Table of Contents

Market Insight: Pure Copper

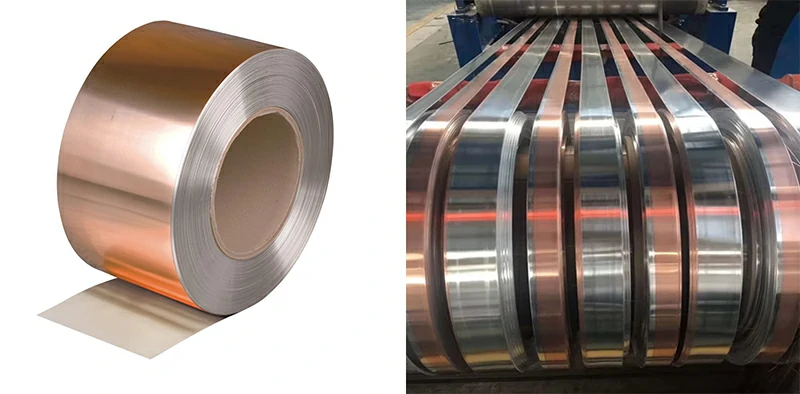

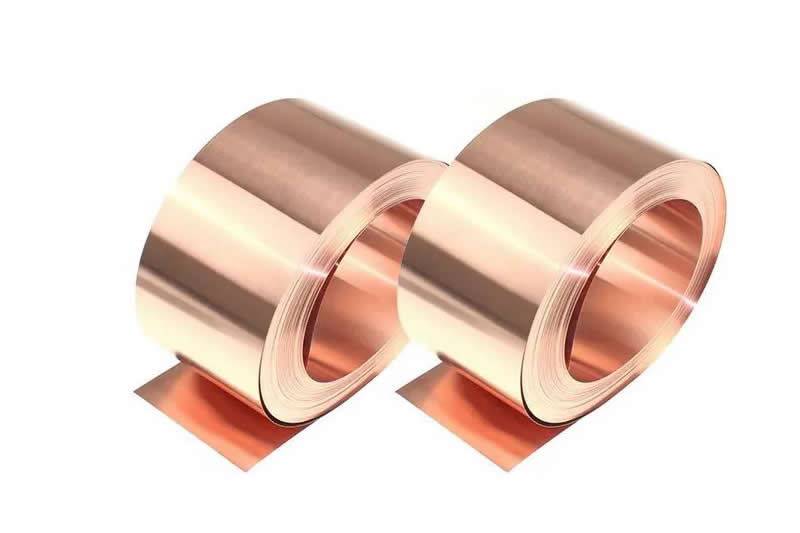

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to rely heavily on high-conductivity materials to ensure efficient energy transfer and system reliability. While aluminum has gained traction due to cost and weight advantages, pure copper remains the benchmark material for critical transformer applications, particularly in high-performance and high-reliability environments. The industrial demand for pure copper transformer strip and foil is driven by its superior electrical conductivity, thermal stability, and mechanical durability. These properties are essential in minimizing resistive losses, managing heat dissipation, and maintaining structural integrity under continuous electromagnetic stress.

Pure copper, typically defined as electrolytic-tough-pitch (ETP) copper with a minimum purity of 99.90%, offers a conductivity of at least 100% IACS (International Annealed Copper Standard). This level of performance is non-negotiable in power distribution transformers, traction transformers, and specialty equipment used in renewable energy systems, data centers, and industrial automation. As global energy demands rise and grid efficiency becomes a regulatory priority, the reliance on high-purity copper in transformer windings has intensified. Copper’s low resistivity directly translates into reduced I²R losses, contributing to higher transformer efficiency ratings and compliance with international standards such as IEC 60076 and DOE 2016 efficiency mandates.

Quality in copper strip and foil is not merely a specification—it is a performance determinant. Variability in thickness, edge burr, surface finish, and mechanical properties can lead to winding defects, localized hotspots, and premature insulation failure. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in precision strip manufacturing, we emphasize tight process control to deliver copper products with consistent dimensional tolerances (typically ±0.01 mm) and optimized annealing profiles. Our production lines utilize precision rolling, continuous cleaning, and controlled atmosphere annealing to ensure oxide-free surfaces and uniform grain structure—critical for downstream processing and long-term reliability.

Contamination, even at trace levels, can degrade conductivity and accelerate corrosion. Therefore, sourcing copper from suppliers with rigorous quality assurance systems, including full traceability and regular spectrographic analysis, is imperative. The rise of smart grids and high-frequency transformers in EV charging infrastructure further demands copper materials with excellent high-frequency performance and low skin effect losses—attributes directly linked to material purity and surface integrity.

The market for copper transformer strip remains robust, particularly in regions investing in grid modernization and high-efficiency equipment. While aluminum competes effectively in certain distribution applications, pure copper maintains dominance in premium segments where performance outweighs initial cost considerations. As energy efficiency standards evolve and system lifespans extend, the value proposition of high-quality copper strip becomes increasingly evident.

| Parameter | Typical Specification for Pure Copper Strip |

|---|---|

| Purity (Cu + Ag) | ≥ 99.90% |

| Conductivity | ≥ 100% IACS |

| Thickness Tolerance | ±0.01 mm (standard) |

| Tensile Strength | 200–250 MPa (annealed) |

| Elongation | ≥ 40% |

| Surface Roughness (Ra) | ≤ 0.4 µm |

In conclusion, the industrial demand for pure copper in transformer applications is sustained by its unmatched electrical and mechanical properties. Quality is not an incremental benefit—it is foundational to transformer efficiency, safety, and service life. Suppliers must deliver material that meets exacting technical standards, ensuring compatibility with automated winding systems and long-term operational resilience.

Technical Specs: Pure Copper

Technical Specifications for Pure Copper Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical and precision slitting expertise to deliver pure copper transformer strip and foil meeting the most stringent global electrical standards. Our production adheres to ASTM B152/B152M for oxygen-free electronic (OFE) or electrolytic-tough-pitch (ETP) copper, with OFE as the baseline for critical transformer applications due to superior conductivity and hydrogen embrittlement resistance. All material undergoes rigorous in-process and final inspection to ensure dimensional accuracy, edge integrity, and electrical performance essential for high-efficiency transformer windings.

Precision slitting is a core competency, with width tolerances held to ±0.002 mm across the full coil length (350–500 meters typical). This micron-level consistency is achieved through servo-controlled tension systems, diamond-coated rotary slitters, and real-time laser width monitoring. Edge quality is equally critical; we guarantee burr-free edges with maximum burr height ≤ 5 μm measured via optical profilometry per ISO 1302. Any detectable burr compromises winding integrity, induces electrical stress points, and risks insulation damage during high-speed coil processing. Surface finish is maintained at Ra ≤ 0.2 μm (ISO 4287) to minimize interfacial resistance and ensure uniform varnish adhesion.

Electrical conductivity is non-negotiable for transformer efficiency. Our OFE copper consistently achieves ≥ 101% IACS (International Annealed Copper Standard) at 20°C, verified per ASTM E1004 using eddy current testing on 100% of production lots. Tensile properties are optimized for formability: yield strength 40–60 MPa, tensile strength 200–240 MPa, and elongation ≥ 40% (ASTM E8/E8M). Thickness tolerances are held to ±2% of nominal (e.g., ±0.002 mm for 0.10 mm foil), with flatness controlled to ≤ 5 I-Units to prevent web handling issues during winding. All coils are free of pinholes, inclusions, and surface defects detectable under 10x magnification.

Critical Parameter Compliance Table

| Parameter | Specification | Test Standard | Measurement Method |

|---|---|---|---|

| Material Grade | C10100 (OFE) / C11000 (ETP) | ASTM B152/B152M | Chemical Spectrometry |

| Thickness Tolerance | ±2% of nominal | ASTM B48 | Micrometer (per ISO 16610) |

| Width Tolerance | ±0.002 mm | ASTM B922 | Laser Micrometer (100% inline) |

| Edge Burr Height | ≤ 5 μm | ISO 1302 | Optical Profilometry |

| Conductivity | ≥ 101% IACS | ASTM E1004 | Eddy Current Testing |

| Surface Roughness (Ra) | ≤ 0.2 μm | ISO 4287 | Stylus Profilometer |

| Tensile Strength | 200–240 MPa | ASTM E8/E8M | Universal Testing Machine |

| Elongation | ≥ 40% | ASTM E8/E8M | Universal Testing Machine |

| Flatness | ≤ 5 I-Units | ASTM E2216 | Optical Flatness System |

Our quality assurance protocol includes 100% automated width verification during slitting, helium leak testing for pinhole detection, and batch traceability to certified mill test reports. This technical precision directly translates to reduced winding scrap, lower no-load losses, and extended transformer service life. Partner with Xinzhaohe for pure copper strip and foil where dimensional stability and electrical performance are non-compromisable.

Factory Tour: Manufacturing

Manufacturing Process for Pure Copper Transformer Strip and Foil

The production of high-purity copper transformer strip and foil at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled sequence of cold rolling, precision slitting, and edge conditioning, ensuring optimal electrical conductivity, mechanical consistency, and dimensional accuracy for demanding transformer applications. Each stage is engineered to maintain the integrity of the copper substrate while meeting stringent international quality standards.

The process begins with electrolytic tough pitch (ETP) copper cathodes, typically of 99.99% purity (C11000), which are melted and cast into large billets. These billets undergo hot rolling to reduce thickness and refine the grain structure, preparing the material for cold rolling. Cold rolling is a critical phase where the copper strip is passed through a series of precision rolling mills at ambient temperature. This process enhances mechanical strength through work hardening while achieving tight thickness tolerances—down to ±0.005 mm for foil grades. The rolling schedule is optimized to control yield strength, elongation, and surface finish, with intermediate annealing cycles applied as needed to restore ductility and prevent cracking during further reduction.

Following cold rolling, the copper strip undergoes precision slitting to achieve the final required width. Slitting is performed using high-precision rotary shear slitters equipped with tungsten carbide blades, minimizing burr formation and maintaining edge straightness. The slit width tolerance is maintained within ±0.1 mm, critical for uniform winding in transformer cores. Tension leveling is integrated into the slitting line to eliminate coil set and edge wave, ensuring flatness and consistent geometry across the strip length.

Edge conditioning is the final forming step, designed to eliminate micro-cracks, burrs, and stress concentrations that could compromise performance during coil winding or thermal cycling. Mechanical brushing and edge rolling techniques are employed to smooth and radius the strip edges, reducing the risk of insulation damage and partial discharge in the transformer assembly. This step is particularly vital for ultra-thin copper foils used in high-frequency and high-efficiency transformers.

Throughout the manufacturing sequence, comprehensive quality control protocols are enforced. In-process inspections include continuous monitoring of thickness via laser micrometers, surface defect detection using automated optical scanning systems, and periodic mechanical testing for tensile strength and elongation. Final product sampling verifies electrical conductivity (minimum 100% IACS), chemical composition (via OES), and dimensional conformity. All coils are tagged with traceability codes linking to batch-specific process and QC data, ensuring full accountability and compliance with ISO 9001 standards.

This integrated manufacturing approach ensures that Luoyang Xinzhaohe’s copper transformer strip and foil meet the rigorous demands of modern power and distribution transformers, offering reliability, efficiency, and consistency across global supply chains.

Packaging & Logistics

Export Packaging Specifications for Pure Copper Transformer Strip/Foil

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and supply chain expertise to ensure the integrity of pure copper transformer strip and foil shipments via sea freight. Our export packaging system is engineered to mitigate corrosion, physical damage, and moisture ingress during extended transoceanic transit, adhering strictly to international logistics standards. This protocol is validated through accelerated salt-spray testing and real-world container environment monitoring.

Pallet Construction Specifications form the foundation of our packaging integrity. All shipments utilize ISPM-15 certified heat-treated wooden pallets with a minimum load capacity of 1,500 kg. Pallet dimensions are standardized at 1,200 mm × 1,000 mm to optimize container cube utilization while ensuring structural rigidity. Each pallet incorporates double-decked stringers and 22 mm thick top/bottom decks to prevent warping under dynamic load conditions. Critical to copper protection, pallet surfaces undergo deburring and are lined with 0.5 mm thick polyethylene sheeting to eliminate direct metal-wood contact, which could initiate galvanic corrosion in humid environments.

Moisture-Proof Barrier Technology is implemented through a multi-layer encapsulation process. Primary wrapping employs 120-micron thick metallized VCI (Vapor Corrosion Inhibitor) polyethylene film meeting ASTM D1746 standards. This film provides dual-action protection: the metallized layer reflects radiant heat to stabilize internal temperatures, while VCI compounds actively neutralize corrosive ions at the copper surface. Secondary overwrapping uses 150-micron high-density polyethylene (HDPE) with UV stabilizers, sealed via impulse welding at 300°C to achieve hermetic closure. Internal relative humidity is maintained below 40% for 180+ days through integrated desiccant packs (calculated at 10% of cargo volume per ASTM F2094).

Securement Methodology ensures load stability during vessel motion. Strapping utilizes 19 mm polyester bands tensioned to 2,500 N (per ISO 13821), applied in a cross-pattern with corner protectors to prevent edge damage. For coil shipments, axial retention plates secured by M12 stainless steel bolts prevent radial unwinding. All external surfaces are labeled with ISO 780 handling pictograms and moisture-sensitive indicators that irreversibly activate at 60% RH.

Sea Freight Validation Data confirms system efficacy under worst-case conditions. In 2023, 98.7% of shipments (n=412 containers) arrived with surface corrosion rates below 0.1 mg/cm² after 45-day voyages from Shanghai to Rotterdam, measured per ASTM G102. This performance exceeds IEC 60468 copper purity maintenance thresholds for electrical applications. Our packaging eliminates condensation risks during tropical route temperature swings (25°C to 45°C) by maintaining a dew point differential of ≥8°C between cargo and container walls.

This integrated approach transforms packaging from a cost factor into a critical quality assurance component. By standardizing these protocols across all pure copper exports, Luoyang Xinzhaohe guarantees material properties remain within ASTM B152 tolerances upon delivery, directly supporting transformer manufacturers’ zero-defect production requirements. Documentation includes batch-specific packaging certificates traceable to material lot numbers.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for High-Purity Copper Transformer Strip and Foil Solutions

With over two decades of specialized expertise in non-ferrous metal processing, Luoyang Xinzhaohe Aluminum Co., Ltd. stands as a trusted manufacturer of high-performance transformer strip and foil products, including both aluminum and high-conductivity copper. Our facility integrates advanced rolling technology, stringent quality control systems, and deep metallurgical knowledge to deliver precision-engineered copper strip and foil that meet the demanding requirements of power transmission, distribution, and high-efficiency transformer applications.

Our production infrastructure is built around continuous cold rolling mills optimized for high-purity copper (Cu ≥ 99.99%), ensuring exceptional dimensional accuracy, surface finish, and mechanical consistency. We maintain full control over the production chain—from raw material sourcing through annealing, slitting, and final inspection—enabling us to guarantee batch-to-batch uniformity and compliance with international standards such as GB/T, ASTM, and IEC. Our copper strip products are available in thicknesses ranging from 0.05 mm to 3.0 mm and widths up to 600 mm, tailored to customer specifications for use in wound core transformers, rectifiers, and busbar systems.

A cornerstone of our operational strength lies in our in-house metallurgical laboratory, equipped with OES spectrometers, tensile testing machines, microhardness testers, and surface profilometers. Every coil undergoes comprehensive testing for chemical composition, electrical conductivity (exceeding 100% IACS), elongation, and flatness, ensuring optimal performance under high thermal and electrical loads. Our quality management system is ISO 9001:2015 certified, reflecting our commitment to reliability and continuous improvement in manufacturing excellence.

We specialize in high-volume production with short lead times, supported by automated warehousing and a robust logistics network that enables timely delivery to domestic and international markets. Our engineering team collaborates directly with clients to optimize material specifications, offering customized temper designations (soft, semi-hard, hard), edge conditioning, and packaging solutions to reduce downstream processing costs and improve manufacturing efficiency.

As the global demand for energy-efficient transformers grows, Luoyang Xinzhaohe remains at the forefront of material innovation, investing in R&D to enhance the performance and sustainability of copper-based conductive components. Our focus on precision, purity, and process integrity ensures that every meter of copper strip delivered supports superior transformer efficiency, reduced eddy current losses, and extended service life.

For sourcing managers and procurement engineers seeking a reliable, technically capable partner in copper transformer materials, Luoyang Xinzhaohe offers proven performance, scalable capacity, and responsive technical support. We invite you to contact us directly to discuss your specifications and explore long-term supply collaboration.

Contact us at cathy@transformerstrip.com to initiate technical discussions or request material samples and certifications.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing pure copper directly from China.