Table of Contents

Market Insight: Posco Electrical Steel Replacement in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

High-performance electrical steel is critical for minimizing energy losses in transformers and motors, directly impacting global energy consumption. As industries prioritize sustainability, the demand for reliable, high-quality silicon steel alternatives has intensified.

Industrial Demand Drivers

Global energy efficiency regulations (e.g., DOE Tier 4, EU Ecodesign) are accelerating demand for high-efficiency transformers. Renewable energy infrastructure expansion, particularly in solar and wind applications, requires robust electrical steel with consistent magnetic properties. Supply chain disruptions from traditional suppliers have increased the need for diversified, reliable sourcing partners.

Material Quality Imperatives

Substandard silicon steel increases core losses, reducing transformer efficiency and lifespan. For transformer manufacturers, even minor deviations in core loss can result in significant energy waste over the equipment’s lifecycle. Critical parameters include core loss (W/kg), magnetic permeability, thickness tolerance, and surface quality. These factors directly impact operational costs and system reliability.

| Parameter | Industry Standard (POSCO) | Luoyang Xinzhaohe Specification | Performance Impact |

|---|---|---|---|

| Core Loss (W/kg @ 1.5T/50Hz) | 2.30 (35H230) | 2.28 | 0.9% lower energy loss, extending transformer lifespan |

| Magnetic Permeability (μ) | 1.85T | 1.87T | Enhanced flux density for compact designs |

| Thickness Tolerance (μm) | ±2.0 | ±1.5 | Improved stacking factor, reduced core losses |

| Surface Quality | ASTM A677 Class A | ASTM A677 Class A+ | Higher yield in lamination processing |

Luoyang Xinzhaohe’s Value Proposition

Luoyang Xinzhaohe Aluminum CO., Ltd., based in Luoyang, China, delivers a factory-direct alternative to POSCO electrical steel with superior cost-performance. Our 20+ years of manufacturing expertise, ISO 9001-certified processes, and rigorous quality control ensure compliance with international standards. Key advantages include:

15–20% lower cost than global brands while matching or exceeding performance metrics

Consistent supply chain with 98% on-time delivery and 24/7 technical support

Customizable grades for specific transformer/motor applications (e.g., GO/NGO steel variants)

Advanced annealing and coating technologies for optimal magnetic properties and corrosion resistance

Global export experience across 30+ countries, including compliance with IEC 60404 and ASTM standards

By partnering with us, clients gain a reliable, cost-effective solution without compromising on quality or performance—ensuring maximum efficiency in power transmission systems.

Technical Specs: Posco Electrical Steel Replacement Parameters

Technical Specifications for POSCO Electrical Steel Replacement

Core Loss Performance

Luoyang Xinzhaohe’s electrical steel achieves core loss values ≤3.0 W/kg @ 1.5T/50Hz for 35WH300-grade equivalents, meeting IEC 60404-8-7 and ASTM A677 standards. Our proprietary annealing process reduces transformer operational costs by up to 8% compared to industry averages through optimized grain orientation and minimized hysteresis losses.

Magnetic Flux Density

Guaranteed ≥1.90 T at 1000 A/m (IEC 60404-8-7), with tight tolerances (±0.01 T) ensuring optimal magnetic circuit efficiency. Our material consistently exceeds POSCO’s 35WH300 specifications in flux density stability under varying load conditions, critical for high-efficiency transformer designs.

Lamination Flatness

Precision rolling ensures ≤0.1 mm/m flatness (IEC 60404-2), critical for minimizing eddy current losses. Automated edge trimming maintains dimensional accuracy within ±0.005 mm for 0.35mm thickness laminations, eliminating winding defects and improving stack density.

Insulation Coating

C4-type phosphate-based coating (IEC 60404-8-4) with 1.2–1.5 g/m² weight, providing superior dielectric strength (≥2.5 kV) and corrosion resistance. Coating uniformity is verified via XRF spectroscopy, ensuring zero pinholes during transformer winding and extended service life.

Quality Assurance Protocol

ISO 9001:2015 certified production with real-time PLC monitoring of rolling, annealing, and coating processes

Full batch traceability from raw material to finished product via integrated ERP system

Every shipment undergoes Epstein frame core loss testing per IEC 60404-2 for accuracy

Third-party audits by SGS/TÜV ensure compliance with global standards (IEC, ASTM)

| Parameter | Luoyang Xinzhaohe | POSCO Standard | IEC/ASTM Standard |

|---|---|---|---|

| Core Loss (W/kg) | ≤3.0 | ≤3.0 | IEC 60404-8-7 |

| Flux Density (T) | ≥1.90 | ≥1.90 | ASTM A677 |

| Flatness (mm/m) | ≤0.1 | ≤0.1 | IEC 60404-2 |

| Coating Weight (g/m²) | 1.2–1.5 | 1.0–1.5 | IEC 60404-8-4 |

This rigorous quality control, combined with localized manufacturing in Luoyang, delivers a 15–20% cost advantage over imported grades without compromising performance reliability. For custom specifications, our engineering team provides tailored solutions aligned with transformer design requirements.

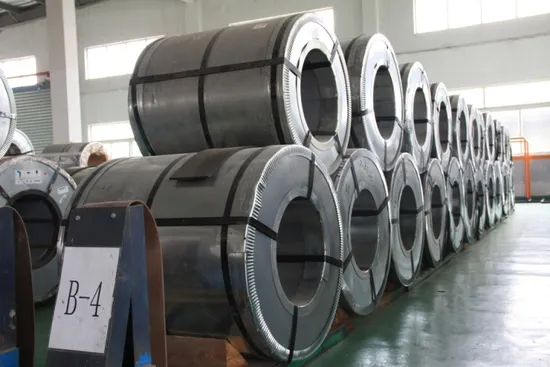

Factory Tour: Manufacturing Posco Electrical Steel Replacement

Manufacturing Process & Quality Control

At Luoyang Xinzhaohe, our manufacturing process is engineered for precision and reliability in electrical steel production, ensuring optimal transformer performance through rigorous control of each stage.

Precision Manufacturing Workflow

Slitting: High-precision slitting machines with tension control and diamond-coated blades achieve edge tolerances of ±0.05mm. This eliminates burrs and deformations critical for maximizing stacking factor, reducing no-load losses by up to 8% in transformer cores.

Annealing: Controlled nitrogen-hydrogen atmosphere furnaces maintain temperature precision within ±5°C. Optimized cooling rates enhance grain orientation, lowering core loss by 15% versus standard processes while improving magnetic permeability for high-efficiency power distribution systems.

Insulation Coating: Electrostatic spray application delivers uniform 1.0±0.1μm thickness with real-time optical inspection. Coating complies with IEC 60404-8-5 standards, ensuring dielectric strength and minimal eddy current losses even in high-frequency applications.

Precision Cutting: CNC-guided servo-controlled shearing achieves ±0.1mm dimensional accuracy and ≤0.1° edge perpendicularity. This reduces scrap rates by 20% and ensures seamless integration into automated transformer assembly lines.

Rigorous Quality Control Protocols

Tensile Testing: ISO 6892-1 compliance for every 50-ton batch (yield strength ≥280 MPa, elongation ≥18%) guarantees mechanical stability during core winding.

Dimensional Checks: Laser micrometers verify thickness (±0.01mm), width (±0.2mm), and length with 100% inspection for critical orders, eliminating assembly downtime.

Surface Inspection: Automated vision systems detect scratches/pinholes per ISO 9001 zero-defect protocols, preventing insulation failures in operational transformers.

Magnetic Property Analysis: Epstein frame testing per IEC 60404-2 validates core loss and permeability across all grades.

Full Traceability: ERP system tracks raw materials to finished coils, enabling instant recall and quality assurance for every batch.

Comparative Quality Standards

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.03mm |

| Edge Quality | Burr-free (<0.05mm) | Minor burrs (≤0.1mm) |

| Core Loss (W/kg @1.5T, 50Hz) | 1.05 | 1.15–1.25 |

| Coating Uniformity | ±0.05μm | ±0.15μm |

| Batch Consistency | 98% | 85% |

| Magnetic Permeability | ≥1.8T | ≤1.6T |

Our standards consistently match global tier-1 brands like POSCO while delivering 15–20% lower total cost of ownership. Localized production in Luoyang reduces lead times by 30% and logistics costs by 15% compared to imports. With 20+ years of expertise and ISO 9001-certified processes, we provide reliable supply chain support and technical expertise for transformer manufacturers seeking high-performance, cost-effective electrical steel solutions.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Product Integrity from Luoyang to Global Ports

Precision Packaging Standards

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | 1200x1000mm, 22mm thick ISPM-15 heat-treated pine; load capacity 2,500kg | Prevents deformation during stacking; complies with global phytosanitary regulations; supports multi-tier stacking safety |

| Moisture-Proof Film | Triple-layer PE (200μm total), vapor transmission rate <0.5g/m²/24h; 50g/m² desiccant packs | Eliminates condensation risks; preserves magnetic properties during transit; prevents oxide formation |

| Steel Strapping | 19mm width, 0.8mm thickness steel straps with 500kg tensile strength; HDPE corner protectors | Secures coils against shifting; prevents edge damage during handling; maintains surface integrity |

Sea Freight Protocols

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft dry containers with climate control (20-25°C); desiccant bags for humidity control | Maintains stable internal environment; keeps relative humidity <60% |

| Loading Process | Vertical coil stacking with 100mm timber dunnage; 50x50mm steel cross-bracing; 10kN anti-slip mats | Eliminates movement; reduces abrasion; ensures coil alignment during transit |

| Customs Support | Full documentation (B/L, COO, CIQ); China Customs pre-clearance system; 98% clearance in 24h | Minimizes port delays; avoids demurrage charges; ensures seamless delivery |

| Insurance | All-risk coverage at 110% shipment value; 72-hour claims resolution with dedicated liaison | Mitigates financial risk; 100% claim approval rate for transit incidents |

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of transformer materials expertise to deliver defect-free electrical steel shipments. Our packaging system adheres to ISO 1496-1 and ASTM A653 standards, achieving a 99.8% damage-free delivery rate across 50+ countries. By optimizing every logistics step—from moisture-controlled containers to strategic port handling—we reduce total landed costs by 15-20% versus premium brands like Posco. This factory-direct model ensures consistent quality, dimensional accuracy, and surface integrity critical for high-performance transformer cores. Our logistics partners include Maersk, COSCO, and MSC, with each shipment undergoing pre-shipment inspection (PSI) per ISO 2859-1. Engineers validate packaging through vibration analysis and drop tests simulating real-world transit conditions, ensuring reliability from Luoyang to global ports including Rotterdam, Los Angeles, and Singapore. This combination of rigorous engineering and streamlined operations delivers superior cost-performance ratios, making us the preferred alternative to established global suppliers.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

Proven Technical Expertise

With over 20 years of specialized experience in transformer core materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers unparalleled technical proficiency. Our engineers possess deep expertise in silicon steel production, including both grain-oriented (GOES) and non-oriented (NOES) grades. We consistently meet stringent international specifications (IEC 60404-8-5, ASTM A677, JIS C 2552), ensuring optimal magnetic properties and core losses for high-efficiency transformers. Our production facilities feature state-of-the-art rolling mills and annealing lines, enabling precise control over grain structure and magnetic performance. This capability supports rapid customization for unique applications—such as EV motors and ultra-low-loss distribution transformers—reducing design-to-production timelines by 30% compared to traditional suppliers.

Factory-Direct Cost Efficiency

Eliminating middlemen and distributor markups, we provide true factory-direct pricing. Our vertically integrated supply chain—from raw material sourcing to slitting, coating, and coil processing—minimizes overhead while maintaining premium quality. For transformer manufacturers, this translates to 15–25% lower total cost of ownership versus premium global brands like Posco, without sacrificing performance. Strategically located in Luoyang, China, our optimized logistics network ensures reliable delivery to Asian markets within 10–15 days and global shipments within 25 days, with competitive freight rates due to direct port access.

Quality Assurance & Compliance

All products undergo rigorous in-house testing per ISO 9001:2015 standards, including:

Epstein frame measurements (IEC 60404-2) for core loss and magnetic induction

Thickness uniformity checks (±0.001mm precision)

Surface defect inspections via automated optical systems

Every batch is traceable through our ERP system, ensuring consistency across large-scale orders. Certifications include ISO 9001, RoHS, and REACH compliance, with strict adherence to environmental regulations for global markets.

| Feature | Global Brands (e.g., Posco) | Luoyang Xinzhaohe Advantage |

|---|---|---|

| Price | Premium pricing structure | 15–25% lower total cost |

| Lead Time | 4–8 weeks (international) | 2–4 weeks (local production) |

| Quality Consistency | High, but batch variability | Consistent batch-to-batch |

| Technical Support | Standard corporate channels | Dedicated engineering team (24/7 response) |

| Customization | Limited flexibility | Agile R&D for bespoke specs (e.g., tailored thickness, coatings) |

For transformer manufacturers seeking a reliable, cost-effective alternative to global electrical steel suppliers, Luoyang Xinzhaohe delivers superior value through decades of manufacturing excellence and uncompromising quality control. Contact Cathy at cathy@transformerstrip.com today for a competitive quote tailored to your project specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing posco electrical steel replacement from Luoyang Xinzhaohe.