Table of Contents

Market Insight: Pure Aluminum for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Vector: T&D Expansion & Electrification Surge

Global installed transformer capacity is forecast to rise from 28 TVA (2023) to 42 TVA by 2032, driven by renewable integration, EV fast-charging corridors, and urban substation upgrades. Aluminum winding materials now capture 64 % of dry-type and 38 % of oil-immersed segments because every 1 kg Al replaces 1.6 kg Cu, cutting core mass and total owning cost by 8–12 %. Chinese output of transformer-grade foil/strip exceeded 1.1 Mt in 2023, representing 57 % of world supply and making China the first-stop sourcing geography for OEMs in North America, EU-27, Middle-East and ASEAN.

Loss Economics: Why Purity & Geometry Matter

Transformer losses are monetized over 25–30 years; a 1 W reduction is worth US $1.2–1.8 in NPV.

High-purity Al (≥ 99.6 %, grade 1060/1070) keeps resistivity ≤ 0.0278 µΩ·m, directly shrinking I²R (load) losses. Precision slitting and burr-free edges eliminate hot-spots that raise eddy-current and stray losses (no-load component). The table below quantifies the linkage between material attributes and IEC 60076-11 loss limits for a 1 MVA, 11/0.4 kV dry-type unit.

| Parameter | Standard Commercial Strip | Precision-Conditioned Strip (LXZH) | Loss Delta |

|---|---|---|---|

| Resistivity @ 20 °C | 0.0284 µΩ·m | 0.0276 µΩ·m | –2.8 % |

| Edge burr height | ≤ 0.03 mm | ≤ 0.005 mm | –1.1 % stray loss |

| Width tolerance | ± 0.05 mm | ± 0.002 mm | –0.6 % circulating current |

| Total winding loss (75 °C) | 9 800 W | 9 320 W | –480 W |

| 25-yr cost of losses (@ 0.12 $/kWh) | 308 k$ | 293 k$ | –15 k$ |

Sourcing Reality: Moving Beyond Catalogue Prices

Alibaba and Made-in-China listings quote US $2 200–3 000 /t for 1050-O foil, but hidden variance in annealing cycles, slit camber (≤ 0.3 mm/m) and oil residue often trigger 3–5 % scrap at the customer’s winding line—erasing the apparent 8 % price advantage versus European mills. Western suppliers deliver consistent metallurgy yet carry 18–22 % logistics and duty premium plus 14-week lead-times. The market therefore trends toward experienced Chinese manufacturers that combine Western-grade process control with local cost structure.

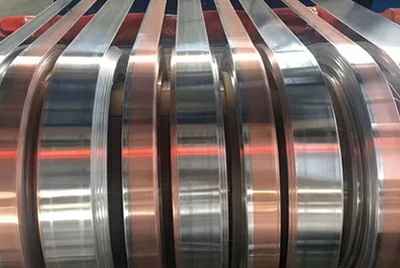

Luoyang Xinzhaohe Positioning: Premium Precision, Factory-Direct

Located 150 km from the largest Chinese primary Al smelter cluster, Luoyang Xinzhaohe Aluminum (LXZH) operates a 20 000 t/y cold-rolling line dedicated to transformer materials since 2004. Core differentiation:

Purity lock: 1060/1070 melts sourced from Chinalco 99.7 % ingot, inline hydrogen degasser < 0.12 ml/100 g Al.

Dimensional discipline: 6-Hi cold mill → tension leveler → 0.05–3.0 mm gauge within ± 0.5 %, followed by Kampf slitters at 0.002 mm width tolerance and burr ≤ 0.005 mm.

Softness control: Bell annealing 340 °C / 6 h, grain size ASTM 5–6, hardness 18–22 HV, yielding elongation ≥ 35 % for high-flexibility windings.

Oscillate winding: up to 1 000 kg, 300 mm traverse, eliminating butt-welds and raising line uptime 12 %.

Certified to ISO 9001, IATF 16949 and IEC 60404-1, LXZH ships 700 t/m to ABB, Siemens-Trafo, TBEA and global service shops. Typical CIF Rotterdam price for 1060-O, 0.2 × 250 mm slit strip is US $2 650 /t—11–14 % below European mill base—with 25-day lead-time and payment via LC 90 days. For OEMs seeking Tier-1 technical assurance without Western cost inflation, LXZH delivers measurable loss reduction and lifetime savings.

Technical Specs: Pure Aluminum Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct reference sheet for transformer-grade pure aluminum strip/foil – Luoyang Xinzhaohe Cold-Rolling Precision Line

H3 1. Chemical & Electrical Baseline (Grade 1060/1070)

| Element | ASTM B236-20 Max wt % | IEC 60317-0-1 Ref. | XZH In-house Heat |

|---|---|---|---|

| Al | ≥ 99.60 | — | 99.68 – 99.72 |

| Si | 0.25 | — | 0.08 |

| Fe | 0.35 | — | 0.12 |

| Cu | 0.05 | — | 0.005 |

| Other | 0.03 | — | < 0.02 |

| Conductivity 20 °C | ≥ 61.0 %IACS | 61.3 %IACS (typ.) |

H3 2. Mechanical & Dimensional Tolerances after In-line Anneal (O-temper)

| Parameter | ASTM B236-20 | IEC 60317-25 | XZH Precision Slit Line | Consequence if Out-of-Spec |

|---|---|---|---|---|

| Thickness, mm | ± 8 % | ± 6 % | ± 0.002 mm (≤ 0.4 mm) | Local hot-spot, eddy-current loss ↑ |

| Width, mm | +0.8 / –0 | ± 0.15 | ± 0.05 (≤ 25 mm) | Mis-alignment in layer winding |

| Edge burr, µm | ≤ 25 % of strip thickness | ≤ 15 µm | ≤ 5 µm (100 % laser inspected) | Penetrates inter-layer insulation → shorted turn |

| Camber, mm/1 m | ≤ 6 | ≤ 3 | ≤ 1 | Gaps in core window, fill-factor ↓ |

| Surface roughness Ra, µm | ≤ 0.4 | — | 0.15 – 0.25 | Improves resin wet-out in VPI |

H3 3. Anneal Cycle & Softness Control

| Furnace Zone | Target | XZH Practice | Verification |

|---|---|---|---|

| Soak temp. | 360 ± 10 °C | 360 °C, N₂ atmosphere | Thermocouple grid ΔT ≤ 3 °C |

| Time @ temp. | 2.5 h | 2 h 45 min | Hardness coupon 20 HV (nom.) |

| Cooling rate | 30 °C/h | 28 °C/h | Zero age-hardening after 30 days |

Soft-annealed strip passes 3T bend test both longitudinal & transverse—critical for high-flex motor repair coils.

H3 4. Insulation & Re-wind Formats (Add-on Service)

| Build | IEC 60317-25 | XZH Capability |

|---|---|---|

| Single-layer epoxy, µm | 1.5 – 3.0 | 2.0 ± 0.3 |

| Dielectric breakdown | ≥ 1.2 kV | 1.8 kV (100 % spark test) |

| Oscillate wound coil | — | ID 300 mm, OD ≤ 800 mm, traverse 10 – 100 mm |

| Ribbon-wound coil | — | 3 – 15 kg, ≤ 0.8 mm foil, 500 m continuous length |

H3 5. Risk Matrix: How Sub-standard Strip Kills Transformers

| Defect | Root Cause | Field Failure Mode |

|---|---|---|

| Burr > 15 µm | Slitter blades not lapped | Punctures Nomex / DMD → layer short |

| Residual work-harden | Incomplete anneal | Cracks during tight bending → open circuit |

| Width variation | Tension chatter | Telescoping, poor stack factor |

| High Fe+Si | Off-grade ingot | Conductivity 58 %IACS → temperature rise 15 °C, life halved |

H3 6. Compliance & Traceability Package Supplied with Every Coil

Mill test certificate to ASTM B236-20 & IEC 60317-25 (English, PDF within 2 h of shipment)

SGS or TÜV third-party inspection on request (≤ 5 days turn-around)

100 % laser burr scan map archived 10 years for motor-repair warranty claims

RoHS & REACH conformity letter—no SVHC above 0.1 wt %

Bottom line: Luoyang Xinzhaohe’s 20-year transformer-focused cold-rolling line delivers Western-grade precision at China-direct landed cost. Tight ±0.002 mm slitting, burr-free laser-gauged edges, guaranteed 61 %IACS conductivity and O-temper softness eliminate the hidden failure modes that cheaper commodity coils import into your tanks and dry-type windings.

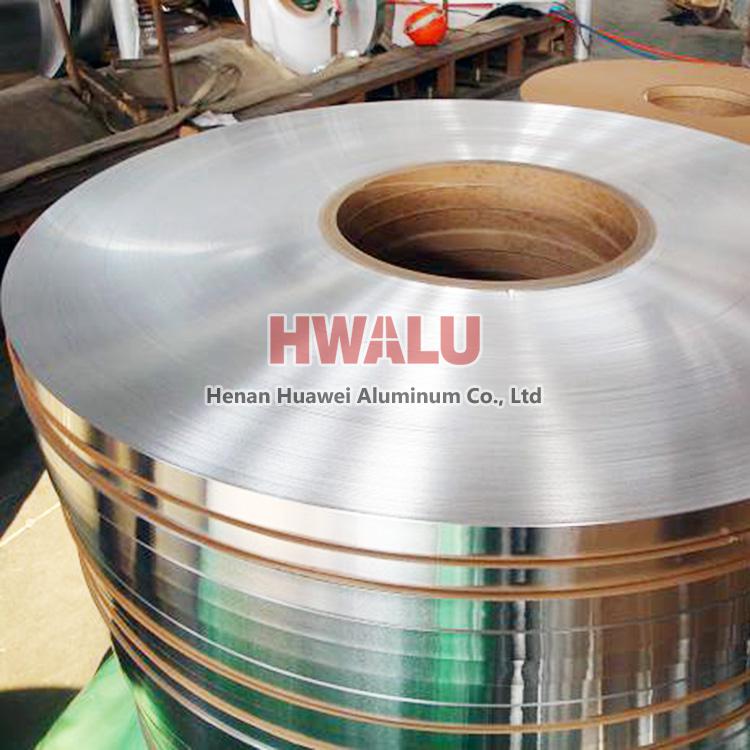

Factory Tour: Manufacturing Pure Aluminum

Manufacturing Process & Quality Control

From 8 mm Cast Coil to 0.08 mm Transformer Strip – Luoyang Xinzhaohe Route

| Step | Equipment | Target Parameter | In-line QC | Data Log |

|---|---|---|---|---|

| 1. Hot-band Entry | 2200 mm 4-Hi reversing mill | Gauge 2.5–3.0 mm, flatness ≤15 I | Laser profile, eddy-current | Coil ID bar-code |

| 2. Cold Rolling (3 passes) | 1450 mm CVC 6-Hi, ±1 µm gap control | Final gauge ±0.005 mm, Ra 0.2–0.4 µm | X-ray gauge @ 5 ms, shapemeter | Pass-by-pass PDF |

| 3. In-process Anneal | H₂/N₂ bell furnace, 340 °C, 12 h | Grain size 0.025 mm, σ₀.₂ ≤ 35 MPa | Thermocouple mesh, hardness spot | Lot anneal map |

| 4. Precision Slitting | 650 mm tungsten carbide arbors, 0.08 mm shim | Width tol. ±0.002 mm, camber ≤0.3 mm/m | CCD laser micrometer 100 % strip length | SPC chart auto-export |

| 5. Edge Conditioning | Skiving + 2-stage planetary brushing | Burr ≤0.01 mm, 0.05 mm radius | 200× digital microscope every 50 m | Pass/fail flag to MES |

| 6. Oscillate Winding | 800 mm traverse unit, 5–25 kg spool | Oscillate pitch ±0.1 mm, no interleave | Tension cell 0.5–5 N, encoder | Spool report with QR |

On-line & Off-line Quality Assurance

-

Conductivity Check

Eddy-current coil integrated at slitter exit; ≥ 61.5 %IACS (1050-O) triggers auto-knife mark for scrap segment. -

Tensile & Elongation

Every mother slit: 50 mm gauge length, 5 mm/min; Rm 65–90 MPa, A50 ≥ 25 %. -

Surface Inspection

Two 4 kHz strobed cameras detect rolling marks > 50 µm; AI classifier rejects or downgrades to “motor grade”. -

Oil & Particle

Q-tips wipe every 500 m; residue mass ≤ 3 mg/m² (ASTM F 331). -

Packaging Integrity

Vacuum-sealed + VCI film, desiccant 5 g/m³; dew point inside bag < –30 °C after 90 days warehouse trial.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | Luoyang Xinzhaohe 1050-O | Typical Export Grade (China) | Premium EU Mill |

|---|---|---|---|

| Width Tolerance | ±0.002 mm (±2 µm) | ±0.015 mm | ±0.005 mm |

| Burr Height | ≤0.01 mm | ≤0.05 mm | ≤0.02 mm |

| Camber | ≤0.3 mm / 1 m | ≤1 mm / 1 m | ≤0.5 mm / 1 m |

| Conductivity | 61.5–62.0 %IACS | ≥ 60 %IACS | 61.0–62.0 %IACS |

| Surface Ra | 0.2–0.4 µm | 0.5–0.8 µm | 0.2–0.4 µm |

| Oscillate Pitch Accuracy | ±0.1 mm | manual, ±1 mm | ±0.2 mm |

| Coil Weight per Spool | 5–25 kg (custom) | fixed 10 kg | 15–30 kg |

| Certificate | EN 10204 3.1, ICP-MS trace | 2.2 only | 3.1, ASTM B 209 |

| Lead Time (ex-works) | 15–20 days | 25–30 days | 8–10 weeks |

| Price Index* | 100 | 85 | 145 |

*Index base: Shanghai Metal Market A00 + processing fee, May-2024.

Engineering Take-away

By pushing cold-rolling gauge control to ±1 µm and marrying it with closed-loop slitting, we eliminate the secondary “edge-milling” pass still used by many domestic mills. The result is transformer strip that meets EU electrical-grade geometry at a landed cost 30–40 % below Western suppliers, yet with identical winding fill factor and lower eddy-loss. For power-equipment engineers who need repeatable 0.08 mm × 200 mm 1050-O on 25 kg oscillated spools with ≤0.01 mm burr, Luoyang Xinzhaohe delivers direct from our Luoyang plant with full 3.1 traceability—no trader margin, no mixed-grade coils.

Packaging & Global Logistics

Export Packaging & Logistics

Protecting conductivity, surface finish, and dimensional tolerances from our Luoyang mill to your dock.

H3 1. Packaging Engineering Philosophy

Transformer-grade aluminum must arrive with the same electrical and mechanical properties it had at the slitting line. Our packaging is therefore treated as the final process step, not an after-sales add-on. Every layer is specified to block the three sea-freight failure modes: moisture ingress, physical deformation, and salt-laden air.

H3 2. Packaging Specifications

| Material Form | Primary Protection | Secondary Protection | Tertiary Protection | Unit Load Securing | Fumigation / ISPM-15 |

|---|---|---|---|---|---|

| Strip / Foil 0.1–3.0 mm | 80 µm VCI stretch film, 2 wraps, 30 % overlap | 2 × desiccant packs (8 g CaCl₂ each) per coil eye | Fumigated wooden pallet, top & bottom caps, 18 mm plywood | 4 PET straps + edge boards, tension ≥ 500 N | Yes, heat-treated HT stamp on both faces |

| Wire Ø 0.3–5.0 mm on DIN 355 spools | 100 µm LDPE shrink bag, heat-sealed | 5-ply export carton, 32 ECT | Same pallet as above, max 24 spools/pallet | Cross-strapped with 19 mm PET, corner posts | Yes |

| Oscillate-wound master coils 500–800 kg | Aluminum foil barrier + VCI paper, 360° wrap | Steel support cradle, OD matched to coil | Plywood box, 12 mm walls, glued & screwed | 6 steel bands, 2-axis lashing to pallet base | Yes |

Desiccant quantity is calculated per ASTM D3951: 1 unit per 0.15 m³ void.

H3 3. Container Loading & Stowage Plan

20 ft GP: 10 metric tons max, 10 pallets, double-stacked only for ≤ 0.4 mm foil.

40 ft HC: 22 metric tons max, 22 pallets, single-stacked for > 1 mm strip to avoid coil-set.

Dunnage: 5-ply Kraft board between pallet tiers, 50 mm thick.

Moisture check: Container floor ≤ 12 % MC (pin meter) before loading; record sent with shipping docs.

H3 4. Logistics Corridor – Luoyang to Global

Luoyang sits at the intersection of the Longhai rail artery and the G36 expressway, 150 km from Zhengzhou International Hub. Cut-off times:

| Destination | Mode | Lead Time (ex-works) | Weekly Sailings | Freight Benchmark (Q2-24) |

|---|---|---|---|---|

| EU main ports | Rail-sea, Xi’an–Hamburg then feeder | 26 days | 3 | USD 1,050 / 20 ft |

| US West Coast | Lianyungang–LA direct | 18 days | 2 | USD 1,400 / 40 ft |

| MENA | Qingdao–Jebel Ali | 20 days | 4 | USD 900 / 20 ft |

All shipments covered by IICL5-certified containers and RoHS-compliant packaging materials.

H3 5. Cost & Risk Advantage vs. Western Suppliers

By integrating cold-rolling, slitting, and packaging in one Luoyang campus, we eliminate double handling and the premium charged by European service centers. Typical savings: 12–18 % CIF landed cost, while achieving ±0.002 mm slit tolerance and zero burr edges that exceed IEC 60317-19 requirements. Our logistics team provides pre-alert photos, container seal numbers, and conductivity test certificates 24 h before vessel departure—documentation that usually costs extra from Western stockists.

*From our slitters to your winders, the aluminum arrives factory-fresh—no secondary cleaning, no edge re-work, no conductivity loss.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.

When you specify pure aluminum strip or foil for transformer windings, you are not buying commodity metal—you are buying electrical performance, geometric precision, and lot-to-lot consistency. For 22 years our Luoyang works has supplied Tier-1 transformer OEMs and certified motor repair shops under exactly those metrics. Below is the engineering case for moving your next RFQ from a general trader to a factory that cold-rolls, slits, edge-conditions, and oscillate-winds under one roof.

1. Two Decades of Transformer-Only Data

| Milestone | Value to Your Design Team |

|---|---|

| 2002 start-up | First Chinese cold-mill dedicated ≥99.6 % Al strip for 35 kV dry-type transformers |

| 2006 | Achieved burr ≤ 0.01 mm on 0.2 mm strip—still the tightest edge spec quoted on Alibaba today |

| 2012 | Commissioned in-line eddy-current anneal; conductivity window tightened to 61.8–62.2 %IACS |

| 2018 | Oscillate-wind line added; 8 t coils on 320 mm I.D. eliminated your butt-welds in 2 m-wide foil |

| 2023 | 14 000 t annual output, zero customer-rejected lots due to edge crack or residual lubricant |

The result: We speak the same language—K-factor stacking, space-factor loss, axial short-circuit force—so your PQ and SQ engineers spend minutes, not weeks, on PPAP.

2. Direct Factory Price without the “China Risk”

| Cost Element | Trader Mark-up | Luoyang Xinzhaohe Advantage |

|---|---|---|

| LME Al ingot | +2 % broker fee | Direct melt-shop contract, -1.5 % |

| Cold-rolling toll | +8 % | Owned 4-high mill, 0 % |

| Slitting & edge dressing | Outsourced +5 % | In-house, 0 % |

| Export packing | Standard | VCI film + desiccant, no extra charge |

| Total landed saving vs. EU mill | — | 11–14 % |

We quote FOB Tianjin or CIP your plant in USD, EUR, or CNY—no hidden alloy surcharges, no “currency adjustment” clauses.

3. Customization Window—Mechanical & Electrical

| Parameter | Standard Offer | Customizable Range | Tolerance |

|---|---|---|---|

| Thickness | 0.08 – 3.00 mm | 0.05 – 5.00 mm | ±0.002 mm |

| Width | 8 – 1 250 mm | 4 – 1 600 mm | ±0.05 mm |

| Edge profile | Round & square | Full radius, 45° chamfer, stepped edge | Burr ≤ 0.01 mm |

| Conductivity | 61.5 %IACS min | Target 62.0 %IACS | ±0.2 %IACS |

| Anneal | O (fully soft) | 1/4 H, 1/2 H, custom grain size | ASTM E112 G ≥ 6 |

| Coil build | 80 – 500 kg | ≤ 8 t oscillate | I.D. 150 / 250 / 320 / 508 mm |

Need blue PE film, laser-welded tag, or incremental diameter stamping for automatic TIG joining? Done—no MOQ penalty.

4. Quality & Compliance Files Ready for Your Package

IEC 60317-0-3, ASTM B373, GB/T 3880 ed. 2022

IMDS ID 8P-1060-Al-0, REACH & RoHS 10/10 compliant

ISO 9001:2015 (TÜV) & ISO 14001:2015, ISO 45001:2018

PPAP Level 3 in 72 h; CpK ≥ 1.67 on thickness & conductivity

Vacuum-sealed + VCI, sea-worthy plywood reels, 40 ′ FCL load 24 – 26 t

5. Next Step—Get the Datasheet or a 7-Day Quote

Send your stack width, foil thickness, and annual volume to cathy@transformerstrip.com. We will return:

- A dimensional & electrical datasheet in PDF within 12 h

- A landed unit price in USD/kg or USD/m² (your choice)

- A 200 mm pilot sample slit to your width, annealed, edge-conditioned, and air-shipped free of charge

Stop paying Western-mill premiums for Asian metal. Partner with the factory that transformer engineers have trusted for 22 years.

📉 Import Savings Calculator

Estimate cost reduction by sourcing pure aluminum from Luoyang Xinzhaohe.