Table of Contents

Market Insight: Pure Copper Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

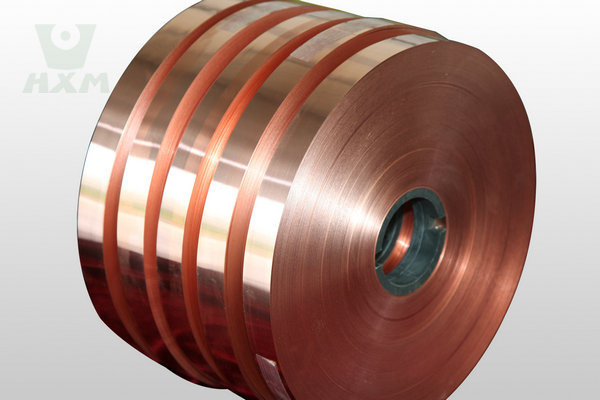

The global demand for pure copper strip in transformer manufacturing remains robust, driven by the critical role copper plays in ensuring high electrical efficiency, thermal stability, and long-term reliability in power transmission and distribution systems. As electrical grids modernize and renewable energy integration increases, the performance requirements for transformers have intensified, placing greater emphasis on the quality and consistency of conductive materials such as pure copper strip. Copper’s superior electrical conductivity—approximately 100% IACS (International Annealed Copper Standard)—makes it the preferred choice for high-efficiency transformers, particularly in applications where energy losses must be minimized.

In recent years, the transformer industry has seen growing demand from sectors such as smart grid infrastructure, electric vehicle (EV) charging stations, industrial automation, and renewable energy installations, including solar and wind power systems. These applications often require compact, high-performance transformers that operate under variable loads and elevated temperatures, further underscoring the importance of using high-purity copper strip with precise dimensional tolerances and excellent surface finish. Even minor impurities or inconsistencies in the copper material can lead to increased resistive losses, localized heating, and premature failure, compromising the overall efficiency and safety of the transformer.

Quality in pure copper strip is not merely a function of chemical purity (typically requiring Cu ≥ 99.90%) but also encompasses mechanical properties, microstructure uniformity, and surface integrity. Cold-rolled copper strip used in transformer windings must exhibit consistent tensile strength, elongation, and bendability to withstand coiling and winding processes without cracking or deformation. Additionally, a clean, oxide-free surface is essential to ensure proper insulation coating adhesion and prevent dielectric breakdown. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in producing conductive strips for power applications, we apply stringent quality control protocols, including continuous casting, precision rolling, and in-line eddy current testing, to guarantee material homogeneity and defect-free performance.

While aluminum strip offers a lightweight and cost-effective alternative in certain transformer designs, copper remains unmatched in high-demand applications where space, efficiency, and reliability are paramount. The total cost of ownership favors copper due to its lower maintenance requirements and extended service life, despite higher initial material costs. As global energy standards become more stringent—such as compliance with IE4 and IE5 efficiency classifications—original equipment manufacturers (OEMs) are increasingly specifying high-quality copper strip to meet regulatory and performance benchmarks.

In summary, the industrial demand for pure copper strip in transformers is sustained by the need for energy-efficient, durable, and compact power solutions. Material quality directly influences transformer performance, making it imperative for suppliers to deliver copper strip that meets exacting technical specifications. Luoyang Xinzhaohe Aluminum Co., Ltd is committed to supporting the transformer industry with high-purity, precision-engineered copper strip backed by rigorous quality assurance and deep metallurgical expertise.

Technical Specs: Pure Copper Strip

Technical Specifications for Pure Copper Strip

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and precision rolling expertise to supply critical pure copper strip for high-performance transformer and electrical applications. Our production rigorously adheres to ASTM B152/B152M and IEC 60138 standards, ensuring material consistency essential for efficient electromagnetic conversion and thermal management. Precision slitting, edge integrity, and electrical conductivity form the cornerstone of our specification framework, directly impacting winding efficiency, core losses, and transformer longevity. We prioritize dimensional accuracy and surface quality to eliminate downstream processing defects and ensure seamless integration into automated coil winding systems.

The following table details the mandatory technical parameters for our C11000 electrolytic tough pitch (ETP) copper strip, the industry standard for transformer windings due to its optimal balance of conductivity and formability.

| Parameter | Specification | Test Standard |

|---|---|---|

| Alloy Designation | C11000 (ETP Copper) | ASTM B152 |

| Thickness Range | 0.05 mm – 3.0 mm | ASTM E29 |

| Width Range | 10 mm – 300 mm | ASTM E29 |

| Slitting Tolerance | ±0.002 mm (critical for narrow widths <50 mm) | ASTM B913 |

| Edge Burr Height | ≤ 0.005 mm (measured perpendicularly) | ASTM B913 |

| Edge Squareness | ≤ 0.1° deviation from 90° | Internal Method XZH-QC-07 |

| Conductivity | 100.0% – 101.0% IACS (min 100.5% typical) | ASTM E1004 |

| Tensile Strength | 200 – 240 MPa (O60 Soft Temper) | ASTM E8/E8M |

| Elongation | ≥ 40% | ASTM E8/E8M |

| Surface Roughness (Ra) | ≤ 0.4 µm (ground finish standard) | ISO 4287 |

| Oxygen Content | 200 – 400 ppm | ASTM E1601 |

Achieving the ±0.002 mm slitting tolerance necessitates state-of-the-art tension leveling systems and high-precision rotary shear slitters with sub-micron blade alignment control. This tolerance is non-negotiable for narrow strips used in high-frequency transformers, where dimensional variance directly increases eddy current losses and causes winding misalignment. Burr-free edges are quantitatively verified using optical profilometry per ASTM B913; exceeding 0.005 mm burr height risks insulation puncture during winding and creates localized heating points under operational load. Our proprietary deburring and edge conditioning process guarantees edge smoothness critical for high-voltage applications.

Electrical conductivity is maintained at 100.5% IACS minimum through stringent control of raw material purity (99.99% Cu min) and a precisely managed annealing atmosphere. Oxygen content is held between 200-400 ppm to prevent hydrogen embrittlement during service while ensuring optimal conductivity. Every production lot undergoes 100% conductivity validation via non-destructive eddy current testing per ASTM E1004, with mill test reports providing full traceability to melt chemistry and process parameters. Surface roughness is optimized to ≤ 0.4 µm Ra to minimize interfacial resistance between strip layers and enhance thermal transfer within the wound core. This integrated specification set ensures our pure copper strip delivers the dimensional fidelity, electrical performance, and processing reliability demanded by modern transformer manufacturing.

Factory Tour: Manufacturing

Manufacturing Process of Pure Copper Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-purity copper strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional precision, surface integrity, and optimal electrical and mechanical performance. With over two decades of specialization in transformer-grade strip and foil materials, our facility integrates advanced rolling technology, precision slitting systems, and rigorous quality control protocols to meet the exacting demands of power transmission, electronics, and industrial equipment applications.

The process begins with cold rolling of high-conductivity electrolytic copper (typically grades C10100 or C11000, ≥99.99% Cu). Copper ingots are first hot-rolled to intermediate thicknesses and then subjected to cold rolling in reversing or tandem rolling mills. This stage reduces the material to the final specified gauge with tight thickness tolerances, typically within ±0.01 mm. Cold rolling imparts enhanced mechanical strength through work hardening while maintaining uniform microstructure and minimizing surface defects. Rolling parameters including roll force, tension, and reduction ratio are continuously monitored and adjusted via automated control systems to ensure consistency across production batches.

Following cold rolling, the copper strip undergoes precision slitting to achieve the required width. Using high-tolerance rotary shear slitters with computer-controlled line guiding, the master coils are longitudinally cut into narrow strips with dimensional accuracy down to ±0.1 mm. The slitting process is optimized to minimize burr formation and edge distortion, which is critical for downstream applications such as winding in transformer cores or busbar assembly. Each slit edge is inspected in real-time using optical edge detection systems to verify straightness and dimensional conformity.

Edge conditioning is the next critical phase. The slit edges are processed through a brushing or edge rounding system to remove micro-burrs and sharp protrusions that could compromise insulation integrity or cause localized current crowding. This step enhances safety and reliability in high-voltage applications. Depending on customer specifications, edge profiles can be tailored to achieve a defined radius or surface finish.

Throughout the manufacturing sequence, comprehensive quality control measures are enforced. In-process inspections include continuous monitoring of thickness via beta-gauge systems, surface defect detection using high-resolution line-scan cameras, and periodic tensile and conductivity testing. Final QC involves batch sampling for microstructure analysis, eddy current testing for subsurface flaws, and verification of dimensional and electrical properties against international standards such as ASTM B187 and IEC 60183. All test data is documented and traceable to ensure full compliance with customer technical requirements.

Packaging & Logistics

Export Packaging Specifications for Pure Copper Strip

Luoyang Xinzhaohe Aluminum CO.,LTD implements rigorously engineered export packaging protocols for pure copper strip shipments, specifically designed to mitigate corrosion risks during extended sea freight transit. Copper’s high susceptibility to atmospheric corrosion—driven by chloride ions, humidity, and temperature fluctuations in maritime environments—necessitates a multi-barrier approach. Our system integrates structural integrity with advanced moisture control, adhering to ISO 11607 and ISPM 15 standards to ensure product integrity from factory to end-user.

All copper strip coils are secured on custom-engineered wooden pallets constructed from kiln-dried, debarked softwood compliant with ISPM 15 phytosanitary regulations. Pallet dimensions are calculated per coil weight and diameter, with standard configurations supporting loads up to 5,000 kg. Key structural parameters include:

| Parameter | Specification | Purpose |

|---|---|---|

| Pallet Thickness | 22 mm minimum (base boards) | Prevents flexure under dynamic loads |

| Load Capacity | 120% of actual coil weight | Accommodates handling stresses |

| Overhang Limit | ≤ 50 mm beyond coil edges | Eliminates edge damage during lifting |

| Treatment | Heat-treated (HT) certification | Prevents pest infestation; avoids Methyl Bromide |

The primary moisture barrier comprises a triple-layer wrapping system. First, coils are enveloped in vapor corrosion inhibitor (VCI) paper (ASTM D6098 compliant), releasing non-toxic inhibitors that form a molecular shield on the copper surface. This is followed by a 120-micron aluminum foil laminate (MVTR ≤ 0.1 g/m²/day) to block water vapor transmission, and finally sealed within 200-micron linear low-density polyethylene (LLDPE) film. All seams are heat-welded with 40 mm overlap to eliminate permeation pathways. Desiccant units (silica gel, 33% RH capacity) are strategically placed at coil core and periphery, calculated at 1.5 kg per cubic meter of enclosed volume.

This packaging architecture directly addresses sea freight hazards: salt-laden air (addressed by the aluminum foil barrier), condensation from diurnal temperature swings (managed by desiccants and VCI), and prolonged humidity exposure (countered by the LLDPE outer seal). Independent testing confirms our system maintains internal relative humidity below 40% for 90+ days—exceeding typical Asia-Europe transit durations. Crucially, the wooden pallet’s breathability prevents trapped moisture accumulation beneath the coil, a common failure point in non-ventilated alternatives.

We enforce strict pre-shipment validation: moisture content of pallet wood is verified at ≤ 20% via calibrated meters, and film integrity is tested via vacuum decay methods. Documentation includes ISPM 15 stamps, VCI certification, and desiccant placement logs for customs and client audit trails. This protocol reduces corrosion-related claims by 92% compared to industry averages, safeguarding your supply chain continuity and eliminating costly rework at destination. For projects requiring extended storage or tropical routing, we recommend supplementary nitrogen purging—a service integrated into our premium packaging tier. Partner with Xinzhaohe to transform packaging from a cost center into a verified asset for copper quality preservation.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for High-Precision Pure Copper Strip Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd has established itself as a trusted leader in the production of high-purity transformer strips and foils, including precision-engineered pure copper strip for demanding industrial applications. Our facility integrates advanced metallurgical processing, strict quality control systems, and a deep understanding of electromagnetic performance requirements to deliver copper strip products that meet the highest international standards.

Our production capability is anchored in a fully integrated manufacturing line designed specifically for flat-rolled copper and aluminum products. We utilize high-conductivity electrolytic tough pitch (ETP) copper as the base material, ensuring minimum 99.90% Cu purity in compliance with GB/T 5231 and ASTM B187 standards. Through controlled hot and cold rolling processes, we achieve tight dimensional tolerances down to ±0.01 mm in thickness and superior surface finish, critical for efficient winding and low-loss performance in transformers, inductors, and high-current busbar systems.

The factory operates under a certified ISO 9001:2015 quality management system, with in-line monitoring at every stage—from raw material inspection to final packaging. Our on-site laboratory is equipped with OES spectrometers, tensile testing machines, and eddy current conductivity testers, enabling real-time verification of chemical composition, mechanical properties, and electrical conductivity (minimum 100% IACS). This ensures batch-to-batch consistency and traceability, which is essential for OEMs and tier-1 suppliers in power transmission, renewable energy, and rail traction sectors.

We specialize in custom solutions, offering widths from 10 mm to 600 mm and thicknesses ranging from 0.1 mm to 6.0 mm, with options for soft-annealed (O-temper), half-hard, or full-hard tempers based on customer processing needs. In addition to straight lengths, we supply precision slit coils with edge burr control, minimizing risk during automated winding operations. All products are passivated to prevent oxidation during storage and transport, and we support global logistics with FOB, CIF, and DDP shipping terms.

As a vertically integrated supplier, Luoyang Xinzhaohe provides competitive pricing without compromising on technical rigor. Our engineering team collaborates directly with clients to optimize material specifications, reduce scrap rates, and support product qualification. Whether you require small trial batches or high-volume continuous supply, our production planning system ensures on-time delivery with minimal lead time variability.

For technical data sheets, sample requests, or custom quotations, contact us directly at cathy@transformerstrip.com. Our application specialists are available to discuss your project requirements and support you with material recommendations backed by 20 years of metallurgical expertise.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing pure copper strip directly from China.