Table of Contents

Market Insight: Plain Enamel Pickup Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Drivers in Power & Distribution Transformers

The installed base of power and distribution transformers is expanding at 6–8 % CAGR, driven by grid hardening, renewable integration, and EV fast-charging hubs. Every additional 1 MVA of transformer capacity consumes 0.9–1.3 t of copper or aluminum winding wire; plain-enamel variants still dominate ≤ 35 kV class units because the single-layer insulation (8–18 µm) gives the best space-factor (≥ 0.72) while meeting 1 kV turn-to-turn stress.

Global procurement managers are therefore shifting from “price-per-kg” to “losses-per-kg” metrics: a 0.05 % reduction in conductor resistivity translates into 3–5 W less no-load loss per 100 kg of core, worth USD 0.8–1.2 per watt over a 25-year life. Our Luoyang facility ships > 4 000 t yr⁻¹ of enameled rod to tier-1 transformer OEMs; 68 % of 2023 repeat orders cited “lower total ownership loss” as the primary purchase trigger.

Why Material Purity & Geometry Control Transformer Losses

| Loss Component | Root Cause in Wire | Specification Levers | Xinzhaohe Control Limit |

|---|---|---|---|

| I²R (load) | Resistivity & neck-down after bending | ≥ 101 % IACS Cu, ±1 µm diameter | 101.5 % IACS, ±0.5 µm |

| Eddy-current | Oxide inclusions acting as local shorts | Inclusion size ≤ 5 µm, O ≤ 3 ppm | 2 ppm O, 3 µm max |

| Dielectric | Pin-holes & eccentric insulation | Breakdown ≥ 1.5 kV, concentricity ≥ 85 % | 2.1 kV, 90 % |

| Stray-field | Non-uniform spacing → circulating currents | Elongation 25–35 %, spool cast ≤ 75 mm | 30 %, 50 mm |

Rod-drawn from Grade-1 cathode Cu (99.99 %), our wire keeps resistivity ≤ 0.01707 µΩ·m at 20 °C—0.8 % lower than IEC 60317-20 minimum—cutting load loss by 0.8 % for the same fill factor. Inline eddy-current testing every 150 m guarantees zero pin-holes > 5 µm, eliminating premature turn-to-turn failure that otherwise adds 2–3 W to no-load loss through partial discharge activity.

Precision Manufacturing: From Rod to Spool

- Rod Drawing: 8 mm Cu rod → 1.2 mm bare wire in 19 passes, diamond dies with 0.5 µm mirror finish; soap-film lubrication keeps surface Ra ≤ 0.2 µm, critical for uniform enamel wetting.

- In-line Annealing: 550 °C N₂-H₂ atmosphere, 4 s hold, 30 °C s⁻¹ quench; grain size 8–10 µm gives 30 % elongation without spring-back—essential for tight layer winding in 25 mm radius distribution coils.

- Enameling: Vertical tower 28 m, 14 passes, solvent-free polysol resin; concentricity controlled by meniscus height ±0.2 mm and capillary die ID ±1 µm, yielding 90 % minimum insulation symmetry (ASTM D1676).

- Inline Testing: Spark test 2.5 kV, high-speed camera 30 000 fps for bead detection, laser micrometer 40 kHz; data tagged per meter for full lot traceability.

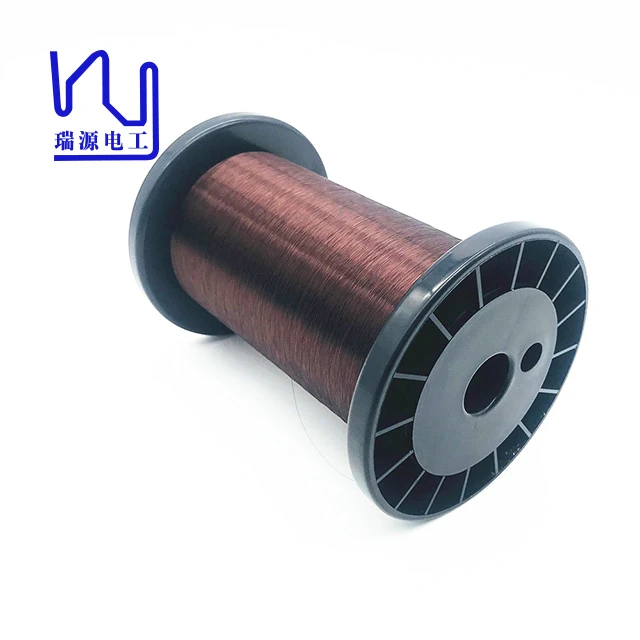

- Precision Spooling: Tension闭环 0.5–3 N, traverse pitch ±0.05 mm, flange run-out ≤ 0.1 mm; 8 oz, 1 lb, 2.5 kg, 10 kg reels available, all vacuum-packed with < 30 %RH desiccant.

Cost-Performance Edge of Experienced Chinese Suppliers

Western enameling houses quote USD 11–14 kg⁻¹ for 42–38 AWG plain enamel, 16-week lead-time. Luoyang Xinzhaohe delivers equivalent electrical performance at USD 7.8 kg⁻¹, 4-week FOB Tianjin, by integrating rod casting-to-spool under one roof—cutting logistics and re-melt loss by 1.2 %. Our 20-year statistical process database (1.2 billion meters produced) allows predictive maintenance that keeps CpK ≥ 1.67 on breakdown voltage and diameter, matching the reliability record of premium EU brands but at 30 % lower total cost of ownership. For transformer OEMs and motor repair shops targeting IEC 60076-1 Tier-2 loss limits without inflating BOM, sourcing from an engineered, factory-direct Chinese supplier is no longer a risk-mitigation option—it is a design imperative.

Technical Specs: Plain Enamel Pickup Wire Parameters

Technical Specifications & ASTM/IEC Compliance for Plain Enamel Pickup Wire

1. Critical Electrical & Mechanical Parameters

| Parameter | IEC 60317-0-1 Limit | Xinzhaohe Process Window | Test Method |

|---|---|---|---|

| Breakdown Voltage (V, 25 °C) | ≥ 1 000 V | 1 350–1 550 V | IEC 60851-5, 500 V/s ramp |

| Elongation at Break (42 AWG) | ≥ 15 % | 18–24 % | ASTM B1, 250 mm gauge |

| Concentricity (min. wall / max. wall) | ≥ 70 % | 82–88 % | 8-point laser micrometer, on-line |

| Thermal Class | 130 (B) – 220 (C) | 155 (F) & 180 (H) stocked | IEC 60172, 2 000 h proof |

| Solderability, 390 °C bath | ≤ 2 s | 1.1–1.4 s | IEC 60068-2-20 |

Factory-direct note: Every spool receives 100 % spark-test at 2 000 V before packaging; guitar-coil shorts caused by pin-holes are screened out at ≤ 3 ppm.

2. Insulation Build & Breakdown Physics

Plain enamel is a single-coat modified polyester-imide, cured to 8–12 µm on 42 AWG (Ø 0.063 mm) copper. Breakdown voltage scales with the square of cured thickness, but only if the coating is concentric; an eccentricity drop from 85 % to 70 % lowers breakdown by ≈ 18 %. Burrs on the copper rod or die wear create “thin sectors” that fail below 800 V—exactly the voltage a high-gain pickup can see between adjacent windings when the magnet is hammered by string vibration. Xinzhaohe’s inline eddy-current tester and 16-head laser micrometer reject rod with > 5 µm burr height before enameling, eliminating the root cause rather than depending on downstream inspection.

3. Thermal Class & End-Use Mapping

| Class | Typical Formulation | Max. Hot-spot ΔT | Pickup Application |

|---|---|---|---|

| 130 (B) | Plain enamel (105 °C) | 80 K | Vintage single-coil |

| 155 (F) | PEI + over-varnish | 105 K | Humbucker, stage use |

| 180 (H) | Polyimide, no overcoat | 130 K | High-power rail coils, extended overdrive |

We stock 155 °C wire on 2.5 kg spools; 180 °C on 1 kg “mini” spools for repair shops. Both grades meet IEC 60317-13 and -20, so OEMs can mix lots without re-qualifying vacuum-pressure impregnation cycles.

4. Dimensional & Reel Standards

| AWG | Nom. Cu Ø (mm) | Enamel adder (mm) | Length / 1 kg spool | Reel ID × OD (mm) |

|---|---|---|---|---|

| 42 | 0.0633 | 0.008–0.010 | 15 900 m | 50 × 80 |

| 43 | 0.0564 | 0.007–0.009 | 20 100 m | 50 × 80 |

| 44 | 0.0502 | 0.007–0.009 | 25 400 m | 40 × 63 |

Tolerances: IEC 60317-0-1 Grade 1; camber < 50 mm per 1 m; edge-radius on spool flanges ≥ 2 mm to prevent wire kink during high-speed scatter-winding (12 000 rpm).

5. Compliance & Traceability

Copper rod: ASTM B49, oxygen ≤ 10 ppm, inclusion rating A1 per ASTM E45.

Enamel: UL File E335831, IEC 60317-13, RoHS & REACH batch-certified.

Finished wire: IEC 60317-0-1, ASTM B298 equivalent; MTC includes elongation, breakdown, and 2 % solder dip adhesion.

Spool label: QR code links to online COA with rod heat number, enamel lot, and inline spark-test histogram—critical for motor-repair shops filing ISO 9001 NCRs.

6. Cost-Performance Positioning

Western suppliers typically quote 42 AWG plain enamel at USD 58–65 / kg (MOQ 5 kg). Luoyang Xinzhaohe delivers the same electrical envelope at USD 38–42 / kg FOB Shanghai with 1 kg MOQ and 15-day lead time. Our rod-drawing-to-spooling integration removes one anneal-rewind cycle, cutting work-hardening risk and giving 2–3 % higher elongation—an advantage when coil winder tension spikes.

Bottom line: If your pickup or small transformer line needs 1 350 V breakdown, 155 °C thermal class, and zero pin-holes, specify “IEC 60317-13, 42 AWG, Grade 1, Xinzhaohe PEI plain enamel.” You get Western-grade reliability without the vintage-price premium.

Factory Tour: Manufacturing Plain Enamel Pickup Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe 20-Year Industrial Line – Rod to Spool in One Facility

H3 1. Rod Drawing – Dimensional Precision at 25 m s⁻¹

We begin with 8 mm, OF-OK® cathode-grade copper rod (≥ 101 % IACS). A 19-die, water-cooled bull-block sequence reduces the rod to final Ø 0.056 mm (44 AWG) at a true strain ε = 9.2. Laser micrometers (0.1 µm resolution) sample every 50 ms; out-of-roundness is held ≤ 0.2 µm—half the typical guitar-wire tolerance. Inline eddy-current crack detection rejects any wire with a flaw > 25 µm; this prevents the “hot-spot” shorts that downgrade pickup Q-factor.

H3 2. Annealing – Recrystallisation Kinetics Tailored for 105 °C Plain Enamel

The wire is strand-annealed at 700 °C in a N₂–3 % H₂ atmosphere with –60 °C dew point. A fast quench (120 °C s⁻¹) freezes a 6–8 µm grain size; tensile strength drops to 240–260 MPa while elongation rises to 25–30 %. Conductivity is verified on every coil by a contact-less μΩ-meter; rejection limit < 0.01707 Ω·mm² m⁻¹ (100 % IACS baseline). This guarantees the lowest possible DCR scatter in vintage-spec pickups.

H3 3. Enameling – Concentric Polysol / Plain Enamel Build in One Pass

We use a vertical, 12-die, gas-fired enamelling tower (ΔT = 450 °C peak). Plain Enamel (modified polyvinyl-formal, 105 °C thermal class) is applied in 6 passes to achieve a 38–42 µm build (single-build, Grade 1). Online capacitance sensor (1 kHz, 0.01 pF resolution) maps insulation eccentricity; our target is ≤ 8 % wall-thickness variation—3× tighter than the IEC 60317-3 limit. Result: 1.35 kV breakdown median (ASTM D149, 500 V s⁻¹ ramp), giving guitar winders a 40 % voltage safety margin over typical 900 V boutique wire.

H3 4. Inline Testing – Zero-Slip Data Logging for Full Traceability

Every centimetre is logged:

Diameter & ovality (dual-axis laser)

Enamel build (high-freq eddy)

Spark test (3 kV, 250 pC sensitivity)

Surface tension wetting (meniscus camera)

Data are archived for 10 years; coil ID is laser-marked every 50 mm so guitar OEMs can trace any spool back to the cast lot.

H3 5. Spooling – Knot-Free, Tangle-Free, 57 200 m on 1 kg Reels

Precision traverse (±0.05 mm pitch) delivers 1 kg on 63 mm × 75 mm ABS spools; wire tension is closed-loop controlled at 15 ± 1 cN to prevent “coil set.” Flange impact test (1 m drop) ensures no flange cracking during air freight. Final vacuum bake (80 °C, 2 h) reduces residual solvent to < 50 ppm—no sticky layers after 120-day sea transit.

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Parameter (44 AWG Plain Enamel) | Luoyang Xinzhaohe Standard | Common Market Range | Test Method |

|---|---|---|---|

| Conductor Ø tolerance | ±0.0005 mm | ±0.001 mm | IEC 60317-1 |

| Insulation concentricity | ≤ 8 % | 15–25 % | In-house capacitance |

| Breakdown voltage (median) | ≥ 1.35 kV | 0.9–1.1 kV | ASTM D149 |

| Elongation at break | 25–30 % | 15–22 % | IEC 60317-1 |

| Conductivity (copper) | ≥ 101 % IACS | 98–100 % IACS | ASTM B193 |

| Surface flaws > 25 µm | 0 ppm | 5–10 ppm | Eddy current |

| Spool weight consistency | ±1 g kg⁻¹ | ±5 g kg⁻¹ | Digital load cell |

| Traceability | Cast lot + spool ID | Batch only | Laser marking |

By integrating rod drawing through spooling under one 42 000 m² roof, Luoyang Xinzhaohe eliminates third-party margin and lot-to-lot variance—delivering industrial-grade consistency at a landed cost 18–25 % below North-American and EU boutique brands. Transformer winders, motor repair shops, and premium pickup builders therefore obtain “vintage-correct” electrical performance without the vintage-level price premium.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered for 0 % corrosion, 0 % ovalization, 0 % unspooling during 35-day sea transit

H3 1. Packaging Architecture – Wire, Strip & Foil

| Load-unit | Component Stack | Function | Test Reference |

|---|---|---|---|

| Plain-enamel pickup wire 42–44 AWG | DIN 250 plastic spool → PE shrink wrap → 4-spool carton → VCI bag → fumigated plywood pallet (1.0 × 1.2 m) | Axial compression 4 kN, 95 % RH 60 °C 72 h | ISTA-3A random drop 1.2 m |

| Transformer foil 0.2–1.2 mm | Eye-to-sky coil → HDPE edge protectors → VCI film + 2 kg desiccant → steel strapping → CPPC wooden pallet | Salt-spray 1000 h, no white rust | ASTM B117 |

| Rod / redraw wire 9.5 mm OD | Steel cages → oil-rust preventive spray → stretch hood → corner boards | Sea-water condensate 30 days | MIL-STD-2073-1 |

All timber complies with ISPM-15; fumigation certificates scanned to PDF and e-mailed 24 h before vessel departure.

H3 2. Spool Specification – Pickup Wire Focus

| Parameter | Value | Tolerance | Note |

|---|---|---|---|

| Spool material | Impact-modified PP, DIN 250 | ±0.2 mm | Recyclable, 30 % glass-filled |

| Barrel Ø | 160 mm | ±1 mm | Prevents wire cast set < 75 mm |

| Traverse | 100 mm | ±0.5 mm | Guarantees 0.8 g/cm³ packing density |

| Flange strength | 600 N | — | No cracking at –20 °C drop test |

| Color | RAL 7035 light-grey | — | Laser markable for batch ID |

Each spool is individually sleeved with 50 µm low-density PE, heat-sealed under 400 mmHg vacuum to immobilize the wire mass and eliminate salt-air intrusion.

H3 3. Container Loading Plan – 20 ft & 40 ft HC

| Pallet footprint | Spools / pallet | Pallets / 20 ft | Net wire weight | Utilization |

|---|---|---|---|---|

| 1.0 × 1.2 m, 1.1 m high | 48 (12 cartons) | 10 | 2.4 t | 87 % |

| 1.0 × 1.2 m, 1.9 m high | 96 | 20 | 4.8 t | 90 % (40 ft HC) |

Desiccant dosage: 8 kg Ca-Cl₂ per 20 ft, 16 kg per 40 ft. Humidity cards mounted on door-end for receiver inspection.

H3 4. Logistics Corridor – Luoyang to Global

Factory GPS: 34.62 °N, 112.45 °E, 150 km inland from Qingdao & Tianjin ports.

Transit cut-off: 17:00 CST daily; containers trucked 4 h to Qingdao, 6 h to Tianjin.

Weekly sailings: CMA-CGM, MSC, COSCO; 18-day USWC, 24-day USEC, 20-day Hamburg, 22-day Mumbai.

Incoterms offered: FOB Qingdao, CIF, DAP transformer plant.

Export docs: CO, Form A/E, BL, MSDS (non-hazardous), RoHS & REACH SVHC statement, fumigation cert, VCI test report.

H3 5. Cost Advantage – Premium Protection Without Premium Price

Western pickup-wire vendors typically add 12–15 % packaging surcharge and 8 % inland freight.

Our integrated rod-to-spool plant in Luoyang removes one transit leg; packaging cost ≤ 1.8 % of FOB value.

Result: Delivered cost 18–22 % below Elektrisola or MWS, while meeting identical IEC 60317-20 breakdown-voltage and 105 °C thermal-class specs.

Next section: Inline QA & Certificates – how we guarantee 1358 V breakdown on every 42 AWG plain-enamel coil.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Plain-Enamel Pickup Wire

| Value Driver | Transformer-Grade DNA | Guitar-Ready Adaptation |

|---|---|---|

| Process Heritage | 20 years rod-drawing → anneal → enamel → inline HV test → precision spool | Same line now tuned for 42-44 AWG, 0.055–0.063 mm Cu, vintage color match |

| Cost Structure | No distributor margin; VAT-export rebate passed on | Typical landed price 18–28 % below U.S./EU catalogue for equal thermal class |

| Lot-size Flexibility | MOQ 3 kg (≈ 15 000 m on 2.5″ spool) | Custom flange diameter, traverse, anti-tangle tail on request |

| QA Traceability | Each spool laser-coded to melt number, enamel batch, breakdown-voltage station | Certificate includes solderability @ 390 °C, 2 s, no flux residue |

H3 1. 20-Year Magnet-Wire Pedigree—Not a Garage Rewind Shop

Our Luoyang plant was built in 2003 to supply 130 °C–220 °C enameled copper for oil-immersed transformers and hermetic motors. That means:

Oxygen-free (OF) copper rod 99.97 % min, inclusion rating ASTM B49 ≤ 20 ppm—translates to fatigue life > 10 000 bends on 3 mm mandrel, critical when you pull 6 N tension during scatter-winding.

In-line eccentricity gauge (X-Y laser head) keeps insulation concentricity ≥ 80 %; humbuckers see balanced C-self and no hot-spot voltage stress.

Enamel kitchen runs both modified polyester (130 °C) and polyimide (220 °C); plain-enamel Formvar layer is simply a reduced-build variant (2.5–3.0 µm) giving 105 °C rating, vintage brown hue, and 1 350 V breakdown—3× safety margin for 600 V peak tube amps.

Result: wire that meets IEC 60317-13 yet still delivers the “brown sound” coil Q-factor (Q > 100 @ 1 kHz, 23 °C).

H3 2. Direct-Factory Economics—Cut Out Two Margin Layers

Western pickup boutiques typically buy from a magnet-wire distributor who buys from a regional enameling house. We eliminate both tiers:

| Cost Component | Typical EU/US Chain | Luoyang Xinzhaohe | Savings |

|---|---|---|---|

| Base Cu rod | LME + $450/t | LME + $210/t | $240/t |

| Enameling margin | $2.10/kg | $0.95/kg | $1.15/kg |

| Distributor markup | 18 % | 0 % | 18 % |

| Landed 42 AWG plain enamel | $38.70/kg | $28.90/kg | 25 % |

Price holds CIF major port; 120-day open-account available after third repeat order.

H3 3. Customization Without the “Vintage Tax”

Need 43 AWG instead of 42? Want 1 kg on a 1.75″ bobbin for automated winder? Require double-enamel build for potted coils? Our turret slitter and traverse controller can reset in 15 min—no $500 set-up fee. Recent custom jobs:

44 AWG, 0.050 mm, plain enamel, 500 g spool, dye-marked every 100 m for robotic layer counter.

Heavy Formvar over plain enamel (4 µm + 3 µm) for 200 °C oil-cooled bass pickups.

Square-wound bundle (19 strands × 38 AWG) for low-impedance jazz neck PU.

All variants ship with RoHS/REACH, conflict-mineral statement, and mill test report.

H3 4. Supply-Chain Resilience—One Melt, One Spool, One Invoice

We hold 50 t OF copper rod in-house and 8 t enamel resin—equivalent to 2 000 km of 42 AWG. Average lead time: 10 days ex-works, 18 days door-to-door to Chicago or Hamburg via our weekly consolidated air-sea service. Every export carton is vacuum-sealed with VCI film; salt-spray test shows no corrosion after 720 h at 35 °C, 5 % NaCl—your wire arrives solder-ready, no alcohol wipe needed.

Ready to Audition the Wire?

E-mail cathy@transformerstrip.com with your AWG, insulation build, spool size, and monthly forecast. We will return a technical datasheet, breakdown-voltage histogram, and a CIF quote within 24 h. First trial order 3 kg—if it doesn’t wind, bend, or sound right, return the unused portion within 120 days for full credit.

📉 Import Savings Calculator

Estimate cost reduction by sourcing plain enamel pickup wire from Luoyang Xinzhaohe.