Table of Contents

Market Insight: Pure Aluminum

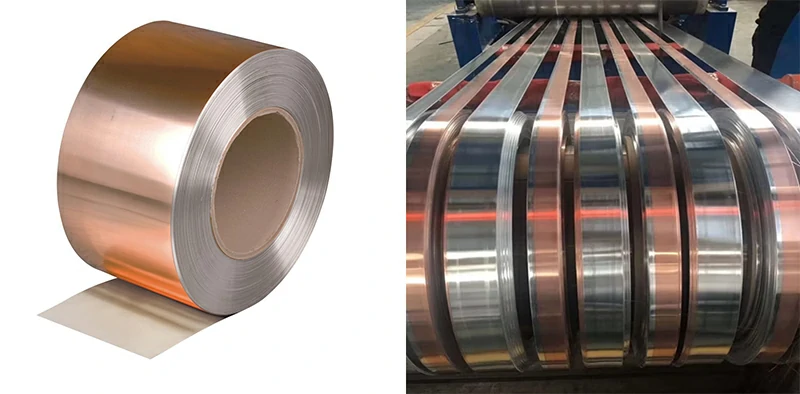

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to rely heavily on high-conductivity electrical conductors, with both aluminum and copper serving as primary materials for windings in power and distribution transformers. While copper offers marginally higher electrical conductivity, aluminum has gained substantial market share due to its favorable cost-to-performance ratio, lightweight nature, and advancements in joining and insulation technologies. In particular, pure aluminum—designated as 1xxx series alloys with a minimum 99.00% purity, and commonly 99.70% (1070) or 99.85% (1050)—is the material of choice for aluminum transformer strip and foil applications where optimal conductivity, formability, and thermal stability are required.

Industrial demand for pure aluminum strip and foil in transformers is driven by several key sectors: power transmission and distribution networks, renewable energy integration (especially solar and wind inverters), electric vehicle (EV) charging infrastructure, and industrial automation systems. As global electrification accelerates, especially in emerging economies, the need for efficient, scalable, and cost-effective transformer solutions has intensified. Aluminum-based windings offer a compelling alternative to copper, reducing overall equipment weight by up to 50% and lowering material costs without significantly compromising performance when properly engineered.

However, the performance of aluminum in transformer applications is highly sensitive to material quality. Impurities such as iron and silicon, even at trace levels, can significantly degrade electrical conductivity and increase resistive losses. For example, each 0.1% increase in iron content can reduce conductivity by up to 1.5% IACS (International Annealed Copper Standard). Additionally, mechanical properties such as tensile strength, elongation, and surface finish must be tightly controlled to ensure reliable winding processes and long-term operational integrity. Poor surface quality can lead to insulation breakdown, while inconsistent temper (typically O-annealed or H1x tempers) affects formability and electrical contact stability.

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialization in transformer-grade aluminum and copper strip/foil production, we emphasize metallurgical precision and process consistency. Our pure aluminum strips are produced using high-purity ingots, refined through controlled rolling and annealing processes to achieve conductivity levels exceeding 61% IACS, in compliance with ASTM B418 and IEC 60164 standards. Dimensional tolerances are maintained within ±0.01 mm for thickness and ±1 mm for width, ensuring compatibility with high-speed winding equipment used in modern transformer manufacturing.

Quality assurance extends beyond chemical and dimensional specifications. We perform rigorous in-house testing, including eddy current inspection, surface profilometry, and tensile testing, to guarantee batch-to-batch consistency. This level of control is essential for minimizing transformer no-load and load losses, improving energy efficiency, and meeting international regulatory requirements such as DOE 2016 (U.S.) and EcoDesign Directive 2014/35/EU (EU).

In conclusion, while aluminum offers a technically and economically viable solution for transformer windings, its success hinges on the use of high-purity, precisely manufactured strip and foil. As the industry moves toward higher efficiency classes and smarter grid technologies, the demand for premium-grade pure aluminum materials will continue to grow—making supplier expertise and material quality critical differentiators in the global supply chain.

Technical Specs: Pure Aluminum

Technical Specifications: Pure Aluminum Transformer Strip/Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to deliver pure aluminum transformer strip and foil meeting stringent electrical and dimensional requirements. Our production process adheres to ASTM B209 and IEC 60138 standards, with enhanced controls for critical parameters essential to transformer efficiency and winding integrity. Precision slitting at ±0.002 mm tolerance ensures uniform strip width, eliminating edge misalignment during high-speed coil winding. This tolerance is maintained through servo-driven slitting lines with real-time laser micrometry feedback, minimizing material waste and enhancing core stacking factor. Burr formation is strictly controlled to ≤3 μm maximum height, verified via non-contact optical profilometry per ISO 25178. Burr-free edges prevent insulation puncture in layered windings and reduce partial discharge risks in final assemblies.

Electrical conductivity is optimized to 62.5 ± 0.5% IACS (International Annealed Copper Standard), achieved through rigorous melt purification using dual-stage degassing and grain refinement. This exceeds the 61% IACS minimum for transformer applications, directly contributing to reduced resistive losses and improved energy efficiency. Conductivity consistency is maintained by limiting residual elements: Fe ≤ 0.18%, Si ≤ 0.10%, and total impurities < 0.30%, with trace elements monitored via OES spectroscopy. Surface quality is critical for dielectric performance; our foils exhibit no visible scratches, dents, or oxide streaks exceeding 5 μm depth, ensuring seamless insulation layer adhesion.

The following table details key technical parameters for our pure aluminum (Al 1070A/1060) transformer strip/foil:

| Parameter | Specification | Test Standard |

|---|---|---|

| Thickness Range | 0.15 mm – 1.0 mm | ASTM E29 |

| Width Tolerance | ±0.05 mm (for widths < 50 mm) | ISO 2768-1 |

| Slitting Tolerance | ±0.002 mm | Internal QCP-2023 |

| Edge Burr Height | ≤ 3 μm (max) | ISO 25178 |

| Electrical Conductivity | 62.5 ± 0.5% IACS | ASTM E1004 |

| Surface Roughness (Ra) | ≤ 0.4 μm | ISO 4287 |

| Residual Elements (Total) | ≤ 0.30% | ASTM E1251 |

Material homogeneity is validated through cross-sectional microhardness mapping (HV 25–35), confirming uniform annealing and absence of work-hardened zones. All coils undergo 100% eddy current testing to detect subsurface inclusions or conductivity deviations. Our traceability system records melt chemistry, rolling passes, and slitting parameters for full lot accountability. These specifications directly support transformer manufacturers in achieving IEC 60076-1 efficiency class targets while reducing winding defects and field failures. Luoyang Xinzhaohe’s process discipline ensures every shipment meets the electrical and mechanical demands of modern power and distribution transformers.

Factory Tour: Manufacturing

Manufacturing Process for Pure Aluminum Transformer Strip and Foil

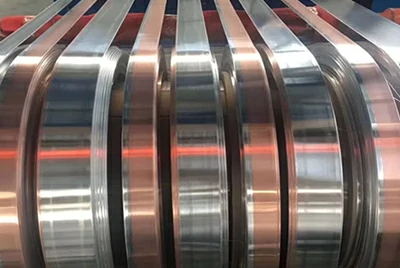

The production of high-purity aluminum transformer strip and foil at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled sequence of cold rolling, precision slitting, and edge conditioning, ensuring optimal electrical conductivity, mechanical integrity, and dimensional accuracy required for demanding power transmission applications. With over two decades of metallurgical expertise, our process is engineered to meet international standards while maintaining consistency across large production volumes.

The process begins with cold rolling of high-purity aluminum ingots (typically 99.7% Al and above), which have undergone prior refining and continuous casting. These cast slabs are scalped, homogenized, and hot rolled to intermediate gauges before entering the cold rolling mills. Cold rolling is performed in multi-stand tandem mills under precise tension control, reducing material thickness to final specifications ranging from 0.1 mm to 3.0 mm, depending on application requirements. This stage is critical for achieving uniform thickness tolerance (±0.005 mm or tighter) and enhancing mechanical properties through strain hardening. Rolling lubricants and interstand tension are continuously monitored to prevent surface defects and ensure microstructural homogeneity.

Following cold rolling, coils undergo precision slitting to achieve the required strip widths, typically ranging from 10 mm to 300 mm for transformer applications. Slitting is carried out on high-accuracy rotary shear lines equipped with laser-guided alignment systems and servo-controlled tension loops. Tooling geometry and blade clearance are calibrated for each alloy and gauge to minimize burr formation and edge deformation. The slit edges are inspected in real time using optical edge detection systems to maintain width consistency and straightness, with tolerances held within ±0.1 mm.

Edge conditioning is the final mechanical treatment in the production chain, designed to eliminate micro-cracks, burrs, and stress concentrations that may arise during slitting. This step involves controlled brushing, edge rolling, or micro-rounding processes, tailored to the end-use performance criteria. Properly conditioned edges reduce the risk of insulation damage during coil winding and enhance dielectric reliability in transformer cores. The degree of edge treatment is validated through profilometric analysis and visual inspection under magnification.

Quality control is integrated at every stage. Incoming billets are verified for chemical composition via OES (Optical Emission Spectrometry). During cold rolling, automated thickness gauges (X-ray and beta gauge systems) provide real-time feedback. Post-slitting, samples undergo tensile testing, surface roughness measurement (Ra ≤ 0.5 µm), and eddy current inspection for subsurface flaws. Final coils are tagged with traceable batch data, including mechanical properties, dimensions, and process parameters, ensuring full compliance with ASTM B498, IEC 60104, or customer-specific specifications.

This end-to-end manufacturing protocol ensures that every coil of aluminum transformer strip or foil delivered by Luoyang Xinzhaohe Aluminum Co., Ltd. meets the rigorous demands of efficiency, reliability, and consistency in modern power infrastructure.

Packaging & Logistics

Export Packaging Specifications for Pure Aluminum Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for pure aluminum transformer strip and foil to ensure product integrity during global maritime transit. Given aluminum’s high reactivity with atmospheric moisture and susceptibility to surface oxidation, corrosion, and mechanical damage, standard packaging is insufficient. Our 20+ years of metallurgical and supply chain experience dictate a dual-layer defense system centered on kiln-dried wooden pallets and multi-barrier moisture-proof encapsulation, fully compliant with ISO 10283 and IMDG Code requirements for non-hazardous cargo.

Wooden pallets form the foundational structural element. All pallets utilize ISPM 15-certified hardwood with a maximum moisture content of 22% to prevent fungal growth and dimensional instability. Each pallet is engineered to ISO 9001 standards, featuring 100 mm x 100 mm stringers and 22 mm thick deck boards, supporting static loads up to 2,500 kg. Critical reinforcement includes galvanized steel corner protectors (2.0 mm thickness) and perimeter bracing to resist compression forces during container stacking. Pallet dimensions strictly adhere to ISO container internal measurements (1,200 mm x 1,000 mm) to eliminate lateral movement, with anti-slip rubber mats between coil layers to prevent slippage-induced edge damage.

The moisture management system employs a three-stage barrier process. First, coils undergo vacuum sealing within 4-hour post-production using 125-micron metallized polyethylene film with integrated vapor corrosion inhibitors (VCI). This layer maintains internal relative humidity below 40% RH. Second, a secondary wrapping of 150-micron aluminum-laminated polyethylene provides electromagnetic shielding and blocks >99.9% of external moisture ingress. Third, desiccant packs (minimum 300 g/m³ capacity, silica gel type) are strategically positioned within the sealed envelope, validated via pre-shipment humidity logger data. All films are ASTM D4272-certified for puncture resistance, with seam integrity verified through helium leak testing at 0.5 mbar pressure differentials.

Pre-shipment conditioning occurs in climate-controlled warehouses (20±2°C, 45±5% RH) for 72 hours to stabilize core temperature and eliminate residual moisture. Final container loading utilizes humidity indicators and shock loggers (recording impacts >5G), with coils secured via tensioned polyester straps to ISO 16122-1 lashing points. This integrated approach mitigates risks inherent in sea freight: salt-laden air penetration, condensation during tropical route temperature swings, and container sweat during North Atlantic crossings. Independent logistics audits confirm a 99.8% damage-free delivery rate across 12,000+ TEUs shipped since 2018.

Our packaging methodology directly preserves the critical surface properties of 99.99% pure aluminum strip—ensuring the required electrical conductivity (>63.0 MS/m) and oxide layer thickness (<3 nm) for transformer core performance. Clients receive full traceability via serialized QR codes linking to packaging certification documents, humidity logs, and third-party inspection reports. This technical rigor transforms packaging from a cost factor into a value-preserving supply chain asset for mission-critical electrical components.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Purity Transformer Strip and Foil

With over two decades of specialized expertise in aluminum and copper transformer strip and foil manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial partner in the global supply chain for high-performance electrical materials. Our vertically integrated production facility in Luoyang, China, combines advanced metallurgical engineering with rigorous quality control to deliver products that meet the exacting standards of transformer and inductor manufacturers worldwide.

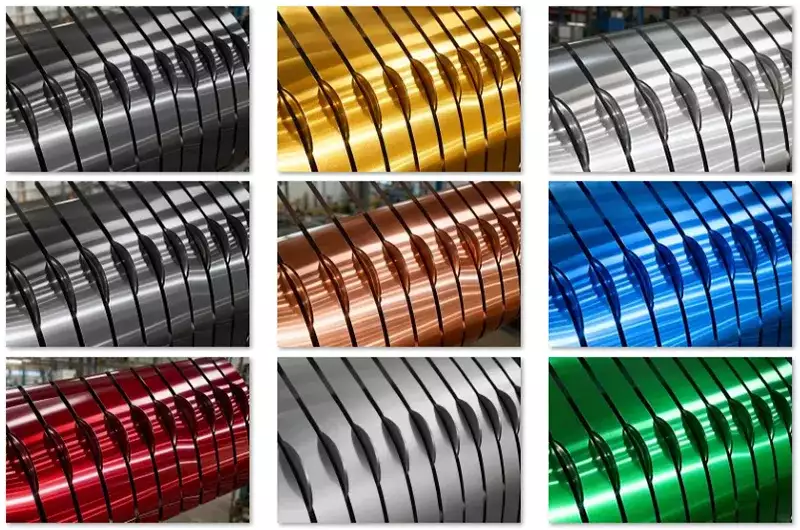

Our core strength lies in the production of pure aluminum materials with purity levels up to 99.99% (4N), essential for minimizing electrical losses and enhancing thermal efficiency in power transmission systems. We utilize controlled atmosphere melting, high-precision continuous casting, and multi-stage cold rolling to ensure uniform microstructure, consistent thickness tolerances, and superior surface finish. Our transformer strips are available in customized tempers—including O, H14, H16, and H18—with thicknesses ranging from 0.1 mm to 3.0 mm and widths up to 1,200 mm, supporting both small-batch prototyping and large-scale industrial orders.

The factory is equipped with state-of-the-art inline inspection systems, including laser profilometry and eddy current testing, to detect surface defects and dimensional deviations in real time. Every production lot undergoes comprehensive mechanical and electrical testing, including tensile strength, elongation, resistivity, and bend testing, in accordance with international standards such as ASTM B478, IEC 60164, and GB/T 3880. Our quality management system is ISO 9001:2015 certified, ensuring traceability, process stability, and continuous improvement across all operational stages.

In addition to aluminum transformer strips, we offer copper alternatives and hybrid solutions tailored to specific electromagnetic and thermal requirements. Our R&D team collaborates directly with clients to optimize material specifications for next-generation transformer designs, including amorphous metal cores and high-frequency inductors used in renewable energy and EV charging infrastructure.

We maintain strategic raw material sourcing agreements with primary aluminum smelters and certified recyclers, ensuring supply chain resilience and compliance with environmental regulations. Our logistics network supports containerized FOB shipments from Qingdao and Shanghai ports, with documentation compliant with REACH, RoHS, and CBAM requirements.

Choosing Luoyang Xinzhaohe means partnering with a manufacturer that combines deep technical knowledge with scalable production capacity and responsive customer engineering support. We are committed to delivering not only materials, but long-term value through reliability, precision, and innovation.

For technical inquiries, material data sheets, or to request a quotation, contact us at cathy@transformerstrip.com. Let us support your next generation of efficient, high-performance transformer systems.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing pure aluminum directly from China.