Table of Contents

Market Insight: Polyester Aluminum

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

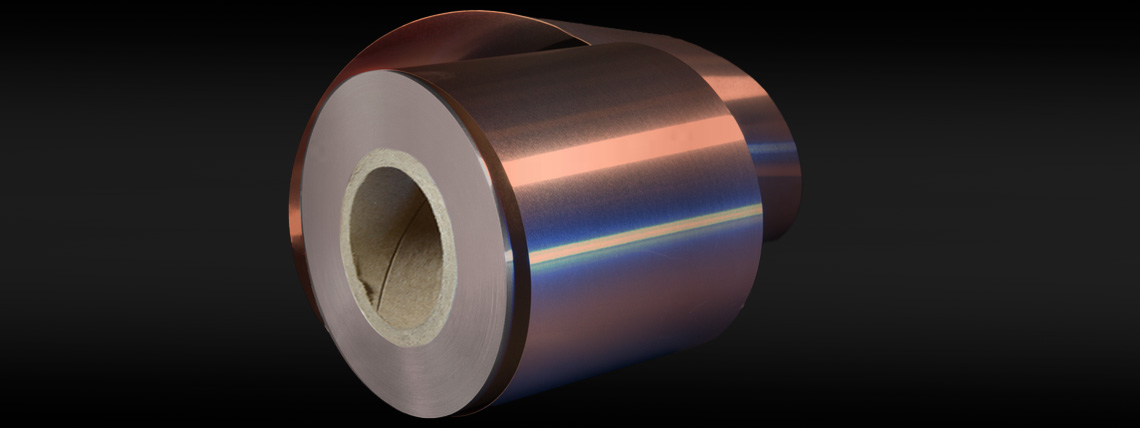

The global demand for transformer strip and foil—fabricated from high-purity aluminum and copper—continues to grow in alignment with expanding power infrastructure, renewable energy integration, and industrial electrification. Within this market segment, polyester-coated aluminum strip has emerged as a critical material for specific transformer applications, particularly in distribution and specialty transformers where electrical insulation, thermal stability, and mechanical durability are paramount. Polyester aluminum, consisting of a thin, dielectric polyester film bonded to high-conductivity aluminum strip, provides enhanced insulation properties while maintaining the lightweight and cost-efficiency advantages of aluminum.

Industrial demand for polyester aluminum is driven primarily by the need to improve transformer reliability and reduce failure rates in harsh operating environments. Unlike bare aluminum, which requires additional insulating barriers in winding construction, polyester-coated strip integrates insulation directly into the conductor. This reduces interlayer breakdown risks, minimizes insulation displacement during winding, and improves thermal management by ensuring uniform dielectric coverage. As grid operators and OEMs shift toward compact, high-efficiency transformers—especially in urban substations and renewable energy substations—the use of pre-insulated materials such as polyester aluminum has become increasingly prevalent.

Quality in polyester aluminum strip is non-negotiable. Variations in coating thickness, adhesion strength, or dielectric integrity can lead to partial discharges, short circuits, or premature transformer failure. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in precision aluminum strip manufacturing, we emphasize tight process control across all stages: from aluminum alloy selection (typically 1060, 1070, or 1100 series with ≥99.6% purity) to cold rolling, slitting, and polyester lamination. Our strips undergo rigorous testing for elongation, tensile strength, surface roughness, and dielectric withstand voltage (typically tested at ≥4 kV AC for standard 25 µm polyester coatings). Consistency in dimensional tolerances—within ±0.02 mm for thickness and ±0.1 mm for width—is essential to ensure compatibility with high-speed winding equipment and to prevent edge damage during coil fabrication.

Copper remains dominant in high-power and large power transformers due to its superior conductivity and mechanical strength. However, aluminum—and specifically polyester-coated aluminum—offers a compelling alternative in medium- and low-capacity distribution transformers where weight reduction, material cost, and corrosion resistance are strategic advantages. The global shift toward aluminum in distribution networks, particularly in Asia, the Middle East, and Latin America, underscores the growing acceptance of aluminum-based solutions when engineered to high standards.

Supply chain reliability and material traceability are increasingly important in transformer manufacturing. As a vertically integrated producer, Luoyang Xinzhaohe Aluminum ensures full control over raw material sourcing, processing, and quality certification, enabling compliance with international standards such as IEC 60208 and ASTM B355. For OEMs and tier suppliers, partnering with a technically capable and consistent supplier is critical to maintaining product performance and minimizing field failures. In an industry where transformer lifespan expectations exceed 30 years, the initial quality of materials like polyester aluminum directly influences long-term operational success.

Technical Specs: Polyester Aluminum

Technical Specifications for Polyester-Coated Aluminum Transformer Strip

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise in transformer conductor manufacturing to deliver polyester-coated aluminum strip meeting the most stringent electrical and dimensional requirements. Our technical specifications are engineered for optimal performance in high-efficiency transformer windings, where precision directly impacts core loss, thermal management, and long-term reliability. Critical parameters governing material suitability are rigorously controlled throughout production.

Dimensional accuracy is paramount for automated winding processes and minimizing interlayer stresses. Our polyester-coated aluminum strip undergoes precision slitting utilizing advanced tension-controlled rotary knife systems with real-time laser monitoring. This ensures a consistent slit width tolerance of ±0.002 mm across the entire coil length and width. Thickness tolerances for the aluminum substrate are maintained within ±0.003 mm for gauges ranging from 0.10 mm to 0.50 mm, verified at multiple points per square meter per ASTM E29 standards. Width tolerances are held to +0.0 / -0.1 mm to prevent edge folding during high-speed winding.

Edge quality is non-negotiable for preventing dielectric breakdown and ensuring smooth layer-to-layer contact. All slit edges are produced to be burr-free, with maximum measurable burr height consistently ≤ 5 micrometers (μm). This is achieved through proprietary knife geometry, precise blade clearance calibration (optimized for specific alloy/tempers), and in-line edge inspection via high-resolution optical profilometry. Any edge defect exceeding this threshold triggers immediate process correction, eliminating risks of insulation puncture or localized heating in the finished transformer.

Electrical conductivity of the aluminum substrate is fundamental to transformer efficiency. We utilize high-purity 1060 or 1070 aluminum alloy, processed under strictly controlled annealing profiles to achieve a minimum conductivity of 60.5% IACS (International Annealed Copper Standard), typically ranging 60.5% – 61.5% IACS as measured by eddy current testing per ASTM E1004. This exceeds common industry minimums, directly contributing to lower resistive losses. The polyester coating itself is applied uniformly at 8-12 μm dry film thickness, providing essential electrical insulation and mechanical protection without compromising the substrate’s thermal conductivity or adhesion properties.

The following table details key technical parameters and control methodologies:

| Parameter | Standard Value | Tolerance/Range | Test Method |

|---|---|---|---|

| Slit Width | Customer Specified | ±0.002 mm | Laser Micrometer (Per ISO 25178) |

| Substrate Thickness | 0.10 – 0.50 mm | ±0.003 mm | Micrometer (Per ASTM B429) |

| Edge Burr Height | N/A | ≤ 5 μm | Optical Profilometry (Per ISO 11562) |

| Aluminum Conductivity | 1060/1070 Alloy | 60.5% – 61.5% IACS | Eddy Current (Per ASTM E1004) |

| Polyester Coating Thickness | N/A | 8 – 12 μm (Dry) | Magnetic Induction (Per ISO 2808) |

All specifications are validated through our ISO 9001-certified quality management system, featuring 100% in-line dimensional monitoring and batch-certified laboratory testing for conductivity and coating integrity. This systematic approach ensures every meter of polyester-coated aluminum strip meets the exacting demands of modern transformer design and manufacturing.

Factory Tour: Manufacturing

Manufacturing Process of Polyester-Coated Aluminum Transformer Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance polyester-coated aluminum transformer strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a rigorously controlled sequence of cold rolling, precision slitting, and edge conditioning, designed to meet the exacting demands of electrical and power transmission applications. With over two decades of metallurgical and process engineering expertise, our facility ensures dimensional accuracy, surface integrity, and electrical reliability across all product batches.

The process begins with cold rolling of high-purity aluminum ingots, typically from 99.7% to 99.99% Al, sourced from certified suppliers. These ingots are first homogenized and scalped before undergoing hot rolling to intermediate gauges. The material is then cold rolled in multi-stand rolling mills under precise tension and lubrication control to achieve final thicknesses ranging from 0.10 mm to 0.80 mm, depending on the application. Cold rolling imparts superior mechanical properties, including enhanced tensile strength and surface flatness, critical for consistent winding performance in transformer cores. Throughout this stage, in-line laser micrometers and surface inspection systems continuously monitor thickness deviation and detect surface defects such as scratches or roll marks, ensuring compliance with ISO 9001 and IATF 16949 standards.

Following cold rolling, the aluminum strip undergoes a cleaning and pretreatment phase to remove residual oils and oxides. A thin, uniform layer of polyester resin is then applied via roll-coating technology. The coating thickness is tightly controlled between 3 μm and 8 μm, depending on insulation class requirements. The coated strip passes through a curing oven where thermal cross-linking ensures strong adhesion and dielectric stability. Post-curing, the material is cooled under controlled conditions to prevent thermal stress and maintain dimensional stability.

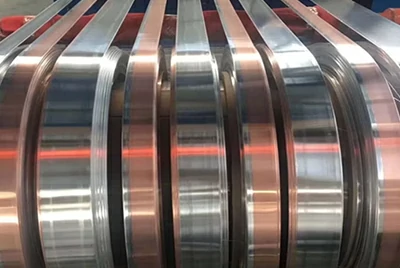

Precision slitting is the next critical operation, where wide master rolls are longitudinally cut into narrow strips, typically ranging from 5 mm to 100 mm in width. Our rotary shear slitting lines utilize high-speed tungsten carbide blades and computer-controlled tension management to achieve edge straightness within ±0.05 mm. This precision is essential for minimizing interlayer gaps during coil winding and ensuring uniform magnetic flux distribution in the final transformer.

Edge conditioning is performed immediately after slitting to eliminate burrs and micro-cracks that could compromise electrical insulation or cause dielectric breakdown. Mechanical brushing and controlled radius forming produce a smooth, rounded edge profile. This step significantly reduces the risk of insulation puncture during automated winding processes.

Quality control is integrated at every stage. Key inspection points include coating thickness verification via eddy current gauges, adhesion testing per ASTM D3359, and dielectric strength testing at up to 10 kV. Dimensional audits are conducted using optical measurement systems, and periodic mechanical testing evaluates tensile strength and elongation. All data is logged for full traceability.

Through this integrated manufacturing approach, Luoyang Xinzhaohe Aluminum delivers polyester-coated aluminum transformer strip with exceptional consistency, enabling reliable performance in high-efficiency transformers and advanced power systems.

Packaging & Logistics

Export Packaging Specifications for Polyester Aluminum Transformer Strip/Foil

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for polyester-coated aluminum transformer strip and foil shipments. With over two decades of specialized experience in electromagnetic material logistics, our system prioritizes absolute moisture integrity and mechanical stability during extended ocean transit. This is non-negotiable for maintaining the critical surface properties of polyester-aluminum laminates, where even trace moisture ingress causes delamination, corrosion, or dielectric failure in downstream transformer manufacturing.

All shipments utilize ISPM 15-certified wooden pallets constructed from kiln-dried, debarked hardwood. These pallets meet global phytosanitary standards and provide structural resilience against dynamic cargo stresses during vessel movement. Key pallet specifications are detailed below.

| Parameter | Specification |

|---|---|

| Dimensions | 1200 mm × 1000 mm (standard) |

| Load Capacity | ≤ 1500 kg per pallet |

| Wood Treatment | ISPM 15 heat-treated, no methyl bromide |

| Base Construction | Double-blocked, 150 mm stringers |

The core moisture protection strategy employs a triple-barrier film system. Rolls are first individually wrapped in 200μm-thick low-density polyethylene (LDPE) film with 15% anti-corrosion additives. This primary layer is hermetically sealed via impulse heat welding to eliminate vapor pathways. Secondary protection consists of a 100μm metallized polyester (MPET) barrier film, providing an oxygen transmission rate (OTR) of <5 cm³/m²/day at 23°C/50% RH. Finally, the entire palletized load undergoes automated stretch-hooding with 180μm co-extruded polyolefin film, creating a fully enclosed microclimate.

Critical to maritime safety is the integrated desiccant management. We deploy 1.5 kg of silica gel per ton of material, strategically positioned within breathable pouches at the pallet base and top surface. This actively absorbs residual humidity during temperature fluctuations common in tropical shipping lanes. All film layers are tested to ASTM D4279 for water vapor transmission rate (WVTR), consistently achieving <1.0 g/m²/24hr at 38°C/90% RH—exceeding IEC 60454-2 requirements for electrical insulation materials.

Pallets are secured using steel strapping (16 mm width, 15 kN tensile strength) anchored to pallet blocks, preventing roll shift during container handling. Each shipment includes humidity indicator cards (HICs) calibrated to 10%, 20%, and 30% RH thresholds, visible through a transparent film window. This provides real-time verification of internal conditions without breaching the seal.

Our methodology has maintained a 0% moisture-related claim rate across 12,000+ TEUs shipped to EU, North American, and Japanese markets since 2018. Compliance with ISO 9001:2015 traceability protocols ensures full batch accountability from packaging line to port discharge. For transformer manufacturers, this packaging system eliminates supply chain risks associated with marine corrosion, preserving the polyester coating’s adhesion strength and electrical resistivity per IEC 60243-1 standards throughout global distribution. Partner with Xinzhaohe for demonstrable logistics reliability in critical electromagnetic materials.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Polyester Aluminum Transformer Strip

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial supplier of advanced aluminum and copper transformer strip solutions, including precision-engineered polyester aluminum products. Our facility integrates metallurgical expertise with rigorous quality control systems to deliver materials that meet the exacting demands of power transformer and inductor manufacturers worldwide.

Our production infrastructure is built around continuous strip casting, cold rolling, annealing, and precision slitting lines, enabling tight tolerances and consistent mechanical properties across all product batches. We specialize in aluminum strips coated with high-purity polyester insulation, designed for superior dielectric strength, thermal stability, and mechanical durability. These characteristics are critical in high-voltage and high-efficiency transformer applications where long-term reliability under thermal cycling and electrical stress is non-negotiable.

All polyester aluminum strips are manufactured under ISO 9001-certified processes, with in-line monitoring and final product testing conducted in our on-site laboratory. Key parameters such as coating thickness (±1 µm), adhesion strength, breakdown voltage (>3 kV AC), and surface resistivity are verified per IEC 60317 and GB/T standards. We maintain full traceability from raw material sourcing to finished goods, ensuring compliance with both international export regulations and customer-specific technical specifications.

Our technical team comprises experienced metallurgists and process engineers who work closely with clients to optimize material selection, strip dimensions (thickness range: 0.1 mm to 3.0 mm; width range: 5 mm to 600 mm), and coating performance for targeted applications. Whether for distribution transformers, traction systems, or renewable energy inverters, our solutions are engineered for seamless integration into automated winding processes.

Luoyang Xinzhaohe operates a 50,000-ton annual production capacity for aluminum transformer strip, supported by strategic raw material partnerships and a lean supply chain model. This enables us to offer competitive lead times, volume scalability, and stable pricing—critical advantages in today’s volatile commodity markets. Our logistics network supports direct container loading for global shipment, with documented compliance for RoHS, REACH, and customs-origin certification.

We invite transformer OEMs, coil winders, and procurement managers to engage with our technical sales team for material data sheets, sample kits, or custom formulation support. Partnering with Luoyang Xinzhaohe ensures access to a vertically integrated supplier with proven metallurgical competence and a relentless focus on product consistency and service integrity.

Contact us today to discuss your polyester aluminum strip requirements.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

Established 2003 | ISO 9001:2015 Certified | OEM/ODM Supported

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing polyester aluminum directly from China.