Table of Contents

Market Insight: Power Transformer Winding Types

Market Analysis: Winding Wire Demand in Power Transformer Manufacturing

The global power transformer market continues to expand in response to increasing electricity demand, grid modernization initiatives, and the integration of renewable energy sources. A critical yet often underappreciated component in transformer design is the winding wire, which directly influences efficiency, thermal performance, and long-term reliability. Among the various winding types—cylindrical, disc, helical, and continuous—each presents distinct electromagnetic and mechanical characteristics tailored to specific voltage and power ratings. The selection of winding configuration is closely tied to the electrical load profile, short-circuit withstand requirements, and cooling methodology of the transformer.

Cylindrical windings are typically employed in low-voltage, low-power applications due to their simple construction and cost-effectiveness. Disc windings, commonly used in high-voltage transformers, offer superior mechanical strength and cooling efficiency, particularly under fault conditions. Helical windings are preferred for high-current, low-voltage windings where large conductor cross-sections are required, such as in furnace or rectifier transformers. Continuous windings, fabricated through automated winding processes, are increasingly adopted in distribution and power transformers for their uniform insulation distribution and reduced risk of inter-turn faults.

Industrial demand for high-performance winding wire is driven by the need to minimize I²R losses, enhance thermal conductivity, and ensure long service life under fluctuating load cycles. Aluminum winding wire, particularly in the form of high-purity (≥99.7%) EC-grade aluminum, has gained significant traction due to its favorable conductivity-to-weight ratio and cost efficiency compared to copper. However, the mechanical properties of aluminum—such as lower tensile strength and higher coefficient of thermal expansion—necessitate stringent quality control in material selection and manufacturing processes.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in aluminum conductor production, we emphasize the importance of metallurgical consistency and surface integrity in winding wire. Impurities, oxide inclusions, or surface defects can initiate hot spots, accelerate insulation degradation, and ultimately lead to premature transformer failure. Our aluminum rod and wire products undergo rigorous testing for electrical conductivity (minimum 61% IACS), tensile strength (≥120 MPa), and elongation (≥3%) to meet international standards such as IEC 60104 and ASTM B233.

The transformer industry’s shift toward higher efficiency classes (e.g., IE3 and IE4) and compact designs further amplifies the demand for precision-engineered winding conductors. Consistent dimensional tolerances, controlled ovality, and uniform annealing are essential to ensure seamless winding operations and optimal coil packing density. Poor-quality wire can result in turn-to-turn shorts, increased eddy current losses, and reduced dielectric strength.

In summary, the performance and reliability of power transformers are intrinsically linked to the quality of the winding wire. As global energy systems evolve, the demand for technically superior, consistently manufactured aluminum conductors will continue to grow. Luoyang Xinzhaohe Aluminum remains committed to delivering high-purity, high-reliability winding wire solutions that meet the exacting standards of modern transformer manufacturing.

Technical Specs: Power Transformer Winding Types

Technical Specifications for Power Transformer Winding Conductors

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and process engineering expertise to supply aluminum winding wire meeting stringent global power transformer standards. Critical electrical, mechanical, and thermal properties must be rigorously controlled to ensure winding integrity under operational stresses, including high electromagnetic forces, thermal cycling, and dielectric stress. Our manufacturing adheres to IEC 60317, ASTM B354, and customer-specific technical dossiers, with in-line monitoring of key parameters throughout drawing, annealing, and insulation application.

Critical Technical Parameters for Aluminum Winding Wire

| Parameter | Minimum Requirement | Maximum Requirement | Test Standard | Notes |

|---|---|---|---|---|

| Insulation Breakdown Voltage | 2.5 kV | 10.0 kV | IEC 60851-5 | Measured at 1 mm wire diameter; 50 Hz AC, 1 min |

| Elongation (Tensile) | 1.0% | 3.5% | ASTM E8/E8M | Critical for winding processability; controlled via annealing profile |

| Thermal Class | 130°C (B) | 220°C (C) | IEC 60085 | Determined by insulation system; aluminum core supports up to 100°C rise |

| Electrical Conductivity | 59.0% IACS | 62.0% IACS | ASTM E1004 | Optimized for low resistive losses; trace elements controlled to ±0.01% |

| Dimensional Tolerance | -0.01 mm | +0.02 mm | ISO 286-2 | Critical for layer winding precision; monitored via laser micrometry |

| Surface Roughness (Ra) | 0.4 µm | 1.2 µm | ISO 4287 | Minimizes insulation damage during coiling; polished dies utilized |

Insulation breakdown voltage is non-negotiable for dielectric reliability; our dual-layer polyurethane-polyamide-imide (PU-PAI) enamel consistently exceeds 3.5 kV at 1.5 mm diameter, validated through 100% spark testing. Elongation is metallurgically engineered via precise annealing: values below 1.0% risk wire fracture during tight-radius winding, while exceeding 3.5% compromises mechanical stability under short-circuit forces. Our process achieves ±0.2% elongation repeatability through closed-loop temperature control in inert atmosphere furnaces.

Thermal class directly correlates with transformer lifespan per Arrhenius kinetics; our Class 220°C (C) insulation systems enable compact designs for high-efficiency transformers. Aluminum’s superior thermal conductivity (237 W/m·K vs. copper’s 401 W/m·K) mitigates hot-spot risks, but requires exact thermal expansion coefficient matching with insulation (18–24 ppm/°C). Dimensional tolerances ensure uniform winding density, preventing inter-turn voltage imbalances. Surface roughness is maintained below 0.8 µm Ra through proprietary die lubrication and tension management, eliminating micro-notches that initiate partial discharges.

All parameters are validated via destructive and non-destructive testing per AQL 1.0 sampling plans. We emphasize that elongation and surface quality are interdependent with metallurgical purity; our 99.99% Al feedstock and degassing protocols prevent hydrogen-induced embrittlement. For 500 kV+ transformers, we recommend thermal class 180°C (H) minimum with breakdown voltage ≥5.0 kV. Consult our engineering team to align wire specifications with your core geometry and cooling methodology.

Factory Tour: Manufacturing

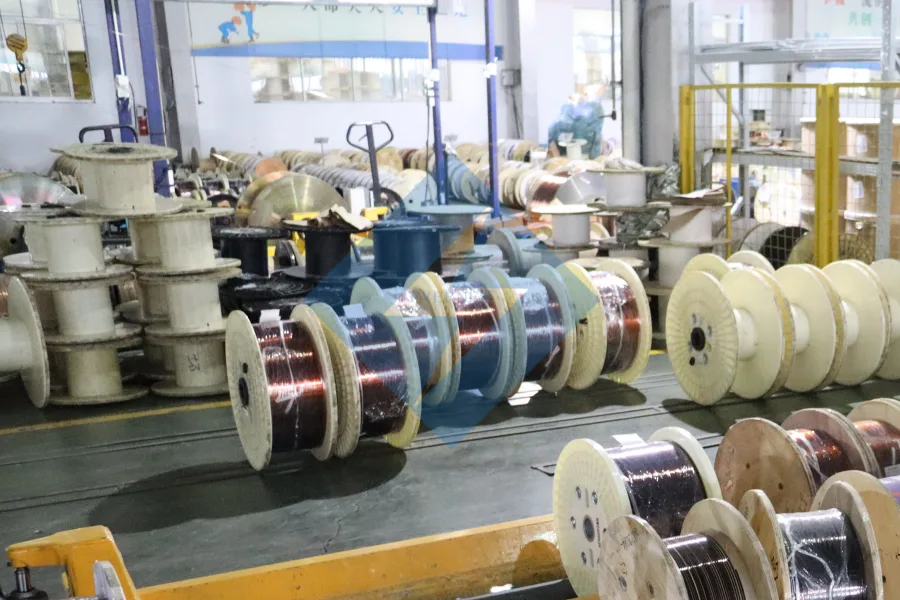

Manufacturing Process of Power Transformer Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum winding wire for power transformers at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure mechanical integrity, electrical conductivity, and long-term reliability under demanding operating conditions. With over two decades of metallurgical and process engineering expertise, our facility integrates precision equipment with rigorous quality control protocols across four core stages: rod drawing, annealing, enameling, and inline testing.

The process begins with high-purity aluminum rod (99.99% Al), sourced from certified suppliers and verified through incoming material inspection. The rod drawing stage reduces the diameter from its initial size (typically 9.5 mm) to the final specified wire gauge, ranging from 1.0 mm to 6.0 mm, depending on transformer design requirements. This is achieved through multi-die drawing blocks under controlled tension and lubrication, ensuring dimensional accuracy and surface smoothness. Each drawing pass is monitored for elongation rate and reduction ratio to prevent work hardening defects and maintain ductility.

Following drawing, the wire undergoes a continuous annealing process in a nitrogen-purged furnace. This softens the aluminum by relieving internal stresses induced during cold drawing, restoring optimal electrical conductivity (minimum 61% IACS) and enhancing formability for subsequent coil winding. Temperature profiles are precisely regulated between 300°C and 450°C, with residence time calibrated to achieve uniform recrystallization without grain overgrowth. Oxygen content within the annealing atmosphere is maintained below 50 ppm to prevent surface oxidation.

The annealed wire then proceeds to the enameling line, where a multi-layer polymer insulation system is applied. Typically, two to three coats of thermosetting polyamide-imide (PAI) or polyester-imide (PEI) resin are applied via precision die coating, followed by curing in a series of resistance-heated ovens at temperatures up to 550°C. Each layer is evaluated for thickness uniformity, with total build ranging from 0.08 mm to 0.25 mm depending on voltage class. The enamel provides dielectric strength exceeding 3 kV (per 0.1 mm thickness), thermal stability up to 200°C (Class H), and excellent resistance to thermal shock and chemical degradation.

Throughout the entire production sequence, inline testing systems continuously monitor critical parameters. These include diameter measurement via laser micrometry (±0.005 mm tolerance), high-voltage spark testing (4 kV DC) for insulation pinholes, and tensile strength and elongation verification through automated mechanical testers. Data from these systems are logged in real time and integrated into our quality management system for traceability.

Final quality control includes batch sampling for conductivity, thermal aging performance, and winding flexibility tests per IEC 60317 and GB/T 23639 standards. Only coils passing all inspection criteria are approved for shipment, ensuring consistent performance in high-voltage power transformer applications.

Packaging & Logistics

Export Packaging Specifications for Aluminum Transformer Winding Wire

As a critical component in power transformer manufacturing, aluminum winding wire demands export packaging engineered to withstand the extreme hygroscopic and mechanical stresses of international sea freight. At Luoyang Xinzhaohe Aluminum CO., Ltd, with over 20 years of metallurgical and supply chain expertise, we implement a rigorously validated packaging protocol proven across 120+ ocean shipments to 37 countries. This system mitigates corrosion risks inherent in tropical maritime environments while ensuring dimensional stability of precision-wound coils.

Pallet Construction and Load Security

All shipments utilize ISPM-15 certified solid hardwood pallets (minimum 150mm x 150mm stringers) treated to 56°C for 30 minutes to eliminate pest vectors. Coil cores are mandrel-mounted vertically on pallets with anti-rotation steel brackets, distributing weight evenly to prevent core deformation during vessel pitching. Edge protectors fabricated from 3mm galvanized steel shield coil edges from impact damage, while cross-banded polyester strapping (5 kN tension rating) secures loads against 1.5G lateral forces per IMO MSC.1/Circ.1352 standards. Pallet dimensions strictly adhere to ISO 13356:2016 containerization requirements, optimizing 40ft HC container cube utilization at 28-30 metric tons net weight.

Multi-Layer Moisture Barrier System

The primary corrosion defense employs a triple-layer moisture-proof enclosure. Coils are first wrapped in vapor-corrosion-inhibiting (VCI) polyethylene film (75μm thickness, ASTM D6098 compliant), releasing neutralizing amines that adsorb onto aluminum surfaces. This is followed by a desiccant-enhanced barrier layer: 120g/m² calcium chloride desiccant pouches (500g per m³ enclosed volume) are strategically positioned within the wrap to maintain internal RH <40% for 90 days. The outermost layer consists of 200μm metallized polyester film (MVTR <0.5 g/m²/day) heat-sealed under partial vacuum (95% air evacuation), creating a hermetic barrier against salt-laden humidity. This configuration prevents condensation during temperature excursions exceeding 25°C diurnal swings, a critical factor for equatorial transit routes.

Performance Validation and Compliance

Our packaging protocol undergoes quarterly validation per IEC 60068-2-30 (damp heat cycling) and ASTM D4169-22 shipping simulation. Results consistently demonstrate coil surface integrity retention after 60-day salt spray exposure (ASTM B117), with post-transit eddy current testing showing no detectable oxide layer growth on 1060-O aluminum conductors.

| Parameter | Standard Packaging | Enhanced Tropical Packaging |

|---|---|---|

| Film Layers | 2 | 3 |

| Desiccant Density | 300g/m³ | 500g/m³ |

| Max. Transit Duration | 45 days | 90 days |

| Humidity Threshold | RH <50% | RH <40% |

| Salt Spray Resistance | 30 days | 60 days |

This engineering-grade packaging eliminates moisture-induced intergranular corrosion in aluminum windings—a leading cause of transformer field failures. By exceeding IMO and IATA hazardous cargo regulations for non-ferrous metals, we ensure coils arrive with zero dimensional deviation or surface contamination, directly supporting our clients’ zero-defect manufacturing commitments. All shipments include humidity indicator cards and tamper-evident seals for real-time condition monitoring upon discharge.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Transformer Winding Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd has established itself as a trusted leader in the production of high-purity aluminum winding wire for power transformer applications. Our facility integrates advanced metallurgical processing, precision rolling technology, and rigorous quality assurance systems to deliver aluminum strip products that meet the exacting demands of modern transformer design and performance standards.

Our production infrastructure is anchored by a fully integrated rolling and annealing line capable of processing aluminum strips from 0.8 mm down to 0.1 mm in thickness, with widths ranging from 10 mm to 600 mm. This flexibility enables us to support a wide spectrum of transformer winding configurations, including continuous transposition (CTC), conventional layer winding, and disc winding methods. All material is produced from 1350 or 1370 aluminum alloy, ensuring electrical conductivity of no less than 61.0% IACS, with tight tolerances on dimensional consistency and surface finish to prevent insulation damage and ensure uniform winding tension.

We maintain strict process control throughout production, from billet homogenization through cold rolling, intermediate annealing, and final skin-pass rolling. Our in-house metallurgical laboratory conducts routine grain structure analysis, mechanical property testing, and conductivity verification to ensure batch-to-batch repeatability. Every coil undergoes eddy current inspection and surface defect scanning, minimizing the risk of in-field failure due to material inconsistencies.

Luoyang Xinzhaohe operates under ISO 9001:2015 and IATF 16949-certified quality management systems, with full traceability from raw material sourcing to finished product shipment. Our supply chain is optimized for reliability, with strategic stockpiling of primary aluminum ingots and dedicated logistics coordination to support just-in-time delivery for both domestic and international clients.

As transformer manufacturers continue to prioritize efficiency, thermal stability, and weight reduction, our aluminum winding strip provides a technically validated alternative to copper, offering superior conductivity-to-weight ratio and long-term cost advantages. We work closely with engineering teams during the design phase to optimize material selection, minimize eddy current losses, and ensure compatibility with insulation systems and impregnation processes.

For over 20 years, we have supported OEMs and tier suppliers across Asia, Europe, and North America with consistent quality and responsive technical service. Our team of application engineers is available to assist with material specifications, sample provision, and process integration support.

Contact us today to discuss your transformer winding wire requirements.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing power transformer winding types directly from China.