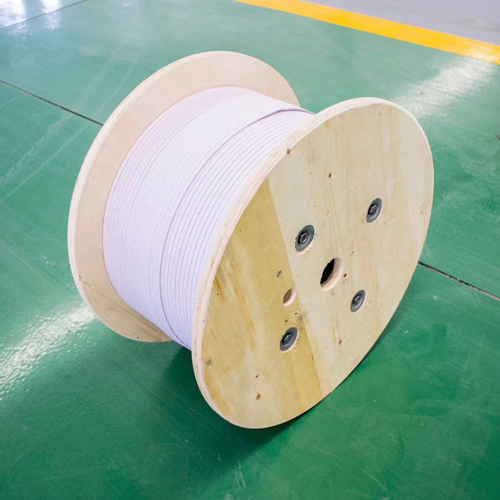

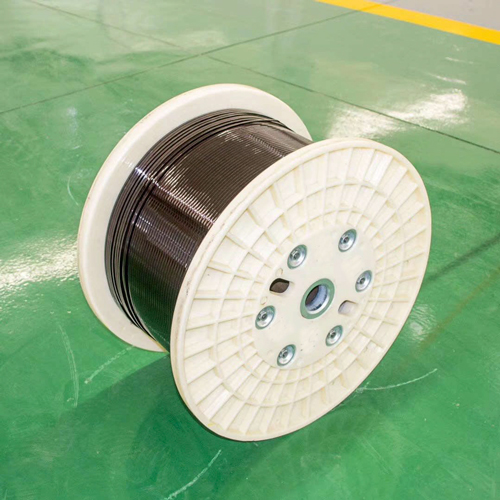

Enameled Wire

The enameled wire, also known as the magnet wire or winding wire, is a type of wire used in transformers. It is made by coating a thin layer of insulation material, such as enameled or polyurethane, over a conductive wire. This insulation coating provides electrical insulation and protection to prevent short circuits.

Technological parameters of enameled wire include:

1. Conductor Material: The core wire is typically made of copper or aluminum due to their excellent conductivity properties.

2. Insulation Material: The insulation coating is usually made of enameled or polyurethane, which provides high electrical resistance and thermal stability.

3. Wire Diameter: available in various diameters, ranging from very thin wires used in small transformers to thicker wires for larger power transformers.

4. Temperature Rating: designed to withstand high temperatures generated during transformer operation. It is rated based on its ability to operate at a specific temperature without deteriorating the insulation.

5. Voltage Rating: have different voltage ratings depending on their intended application. Higher voltage ratings are required for transformers used in power distribution systems.

6. Thermal Class: The thermal class indicates the maximum allowed operating temperature of the wire. It is denoted by a letter, such as F (155°C), H (180°C), or C (220°C), representing different levels of temperature resistance.

7. Flexibility: can be solid or stranded. Stranded wires offer more flexibility, making them suitable for applications that require frequent bending or movement.

These parameters ensure that the enameled wire meets the electrical and thermal requirements of transformers, ensuring their efficient and reliable operation.

Enameled wire product category:

130 polyester enameled wires;

155 modified polyester enameled rectangle wires;

180 polyester imide enameled copper(aluminum) rectangle wires;

200 polyester imide / polyamide-imide composite enameled copper(aluminum) rectangle wires;

120 acetal enameled copper(aluminum) rectangle wires.

Soft copper rectangle wire of enameled rectangle wire complies with the provisions of GB5584.2-2009,when 20℃,resistivity ≤0.017241Ω·mm²/m, according to different mechanical strength requirements.

Soft aluminum rectangle wire of enameled rectangle wire complies with the provisions of GB5584.2-2009,when 20℃,resistivity ≤0.02801Ω·mm²/m. According to different insulation requirements, can choose thin from 0.06 to 0.11mm or thick film from 0.12 to 0.17mm.

The thickness of hot adhesive enameled rectangle wire self-adhesive layer is generally 0.03-0.06mm. Our company monitor the thickness with dielectric loss meter.

Above painting thickness could be manufactured according to specifications provided by customers.

The enameled wire, also known as the magnet wire or winding wire, is a type of wire used in transformers. It is made by coating a thin layer of insulation material, such as enameled or polyurethane, over a conductive wire.

This insulation coating provides electrical insulation and protection to prevent short circuits.

Technological parameters of enameled wire include:

1.Conductor Material: The core wire is typically made of copper or aluminum due to their excellent conductivity properties.

2.Insulation Material: The insulation coating is usually made of enameled or polyurethane, which provides high electrical resistance and thermal stability.

3.Wire Diameter: enameled wires are available in various diameters, ranging from very thin wires used in small transformers to thicker wires for larger power transformers.

4.Temperature Rating: The enameled wire is designed to withstand high temperatures generated during transformer operation. It is rated based on its ability to operate at a specific temperature without deteriorating the insulation.

Voltage Rating: enameled wires have different voltage ratings depending on their intended application. Higher voltage ratings are required for transformers used in power distribution systems.

Thermal Class: The thermal class indicates the maximum allowed operating temperature of the wire. It is denoted by a letter, such as F (155°C), H (180°C), or C (220°C), representing different levels of temperature resistance.

Flexibility: enameled wires can be solid or stranded. Stranded wires offer more flexibility, making them suitable for applications that require frequent bending or movement.

Although the production process of enameled wire is complicated, our products have stable performance, long service life, and can significantly improve efficiency and reduce energy consumption in transformers and other equipment, so it has a high cost-effective.

In summary, the transformer enameled wire with its excellent insulating properties, high conductivity, high temperature characteristics and good mechanical properties, become an indispensable key material in the manufacture of transformers!

Electrical Transformer Forum: https://electricityforum.com/news

Local steel news: https://www.transformerstrip.com/top-super-enamelled-copper-wire-manufacturer-compare/