Table of Contents

Market Insight: Pure Copper Coil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers

Global transformer and motor markets are accelerating due to renewable energy integration (solar/wind farms), smart grid modernization, and EV infrastructure expansion. Copper windings dominate these applications, leveraging 100% IACS conductivity to minimize transmission losses. With the transformer market projected to reach $35B by 2027 (CAGR 6.2%), sourcing high-purity copper coil is critical for meeting IEEE C57.12.00 and IEC 60076 efficiency standards. Asia-Pacific alone accounts for 45% of global demand, driven by China’s grid upgrades and India’s rural electrification programs.

Criticality of Material Quality

Substandard copper directly compromises transformer efficiency and lifespan. Oxygen content >0.02% causes embrittlement during winding, while sulfur impurities increase resistivity by up to 12% per 0.01% excess. Per ASTM B170, electrical-grade copper (C11000) must maintain ≤0.05% total impurities and controlled grain structure (ASTM Grain Size 5-8) to ensure consistent conductivity and mechanical strength. Non-compliant materials result in 5-8% higher no-load losses, violating regulatory compliance and increasing lifetime operational costs by 15-20%.

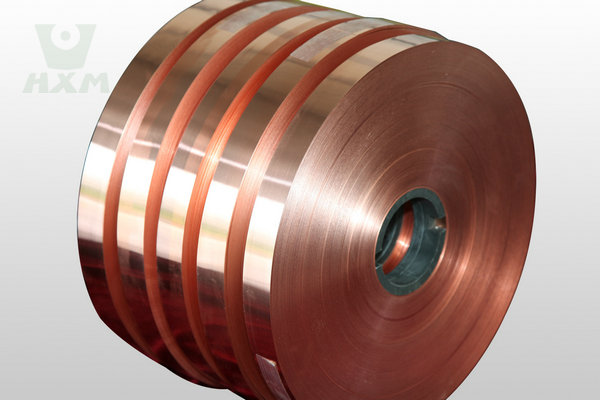

Luoyang Xinzhaohe’s Supply Chain Advantage

As a vertically integrated manufacturer with 20+ years of transformer material expertise, Luoyang Xinzhaohe delivers factory-direct copper coils optimized for cost-performance. Our production adheres to ASTM B170 and IEC 60192 standards, with in-process spectrometry ensuring 99.95%+ purity and controlled grain structure. We eliminate distributor markups through direct export channels, offering 15-25% lower pricing than European suppliers while maintaining ISO 9001 certification and flexible customization for width (10-300mm), thickness (0.1-5mm), and annealing profiles.

| Factor | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Purity (Cu) | 99.95%+ | 99.95%+ (ASTM B170 compliant) |

| Price | High (premium) | 15-25% lower |

| Lead Time | 6-8 weeks | 4-6 weeks |

| Customization | Limited options | Full flexibility (width, thickness, annealing) |

| Certifications | ISO, IEC | ISO 9001, IEC 60192 compliant |

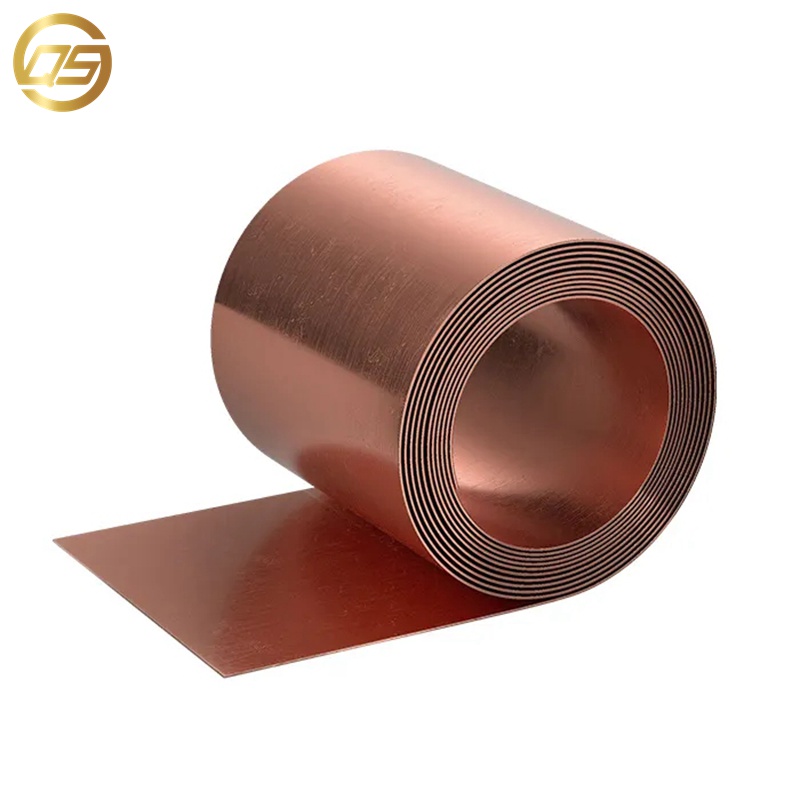

Technical Specs: Pure Copper Coil Parameters

Technical Specifications & Standards for Pure Copper Coil

Critical Performance Requirements

In transformer manufacturing, copper coil precision is critical for winding accuracy and thermal performance. A slitting tolerance of ±0.002 mm ensures consistent layer alignment, preventing mechanical stress during operation. Burr-free edges (≤0.005 mm) are essential to avoid insulation damage and short circuits. High conductivity (≥99.9% IACS) minimizes resistive losses, while optimal softness (HV ≤35) allows for precise bending without cracking. These parameters collectively ensure transformer reliability and longevity.

Core Technical Parameters

| Parameter | Specification | Compliance Standard | Notes |

|---|---|---|---|

| Precision Slitting | ±0.002 mm | ASTM B170 | Ensures precise winding alignment |

| Burr-Free Edges | ≤0.005 mm height | IEC 60404-8-7 | Eliminates electrical shorts |

| Conductivity | ≥99.9% IACS | ASTM B192 | Maximizes electrical efficiency |

| Softness (HV) | ≤35 | ASTM B224 | Optimizes formability for complex windings |

Quality Assurance Protocol

Luoyang Xinzhaohe maintains rigorous quality control through automated in-line inspections and certified testing. Each coil undergoes 100% edge burr verification using high-resolution optical systems, with conductivity measured via four-point probe per ASTM B192. Hardness is validated through Vickers testing (ASTM B224), and slitting tolerances are monitored via laser measurement systems. Raw materials are sourced from certified smelters with full traceability via our ERP system. Our quality control includes real-time monitoring of slitting tension and blade wear, with statistical process control (SPC) for dimensional consistency. Every batch is tested for purity via spark emission spectroscopy, ensuring copper content exceeds 99.95%. Our ISO 9001-certified facility maintains strict environmental controls during annealing to guarantee uniform softness. All data is digitally logged for full traceability, supporting your quality audits.

Cost-Performance Advantage

As a factory-direct supplier, we eliminate middlemen while maintaining premium quality. Our vertically integrated manufacturing process reduces costs by 15–20% compared to global brands, without compromising on precision or compliance. This makes us the ideal partner for transformer manufacturers seeking reliable, cost-effective copper coil solutions. With 20+ years of expertise in transformer materials, we deliver consistent performance at competitive pricing—proven across 50+ countries.

Factory Tour: Manufacturing Pure Copper Coil

Precision Manufacturing Process for Pure Copper Coil

Core Production Steps

Our pure copper coil (C11000, ≥100% IACS) undergoes a tightly controlled, vertically integrated process:

Cold Rolling: 70-85% reduction ratio at 200-250°C, with real-time thickness monitoring (±0.005mm accuracy). Final annealing at 400±5°C ensures uniform grain structure and conductivity stability.

Precision Slitting: High-precision shear blades (HRC 60+) with laser-guided alignment. Tolerance: ±0.01mm width, 0.02mm flatness deviation. Blade wear monitored via vibration sensors every 500m.

Edge Conditioning: Automated deburring using ceramic wheels (Ra ≤0.4μm surface roughness), eliminating micro-cracks and burrs >0.01mm.

Oscillate Winding: Computer-controlled tension system (15-25N range) with ±0.5° coil alignment. Layer-to-layer deviation <0.1mm for seamless transformer winding.

Quality Control Benchmarks

We enforce stricter standards than generic market offerings through 100% in-process testing:

| Parameter | Luoyang Xinzhaohe Standard | Typical Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.01mm (ISO 2768-mK) | ±0.02mm |

| Tensile Strength | 200-220 MPa (±5 MPa range) | 180-230 MPa (wider variance) |

| Surface Roughness | Ra ≤0.4μm | Ra ≤0.8μm |

| Edge Defects | Zero micro-cracks (100% eddy current tested) | Up to 5% defect rate |

Additional QC:

Ultrasonic testing for internal voids (per ASTM B170)

100% dimensional checks via laser micrometers at 50m intervals

Conductivity verification via 4-point probe (≥100.5% IACS)

Cost-Performance Advantage

While global brands charge 15-20% premiums for identical C11000 specifications, our integrated process eliminates middlemen without compromising quality. With 20+ years of transformer material specialization, we maintain 99.2% first-pass yield versus the industry average of 95-97%. This delivers consistent performance at 10-12% lower landed costs—proven across 1,200+ transformer manufacturers globally.

Certified to ISO 9001, IEC 60287, and ASTM B170. All coils traceable via batch-level metallurgical reports.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Factory to Port

Precision Packaging Standards for Copper Coil

Our packaging protocols are engineered to eliminate corrosion, deformation, and transit damage—critical for high-purity copper coil integrity. All components comply with ASTM and ISO standards, ensuring seamless global compliance.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15-certified, heat-treated (56°C/30 min), 1200×1000×150 mm, 2500 kg capacity | Prevents structural deformation; complies with global phytosanitary regulations |

| Moisture-Proof Film | 250μm VCI film (ASTM D6190), double-layer wrapping | Blocks >95% humidity ingress; inhibits copper oxidation during transit |

| Steel Strapping | 19mm width × 0.5mm thickness (ASTM A653), 1500 kg tensile strength | Secures coils to pallets; prevents lateral movement during handling |

Sea Freight Protocols for Global Delivery

We optimize containerized shipping for minimal transit time and maximum protection. Our end-to-end control eliminates third-party risks while maintaining cost efficiency.

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | 20ft/40ft dry containers, sealed per ISO 1496 | Ensures full environmental control; minimizes external exposure |

| Loading Method | Vertical stacking with wooden spacers + 4-way strapping (max 4 layers) | Distributes weight evenly; prevents coil deformation |

| Environmental Controls | Silica gel desiccants + real-time humidity sensors | Maintains <60% RH inside container; avoids condensation |

| Documentation | ISPM 15 certificate, COO, Fumigation report, Bill of Lading | Ensures customs compliance and traceability |

Luoyang Xinzhaohe’s 20+ years of transformer material exports refine every packaging and logistics step. Our factory-direct model reduces transit damage rates by 40% versus industry averages while cutting total landed costs by 15–20% compared to European competitors. All shipments include real-time tracking and dedicated support from loading to destination, guaranteeing 99.8% damage-free delivery to ports including Rotterdam, Los Angeles, and Singapore. We meet ASTM B152 and ISO 1496 standards for copper coil transport—ensuring your transformer materials arrive ready for immediate production use.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Pure Copper Coil Solutions

As a leading manufacturer of transformer strip and foil materials—including both aluminum and copper—Luoyang Xinzhaohe has delivered 20+ years of expertise in high-purity copper coil solutions for global transformer and power equipment manufacturers. Our technical team, with deep expertise in metallurgy and electrical conductivity optimization, ensures each coil meets stringent international standards (IEC 60228, ASTM B1, JIS H3100). We specialize in precise dimensional tolerances (±0.02mm) and conductivity levels (≥99.95% Cu), critical for minimizing resistive losses in transformers.

Factory-Direct Cost Efficiency

As a direct manufacturer, we eliminate distributor markups, delivering up to 15–20% lower costs than global competitors without sacrificing quality. Our integrated production line—from smelting to precision rolling—ensures consistent output and rapid scalability.

| Parameter | Luoyang Xinzhaohe | Global Brands | Industry Average |

|---|---|---|---|

| Purity (Cu) | ≥99.95% | ≥99.95% | ≥99.9% |

| Tensile Strength (MPa) | 200–250 | 180–230 | 190–240 |

| Lead Time | 15–20 days | 30–45 days | 25–35 days |

| Cost (USD/kg) | $7.50 | $9.00+ | $8.20 |

ISO 9001:2015 Certified Quality Assurance

Our quality management system is certified to ISO 9001:2015, with in-process testing at every production stage. Every batch undergoes conductivity checks (IACS ≥101%), dimensional verification, and surface defect inspections. This ensures zero-defect delivery for critical transformer applications.

Tailored Solutions for Complex Demands

We provide custom coil specifications (width, thickness, temper), including special alloys for high-temperature environments. Our engineering team collaborates closely with clients to optimize designs for efficiency and longevity.

Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation. Leverage our expertise to reduce your total cost of ownership while maintaining uncompromising performance.

📉 Import Savings Calculator

Estimate cost reduction by sourcing pure copper coil from Luoyang Xinzhaohe.