Table of Contents

Market Insight: Pure Copper Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) – Pure Copper Coil Demand and Quality Imperatives

Global demand for pure copper coil in transformer manufacturing continues to exhibit robust growth, driven by critical infrastructure modernization and the accelerating energy transition. Primary demand vectors include the expansion of high-voltage transmission networks to integrate renewable energy sources, the proliferation of electric vehicle charging infrastructure requiring robust distribution transformers, and stringent global efficiency regulations (e.g., DOE 2016, EU Ecodesign). While aluminum strip/foil serves cost-sensitive segments, pure copper coil remains indispensable for high-performance, high-reliability applications where electrical and thermal conductivity are paramount. The global transformer market, valued at approximately USD 120 billion in 2023, projects a compound annual growth rate (CAGR) of 7.2% through 2030, with the high-efficiency segment demanding premium copper materials growing at an accelerated pace.

| Market Segment | Key Driver | Copper Coil Demand Impact |

|---|---|---|

| Power Transmission | Grid modernization, HVDC projects | High (Critical for HV windings) |

| Renewable Integration | Solar/Wind farm step-up transformers | Very High (Reliability focus) |

| EV Charging | Fast-charging station deployment | Rapidly Increasing |

| Industrial Distribution | Efficiency mandates (Tier 4+) | Sustained High |

The technical superiority of electrolytic-tough-pitch (ETP) copper (C11000) for transformer windings stems from its unmatched electrical conductivity (minimum 100% IACS per ASTM B3/B301) and superior thermal management properties compared to aluminum. Copper’s higher conductivity density allows for more compact winding designs without compromising current-carrying capacity, directly enhancing transformer efficiency and power density—critical factors under modern efficiency standards. Crucially, copper exhibits significantly lower creep susceptibility and superior resistance to electromigration under thermal cycling stress, mitigating long-term reliability risks inherent in aluminum alternatives for demanding applications.

Quality control for pure copper coil is non-negotiable in transformer manufacturing. Deviations in critical parameters directly correlate with catastrophic field failures. Oxygen content must be strictly controlled (typically 200-400 ppm) to prevent hydrogen embrittlement during annealing; excessive oxygen forms Cu₂O inclusions that act as nucleation sites for voids under operational stress. Surface integrity is equally vital; microscopic scratches or pits from inadequate drawing/lubrication become initiation points for partial discharge, accelerating insulation degradation. Dimensional precision (thickness tolerance ≤ ±0.005mm) ensures consistent winding tension and prevents inter-turn faults. Contaminants such as iron (>10 ppm) or sulfur (>5 ppm) create localized hot spots through increased resistivity, while inconsistent grain structure from improper annealing induces anisotropic mechanical properties, heightening vulnerability to vibration-induced fatigue.

Luoyang Xinzhaohe Aluminum leverages two decades of metallurgical expertise to emphasize that material selection is application-specific. While aluminum strip/foil offers viable economics for distribution transformers, pure copper coil remains the engineering benchmark for mission-critical power and high-frequency applications. Sourcing copper coil demands rigorous validation of supplier metallurgical processes—not merely dimensional compliance—to ensure the microstructural homogeneity and surface perfection required for 30+ year operational lifespans. Strategic sourcing must prioritize certified mills with demonstrable process control over oxygen content, annealing profiles, and surface finishing, as these factors fundamentally determine transformer reliability and total cost of ownership.

Technical Specs: Pure Copper Coil

Technical Specifications for Pure Copper Coil – Transformer Strip/Foil Application

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers high-performance pure copper coil products engineered specifically for precision transformer strip and foil applications. With over two decades of metallurgical and supply chain expertise, our manufacturing processes are optimized to meet the stringent dimensional, electrical, and surface quality requirements of modern power and electronic transformers. The following technical specifications outline the critical parameters governing our pure copper coil production, ensuring consistency, reliability, and compliance with international standards including ASTM B187 and IEC 60137.

Our pure copper coils are manufactured from high-purity electrolytic tough pitch (ETP) copper (Cu-ETP, C11000), with a minimum copper content of 99.90%. This base material ensures excellent electrical conductivity and formability, essential for high-efficiency transformer windings. Conductivity is rigorously tested and maintained at a minimum of 100% IACS (International Annealed Copper Standard) at 20°C, with typical values ranging between 100–101% IACS. This guarantees minimal resistive losses and optimal thermal performance under continuous load conditions.

Precision slitting is a core competency in our production line, enabling tight width tolerances critical for automated winding processes. All coils are slit to customer-defined widths with a dimensional tolerance of ±0.002 mm. This level of accuracy is achieved through servo-controlled slitting machines equipped with high-precision tooling and real-time laser monitoring systems. Consistent width control reduces material waste, prevents winding misalignment, and enhances the overall reliability of the final transformer assembly.

Edge quality is equally critical. Our proprietary deburring and edge-finishing technology ensures completely burr-free edges after slitting. Burr height is consistently maintained below 2% of material thickness, eliminating the risk of interlayer short circuits and dielectric breakdown in high-voltage applications. Surface finish is smooth and uniform, with a roughness average (Ra) typically between 0.3–0.6 µm, minimizing friction during winding and reducing the potential for insulation damage.

Mechanical properties are tailored through controlled annealing processes. Typical tensile strength ranges from 200–240 MPa, with elongation exceeding 40%, providing an optimal balance of strength and ductility. Coils are supplied in soft (annealed) temper (O-temper), ensuring excellent formability for tight-radius winding without cracking or edge splitting.

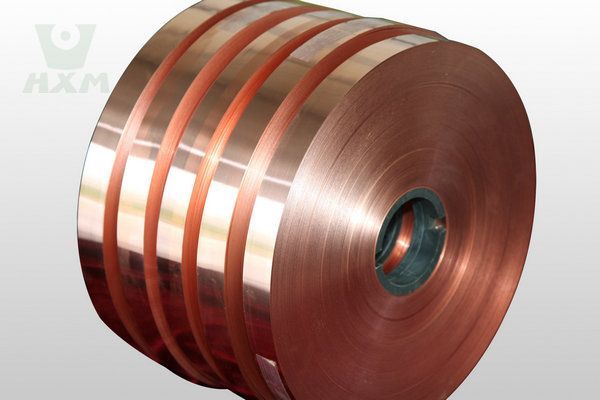

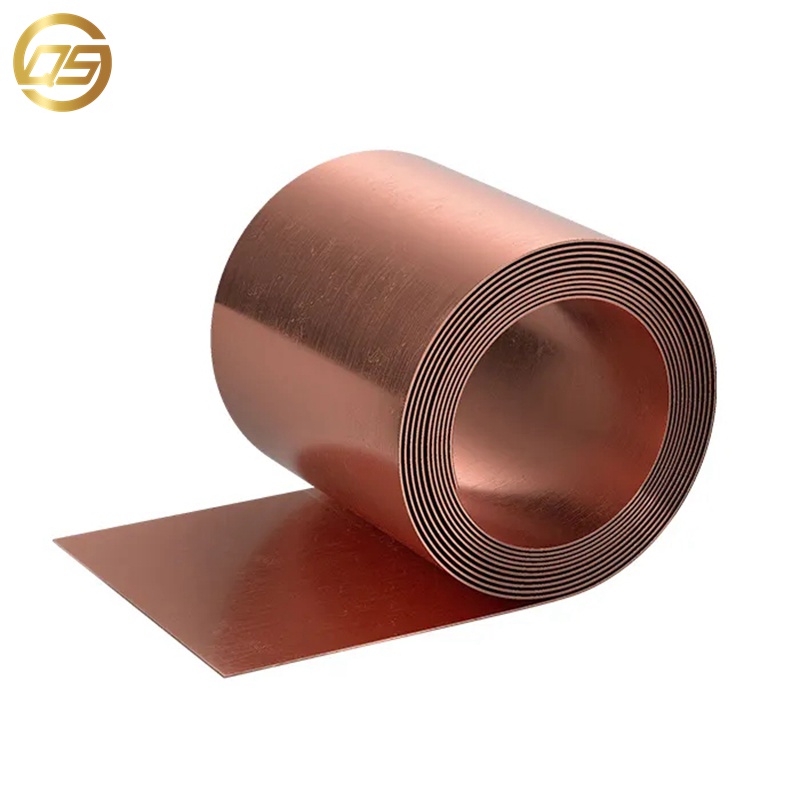

All coils are precision-wound on sturdy cores with consistent tension control to prevent telescoping, edge damage, or ovality. Standard inner diameters are 508 mm (20″) or 610 mm (24″), with outer diameters up to 1200 mm. Coil weights are optimized for handling and processing efficiency, typically ranging from 800 to 2500 kg.

| Parameter | Specification |

|---|---|

| Material | Cu-ETP (C11000), min 99.90% Cu |

| Conductivity | ≥100% IACS (typically 100–101%) |

| Thickness Range | 0.05 mm – 3.0 mm |

| Width Tolerance | ±0.002 mm |

| Burr Height | <2% of thickness, burr-free edges |

| Surface Roughness (Ra) | 0.3–0.6 µm |

| Temper | O (Annealed) |

| Tensile Strength | 200–240 MPa |

| Elongation | ≥40% |

| Core ID | 508 mm or 610 mm |

| Max Outer Diameter | 1200 mm |

| Coil Weight Range | 800–2500 kg |

| Standards Compliance | ASTM B187, IEC 60137 |

Factory Tour: Manufacturing

Pure Copper Coil Manufacturing Process for Transformer Applications

Pure copper coil production for transformer strip and foil demands rigorous metallurgical control to ensure electrical conductivity, dimensional precision, and surface integrity. At Luoyang Xinzhaohe Aluminum Co., Ltd., our 20+ years of specialized experience in non-ferrous rolling translates into a disciplined three-stage process for oxygen-free electrolytic tough pitch (OFE/ETP) copper, adhering to ASTM B152 and IEC 60138 standards.

Cold rolling initiates the process, where continuously cast copper billets undergo multi-pass reduction under precisely controlled tension and inter-annealing cycles. Initial hot-rolled strips (typically 3–6 mm thick) enter our 4-high reversing cold mills with computerized roll gap adjustment, achieving reductions down to 0.05–0.5 mm. Critical parameters include interpass annealing at 450–550°C in oxygen-free atmospheres to relieve work hardening while maintaining grain structure uniformity. Real-time X-ray gauges monitor thickness deviations, ensuring tolerances within ±0.005 mm across the coil width. Surface quality is concurrently verified via automated optical inspection systems detecting inclusions, scratches, or roll marks exceeding 5 µm depth.

Precision slitting follows, converting master coils into narrow strips conforming to transformer winding specifications. Our tension-leveling slitters utilize laser-guided knife positioning with micron-level accuracy, maintaining strip flatness through active tension control. Width tolerances are held to ±0.05 mm for strips below 50 mm width, critical for minimizing inter-winding gaps in transformer cores. Each slit edge undergoes immediate inline monitoring via high-resolution cameras to detect micro-burrs or edge waviness, triggering automatic knife recalibration if deviations exceed 10 µm.

Edge conditioning constitutes the final mechanical stage, eliminating residual burrs from slitting that could compromise insulation integrity in transformer windings. Strips pass through precision brushing and edge-radiusing units, where rotational abrasive belts apply controlled pressure to achieve a smooth, uniform edge profile. This step reduces edge roughness to Ra ≤ 0.8 µm, validated through profilometer scans at 1-meter intervals. Concurrently, residual stress relief annealing at 250–300°C ensures dimensional stability during subsequent coil winding.

Quality control is embedded at every phase, culminating in comprehensive final inspection. All coils undergo 100% surface scanning, thickness profiling, and edge quality validation. Electrical properties are certified via four-point probe resistivity testing, guaranteeing minimum 100% IACS conductivity. Traceability is maintained through laser-etched batch codes linked to melt chemistry records.

Final Product Verification Parameters

| Parameter | Specification | Test Method | Frequency |

|---|---|---|---|

| Thickness Tolerance | ±0.005 mm | Laser Micrometer | Continuous |

| Width Tolerance | ±0.05 mm | Optical Gauge | Per 50 m |

| Edge Burr Height | ≤ 10 µm | Profilometer | Per coil end |

| Resistivity | ≥ 1.724 µΩ·cm | Four-Point Probe | Per melt batch |

| Surface Defects | None > 5 µm depth | Automated Optical Scanner | 100% |

This integrated approach ensures our pure copper coils deliver the metallurgical consistency and geometric precision demanded by high-efficiency transformer manufacturing, with full documentation supporting ISO 9001-certified traceability from cathode to coil.

Packaging & Logistics

Export Packaging for Pure Copper Coil: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in the production and international distribution of high-purity copper and aluminum transformer strip and foil, we recognize that robust export packaging is critical to preserving material integrity during prolonged sea freight transit. Our packaging protocol for pure copper coil shipments is engineered to mitigate environmental exposure, mechanical stress, and logistical risks inherent in global maritime transport.

All copper coils are mounted on precision-engineered wooden pallets constructed from high-density, kiln-dried hardwood. These pallets are designed to support the coil’s structural weight—typically ranging from 500 kg to 5,000 kg per unit—while maintaining dimensional stability under dynamic load conditions. Each pallet undergoes treatment in compliance with ISPM 15 standards, ensuring phytosanitary safety and regulatory acceptance across international borders. The wooden base is reinforced with steel strapping where necessary to prevent lateral displacement during vessel loading, stacking, and offloading.

Immediately following coil placement on the pallet, the assembly is sealed within a multi-layer moisture-proof packaging system. This consists of an inner wrapping of anti-corrosion paper (VCI—Vapor Corrosion Inhibitor treated), followed by a primary barrier of high-tensile polyethylene film with a minimum thickness of 125 microns. The film provides a hermetic seal against humidity, salt-laden air, and condensation—common challenges in tropical and marine climates. An additional outer layer of UV-resistant polypropylene shrink wrap may be applied for extended voyages or regions with elevated solar exposure.

To further enhance protection, desiccant packs are strategically placed within the sealed envelope to absorb residual moisture and maintain a controlled internal atmosphere. Each packaged unit is labeled with orientation indicators, handling instructions, and tracking identifiers compliant with international logistics standards (ISO 780 and ISO 2274). Weight, coil ID, batch number, and material specifications are clearly marked to facilitate customs clearance and inventory management at the destination port.

Our packaging design has been validated through accelerated aging tests and real-world shipping trials across major trade routes, including trans-Pacific and trans-Indian Ocean shipments. These evaluations confirm the system’s efficacy in preventing surface oxidation, edge damage, and dimensional deformation over transit durations exceeding 45 days.

For clients sourcing pure copper coil for transformer and electrical applications, material purity and surface finish are non-negotiable. Our export packaging protocol ensures that the product delivered matches the product manufactured—free from contamination, corrosion, or mechanical compromise. This commitment to packaging integrity reflects Luoyang Xinzhaohe’s broader philosophy: that excellence extends beyond production to every phase of the supply chain.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Pure Copper Coil Supply

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and manufacturing expertise to deliver pure copper coil meeting the exacting demands of the global transformer and electrical component industry. Our core strength lies in the precise control of material properties essential for high-efficiency electromagnetic applications, extending beyond our foundational aluminum capabilities to encompass high-purity copper processing. We understand that transformer performance hinges on the fundamental electrical and mechanical characteristics of the conductor material, and our integrated production system is engineered to consistently achieve these critical parameters.

Our metallurgical process begins with stringent raw material selection, utilizing only oxygen-free electrolytic copper cathode meeting ASTM B152 Grade C10100 or C10200 specifications, ensuring minimum 99.99% Cu purity with controlled oxygen content below 10 ppm. Advanced continuous casting and precision rolling lines operate under tightly monitored thermal and mechanical conditions to optimize grain structure, conductivity, and surface integrity. Each coil undergoes controlled annealing in protective atmospheres to achieve the target temper (typically H00 soft annealed) while maintaining uniform tensile strength between 200-240 MPa and minimum 100% IACS conductivity. This granular control over the recrystallization process is vital for subsequent winding operations and long-term thermal stability within transformer cores.

Quality assurance is embedded at every stage, not merely as final inspection. In-process monitoring includes real-time eddy current testing for subsurface defects, laser micrometry for dimensional tolerance control (width tolerance ±0.05mm, thickness tolerance ±0.005mm), and automated surface inspection systems. Final validation utilizes certified laboratory testing per IEC 60138 and ASTM B3, encompassing chemical composition verification via spark-OES, precise conductivity measurement using the voltmeter-ammeter method, and mechanical property confirmation through tensile and bend testing. Comprehensive mill test reports accompany every shipment, providing full traceability from cathode lot to finished coil.

Our supply chain infrastructure is designed for reliability in critical component sourcing. Strategically located manufacturing facilities in Luoyang, Henan Province, integrate seamlessly with major Chinese ports and rail networks, enabling efficient global logistics. We maintain flexible production scheduling to accommodate both large-volume framework agreements and urgent, smaller-batch requirements typical in transformer manufacturing cycles. Customization capabilities extend beyond standard dimensions to include specialized edge conditioning, tailored annealing profiles, and bespoke packaging solutions to prevent transit damage. This operational agility, combined with ISO 9001 and IATF 16949 certified processes, ensures consistent on-time delivery of material that performs as specified in your winding and impregnation processes.

Partnering with Luoyang Xinzhaohe provides direct access to a vertically integrated supplier whose metallurgical discipline and process control minimize material-related performance variances in your transformer production. We translate decades of transformer strip and foil experience into tangible value through reduced scrap rates, enhanced winding efficiency, and guaranteed electrical performance. For technical specifications, production capacity details, or to discuss your specific pure copper coil requirements, contact Cathy Zhang directly at cathy@transformerstrip.com to initiate a precision supply solution.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing pure copper coil directly from China.