickness monitoring. Each batch undergoes stringent testing for resistivity, tensile strength, elongation, and surface quality to meet the exacting standards of transformer manufacturers.

The shift toward smart grids, energy efficiency regulations (e.g., DOE 2016, EU EcoDesign), and distributed generation systems further elevates the importance of material consistency and performance. As transformer design evolves to minimize losses and maximize lifespan, the role of high-quality strip material becomes increasingly decisive. Sourcing from suppliers with proven metallurgical expertise and process stability is not merely a cost consideration—it is a direct contributor to transformer reliability, efficiency, and compliance with global energy standards.

Technical Specs: Pure Strip

Technical Specifications for Pure Transformer Strip and Foil

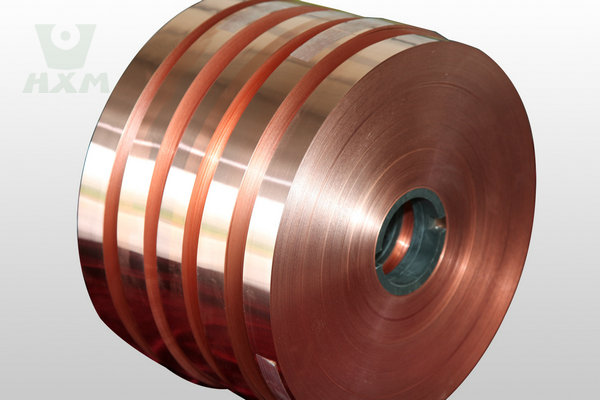

Luoyang Xinzhaohe Aluminum CO.,Ltd delivers precision-engineered pure aluminum and copper strip/foil for high-efficiency transformer cores. Our 20+ years of metallurgical expertise ensures strict adherence to critical parameters that directly impact magnetic performance, winding integrity, and thermal stability. Dimensional accuracy and material purity are non-negotiable; deviations beyond specified tolerances induce eddy current losses, vibration, and premature failure. We prioritize zero-compromise manufacturing control, particularly in slitting precision, edge quality, and electrical conductivity—key determinants of transformer efficiency and lifespan.

The following table details mandatory technical parameters for pure aluminum (1060/1070/1100 series) and electrolytic-tough-pitch copper (C11000) strip/foil. All values reflect minimum guaranteed performance under ASTM B922, GB/T 3880, and IEC 60404-1 standards.

| Parameter | Aluminum Strip/Foil | Copper Strip/Foil | Test Method |

|---|---|---|---|

| Thickness Range | 0.10–3.00 mm | 0.10–2.50 mm | ASTM E29 |

| Width Tolerance | ±0.002 mm | ±0.002 mm | Laser Micrometer |

| Edge Burr Height | ≤ 2 μm | ≤ 1.5 μm | Optical Profilometry |

| Surface Roughness (Ra) | ≤ 0.4 μm | ≤ 0.3 μm | ISO 4287 |

| Electrical Conductivity | ≥ 61.0% IACS | ≥ 100.0% IACS | ASTM E1004 |

| Tensile Strength | 60–95 MPa | 200–240 MPa | ASTM E8 |

| Elongation | ≥ 35% | ≥ 40% | ASTM E8 |

| Flatness Deviation | ≤ 3 mm/m | ≤ 2.5 mm/m | GB/T 3280 |

| Purity | ≥ 99.60% Al | ≥ 99.90% Cu | ICP-MS |

Width tolerance of ±0.002 mm is achieved through servo-driven precision slitting lines with real-time laser monitoring, eliminating cumulative width drift across coil lengths of 500–5000 meters. Burr-free edges are validated via automated optical inspection systems measuring micro-deformations at 500x magnification; burrs exceeding 2 μm (Al) or 1.5 μm (Cu) trigger immediate process correction. This eliminates wire breakage during high-speed winding and prevents interlayer short circuits. Conductivity is maintained at 61.0–62.5% IACS for aluminum and 100.0–101.0% IACS for copper through proprietary annealing protocols in oxygen-free atmospheres, ensuring optimal electron mobility and thermal dissipation. Surface roughness is controlled via precision-rolled mill finishes and tension leveling, critical for minimizing hysteresis losses in laminated cores.

All strips undergo 100% inline dimensional verification and batch-certified conductivity testing. Traceability to raw material heats (via MTRs) and process parameters (temperature, tension, speed logs) is provided. Our slitting process utilizes diamond-coated knives with geometric optimization for clean shearing, avoiding thermal recast layers that degrade conductivity. For transformer applications, consistent width tolerance directly correlates with core stacking factor—deviations >±0.002 mm reduce effective cross-sectional area by up to 1.8%, increasing no-load losses. Similarly, edge burrs >3 μm elevate hotspot risks by 15–20% during overload conditions. We enforce these specifications rigorously because in transformer design, micron-level variances translate to measurable efficiency penalties over operational lifetimes. Partner with Xinzhaohe for strips where electrical and dimensional precision are engineered, not estimated.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Strip/Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-purity aluminum and copper strips for transformer applications at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to meet the stringent electrical, mechanical, and dimensional requirements of the power transmission and distribution industry. With over two decades of metallurgical expertise, our facility integrates advanced cold rolling technology with precision slitting and edge conditioning to deliver consistent, high-performance strip products.

The process begins with cold rolling of high-conductivity aluminum (typically 1060, 1070, or 1350 alloys) or electrolytic tough pitch (ETP) copper. Incoming hot-rolled coils are first inspected for surface integrity and chemical composition. These coils are then fed into reversible cold rolling mills where they undergo multiple passes to achieve the target thickness, typically ranging from 0.1 mm to 3.0 mm. The cold rolling stage is critical for enhancing mechanical strength and achieving precise dimensional tolerances. Throughout this phase, roll gap calibration, tension control, and lubrication systems are continuously monitored to ensure uniform thickness and surface finish. The reduction per pass is carefully managed to prevent work hardening beyond acceptable limits, preserving the material’s ductility and electrical conductivity.

Following cold rolling, the coils proceed to the precision slitting line. Here, master rolls are longitudinally cut into narrow strips according to customer-specified widths, often within tight tolerances of ±0.1 mm. The slitting process employs high-precision circular knives with automated alignment systems to minimize burr formation and maintain edge straightness. Tension leveling is applied during slitting to eliminate coil memory and ensure flatness, a critical factor in downstream winding operations for transformer cores.

Edge conditioning is the next critical stage, particularly for strips used in wound core transformers. The slit edges undergo deburring and radius forming to remove micro-burrs and sharp asperities that could compromise insulation integrity or cause localized eddy current losses. This is achieved through controlled mechanical brushing, roller burnishing, or precision edge rolling, depending on the material and application requirements. Edge quality is validated using optical profilometry and tactile measurement systems.

Quality control is embedded throughout the manufacturing chain. In-process inspections include continuous thickness measurement via laser gauges, surface defect scanning using machine vision systems, and periodic sampling for tensile testing, conductivity measurement (IACS), and metallographic analysis. Final inspection includes coil-to-coil traceability, packaging verification, and certification of compliance with international standards such as ASTM B419 (copper) or ASTM B209 (aluminum). Each shipment is accompanied by a full material test report (FMTR) detailing mechanical, electrical, and dimensional properties.

This integrated approach ensures that every meter of transformer strip produced at Luoyang Xinzhaohe meets the highest standards of performance, reliability, and consistency required in modern power infrastructure.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols to safeguard aluminum and copper transformer strip and foil during global maritime transit. With over two decades of metallurgical and supply chain expertise, our methodology prioritizes moisture elimination and structural integrity, directly addressing the corrosive threats inherent in sea freight environments. This ensures product conformity to IEC 60404-8-5 and ASTM B209 standards upon delivery.

All coils undergo multi-stage preparation prior to unitization. Strips are surface-cleaned to remove residual rolling oils and inspected for micro-defects. Each coil is then hermetically sealed using a triple-layer moisture-proof barrier: an inner layer of vapor-corrosion inhibitor (VCI) film, a middle metallized polyester layer (125μm thickness, WVTR ≤0.1 g/m²/day), and an outer high-density polyethylene wrap. Critical edge sealing employs heat-welded lap joints with 50mm overlap to prevent capillary moisture ingress, validated through ASTM D3078 vacuum decay testing. Desiccant units (silica gel, 33% relative humidity capacity) are deployed at 500g per m³ of container volume, supplemented by humidity indicator cards for real-time monitoring.

Coils are mounted on custom-engineered wooden pallets compliant with ISPM 15 regulations. Pallets utilize kiln-dried (KD) hardwood with a minimum density of 650 kg/m³, featuring chamfered edges to prevent film abrasion. Load-bearing dimensions adhere to ISO 1161 standards (1200 × 1000 mm), supporting static loads up to 2500 kg. Coils are secured via steel strapping (16 mm width, 15 kN tensile strength) tensioned to 25% of breaking load, with edge protectors distributing pressure to avoid core deformation. Palletized units are further stabilized using dunnage and container wall bracing per CTU Code guidelines to mitigate shifting during transoceanic voyages exceeding 30 days.

This integrated system neutralizes three primary sea freight risks:

1. Condensation Control: The barrier film maintains internal RH below 40% for 90+ days, critical for preventing aluminum pitting (per ASTM G114) and copper tarnishing.

2. Mechanical Protection: Pallet rigidity and strapping prevent coil collapse under 1.5G lateral acceleration forces.

3. Contamination Prevention: Fully enclosed packaging blocks salt aerosol penetration, preserving surface resistivity for subsequent winding processes.

Verification occurs at three checkpoints: pre-sealing moisture mapping, post-palletization drop testing (0.8 m height), and container humidity logging. Our 99.2% damage-free shipment record across 1,200+ containers since 2020 underscores the efficacy of this approach. For extended voyages to tropical regions, we recommend optional nitrogen purging—reducing O₂ levels to <1%—to eliminate oxidation risks during monsoon-season transits. This packaging framework is not merely logistical; it is metallurgical insurance ensuring strip integrity from our mill to your transformer winding line.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Purity Transformer Strip and Foil

For over two decades, Luoyang Xinzhaohe Aluminum CO., Ltd has established itself as a leading manufacturer and supplier of high-purity aluminum and copper transformer strip and foil in the global industrial market. Located in the industrial hub of Luoyang, China, our facility integrates advanced metallurgical processing, strict quality assurance protocols, and scalable production capacity to meet the exacting demands of transformer and electrical equipment manufacturers worldwide.

Our manufacturing infrastructure is engineered for precision and consistency. We operate state-of-the-art cold rolling mills, continuous annealing lines, and precision slitting systems, all calibrated to produce transformer strip with tight dimensional tolerances, superior surface finish, and optimal electrical conductivity. With an annual production capacity exceeding 30,000 metric tons, we support both high-volume OEM contracts and specialized low-volume orders, ensuring flexibility without compromising on quality.

Material purity is at the core of our product performance. Our aluminum transformer strip is produced from 1xxx series alloys, primarily grades 1060, 1070, and 1350, with aluminum content exceeding 99.6%. Copper strip is sourced from high-conductivity electrolytic tough pitch (ETP) copper, meeting ASTM B187 and IEC 60164 standards. Each batch undergoes rigorous chemical analysis via optical emission spectrometry (OES) and mechanical testing to ensure compliance with international specifications.

Quality control is embedded at every stage of production. Our in-house laboratory is equipped with tensile testing machines, microhardness testers, eddy current flaw detectors, and surface profilometers, enabling real-time monitoring of mechanical properties, electrical resistivity, and surface integrity. All products are traceable through batch coding and full material certification (MTC) in accordance with ISO 9001:2015 requirements.

We specialize in custom configurations to meet client-specific design needs. Our engineering team supports clients with strip widths ranging from 10 mm to 800 mm, thicknesses from 0.1 mm to 6.0 mm, and various temper conditions including O (annealed), H14, H16, and H18. We also offer slit-to-length cutting, edge conditioning, and coil packaging tailored to automated winding processes used in transformer manufacturing.

Sustainability and supply chain reliability are integral to our operations. We maintain strategic raw material reserves, operate energy-efficient rolling technologies, and have developed long-term partnerships with certified smelters to ensure uninterrupted supply and consistent quality. Our logistics network enables timely delivery to ports in Shanghai, Qingdao, and Tianjin, with options for FOB, CIF, and DDP terms globally.

When you partner with Luoyang Xinzhaohe, you gain more than a supplier — you gain a technical collaborator committed to performance, precision, and long-term reliability in the transformer materials supply chain.

For technical inquiries, material specifications, or sample requests, contact us at:

cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing pure strip directly from China.