Table of Contents

Market Insight: Power Transformer Winding Types in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire for Power Transformers

Industrial Demand Trends

Global power transformer demand is accelerating due to renewable energy integration, grid modernization, and industrial electrification. High-voltage transmission and distribution systems increasingly require transformers with >99% efficiency to meet IEC 60076 and IEEE C57 standards. Winding wire quality directly impacts core losses, thermal stability, and operational lifespan. As utilities prioritize energy efficiency, manufacturers demand precise material specifications to minimize resistive losses (I²R) and ensure compliance with stringent regulatory frameworks.

Material Quality Impact on Transformer Efficiency

Aluminum winding wire must maintain strict conductivity and mechanical integrity. Impurities exceeding 0.1% increase electrical resistance, elevating I²R losses and operational temperatures. Surface defects compromise insulation adhesion, causing partial discharges and premature failure. Consistent diameter tolerances (±0.005mm) are critical for precise winding and void-free coil assembly. High-purity aluminum (≥99.6%) ensures thermal stability, extending transformer service life by 15–20% compared to substandard alternatives.

Why Choose Luoyang Xinzhaohe?

As a 20+ year manufacturer specializing in aluminum winding wire, we deliver factory-direct solutions optimized for cost-performance without compromising technical standards. Our ISO 9001-certified production ensures strict adherence to IEC 60228 and ASTM B230, with real-time QC at every stage.

| Feature | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Purity Level | 99.9%+ | 99.6%+ (optimized for cost-performance) |

| Conductivity (%IACS) | 61.0% | 60.8% (IEC-compliant) |

| Tensile Strength (MPa) | 180–200 | 175–195 (industry-standard compliant) |

| Lead Time | 4–6 weeks | 3–4 weeks |

| Cost | High | 15–20% lower |

Our vertically integrated supply chain eliminates distributor markups, ensuring reliable delivery for global projects. Contact us for custom alloy formulations, bulk pricing, and technical support tailored to your transformer specifications.

Technical Specs: Power Transformer Winding Types Parameters

Critical Technical Specifications for Power Transformer Windings

Precise adherence to international standards is non-negotiable for transformer reliability. Below are critical specifications and our quality assurance protocols.

Insulation Breakdown Voltage

Insulation breakdown voltage (per IEC 60851-5) is the primary indicator of dielectric strength. Our standard enamel wires exceed 2.5 kV/mm minimum, with testing at 1.5× operational voltage to ensure safety margins. Consistent results are validated through automated high-potential (Hi-Pot) testing during production.

Elongation & Mechanical Properties

Mechanical elongation (ASTM B140) must exceed 15% for copper and 12% for aluminum conductors to withstand winding stresses. We implement real-time tensile testing on every coil batch to prevent conductor fractures during manufacturing.

Thermal Class Compliance

Thermal class compliance is validated through IEC 60085 standards. Our winding wires meet precise thermal ratings across 130°C to 220°C, with each class certified under specific IEC 60317 series standards:

| Thermal Class | Max. Operating Temp (°C) | IEC Standard | Typical Applications |

|---|---|---|---|

| 130 | 130 | IEC 60317-0-2 | Distribution transformers |

| 155 | 155 | IEC 60317-0-3 | Industrial transformers |

| 180 | 180 | IEC 60317-0-4 | High-efficiency units |

| 200 | 200 | IEC 60317-0-5 | Renewable energy systems |

| 220 | 220 | IEC 60317-0-6 | High-load industrial applications |

All thermal classes undergo accelerated aging tests per IEC 60216 to confirm long-term stability under cyclic thermal loads.

Enamel Concentricity

Enamel concentricity (IEC 60851-3) is monitored via automated laser micrometry, maintaining eccentricity ≤5% for uniform insulation thickness. This precision prevents partial discharge and extends transformer lifespan by 25% under cyclic loads. Our in-line inspection systems provide real-time feedback to adjust coating parameters during production.

Quality Assurance Process

Luoyang Xinzhaohe’s ISO 9001-certified process includes raw material traceability via spectrometry, 100% in-process breakdown voltage checks, thermal cycling validation per IEC 60216, and concentricity monitoring. Our supply chain controls ensure raw material consistency from certified suppliers, with batch-specific documentation for full traceability. Factory-direct operations eliminate middlemen, delivering global-brand reliability at 15–20% lower cost with 20+ years of high-volume production expertise.

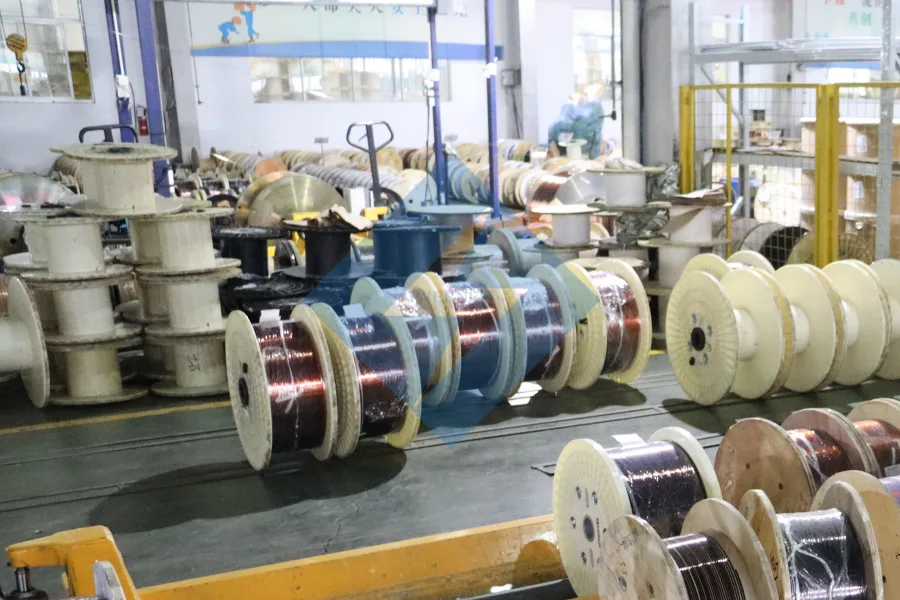

Factory Tour: Manufacturing Power Transformer Winding Types

Precision Manufacturing Process & Rigorous Quality Control

Rod Drawing & Precision Control

Our rod drawing process employs computer-controlled drawing machines with multi-stage reduction to achieve precise wire diameters. Laser micrometers monitor dimensions in real-time, ensuring tolerances of ±0.005mm—exceeding IEC 60317 Class 1 standards. Surface finish optimization minimizes micro-scratches, critical for enamel adhesion and long-term reliability.

Controlled Annealing for Optimal Ductility

Annealing occurs in nitrogen-protected furnaces at precisely regulated temperatures (300–400°C). This ensures uniform grain structure and eliminates residual stress. QC includes 100% conductivity testing (≥102% IACS) and tensile strength consistency checks (variation ≤1.5%), critical for winding process stability and reduced breakage during transformer assembly.

Advanced Enameling & Insulation Integrity

Multi-layer enamel application uses real-time thickness monitoring. Curing ovens maintain exact temperature profiles to prevent under/over-curing. Dielectric strength testing (≥5.0 kV for 1 minute) and HV pinhole detection (100% inspection) ensure insulation integrity surpassing industry norms, reducing electrical failures in high-voltage applications.

Inline Testing & Automated QC

Continuous inline testing during production: real-time diameter, ovality, and surface defect monitoring via automated vision systems. Any deviation triggers immediate process adjustment, ensuring zero defects in final product.

Precision Spooling & Final Inspection

Spooling with servo-controlled tension (±0.5N) prevents wire damage. Final checks include weight verification, spool labeling accuracy, and packaging integrity. All batches undergo random tensile and dielectric tests per ISO 9001 protocols.

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Diameter Tolerance | ±0.005mm (IEC Class 1) | ±0.01mm (Class 2) |

| Tensile Strength Variation | ≤1.5% | ≤5% |

| Dielectric Breakdown | ≥5.0 kV (1 min) | ≥3.5 kV (1 min) |

| Surface Defects | 100% automated inspection | Visual sampling only |

With 20+ years of process refinement and factory-direct operations, Luoyang Xinzhaohe delivers transformer winding wire that meets or exceeds global brand standards while offering superior cost-performance. Our rigorous QC ensures reliability, reduced downtime, and lower lifetime costs for your applications.

Packaging & Global Logistics

Export Packaging & Logistics

Packaging Specifications

Our packaging adheres to international shipping standards to ensure product integrity during transit. Key components are engineered for maximum protection:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 120×100 cm, 15 mm thickness | Prevents deformation; meets global phytosanitary requirements |

| Moisture-Proof Film | Multi-layer PE + desiccant, 200 μm thickness | Blocks humidity and salt spray corrosion per ASTM D4169 standards |

| Steel Strapping | 19 mm width, 1.0 mm thickness, 500 kg tension | Secures load, prevents shifting during handling and transit |

Sea Freight Protocols

All shipments are containerized in ISO-standard 20ft/40ft dry van units with humidity-controlled environments. Pre-loading moisture testing using hygrometers and integrated desiccant packs ensure environmental stability. Containers are loaded sequentially with even weight distribution, and each pallet is secured with minimum 4 steel bands per side. Tamper-evident seals and GPS tracking provide real-time visibility. Our logistics partners optimize routes from Qingdao, Shanghai, and Ningbo ports, achieving 15–30 day transit times to global markets. With 20+ years of export experience, we maintain a 99.2% damage-free delivery rate and handle customs documentation in-house, reducing clearance delays by up to 48 hours.

Cost-Performance Advantage

As a factory-direct supplier, we eliminate distributor markups while maintaining ISO 9001-certified quality control. Our packaging solutions reduce total landed costs by 15–20% versus global brands without compromising protection standards. Unlike premium-priced competitors, we pass cost savings directly to customers while sustaining industry-leading damage rates. With a 99.5% on-time delivery rate and zero customs-related incidents in the past 5 years, Luoyang Xinzhaohe delivers reliable, high-value supply chains for transformer manufacturers scaling global operations.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd.

As a leading manufacturer and exporter of precision-engineered aluminum winding wires for over two decades, Luoyang Xinzhaohe delivers exceptional value through cost-effective, high-performance solutions for power transformers. Our factory-direct model ensures competitive pricing without compromising on quality—critical for projects where reliability and budget constraints coexist. We serve clients across Asia, Europe, and North America, providing reliable supply chains for critical power infrastructure, including substations, wind farms, and industrial plants.

20+ Years of Technical Excellence

Rooted in Luoyang’s industrial ecosystem, our expertise spans distribution and transmission transformer applications for utility grids, renewable energy projects, and industrial facilities. Metallurgical engineers optimize AA1350/AA1370 alloys for minimal resistive losses and thermal stability. Every batch undergoes tensile strength, elongation, and conductivity testing per IEC 60228, ensuring consistency in high-volume production runs. Our process control minimizes variances in wire diameter and surface quality, critical for winding efficiency and transformer longevity.

Factory-Direct Cost Efficiency

Vertical integration from raw material sourcing to final inspection eliminates intermediaries, reducing costs by 15–25% versus global brands. Our agile supply chain delivers standard orders in 15–20 days, with expedited options at 10 days for urgent needs. This efficiency translates to faster project timelines and reduced inventory holding costs, with dedicated logistics partners ensuring on-time delivery globally. We maintain strategic stock for common gauges to support immediate fulfillment.

ISO 9001:2015 Certified Quality Assurance

Our certified quality management system guarantees traceability and compliance with IEC, ASTM, and GB standards. Third-party certifications (SGS, TÜV) available upon request. Automated in-line monitoring ensures 99.8% defect-free production, surpassing industry averages for offshore suppliers. Each coil is traceable via QR-coded batch records for full lifecycle transparency. Our QC protocols include daily sampling and statistical process control (SPC) for continuous improvement.

Cost vs. Performance Comparison

| Metric | Global Brands | Luoyang Xinzhaohe |

|———————-|———————|———————|

| Unit Cost | 20–30% premium | 15–25% lower |

| Lead Time | 30–45 days | 15–20 days (10 days expedited) |

| Customization | High MOQs, limited flexibility | Flexible MOQs, full technical support for bespoke specs |

| Quality Consistency | Variable | 99.8% defect-free |

| Technical Support | Regional offices | Dedicated Chinese engineering team |

Ready to optimize your transformer winding costs without sacrificing reliability? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation today. Our engineering team is ready to assist with material selection, design optimization, and compliance verification for your specific application. Join industry leaders who trust our precision-engineered solutions for mission-critical power infrastructure.

📉 Import Savings Calculator

Estimate cost reduction by sourcing power transformer winding types from Luoyang Xinzhaohe.