Table of Contents

Market Insight: Non-Grain Oriented Electrical Steel

Market Analysis: Non-Grain Oriented Electrical Steel Demand in Transformer Applications

Global demand for non-grain oriented electrical steel (NGOES) within the transformer sector is experiencing steady growth, driven by critical infrastructure modernization and the expansion of renewable energy integration. While grain-oriented electrical steel (GOES) dominates large power transformers due to its superior directional magnetic properties, NGOES serves essential roles in smaller distribution transformers, specialty transformers for renewable inverters, and certain industrial applications requiring isotropic magnetic behavior. The International Energy Agency (IEA) projects a compound annual growth rate (CAGR) of approximately 5% for the global distribution transformer market through 2030, directly correlating with increased NGOES consumption. Key drivers include aging grid replacement programs in developed economies, rural electrification initiatives in emerging markets, and the surge in decentralized power generation necessitating robust, efficient step-down transformers at the grid edge. The inherent isotropic magnetic properties of NGOES make it particularly suitable for transformers handling complex or multidirectional flux patterns, such as those found in variable-frequency drive systems or compact designs where core geometry constraints preclude optimal GOES lamination orientation.

Quality in NGOES is non-negotiable for transformer performance, longevity, and total cost of ownership. Substandard material directly compromises core efficiency, manifesting as elevated no-load losses (primarily hysteresis and eddy current losses). Even marginal deviations in key metallurgical parameters significantly impact operational economics. For instance, a 0.1 W/kg increase in specific core loss (W15/50) across a medium-voltage distribution transformer fleet can translate to hundreds of thousands of dollars in wasted energy annually per utility. Critical quality parameters demanding rigorous control include precise silicon content (typically 1.0-3.0 wt%), tight thickness tolerance (±0.025 mm for 0.35mm grade), exceptional surface insulation resistance, and minimized magnetic aging. Consistent lamination punching characteristics are equally vital to prevent burrs and dimensional inaccuracies that degrade core stacking factor and increase localized losses. The table below summarizes essential NGOES quality thresholds for transformer applications.

| Parameter | Critical Threshold (Typical for M530-50A) | Impact of Deviation |

|---|---|---|

| Specific Core Loss (W15/50) | ≤ 3.80 W/kg | Increased no-load loss, higher operating temperature, reduced efficiency |

| Thickness Tolerance | ±0.025 mm | Inconsistent stacking factor, elevated eddy current losses |

| Insulation Resistance | ≥ 5.0 Ω·m² (after punching) | Interlaminar shorts, excessive eddy currents, hot spots |

| Magnetic Aging (ΔW15/50) | ≤ +0.30 W/kg | Long-term efficiency degradation, premature aging |

Luoyang Xinzhaohe Electrical Steel Co., Ltd. (Note: Despite historical naming convention including “Aluminum”, the company specializes in electrical steel production) emphasizes that sourcing NGOES based solely on initial cost is a false economy. Inferior material accelerates thermal degradation, increases audible noise, and shortens transformer lifespan, incurring substantial maintenance, replacement, and energy penalty costs over the asset’s 25-40 year operational life. Stringent adherence to international standards (IEC 60404-8-7, ASTM A664) and robust supplier quality management systems are imperative to ensure the magnetic consistency, dimensional accuracy, and surface integrity required for high-efficiency, reliable transformer cores in today’s demanding energy landscape. The technical performance of the NGOES fundamentally dictates the transformer’s contribution to grid sustainability and operational resilience.

Technical Specs: Non-Grain Oriented Electrical Steel

Technical Specifications for Non-Grain Oriented Electrical Steel

Non-grain oriented (NGO) electrical steel is a critical material in the construction of efficient electromagnetic cores used in motors, generators, transformers, and various industrial electrical apparatus. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical and supply chain expertise, we provide high-performance NGO electrical steel engineered to meet stringent international standards and application-specific requirements. The performance of NGO steel is primarily evaluated through three core technical parameters: core loss (iron loss), magnetic flux density, and flatness. These parameters directly influence the energy efficiency, thermal performance, and manufacturability of the end product.

Core loss, expressed in watts per kilogram (W/kg), measures the energy dissipated as heat during magnetic cycling. It is typically measured under alternating magnetic fields at 50 Hz or 60 Hz and at specified peak flux densities such as 1.0 T, 1.5 T, or 1.7 T. Lower core loss values indicate higher energy efficiency and are especially critical in applications where thermal management and power consumption are key concerns. Our NGO steel grades are optimized to achieve low core loss through precise control of silicon content (typically 0.5–3.2%), grain size, and annealing processes, which reduce hysteresis and eddy current losses.

Magnetic flux density (B), measured in Tesla (T), reflects the material’s ability to carry magnetic flux. Higher flux density enables more compact and powerful electromagnetic designs. For NGO steel, typical saturation flux density ranges from 1.90 T to 2.05 T, with guaranteed values at standard test conditions (e.g., B50 or B800, representing flux density at 5000 A/m or 800 A/m magnetic field strength). Our production process ensures consistent magnetic performance across coils through controlled rolling and decarburization annealing.

Flatness is a critical dimensional quality parameter, particularly for high-speed stamping operations in motor lamination production. Poor flatness leads to stacking faults, air gaps, and increased core losses. We measure flatness in terms of warp (edge wave) and bow (longitudinal curvature), with maximum allowable deviations typically under 5 mm per meter. This is achieved through precise tension leveling and controlled cooling after annealing.

Below are representative technical parameters for our standard NGO electrical steel grades:

| Grade Designation | Thickness (mm) | Core Loss P1.5/50 (W/kg) | Magnetic Flux Density B50 (T) | Flatness (mm/m) | Silicon Content (%) |

|---|---|---|---|---|---|

| 50WW350 | 0.50 | ≤ 3.50 | ≥ 1.68 | ≤ 5 | 2.9–3.2 |

| 50WW470 | 0.50 | ≤ 4.70 | ≥ 1.65 | ≤ 5 | 2.5–2.8 |

| 35WW300 | 0.35 | ≤ 3.00 | ≥ 1.60 | ≤ 4 | 3.0–3.3 |

| 35WW250 | 0.35 | ≤ 2.50 | ≥ 1.58 | ≤ 4 | 3.1–3.4 |

These specifications are compliant with IEC 60404-8-7 and JIS C 2553 standards. Custom grades are available upon request for specialized applications requiring tighter tolerances or enhanced performance.

Factory Tour: Manufacturing

Manufacturing Process for Non-Grain Oriented Electrical Steel

With two decades of specialization in silicon steel production, Luoyang Xinzhaohe Aluminum Co., Ltd. implements a rigorously controlled sequence for manufacturing high-performance non-grain oriented (NGO) electrical steel. This process ensures optimal magnetic properties, dimensional stability, and surface integrity critical for motor and generator core applications. The core stages are slitting, annealing, insulation coating, and precision cutting, each integrated with stringent quality control protocols.

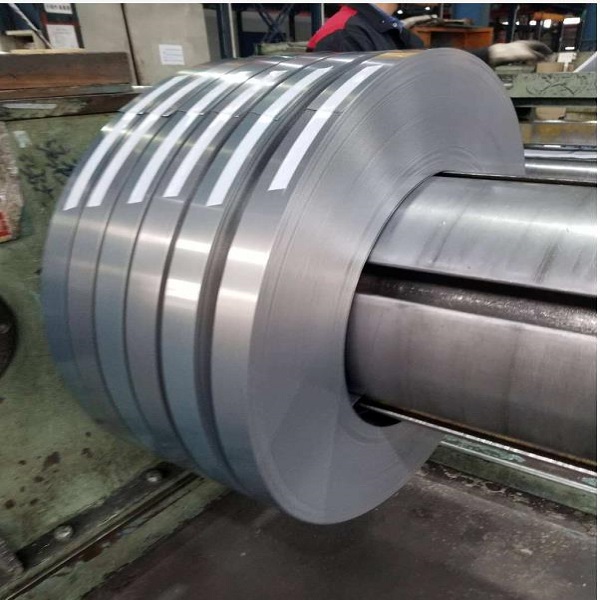

The slitting process begins with master coils of cold-rolled NGO steel. Utilizing precision tension-controlled slitters, the material is longitudinally divided into narrower strips conforming to customer width specifications. Critical parameters monitored include strip edge quality (minimizing edge waviness and burr formation), consistent line speed, and precise width tolerance maintenance typically within ±0.1 mm. Laser micrometers continuously verify strip thickness profile across the width, ensuring uniformity essential for subsequent lamination stacking. Any deviation triggers immediate process adjustment or material segregation.

Following slitting, the annealing stage is executed in continuous controlled-atmosphere furnaces. Strips pass through a precisely defined thermal cycle, typically heated to 750-850°C under a protective nitrogen-hydrogen atmosphere to prevent oxidation and decarburization. This heat treatment relieves residual stresses induced during prior rolling and slitting, recrystallizes the microstructure, and optimizes magnetic permeability while minimizing core loss. Critical quality checks at exit include measurement of magnetic induction (B50, B100) and specific core loss (W10/400, W15/50) against ASTM A664 or IEC 60404-8-7 standards using Epstein frame or single sheet testers. Surface cleanliness is also verified.

Insulation coating application follows annealing. A thin, uniform layer of inorganic or organic-inorganic hybrid coating is applied via roll-coating or spray methods. This coating provides electrical resistivity between laminations, reducing eddy current losses, and offers corrosion resistance. Coating weight is meticulously controlled within 0.5-2.0 g/m² per side, measured using X-ray fluorescence (XRF) or gravimetric analysis. Adhesion strength is tested per ASTM D3359, and surface insulation resistance (SIR) is measured to ensure the coating effectively isolates individual laminations under operating conditions.

The final stage is precision cutting, transforming slit coils into blanks or laminations. High-speed progressive or rotary blanking presses, equipped with hardened tooling, perform this operation under strict environmental control. Dimensional accuracy is paramount, with critical features held to tolerances of ±0.02 mm. Burr height on cut edges is continuously monitored via optical inspection or profilometry, maintained below 3% of material thickness to prevent interlaminar short circuits. Stacking factor verification is performed on sample stacks to confirm minimal air gaps.

Throughout this integrated process, comprehensive traceability is maintained from coil ID through all stages. Final product certification includes full magnetic property data, mechanical properties (yield/tensile strength, elongation), coating characteristics, dimensional reports, and surface quality assessment per ISO 9001 protocols. This systematic approach guarantees the NGO electrical steel delivered meets the exacting demands of efficient electromagnetic device manufacturing.

Packaging & Logistics

Export Packaging Standards for Non-Grain Oriented Electrical Steel at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, the export packaging of non-grain oriented electrical steel is engineered to meet international logistics demands, ensuring material integrity during long-distance sea freight. With over two decades of experience in silicon steel production and global supply, our packaging protocols are designed to mitigate risks associated with moisture, mechanical stress, and extended transit times. All shipments are prepared in compliance with ISO 9001 quality standards and optimized for containerized ocean transport, the primary mode for international delivery of steel products.

Non-grain oriented electrical steel is packaged on robust wooden pallets constructed from high-density, kiln-dried hardwood. These pallets are designed to support the full weight of steel coils or cut sheets, with load capacities exceeding standard industry requirements. Each pallet is treated to ISPM 15 regulations, ensuring phytosanitary compliance for cross-border shipments. The structural integrity of the pallets prevents deformation during stacking and handling, particularly under the dynamic conditions of maritime logistics, including vessel motion and port crane operations.

Immediately following packaging on the pallet, the product is wrapped in multi-layer moisture-proof film. This film consists of a co-extruded polymer blend with a high-barrier aluminum layer, providing an effective vapor transmission rate of less than 0.5 g/m²·24h at 38°C and 90% relative humidity. This specification is critical for preventing oxidation and interlayer corrosion, which can degrade the magnetic properties and surface insulation of electrical steel. The film is hermetically sealed using heat-welded seams and reinforced at stress points to maintain a continuous protective envelope throughout the supply chain.

In addition to primary moisture protection, desiccant packs are strategically placed within the sealed package to absorb residual humidity. Each shipment includes humidity indicators to allow for non-invasive verification of internal conditions upon arrival. This proactive approach to moisture control is essential for maintaining the tight tolerances and surface quality required in electrical steel applications such as motors, transformers, and generators.

All packaged loads are unitized to standard container dimensions, maximizing space utilization in 20-foot and 40-foot dry freight containers. Edge protectors and strapping are applied to prevent coil deformation or sheet slippage during transit. Final inspection includes verification of package integrity, labeling accuracy, and compliance with destination-specific import regulations.

Luoyang Xinzhaohe Aluminum Co., Ltd prioritizes reliability in every stage of export logistics. Our packaging system is not merely a containment solution but an integral component of product performance assurance, reflecting our commitment to delivering non-grain oriented electrical steel in optimal condition, regardless of destination.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Non-Grain Oriented Electrical Steel

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver high-performance non-grain oriented electrical steel (NGOES) for demanding transformer and motor applications. Our vertically integrated manufacturing facility in Luoyang, China, is engineered for consistent quality and technical excellence in silicon steel production, specifically optimized for NGOES requirements. We understand that core loss minimization, magnetic flux density stability, and lamination integrity are non-negotiable for efficient electromagnetic device performance. Our commitment begins with stringent raw material selection, utilizing high-purity iron and precisely controlled silicon content to achieve target magnetic properties while mitigating aging effects.

Our production capabilities encompass a comprehensive NGOES range, supporting thicknesses from 0.10mm to 0.65mm and widths up to 1250mm, catering to diverse core stacking and punching needs. Advanced continuous annealing lines with precise atmosphere control ensure optimal domain refinement and stress relief, directly influencing core loss (W10/400, W15/50) and permeability characteristics. Rigorous in-process quality control is embedded throughout the manufacturing sequence. Statistical Process Control (SPC) monitors critical parameters including thickness tolerance (±0.005mm achievable), surface roughness (Ra), coating weight (MgO or semi-organic), and mechanical properties (yield/tensile strength). Every production lot undergoes comprehensive magnetic testing per international standards, with full traceability from melt to finished coil.

Our technical proficiency extends beyond manufacturing. We maintain an ISO/IEC 17025 accredited metallurgical laboratory equipped for detailed microstructural analysis, chemical composition verification (OES), and precise Epstein frame or Single Sheet Tester (SST) magnetic property evaluation. This enables us to validate conformance against key specifications:

| Standard | Key Properties Verified | Typical Application Focus |

|---|---|---|

| ASTM A664 | Core Loss, Permeability, Thickness | General Purpose Motors |

| IEC 60404-8-7 | Specific Total Loss, Polarization | High-Efficiency Motors |

| GB/T 13789 | Magnetic Aging, Mechanical Props | Domestic Transformer Cores |

Supply chain reliability is paramount. We operate a just-in-time inventory model supported by dedicated logistics coordination, ensuring on-time delivery of coils or slit strips with minimal lead time variance. Our technical team collaborates directly with OEM design and procurement engineers to address application-specific challenges, from optimizing grade selection for reduced eddy current losses to resolving lamination burr issues during stamping.

Partnering with Luoyang Xinzhaohe provides access to a stable source of technically validated NGOES, backed by metallurgical rigor and responsive supply chain execution. We enable your production efficiency through material consistency that reduces scrap rates and enhances final product performance. Contact Cathy Zhang directly at cathy@transformerstrip.com to discuss your NGOES requirements. Provide your target specifications and volume needs to receive a technical dossier and competitive quotation for material engineered to optimize your core losses and manufacturing yield.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing non-grain oriented electrical steel directly from China.