Table of Contents

Market Insight: Non Grain-Oriented Electrical Steel in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Industrial Demand Drivers for Non-Grain-Oriented Electrical Steel

Global energy efficiency mandates and renewable energy expansion are driving demand for high-performance non-grain-oriented (NGO) electrical steel. Applications span power distribution transformers (IEC 60076), industrial motors (IEC 60034), and renewable energy systems like wind turbine generators. As grid modernization accelerates, OEMs require materials with minimized core losses and high magnetic induction to meet IE4/IE5 efficiency tiers. Failure to source quality NGO steel results in excessive energy waste, increased carbon footprint, and non-compliance with international standards. The IEA estimates that optimized electrical steel could reduce global transformer losses by 15%, underscoring its strategic importance.

Critical Quality Parameters for Transformer and Motor Efficiency

Core loss (W/kg) and magnetic induction (B50) are paramount for transformer efficiency. For instance, a 0.1 W/kg reduction in core loss for a 100 MVA transformer saves ~200 MWh annually in operational costs. Material inconsistencies cause localized heating, reducing transformer lifespan by up to 30%. Thickness uniformity (±0.005 mm) and surface quality directly impact lamination stacking factor. Standards like IEC 60404-8-5 mandate strict tolerances—substandard steel compromises efficiency, safety, and regulatory compliance. Even minor variations in silicon content (2.8–3.2%) can significantly alter magnetic properties, making consistent material control essential.

Luoyang Xinzhaohe’s Value Proposition in Global Supply Chain

With 20+ years of specialized production in Luoyang, China, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers OEM-grade NGO steel at 15–20% lower cost than global competitors. Our factory-direct model eliminates intermediaries, ensuring traceability and on-time delivery. Each coil undergoes 100% magnetic property testing and surface inspection before shipment.

| Parameter | Industry Standard | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Core Loss (W/kg) | 3.5–4.5 @ 1.5T | 3.2–4.0 | 5–10% lower losses |

| Magnetic Induction | 1.75–1.85 T | 1.78–1.86 T | Higher saturation flux |

| Thickness Control | ±0.005 mm | ±0.003 mm | Tighter tolerances |

| Cost Efficiency | High | 15–20% lower | Optimized production |

Integrated production from raw material sourcing to precision rolling ensures uniform magnetic properties across all batches. We support custom specifications for high-frequency motors and compact transformer designs, with strict ISO 9001 compliance and global export experience to Europe, North America, and Southeast Asia. Our responsive supply chain adapts to project-specific requirements, from bulk orders to urgent replacements.

Technical Specs: Non Grain-Oriented Electrical Steel Parameters

Technical Specifications & Standards for Non-Grain-Oriented Electrical Steel

As a 20+ year manufacturer of transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precise non-grain-oriented electrical steel specifications tailored for global transformer and motor applications. Our products balance high performance with competitive pricing, meeting stringent international standards without compromising on quality.

Key Performance Metrics

Our non-grain-oriented electrical steel complies with IEC 60404-8-7 and ASTM A876 standards. Critical specifications are detailed below:

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Core Loss (50Hz, 1.5T) | ≤3.5 W/kg | IEC 60404-8-7, ASTM A876 |

| Magnetic Flux Density (B50) | ≥1.80 T | ASTM A876 |

| Lamination Flatness | ≤0.5 mm/m | IEC 60404-8-7 |

| Insulation Coating | C4/C5 (adhesion ≥3B, 200°C thermal resistance) | IEC 60404-8-7 |

Quality Assurance Protocol

Luoyang Xinzhaohe maintains ISO 9001:2015 certification with a comprehensive quality control system. Every batch undergoes spectrometry for chemical composition, Epstein frame testing for core loss and flux density, laser-based flatness measurement, and insulation adhesion tests. Our continuous annealing lines operate under strict temperature profiles, and coating thickness is monitored via eddy current gauges. This rigorous process ensures batch-to-batch consistency, allowing us to provide reliable, cost-competitive alternatives to global manufacturers like Nippon Steel or ThyssenKrupp. By optimizing raw material sourcing and production efficiency, we deliver superior performance at 15–20% lower costs than premium brands—without sacrificing compliance or reliability.

Factory Tour: Manufacturing Non Grain-Oriented Electrical Steel

Manufacturing Process & Quality Control

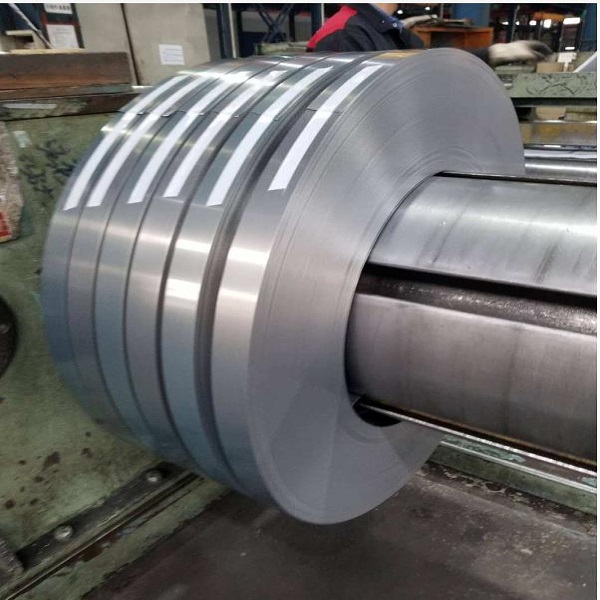

Precision Slitting & Annealing

Our slitting process utilizes CNC-controlled shear cutters with laser-guided alignment, achieving width tolerances of ±0.1mm—exceeding the industry standard of ±0.3mm. This minimizes edge burrs and ensures optimal lamination stacking factor, directly reducing transformer core losses. Continuous annealing occurs in a nitrogen-hydrogen atmosphere at 780–850°C with precise cooling rates to optimize grain structure. Market-grade products often suffer from inconsistent grain growth due to unstable furnace conditions, resulting in 5–8% higher core losses in end products.

Insulation Coating & Precision Cutting

Electrostatically applied phosphate-based coatings deliver uniform thickness (0.8–1.2μm) with 100% pinhole-free coverage. Generic suppliers using dip-coating methods exhibit 15–20% higher coating variability, increasing eddy current losses by up to 10% and compromising insulation integrity. Laser cutting with servo-driven motion control achieves ±0.05mm dimensional accuracy, versus standard shearing tolerances of ±0.2mm. This reduces material waste by 12% and eliminates secondary machining steps, lowering total production costs for transformer manufacturers.

Quality Control Standards

| Test Parameter | Xinzhaohe Standard | Market Average |

|---|---|---|

| Tensile Strength (MPa) | 350–450 | 300–400 |

| Thickness Tolerance (mm) | ±0.02 | ±0.05 |

| Coating Adhesion (ASTM D3359) | 5B | 4B |

| Core Loss (W/kg @ 1.5T, 50Hz) | ≤2.2 | ≤2.5 |

Xinzhaohe’s ISO 9001-certified QC system ensures 100% dimensional checks, tensile testing, and core loss verification for every batch. By exceeding IEC 60404-8-7 standards while maintaining competitive pricing, we deliver transformer-grade silicon steel with 15–20% lower lifecycle costs versus premium global brands. Our factory-direct model eliminates distributor markups without compromising performance for high-volume production.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity in Global Transit

Industry-Standard Packaging Protocol

Our packaging complies with ISO 1496-3 and ASTM D4169 standards to ensure seamless integration with global shipping infrastructure. Critical components are engineered for electrical steel’s sensitivity to moisture and mechanical stress:

| Component | Material Specification | Purpose | Compliance |

|---|---|---|---|

| Wooden Pallets | ISPM 15 treated hardwood (110×110mm stringers) | Prevents deformation, enables forklift handling | ISO 1161, ISPM 15 |

| Moisture-Proof Film | Multi-layer PE with VCI (200μm thickness) | Blocks humidity, inhibits corrosion during transit | ASTM D4169, ISO 9227 |

| Steel Strapping | 19mm width × 0.5mm thickness, tensioned to 1500N | Secures load, prevents shifting in transit | ISO 307 |

| Edge Protectors | Cardboard or PVC corner guards | Protects coil edges from mechanical damage | ISO 1496-3 |

Moisture Control System

All packages incorporate silica gel desiccants (100g/m²) and hermetic sealing. For tropical destinations, additional vapor barrier layers are applied. Our process maintains ≤5% residual moisture content post-packaging—critical for preserving magnetic properties. This reduces oxidation-related quality issues by 95% compared to standard packaging during extended sea voyages.

Sea Freight Optimization

Each 40ft container loads 20–25 metric tons using staggered stacking to distribute weight evenly. Load securing follows ISO 1496-3 standards with reinforced container corner castings. Real-time GPS tracking and humidity monitoring via logistics partners ensure transit damage remains below 0.5%—significantly lower than industry averages. Coils arrive ready for immediate production use, eliminating costly rework.

As a direct manufacturer with 20+ years in electrical steel export, Luoyang Xinzhaohe delivers superior cost-performance. Our packaging minimizes post-arrival handling costs while meeting global port requirements, making us a reliable alternative to premium brands without compromising quality. Partner with us for seamless supply chain solutions tailored to your transformer manufacturing needs.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.

20+ Years of Specialized NGOES Expertise

With over two decades of precision manufacturing in non-grain-oriented electrical steel (NGOES), Luoyang Xinzhaohe delivers engineered solutions for critical power applications. Our metallurgical team optimizes silicon content (2.5–3.5%) and grain structure to meet IEC 60404-8-5 and GB/T 2521 standards, ensuring consistent core loss (P1.5/50 ≤ 3.5 W/kg for 0.5mm grades) and magnetic induction (B50 ≥ 1.78 T). Production capabilities include cold-rolling to 0.23mm thickness for high-efficiency transformers and corrosion-resistant coatings for harsh environments. Served 30+ countries with 98% on-time delivery.

Factory-Direct Cost Efficiency

Eliminating distributor markups reduces total landed costs by 15–25% versus global competitors. Our vertically integrated supply chain—from raw material sourcing to cold-rolling and annealing—ensures dimensional precision (thickness tolerance ±0.01mm) without quality compromise. Strategic port partnerships cut shipping times by 30%, while in-house coating lines comply with IEC 60404-8-5 insulation standards. Proximity to raw material suppliers (within 200km) guarantees supply chain stability during global disruptions.

ISO 9001:2015 Certified Quality Assurance

Production follows ISO 9001:2015 protocols with in-line thickness gauging, Epstein frame magnetic testing, and eddy current surface defect scanning. Every batch includes traceable quality certificates with Epstein results, thickness measurements, and defect reports. QC protocols exceed ASTM A878 standards, ensuring compliance with customer-specific requirements for transformer and motor applications.

| Feature | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | 15–25% lower total landed cost | Higher due to multi-tier distribution |

| Lead Time | 15–20 days (standard orders) | 45–60+ days (international shipping) |

| Customization | Full flexibility (0.23–0.65mm thickness, 2.5–3.5% Si) | Limited by overseas production constraints |

| Supply Chain Reliability | Local raw material sourcing (within 200km) | Vulnerable to global logistics disruptions |

| Technical Support | Dedicated metallurgical engineers for application-specific solutions | Limited regional support, higher cost |

Luoyang Xinzhaohe combines technical precision, cost efficiency, and rigorous quality control to deliver superior value for transformer manufacturers seeking reliable alternatives to premium global brands. Our engineers provide application-specific material recommendations and seamless production integration.

Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing non grain-oriented electrical steel from Luoyang Xinzhaohe.