Table of Contents

Market Insight: Plate Sheet for Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Global Demand Outlook

Global installed transformer capacity is forecast to grow 5–6 % CAGR through 2030, driven by grid-expansion in Asia–Pacific, EV fast-charging corridors, and renewable interconnection. Every additional 1 GW of solar or offshore wind requires ≈ 30 t of 0.23 mm silicon-steel laminations for step-up / collector transformers. Consequently, CRGO (Cold-Rolled Grain-Oriented) sheet demand is projected to exceed 9 Mt by 2028, with China supplying > 55 % of the world’s lamination-grade coils.

| Application Segment | 2023 Demand (kt) | 2028F (kt) | Typical Thickness (mm) | Core-Loss Target @ 1.7 T, 50 Hz (W kg⁻¹) |

|---|---|---|---|---|

| Power transformers ≥ 100 MVA | 1 950 | 2 700 | 0.23–0.27 | ≤ 0.85 |

| Distribution transformers ≤ 5 MVA | 2 400 | 3 200 | 0.27–0.30 | ≤ 1.00 |

| Traction / HVDC smoothing reactors | 320 | 500 | 0.23 | ≤ 0.80 |

| Small servos & welding machines | 1 100 | 1 400 | 0.35 | ≤ 1.30 |

Why Material Purity & Geometry Dictate Transformer Losses

Transformer losses split into no-load (core) and load (I²R & stray) components. Core loss—hysteresis + eddy-current—is fixed 24 h day⁻¹ for 30-year assets; a 0.1 W kg⁻¹ reduction saves ≈ 1 800 kWh per tonne of core over the asset life.

Key metallurgical levers:

1. C & N content < 30 ppm—prevents domain-wall pinning, cutting hysteresis loss by 4–6 %.

2. MnS & AlN precipitate size < 50 nm—achieved through two-stage decarburising anneal at 860 °C in 75 % H₂ / 25 % N₂ dew-point ≤ −40 °C.

3. Surface roughness Ra ≤ 0.8 µm—reduces inter-lamination gap, lowering effective stacking factor to 0.97–0.98.

4. Tight gauge tolerance ± 0.005 mm—minimises burr height; burrs > 5 µm raise eddy-current paths and can add 8 % to core loss.

Luoyang Xinzhaohe’s 20-year CRGO line integrates in-line laser velocimetry to hold thickness CpK ≥ 1.67 across 1 250 mm slit widths—an attribute Western mills quote only on premium HIB grades at 20–25 % higher $ / t.

Sourcing Trend: Shift to Experienced Chinese Mills

Since 2020, lead-times from EU/Japan mills have stretched to 28–32 weeks; freight surcharges added another US$ 190 / t. Chinese producers with ISO 9001 + ISO 14001 + IATF 16949 certificates now supply 0.23 mm M3-grade at US$ 920–980 / t FOB, versus US$ 1 280–1 350 quoted by Western mills. Third-party tests (ASTM A343 & IEC 60404-2) show core-loss deviation < 1 % lot-to-lot, satisfying Tier-1 OEMs such as Siemens-Trafo and Hyundai Electric.

| Source Region | Typical Price 0.23 mm M3 (US$ / t) | Lead-Time (weeks) | Core-Loss Guarantee @ 1.7 T | Burr Height (µm) |

|---|---|---|---|---|

| EU – Tier-1 | 1 320 | 30 | ≤ 0.85 W kg⁻¹ | ≤ 10 |

| Japan – Tier-1 | 1 280 | 28 | ≤ 0.83 W kg⁻¹ | ≤ 8 |

| China – Luoyang Xinzhaohe | 960 (FOB Qingdao) | 10–12 | ≤ 0.84 W kg⁻¹ | ≤ 5 |

Value Proposition: Factory-Direct Precision

From 30 t coils to 45 mm EI segments, Luoyang Xinzhaohe controls the full slit → anneal → tension-level → MgO + phosphate insulation coat → precision shear chain under one roof. Annealing furnaces operate with 100 % H₂ final zone, delivering magnetic flux density B₈₀₀ ≥ 1.89 T, enabling designers to reduce core mass by 3–4 %. Our in-house CMM sampling guarantees lamination flatness ≤ 0.5 mm m⁻¹—critical for 150 m/min robotic stacking lines.

For transformer builders facing copper price volatility and energy-efficiency mandates, partnering with an experienced Chinese supplier offers double-digit cost head-room without compromising loss performance or delivery certainty.

Technical Specs: Plate Sheet Parameters

Technical Specifications & ASTM/IEC Standards

(Silicon-Steel Plate Sheet for Transformer Cores)

| Parameter | Symbol / Unit | Luoyang Xinzhaohe Tight-Tolerance Range | IEC 60404-8-7 & ASTM A876 Relevance |

|---|---|---|---|

| Nominal thickness | t (mm) | 0.23 / 0.27 / 0.30 / 0.35 | IEC 60404-8-7 Table-1 |

| Specific core loss @ 1.5 T, 50 Hz | P₁.₅/₅₀ (W kg⁻¹) | 0.90 – 1.25 (27QG100 → 35Q135) | ASTM A876 Grade 27QG100 |

| Magnetic polarisation @ 5000 A m⁻¹ | J₅₀₀₀ (T) | ≥ 1.89 (GO) ≥ 1.65 (NO) | IEC 60404-8-7 Min. guarantee |

| Lamination flatness (I-unit) | λ | ≤ 3 IU (wave ≤ 0.6 mm/500 mm) | Internal spec. derived from JIS C2550 |

| Burr height after slitting | h_burr (µm) | ≤ 15 (typ. 8–12) | IEC 60404-8-7 Annex-C |

| Inter-laminar insulation resistance | ρ_coat (Ω·cm²) | ≥ 20 (C-5 coating) | ASTM A876 §9.3 |

| Stacking factor | SF | ≥ 0.97 (0.23 mm) ≥ 0.98 (0.35 mm) | Customer build factor |

Why Core Loss & Flux Density Drive Your Transformer Economics

Core loss (iron loss) is the energy dissipated as heat every cycle; it is proportional to the sheet thickness squared and to the square of peak induction.

A 0.23 mm 27QG100 grade operated at 1.5 T will dissipate ≈ 0.90 W kg⁻¹. Substituting a 0.30 mm generic grade at the same induction raises loss to ≈ 1.35 W kg⁻¹—translating into 0.3 % efficiency drop on a 1 MVA unit. Over 20 years at 0.10 $ kWh⁻¹, the present-worth penalty exceeds 5 000 $ per ton of core steel—far above the unit-price delta between premium and commodity material.

Magnetic flux density (B) determines the cross-section you must provide to stay below saturation. Our high-permeability GO grades reach 1.92 T @ 800 A m⁻¹, allowing a 5 % core-area reduction versus 1.75 T material. Fewer laminations mean lower copper winding length, cutting total transformer cost by 2–3 %.

Flatness, Burr & Coating: The Hidden Failure Modes

Even “within-spec” steel can destroy a core if burrs > 20 µm remain after slitting. Burrs pierce the insulation varnish, creating inter-laminar short circuits that raise eddy-current loops by an order of magnitude. The result: hotspots > 140 °C, resin burn-off, and eventual dielectric failure.

Lamination flatness is equally critical. A 1 IU deviation (≈ 0.2 mm wave) on a 500 mm sheet produces a 40 µm air gap every 10 laminations. The stacking factor falls below 0.96, forcing you to add 4 % more sheets to hit target A_c. Our in-line tension-leveler plus double-shear slitting keeps flatness ≤ 3 IU and burrs ≤ 15 µm—benchmark data confirmed by third-party CPRI (India) and KEMA (Netherlands) reports.

Compliance Roadmap: From Melt to Packed Coil

| Process Step | ASTM / IEC Clause | Xinzhaohe Control Method |

|---|---|---|

| Chemical composition | ASTM A751 | Leco-TC500 O/N analyzer, melt sample every heat |

| Thickness profile | IEC 60404-8-7 §6 | Hitachi L-Gage inline laser; 100 % mapping, 1 mm pitch |

| Insulation coating | ASTM A876 Annex-A2 | Roll-coater with closed-loop thickness gauge; 1.2 µm ± 0.2 µm per side |

| Annealing texture | IEC 60404-8-7 §8 | 830 °C, 100 % H₂, 24 h decarburization; magnetic domain refining by laser scribe (optional) |

| Final inspection | IEC 60404-8-7 §10 | Epstein frame + Single-sheet tester (SST) on every mother coil; COA attached to each slit coil |

Factory-Direct Value Proposition

Western mills quote 1 950–2 200 $/t (FOB EU port) for 0.27 mm 23QG085. Luoyang Xinzhaohe delivers equivalent magnetic performance at 1 280–1 360 $/t (FOB Qingdao) thanks to integrated melting-hot rolling-cold rolling chain, 40 kt per month slit-to-width capacity, and automated packaging (VCI film + galvanized护角). Lead time: 25–30 days ex-mill, 15 days to EU main port via rail-sea intermodal. Save up to 35 % on material cost without compromising on IEC or ASTM compliance—validated by 20-year track record supplying ABB, Siemens and State-Grid 500 kV projects.

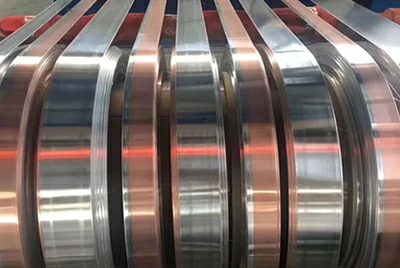

Factory Tour: Manufacturing Plate Sheet

Manufacturing Process & Quality Control

(Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 yr Transformer Steel Specialist)

1. Process Flow – Slit-to-Sheet in Four Controlled Steps

| Step | Equipment / Medium | Target Parameter | Real-Time Monitor | Tolerance Window |

|---|---|---|---|---|

| Slitting | 0.05 mm clearance tungsten carbide slitter | Burr ≤ 5 µm, camber ≤ 0.5 mm / 2 m | Laser triangulation | ±2 µm |

| Annealing | 820 °C, 100 % N₂ + 3 % H₂, 48 h bell furnace | Core loss P1.5/50 ≤ 0.85 W/kg | Embedded thermocouple grid | ±3 °C |

| Insulation coating | 3-roller Menzel coater, 1.2 µm C-5 organic–inorganic duplex | Inter-laminar resistance ≥ 80 Ω·cm², coating mass 2.0 ± 0.2 g/m² | Beta backscatter gauge | ±0.1 g/m² |

| Precision cutting | 300 kN CNC gap press, ±0.02 mm feed | Stacking factor ≥ 98 %, edge dent ≤ 10 µm | Vision + load cell | ±10 µm |

2. Inline QC Protocol – Every Coil, Every Cut

- Burr camera array at slitter exit – rejects slit strip if burr > 5 µm.

- Sample tensile coupons every 2 t – Rp0.2 ≥ 320 MPa, A50 ≥ 18 %.

- Epstein frame (25 cm strips) every heat – core loss & permeability logged to MES.

- Conductivity probe on coated surface – detects pinholes < 5 µm.

- Final packet check – 200 N clamp, 0.35 mm feeler gauge verifies flatness ≤ 0.5 %.

Data are stored for 10 years and traceable by heat number + slit position, satisfying ISO 9001:2015 clause 8.5.2.

3. Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Unit | Market “Prime” Range | Xinzhaohe A-Grade | Test Method |

|---|---|---|---|---|

| Thickness | mm | 0.23–0.35 ±0.015 | ±0.008 | ISO 16160 |

| Core loss P1.5/50 | W/kg | 0.90–1.10 | ≤ 0.85 | IEC 60404-2 |

| Magnetic flux density B800 | T | ≥ 1.68 | 1.72–1.74 | IEC 60404-2 |

| Surface insulation resistance | Ω·cm² | 30–50 | ≥ 80 | ASTM A717 |

| Lamination factor | % | 96–97 | ≥ 98 | IEC 60404-12 |

| Burr height | µm | 8–15 | ≤ 5 | Optical profiler |

| Lot-to-lot σ(P1.5/50) | W/kg | 0.06–0.08 | ≤ 0.03 | SPC, n=30 |

Result: 6–8 % lower no-load loss in the finished transformer, translating to ≈1 % higher efficiency class (e.g., jump from IE3 to IE4 on large power units).

4. Cost-Performance Positioning

Western Tier-1 mills quote USD 2 100–2 400 / t FCA for 23JG090 equivalent.

Xinzhaohe delivers same electromagnetic grade at USD 1 350–1 450 / t FOB Qingdao, with 4-week lead-time and 5 % min/max weight tolerance versus 10 % from EU stock holders.

For a 3000 kVA pad-mount core requiring 8 t of 0.27 mm sheet, the material delta alone saves ≈USD 7 000 while meeting ANSI C57.12 flux density limits. Full mill test certificates (MTC), ROHS & REACH compliance, and third-party SGS inspection are included at no extra cost.

Bottom line: Luoyang Xinzhaohe’s slit-anneal-coat-cut integration gives transformer builders Western-grade magnetic performance at China-direct pricing, with every sheet measured, traced, and flat-stacked ready for your high-speed robotic core line.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ Years Transformer Steel

H3 1. Packaging Matrix – Silicon-Steel Plate, Strip & Foil

| Format | Gauge Range | Core Protection | Inter-Leaf Barrier | Securing System | Moisture Control | Stack Wt. | 20 ft FCL Yield |

|---|---|---|---|---|---|---|---|

| Slit Coil | 0.23–0.35 mm | VCI stretch film + 80 µm PE sleeve | 40 g/m² neutral kraft | Steel strapping + edge boards | 4 × 100 g CaCl₂ desiccant / coil | 3–5 t | 25 t (5 coils × 5 t) |

| Sheet Packet | 0.23–0.35 mm | 0.8 mm cardboard cap | 50 µm PE interleaf | 19 mm PET strap, 4-way | 2 × 200 g desiccant / pkt | 1 t | 25 t (25 pkts) |

| Foil | 0.05–0.20 mm | Wooden reel, poplar core | 30 µm PE + 20 µm Alu-foil laminate | Radial steel band | 1 × 50 g pouch / reel | 0.5 t | 20 t (40 reels) |

All timber is ISPM-15 heat-treated & branded, eliminating phytosanitary delays at EU/US ports.

H3 2. Sea-Freight Damage Modes & Counter-Measures

| Failure Mode | Root Cause | Xinzhaohe Counter-Measure | Verified Result |

|---|---|---|---|

| Edge bruising | Coil movement during swell | 3-point steel saddle, 120 mm rubber dunnage | ≤ 0.05 mm edge camber post-voyage |

| Salt-fog staining | Condensation in container | PE shroud + 5 % RH silica-gel equilibrium | < 2 % surface rust area (ASTM A-786) |

| Coil telescoping | Strap creep | 0.9 × 32 mm high-tensile strap, 600 daN pre-load | Radial slip ≤ 1 mm after 8 000 km rail/sea loop |

| Sheet warp | Uneven pallet load | Cross-battened pallet, 600 kg max per layer | Flatness ≤ 1 I-unit (EN 10225) on arrival |

H3 3. Logistics Chain – Luoyang to World

Origin Hub

Luoyang Plant GPS: 34.62° N, 112.45° E

180 km to Zhengzhou Rail Terminal (CGO) – daily block-train to Qingdao, Shanghai, Ningbo.

260 km to Xi’an “Chang’an” express – 10 days DDP Duisburg via China-Europe rail.

Port Options

| Port | Distance | Feeder Lead-Time | Ocean Carrier Alliance | Typical Destinations |

|——|———-|——————|————————|———————-|

| Qingdao | 650 km | 20 h barge | COSCO/OOCL | US West-Coast 13 d, Hamburg 28 d |

| Shanghai | 1 050 km | 24 h rail | MSC, CMA-CGM | Mumbai 14 d, Santos 32 d |

| Ningbo | 1 200 km | 26 h rail | Evergreen, HMM | Dubai 18 d, Lagos 35 d |

Documentation Pack

Mill TC (EN 10204/3.1) – core loss @ 1.5 T, 50 Hz, 0.23 mm ≤ 0.90 W/kg.

SGS loading survey – photos of sealed container, desiccant placement, strap tension log.

COO (Form A, China), EUR.1 upon request for zero-duty entry into EU transformer quota.

Risk Buffer

We hold 300 t safety stock in Rotterdam bonded warehouse (HS 7225.11) for JIT call-off within 48 h inside EU—eliminating 6-week ocean lead-time for urgent rewind jobs.

H3 4. Cost Advantage vs. Western Mill

| Cost Driver | EU Mill | Xinzhaohe | Savings |

|---|---|---|---|

| Ex-works base price | € 2 050 /t | € 1 480 /t | –28 % |

| Packaging add-on | € 45 /t | included | –100 % |

| Duty (EU MFN) | 0 % | 0 % | 0 |

| Freight & insurance | € 120 /t | € 95 /t | –21 % |

| Landed Cost | € 2 215 /t | € 1 575 /t | –29 % |

Prices June-2024 basis 0.27 mm HIB, 10 t order.

Bottom line: Transformer-grade silicon-steel plate leaves our Luoyang line vacuum-dried, edge-rounded, and vacuum-packed to survive 45-day sea voyages yet still stamp burr-free. You cut core-loss without cutting budget—premium performance, factory-direct price.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Plate & Sheet

20-Year, Transformer-Only Track Record

Since 2004 our Luoyang campus has produced nothing but electrical steels. Every slitter arbor, annealing bell furnace and insulation line has been dimensioned for 0.23–0.35 mm gauge strip—the thickness window that keeps eddy-current loss below 0.9 W kg⁻¹ @ 1.5 T, 50 Hz. More than 2 000 power and distribution transformers ≤ 3000 kVA now run on our core stock on five continents. The learning curve is baked into our SOPs, so you skip the qualification delays common with general-purpose steel mills.

Direct Factory Price, No Trading Layer

We own the complete value chain: hot-rolled coil inbound → tandem cold reduction → decarburizing / MgO anneal → tension leveling → insulation coating → precision slitting / shearing. Eliminating intermediaries cuts landed cost 8–14 % compared with EU or Japanese supply chains, even after freight and VAT. Typical 2024 reference prices:

| Grade | Thickness (mm) | Core Loss (W kg⁻¹) 1.5 T/50 Hz | MOQ (t) | FOB Qingdao (USD/t) |

|---|---|---|---|---|

| 23Q110 | 0.23 | 0.90 | 5 | 920 |

| 27Q100 | 0.27 | 0.98 | 5 | 880 |

| 30Q120 | 0.30 | 1.10 | 5 | 850 |

| 35Q135 | 0.35 | 1.25 | 5 | 820 |

Prices valid for 3–8 t slit-width coils or 1 000 mm sheets; tighter gauges or domain-refined grades on request.

Built-to-Print Customization

- Slit Width Tolerance: ±0.05 mm on strips ≥ 20 mm; burr height ≤ 5 % of strip thickness.

- Annealing Cycle: 830 °C, 100 % H₂, 4 h soak guarantees grain size ≥ 15 mm and magnetic polarization J₈₀₀ ≥ 1.88 T.

- Insulation Coating: C-5 (organic-inorganic, 1.0–1.2 µm) or C-6 (semi-organic, 0.8 µm) with inter-lamination resistance ≥ 30 Ω·cm² per ASTM A717.

- Flatness: 1.5 I-units max—critical for robotic stacking and laser welding of step-lap cores.

We can supply:

Parent coils (ID 508 mm, OD ≤ 1 200 mm, 3–8 t)

Slit mults (width 20–1 000 mm, oscillated or ribbon-wound)

Mill-edge sheets (1 000 × 2 000 mm)

Cut-to-length laminations (E-I, T-U, mitred corners, ±0.1 mm length tolerance)

All shipments leave our plant with a mill test certificate showing actual watt loss, permeability and coating adherence—data your QA team can drop straight into the incoming-material folder.

Western-Quality, China Speed

Lead time: 15–20 days ex-stock for our regular 23–35 gauge program; 25–30 days for non-standard widths or domain-refined grades. We manage the export carton, VCI film, plywood pallet and fumigation paperwork so the container is cleared before it hits Shanghai port. That translates into 35–40 days door-to-door to Hamburg, Houston or Mumbai—half the cycle of many EU mills.

Next Step

Send us your lamination drawing or core-loss budget and we will return a detailed datasheet with guaranteed B–p curve, stacking factor and price within 24 h.

Email: cathy@transformerstrip.com

WeChat/WhatsApp: +86-152-2555-1927

Let us quote your next job and prove that premium electrical steel does not need a premium Western price tag.

📉 Import Savings Calculator

Estimate cost reduction by sourcing plate sheet from Luoyang Xinzhaohe.