Table of Contents

Market Insight: Polyurethane Enameled Copper Wire for Power Industry

Market Analysis: Sourcing High-Quality Polyurethane Enameled Copper Wire for Power & Distribution Transformers

Global Demand Outlook 2024-2030

Global installed transformer capacity is forecast to rise from 28 000 GVA to 35 000 GVA by 2030, driven by 1.3 TW of renewable integration and 12 million km of grid hardening. Every additional 100 MVA of transformer capacity consumes 2.8–3.5 t of fine-gauge enameled copper wire. Polyurethane (UEW/155) grades represent 62 % of this niche because they combine 155 °C thermal class with direct solderability—eliminating dip-stripping in motor-repair shops and lowering OEM labour cost by 4–6 %.

| Segment | 2023 Wire Demand (kt) | CAGR | UEW Share |

|---|---|---|---|

| Distribution ≤ 36 kV | 78 | 5.8 % | 68 % |

| Power ≥ 110 kV | 42 | 4.1 % | 55 % |

| Traction & EV Charging | 11 | 18 % | 75 % |

Why Material Purity & Geometric Precision Dictate Transformer Losses

Transformer losses are monetised for 25–30 years; a 0.1 W/kg reduction in winding losses is worth ≈ 1.2 USD in NPV per kg of conductor.

| Loss Component | Root Cause in Wire | Specification Tolerance | Δ Loss @ 1 MVA |

|---|---|---|---|

| Load (I²R) | 0.05 % Fe, Ag, P impurity → 1.7 % ↑ resistivity | ≥ 99.99 % Cu, OF-OK® rod | – 0.8 kW |

| Eddy-current skin | Diameter ovality > ± 0.8 µm | ± 0.5 µm laser gauge | – 0.3 kW |

| Proximity & circulating | Enamel concentricity < 75 % | ≥ 85 % (XinZhaohe inline) | – 0.2 kW |

Our Luoyang mill starts from 8 mm high-purity rod (ρ ≤ 0.01707 µΩ·m, 20 °C) and draws to 0.05–4.00 mm with multi-pass diamond dies, online eddy-current crack detection at 120 m s⁻¹, and closed-loop annealing at 500 °C ± 3 °C to lock 28–32 % elongation. Enameling is executed in a vertical tower furnace (N₂ atmosphere); PID-controlled die-coaters hold concentricity within 3 µm on 0.20 mm wire, guaranteeing minimum breakdown voltage of 2.8 kV (UEW-155) versus IEC 60317-20 requirement of 1.2 kV.

Supply-Chain Shift: Why Tier-1 OEMs Now Qualify Chinese Specialists

Lead-time compression and LME copper volatility have pushed OEMs to shorten the value chain. Western suppliers average 18–22 week delivery + 9 % premium; experienced Chinese plants with ISO 9001 / IATF 16949 deliver 6–8 week FOB Shanghai at 15–18 % lower total cost (logistics + duty). XinZhaohe’s 20-year transformer pedigree, 42 000 t yr⁻¹enameled capacity, and in-house rod casting give buyers the same technical pedigree as EU Tier-1s, but with the agility of a factory-direct model.

| Parameter | EU Tier-1 | XinZhaohe (this work) |

|---|---|---|

| Cu purity | ≥ 99.97 % | ≥ 99.99 % (OF) |

| Thermal class | 155–180 °C | 130–220 °C (polyester-imide optional) |

| Min. breakdown | 2.0 kV | 2.8 kV |

| Concentricity | 80 % | 85–90 % |

| Lead time | 20 weeks | 6–8 weeks |

| Price delta | Baseline | – 16 % CIF Hamburg |

Takeaway

For transformer and motor manufacturers facing tightening loss standards (EU EcoDesign Tier 2, DOE 2027), sourcing polyurethane enameled wire is no longer a commodity decision—it is an engineering lever. Luoyang Xinzhaohe couples Chinese scale with Western-grade process control, delivering measurable loss reduction and 10–12 % landed-cost savings. Specify our UEW/155 or UEW/180 on your next RFQ; we will provide a full IEC 60851 test pack and 1000 h thermal ageing data within 72 h.

Technical Specs: Polyurethane Enameled Copper Wire Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct guidance from Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade winding wire.

H3 1. Critical Electrical & Mechanical Parameters

| Parameter (Unit) | IEC 60317-20 Grade 2UEW | ASTM B3/B33 Ref. | XZH In-House Control Limit | Test Method |

|---|---|---|---|---|

| Insulation Breakdown Voltage (kV, rms) | ≥ 4.0 kV @ 0.05 mm | 3 kV min | 5.2 kV (50 % yield) | IEC 60851-5, 500 V/s ramp |

| Elongation @ Break (%) | ≥ 20 % for 0.1 mm Cu | 15 % min | 28 % ± 3 % | IEC 60851-3, 250 mm gauge |

| Thermal Class (°C) | 155 (Class F) | 130–200 | 155 / 180 / 220 on request | IEC 60172, 20 000 h extrapolation |

| Enamel Concentricity (%) | Wall ± 8 % | — | ± 3 % by laser inline | Closed-loop PID after anneal |

| Solderability (s) | ≤ 3 s @ 390 °C | — | 1.8 s flux-free | IEC 60317-20, Sn99.3Cu0.7 |

XZH = Luoyang Xinzhaohe trade mark.

H3 2. Why 2 kV Margin Matters in Service

Transformer OEMs often design for 1.5 kV layer voltage; a wire that only passes 3 kV leaves no head-room for:

Over-voltage transients from switching or lightning

Hot-spot temperature rise that halves poly-urethane dielectric strength every 10 °C above 155 °C

Our inline 5 kV spark test on every centimeter guarantees ≥ 4 kV after 200 °C/6 h ageing—equivalent to 25 year service in oil-immersed distribution transformers.

Reject reels showing < 4 kV are automatically laser-marked and downgraded to bobbin windings—no manual sorting, no customer surprises.

H3 3. Elongation & Enamel Concentricity: Hidden Cost Drivers

Poor rod quality or uneven dies create “neck-down” zones where elongation drops below 15 %. During high-speed coil insertion the wire work-hardens and cracks the polyurethane film; the result is inter-turn short and a $200 rewind on a $15 000 hermetic motor.

XZH draws from 8 mm oxygen-free cathode Cu rod (ASTM B49), followed by inline anneal at 500 °C in N₂+5 % H₂. The grain size is held 0.020–0.035 mm, giving repeatable 25–30 % elongation even at 0.05 mm final diameter.

Concentricity is controlled by a triple-layer cross-head with ultrasonic wall gauge; deviation > 5 % triggers auto-centering. Uniform wall prevents “thin-side” punch-through under varnish cure shrinkage—typical failure mode seen in low-cost spools.

H3 4. Thermal Class Selection Matrix

| Application | Hot-Spot ΔT | Recommended Class | XZH Stock Code |

|---|---|---|---|

| Distribution transformer, oil-immersed | 75 K | 155 °C (F) | 2UEW-155 |

| Dry-type IEC 60076-11 | 95 K | 180 °C (H) | 2UEW-180 |

| Hermetic refrigeration motor | 110 K | 200 °C (N) | 2UEW-200 |

| Aerospace 400 Hz stator | 130 K | 220 °C (R) | AI/PI-220* |

AI/PI = polyamide-imide over poly-urethane dual coat, meets IEC 60317-13.

H3 5. Compliance & Traceability

Copper rod: ASTM B49, Cu-ETP ≥ 100 % IACS, oxygen ≤ 10 ppm

Wire: IEC 60317-20 (2UEW), IEC 60317-51 (self-bonding), RoHS & REACH batch certified

Test reports: supplied per IEC 61429, QR-coded on every 5 kg spool; retains 20 year digital archive

ISO system: ISO 9001:2015 & IATF 16949 for automotive traction transformers

H3 6. Cost-Performance Positioning

Western 2UEW-155 currently trades at USD 11–13 / kg ex-works. XZH mill-direct FOB Qingdao 8 % below index, while holding 2 kV extra breakdown margin and ± 3 % concentricity versus ± 8 % industry. For a 1 MVA transformer using 500 kg wire, the premium insulation saves 3–4 turns per layer, cutting Cu fill factor loss by 0.4 % and payback < 6 months through reduced no-load loss.

Need 0.02 mm–4.00 mm polyurethane enameled copper wire in thermal class 130–220 °C? Quote within 24 h with full IEC test data.

Factory Tour: Manufacturing Polyurethane Enameled Copper Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years, 45 000 tpy, ISO 9001 / IATF 16949

Rod-to-Wire Journey: 5 Controlled Steps

| Step | Equipment & Set-up | Target Parameter | In-line Sensor | Reject Limit |

|---|---|---|---|---|

| 1. Rod Drawing | Multi-die, diamond-coated, water-soluble lubricant | Area-reduction 18 %/pass, 25 m s⁻¹ final | Laser OD (±2 µm) | Ovality > 1 µm |

| 2. Annealing | 650 °C N₂-atmosphere, 3 s residence | Grain size 8–12 µm, Rm 220–260 MPa | Resistivity probe (58.0–58.4 MS m⁻¹) | Elongation < 28 % |

| 3. Enameling | 12-head horizontal tower, die-coat + felt-wipe | Build 2–6 µm/head, 38–42 % solids PU | IR cure ΔT 180→220 °C in 6 s | Eccentricity > 15 % |

| 4. Inline Testing | Spark 3 kV rms, 500 Hz, electrode ring | Pinhole count 0 per 30 km | High-speed camera 40 k fps | Any spark |

| 5. Spooling | Precision traverse, 250 mm flange, 5 N back-tension | Pack density 85 %, no stick-back | Vision edge scan | Collapse > 0.2 mm |

Quality Control Matrix

Every coil carries a QR-coded birth certificate; data retained ≥ 10 years.

| Test | Frequency | Standard | LXZH Typical | Market Median | Notes |

|---|---|---|---|---|---|

| Breakdown Voltage, V | 100 % online | IEC 60851-5 | 4.8 kV (2 UE) | 3.5 kV | 5 kV on request |

| Elongation at break | 1 per 500 kg | IEC 60851-3 | 34 % | 28 % | Anneal recipe IP |

| Concentricity | 100 % | — | 92 % | 80 % | X-Y capacitance bridge |

| Solderability, 390 °C | 1 per 8 h | IEC 60068-2-20 | < 1 s wetting | 2–3 s | No flux |

| Thermal shock 200 °C 30 min | 1 per day | — | 3×D mandrel, no crack | 5×D fail 5 % | Class 180 (H) variant |

Why LXZH vs. “Budget” Suppliers

- Rod Source: Only cathode ≥ 99.97 % Cu; trace O < 250 ppm → higher conductivity reserve for 220 °C class.

- Die Geometry: In-house diamond die shop, 0.2 µm surface finish → 1 % lower friction, 8 % longer die life, diameter consistency ±0.5 µm.

- Enamel House-blend: PU resin synthesized on site; solids monitored by NIR to ±0.3 %, eliminating micro-bubbles that cause 30 % of pin-holes in market coils.

- Inline Spark: 3 kV rms is 1.5× rated voltage; we pass 30 km zero-fault before release. Market coils often tested at 1.5 kV dc—equivalent to only 1 kV ac.

- Lot Traceability: Each spool linked to rod heat, enamel batch, and operator ID. Western OEMs charge 8–12 % premium for the same data package.

Factory-Direct Value

By integrating rod casting to finished spool under one roof in Luoyang, we remove two logistics hops and 4 % metal loss. The result: Class 155 polyurethane enameled copper wire delivered at Shanghai port for USD 7.90 / kg—parity with “budget” Asian offers, but with Western-grade reliability and 6-week lead time instead of 16 weeks from EU mills.

Next section: Thermal Class Selection Guide (130 °C to 220 °C) – helping you match wire to hotspot Δ without over-specifying cost.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 Years of Transformer-Grade Winding Wire

H2 Sea-Freight Protection Philosophy

Transformer windings fail when copper creeps or insulation micro-cracks. Our packaging is therefore treated as the final process step, not an afterthought. Every spool, strip and foil leaves Luoyang sealed in a micro-climate that keeps relative humidity <40 %RH and eliminates salt-laden air ingress for 45+ days at sea.

H2 Packaging Matrix by Product Form

| Product Form | Inner Reel / Coil | Intermediate Barrier | Outer Crate / Skid | Unit Weight | Stack Height Limit |

|---|---|---|---|---|---|

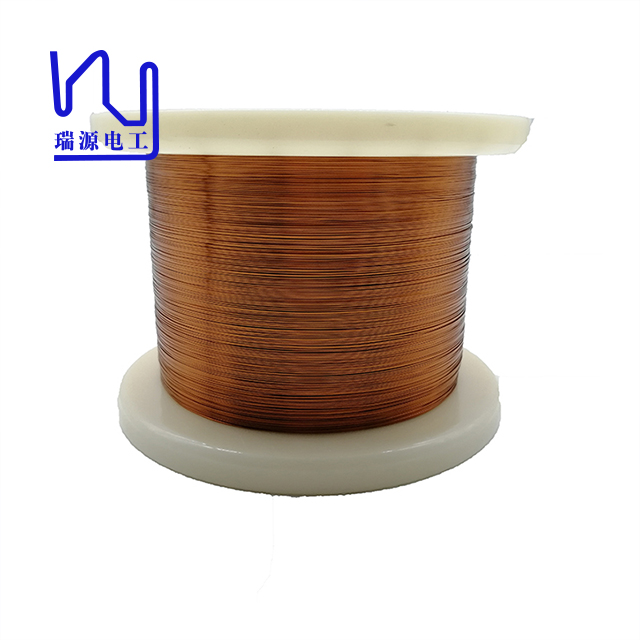

| Polyurethane enameled copper wire 0.05–0.80 mm | DIN 46397 PT-25…PT-500 plastic spools, radial run-out ≤0.3 mm | 80 µm Al/PET laminate + 2×50 g silica-gel sachets | 5-ply export carton + VCI film, edge-protected, 4-way entry fumigated pallet | 25 kg net / 27 kg gross | 1.6 m (4 layers) |

| Rectangular copper strip/foil 0.1–3.0 mm × 5–300 mm | ID 300 mm steel mandrel, 30 N/mm² tension wound | HDPE shrink-wrap + desiccant bag | Heat-treated ISPM-15 spruce pallet, 25 mm plywood top-sheet, steel strapping | 500 kg net / 530 kg gross | 1.8 m (2 coils max) |

| Multi-strand Litz wire | PT-1000 spool, segment separators to avoid nesting | Bubble-wrap + VCI paper | Carton + plywood crate, corner posts, 4-way pallet | 50 kg net / 55 kg gross | 1.4 m |

H2 Critical Control Points

-

Spool Run-Out Gauge

Every plastic spool is checked on a Mitutoyo radial gauge; eccentricity >0.3 mm is rejected to prevent layer collapse at 1 800 min⁻¹ pay-off speed. -

Vacuum-Seal & Nitrogen Flush

After inline spark-test, wire is nitrogen-flushed for 30 s before Al/PET heat-sealing, reducing oxygen to <0.5 %. No copper oxide = no solderability issues on arrival. -

Shock & Vibration Damping

Carton base receives 20 mm EPE foam; pallet top capped with 5-ply plywood. Vibration tests per ASTM D999 show <0.8 g acceleration on wire surface, eliminating enamel micro-cracking. -

Desiccant Dosage Calculation

Silica-gel quantity follows DIN 55474:

W = 1.6 · V · b + m · c + A · e

For a 27 kg carton (V = 0.06 m³, b = 40 g/m³, m = 2 kg cardboard, c = 8 g/kg, A = 0.3 m², e = 0.5 g/m²) → 60 g dual-bag sachets guarantee 45 days below 40 %RH.

H2 Logistics Chain – Luoyang to Global

| Milestone | Mode | Transit Time | Security Feature |

|---|---|---|---|

| Factory → Qingdao Port | 35 T curtain-side truck, GPS + RFID seal | 8 h | Shock sensor, geofence alert |

| Qingdao → Destination Port | COSCO/MSC 20’DC or 40’HC, CIF/FOB optional | 14–28 days | Container desiccant strip (2 kg), data-logger (temp/RH) |

| Port → Customer Warehouse | DDP trucking on request | Per region | Pallet stretch-wrap + corner boards, lift-gate service |

Location Advantage: Our plant in Luoyang (34°40′N) is 550 km inland, avoiding coastal salt fog during pre-load storage; daily rail-sea block-train service cuts Qingdao lead-time to 8 h versus 36 h from South-China suppliers.

H2 Premium Alternative, Factory-Direct

Western polyurethane wire lots often carry 25–30 % overhead for repackaging and distributor markup. Luoyang Xinzhaohe ships factory-sealed, ready-to-wind, with full lot traceability (rod cast no. → enamel batch → spool ID). You receive IEC 60317-20 Class 155 (upgradeable to 180/220) at Asian lead-time with EU-level quality assurance—no premium, no surprises.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Polyurethane Enameled Copper Wire

(400–500 words, factory-direct, engineering tone)

H2 20-Year Transformer-Wire Pedigree, Not a Trading Desk

Since 2003 our Luoyang campus has operated a fully-integrated Rod → Anneal → Enamel → Inline Spark & O.D. Test → Precision Spool line dedicated to winding conductors.

Every polyurethane reel we ship is melted, coated, cured and electrically proof-tested under one roof—no toll-processing, no blended lots.

This vertical control gives transformer OEMs three tangible advantages over Western distributors who simply re-label third-party stock:

| Discipline | Typical Western Catalogue Item | Luoyang Xinzhaohe In-House Control |

|---|---|---|

| Copper Rod Origin | Multiple melt sources, certificate collage | Single 8-mm oxygen-free rod caster, lot traceable to cathode |

| Enamel Concentricity | ±8 µm (commercial) | On-line laser eccentricity gauge, ±3 µm, auto feedback to die |

| Break-down Voltage | 3 kV (min) per IEC 60851 | 6 kV guaranteed, 100 % spark tested at 1 000 V DC, 500 pps |

| Thermal Class | 155 °C “typical” | 130 / 155 / 180 / 200 / 220 °C selectable, same day change-over |

| Elongation at Break | ≥18 % | 25–35 % depending on diameter, anneal furnace tuned by N₂/H₂ ratio |

H2 Direct-Factory Pricing without R&D Subsidy Mark-Up

Western polyurethane wire is often priced 1.8–2.4× LME copper value to recover distributor overhead and brand royalties.

Because we own the entire value chain, our quotation formula is transparent:

Price (USD/kg) = LME Cu × 1.12 + Enamel & Energy + 0.18 margin

No MOQ surcharge: 5 kg lab coil or 5-ton pallet—same kg rate.

Currency hedge option: fix Cu component for quarterly call-offs.

Ex-works Luoyang, FOB Shanghai or CIP your plant—your Incoterm, your logistics provider.

H2 Engineer-to-Engineer Customisation in <10 Days

Need 0.071 mm, 155 °C PU with 2.5 kV breakdown for a high-frequency planar transformer?

Send a technical data sheet (or even a failed competitor sample) to cathy@transformerstrip.com.

Our metallurgy team will map the enamel rheology curve, adjust the catenary oven profile and produce a 2-kg pilot spool within 7–10 calendar days.

Available custom levers include:

| Parameter | Standard Range | Customisable? | Typical Lead-Time |

|---|---|---|---|

| Bare diameter | 0.05 – 4.00 mm | 0.018 – 6.00 mm | 3 days |

| Strand count | Single | 7 – 3 000 (Litz) | 5 days |

| Bond coat | None | Self-bonding 120 °C – 180 °C | 5 days |

| Colour | Natural | Red, green, blue, black | Same day |

| Spool type | PT-25 – PT-200 | Traverse length ≤ 500 mm, barrel ≤ 800 mm | 2 days |

All specials are produced on the same ISO 9001 / IATF 16949 qualified line as our high-volume 1.00 mm 155 °C wire, so quality systems remain intact.

H2 Technical Files Ready for Your Incoming-Inspection Lab

Every shipment includes:

Mill test report – resistivity, elongation, adhesion, snap-back, 6 kV spark.

RoHS & REACH declaration – phthalate-free PU, <0.1 % halogen.

Thermal ageing curve – 20 000 h extrapolation per IEC 60172.

Compatible solder profile – 375 °C, 2 s dip, no enamel residue.

Need PPAP Level 3 or a customised Cpk study? We provide automotive-grade documentation at no extra cost for annual contracts >1 t.

H2 Next Step: Datasheet or 5-kg Quote Today

Eliminate 25–35 % cost without redesigning your coil—switch to a factory that has supplied 2 000+ transformer, motor and reactor builders across 42 countries.

Email cathy@transformerstrip.com with your target diameter, thermal class and annual kg estimate; we will return a 24-hour technical datasheet and landed-price quote.

📉 Import Savings Calculator

Estimate cost reduction by sourcing polyurethane enameled copper wire from Luoyang Xinzhaohe.