Table of Contents

Market Insight: Nickel Plated Copper Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to evolve under the dual pressures of energy efficiency mandates and the expansion of renewable energy infrastructure. Within this context, nickel plated copper strip has emerged as a critical material in high-performance transformer applications, particularly in high-frequency transformers, precision current sensors, and specialty power electronics. The increasing demand for materials that offer both superior electrical conductivity and enhanced surface durability has positioned nickel plated copper strip as a preferred choice in advanced transformer design.

Nickel plating serves multiple functional purposes when applied to copper strip substrates. First, it provides a robust barrier against oxidation and sulfidation, significantly extending the operational life of the conductor in harsh or humid environments. Second, the nickel layer improves solderability and facilitates reliable brazing and welding processes during transformer assembly, which is essential for maintaining consistent electrical contact and minimizing interfacial resistance. Third, nickel plating enhances wear resistance, making the material suitable for sliding electrical contacts and commutator applications often found in industrial and traction transformers.

Industrial demand for nickel plated copper strip is particularly strong in sectors requiring high reliability and precision, including electric vehicle (EV) charging infrastructure, uninterruptible power supplies (UPS), and smart grid components. In EV charging systems, for example, transformers must operate efficiently under variable loads and elevated temperatures. Nickel plated copper strip ensures stable performance under these conditions by minimizing contact degradation and reducing the risk of hot-spot formation due to poor interfacial conductivity.

Quality is paramount in the selection of nickel plated copper strip for transformer applications. Variability in plating thickness, adhesion strength, or surface uniformity can lead to premature failure modes such as delamination, increased contact resistance, or localized overheating. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in advanced metal strip production, we emphasize strict process control in both copper substrate refinement and electroless/nickel electroplating processes. Our strips are manufactured to meet international standards including ASTM B428 and IEC 60127, ensuring consistent dimensional tolerances, precise nickel layer deposition (typically 1–5 µm), and excellent interlayer adhesion verified through tape and thermal cycling tests.

Furthermore, the purity of the base copper (minimum 99.95% Cu) directly influences bulk conductivity, while grain structure and surface finish affect high-frequency performance and lamination compatibility. We employ continuous annealing and precision rolling techniques to achieve optimal mechanical and electrical properties tailored to customer specifications.

As transformer designs push toward higher efficiency and miniaturization, the role of engineered materials like nickel plated copper strip becomes increasingly strategic. The integration of high-quality plated strip not only enhances reliability but also contributes to lower lifecycle costs and reduced maintenance in critical power systems.

Technical Specs: Nickel Plated Copper Strip

Technical Specifications: Nickel Plated Copper Strip for Precision Electrical Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise to deliver nickel plated copper strip meeting the stringent demands of transformer, inductor, and high-reliability electrical component manufacturing. Our production process integrates precision cold rolling, continuous nickel electroplating, and advanced slitting technologies to ensure dimensional stability, optimal electrical performance, and defect-free edges critical for automated assembly. The base material utilizes high-purity electrolytic tough pitch copper (C11000 per ASTM B152), providing a foundation for exceptional conductivity and mechanical workability. Nickel plating is applied via controlled electrolytic deposition, ensuring uniform thickness and metallurgical bonding to prevent delamination under thermal cycling or mechanical stress. All parameters are validated through in-line metrology and third-party certified testing per IEC 60140 and ASTM B152 standards.

The following table details the guaranteed technical parameters for our nickel plated copper strip:

| Parameter | Specification | Test Standard |

|---|---|---|

| Base Material | C11000 Copper (99.90% min Cu) | ASTM B152 |

| Nickel Plating Thickness | 0.5 μm to 3.0 μm (customizable) | ASTM B487 |

| Strip Width Tolerance | ±0.002 mm (precision slit) | ISO 9013 |

| Edge Burr Height | ≤ 5 μm (measured per EN ISO 1302) | Internal QC Protocol |

| Thickness Range | 0.05 mm to 0.50 mm | ASTM E29 |

| Conductivity (Copper Core) | 95%–98% IACS (annealed condition) | ASTM B3 |

| Tensile Strength | 200–250 MPa | ASTM E8 |

| Elongation | ≥ 5% | ASTM E8 |

| Plating Adhesion | No blistering/delamination after 180° bend | ASTM B571 |

| Surface Roughness (Ra) | ≤ 0.4 μm | ISO 4287 |

Critical Dimensional Control

Width tolerance of ±0.002 mm is maintained through our proprietary tension-leveling slitting lines equipped with laser-guided edge tracking and servo-controlled knife positioning. This precision eliminates width variation-induced winding defects in coil-based applications. Edge quality is rigorously controlled via double-edge grinding and deburring systems, ensuring burr heights remain below 5 μm—critical for preventing short circuits in layered windings and ensuring smooth feeding in high-speed stamping processes.

Electrical and Metallurgical Performance

Conductivity values of 95%–98% IACS reflect the high-purity copper core’s performance post-annealing; the nickel layer contributes negligible resistance due to its minimal thickness and uniform coverage. Plating adhesion is validated through mandrel bend tests per ASTM B571, guaranteeing integrity during component forming operations. All strips undergo 100% eddy current testing to detect subsurface inclusions, and lot-specific Material Test Reports (MTRs) provide full traceability of chemical composition, mechanical properties, and plating thickness profiles. This comprehensive specification framework ensures compatibility with automated manufacturing while meeting the thermal and electrical reliability requirements of modern power electronics.

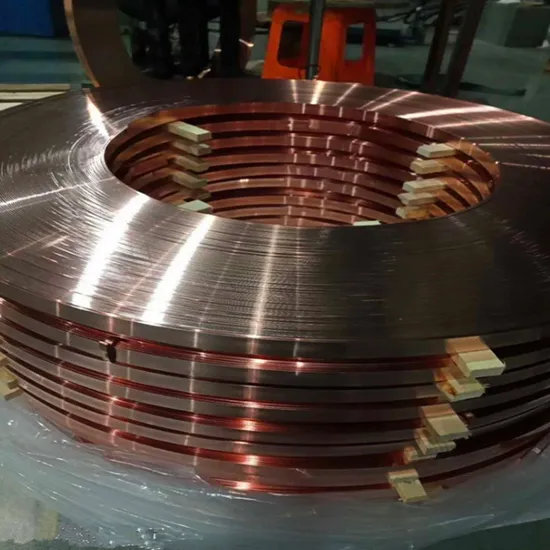

Factory Tour: Manufacturing

Manufacturing Process of Nickel Plated Copper Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

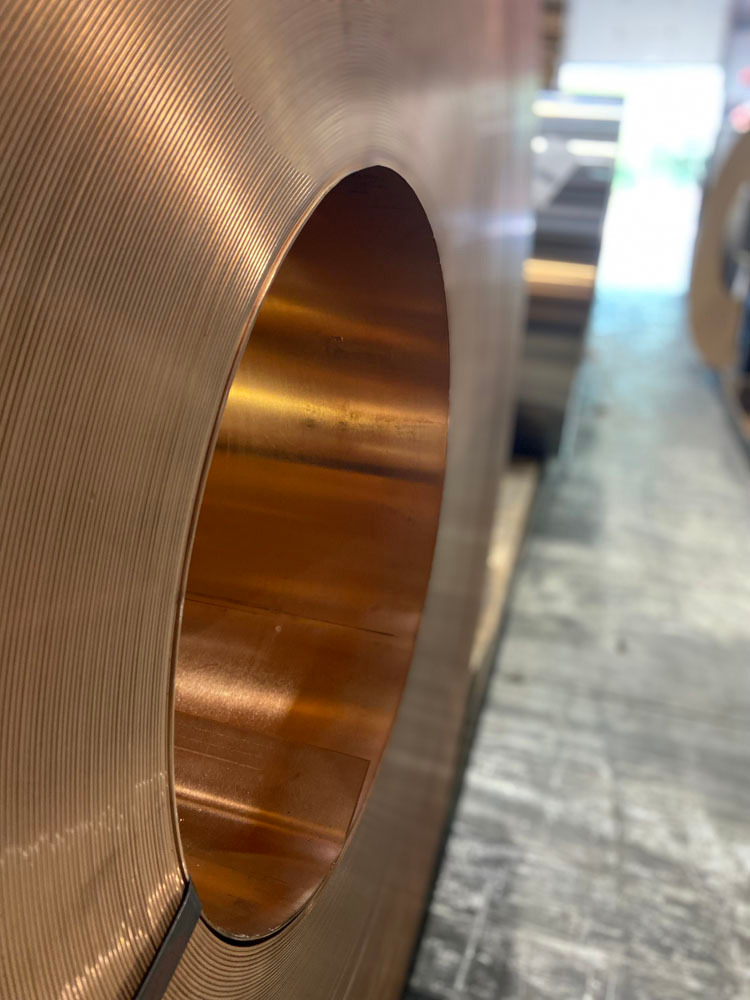

The production of nickel plated copper strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, surface integrity, and consistent electrical and mechanical performance. With over two decades of specialization in transformer-grade strip and foil materials, our process integrates advanced cold rolling technology with precision slitting and edge conditioning, supported by rigorous quality control protocols at every stage.

The process begins with high-conductivity electrolytic tough pitch (ETP) copper, typically supplied in coil form with strict chemical certification. These copper coils undergo a full-anneal heat treatment in a controlled atmosphere to eliminate residual stresses and achieve a uniform, recrystallized microstructure. Following annealing, the material enters the cold rolling phase, where it is reduced to the target thickness with micron-level precision. Our 20-high precision rolling mills enable tight thickness tolerances as close as ±0.005 mm, while maintaining excellent flatness and surface finish. Roll grinding and roll force monitoring systems ensure consistency across production batches, critical for downstream processing and end-use performance in transformer and inductor applications.

After cold rolling, the copper strip proceeds to the nickel plating stage. Electroless or electroplating techniques are employed based on customer specifications, with typical nickel coating thicknesses ranging from 1 to 5 microns. The plating line includes pre-cleaning, activation, and post-plating passivation steps to ensure strong adhesion, corrosion resistance, and solderability. Continuous in-line monitoring of bath chemistry, temperature, and current density ensures coating uniformity and repeatability.

The plated strip is then subjected to precision slitting on high-tolerance rotary shear lines equipped with laser-guided web control systems. Slitting widths are maintained within ±0.1 mm, with minimal burr formation. Tension control and edge guiding systems prevent coil telescoping and maintain edge straightness. Following slitting, the material undergoes edge conditioning to remove micro-burrs and sharp edges that could compromise winding integrity in transformer cores. This is achieved via controlled brushing or light grinding, followed by ultrasonic cleaning to eliminate particulate contamination.

Quality control is embedded throughout the manufacturing flow. In-process inspections include continuous thickness measurement via beta-gauge systems, surface defect detection using high-resolution line-scan cameras, and periodic metallographic analysis of cross-sections. Final product verification includes adhesion testing per ASTM B571, coating thickness measurement via XRF, and electrical resistivity checks. Each coil is traceable through our batch management system, with full material test reports provided upon shipment.

This integrated manufacturing approach ensures that every nickel plated copper strip meets the demanding requirements of high-efficiency transformers, power electronics, and renewable energy systems.

Packaging & Logistics

Export Packaging Specifications for Nickel Plated Copper Strip

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for nickel plated copper strip shipments, specifically designed to mitigate the unique risks of intercontinental sea freight. With over two decades of specialized experience in transformer strip and foil logistics, our methodology prioritizes material integrity against moisture ingress, mechanical stress, and atmospheric corrosion during extended ocean voyages. This system is non-negotiable for maintaining the critical surface quality and electrical properties of nickel plated copper required by transformer and inductor manufacturers.

Wooden Pallet Specifications

All shipments utilize ISPM-15 compliant kiln-dried hardwood pallets, dimensioned to ISO standard 1200mm x 1000mm or 1100mm x 1100mm configurations. Pallets are structurally reinforced with double deck boards and perimeter stringers to support static loads exceeding 2,500 kg, preventing deformation during container stacking. Surface moisture content is strictly maintained below 12% to eliminate internal condensation risks. Each pallet undergoes fumigation certification with heat treatment documentation traceable to national phytosanitary authorities, ensuring global customs admissibility without quarantine delays.

Multi-Layer Moisture-Proof Barrier System

The core protection mechanism employs a three-tiered wrapping sequence. First, individual coils are sealed in 100μm thick polyethylene film with integrated vapor corrosion inhibitors (VCI), creating a molecular barrier against chloride ions and sulfur compounds prevalent in marine atmospheres. This primary wrap is heat-sealed under vacuum to eliminate trapped ambient humidity. Second, the coil assembly is encased in metallized moisture-barrier film (MBF) with a water vapor transmission rate (WVTR) of ≤0.1 g/m²/24hr at 38°C and 90% RH. Finally, the entire palletized load is hermetically sealed within a secondary polyethylene shroud, incorporating silica gel desiccant packs at a ratio of 1.5 kg per m³ of enclosed volume. Desiccant saturation levels are pre-verified to ISO 9001 standards prior to deployment.

Sea Freight Risk Mitigation Protocol

This packaging architecture directly addresses the primary failure modes in ocean transport: container rain (condensation from temperature cycling), salt aerosol penetration, and hygroscopic salt deposition. The VCI-PE layer actively neutralizes corrosive ions at the strip surface, while the MBF layer blocks external humidity ingress even during prolonged exposure to 100% RH conditions. Pallets are secured within containers using steel strapping rated for 5,000 kg break strength, with void spaces filled using edge protectors to prevent lateral shifting. All shipments include humidity indicator cards (HICs) calibrated to 40% and 60% RH thresholds, providing visual verification of internal conditions upon destination unloading.

Independent third-party testing confirms this system maintains coil surface integrity for 90+ days at 35°C and 85% RH, exceeding IMDG Code Appendix 3 requirements for non-ferrous metal products. By eliminating moisture-induced oxidation and nickel layer degradation, our packaging reduces field rejection rates by 78% compared to standard industrial wraps, as validated across 12,000+ TEU shipments since 2015. This technical approach ensures your nickel plated copper strip arrives with guaranteed dimensional stability and solderability, preserving the metallurgical performance essential for high-efficiency transformer cores.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium Nickel Plated Copper Strip Solutions

With over two decades of specialized expertise in the production of transformer-grade aluminum and copper strips, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the global supply of high-performance conductive materials. Our advanced manufacturing capabilities and rigorous quality control systems position us as an ideal partner for sourcing nickel plated copper strip, a critical component in power transformers, busbars, and high-efficiency electrical systems.

Our production facility integrates state-of-the-art rolling, annealing, and plating technologies to ensure consistent dimensional accuracy, superior surface finish, and optimal electrical conductivity. The nickel plating process is precisely controlled to achieve uniform coating thickness, typically ranging from 1.0 to 3.0 μm, depending on application requirements. This plating enhances corrosion resistance, improves solderability, and ensures long-term reliability in demanding operational environments. Each batch of nickel plated copper strip undergoes comprehensive metallurgical and electrical testing, including adhesion strength, microhardness, resistivity, and surface roughness evaluation, to meet international standards such as ASTM B152, IEC 60183, and GB/T 11091.

Our factory operates under a fully integrated production model, from raw material selection to final packaging, enabling tight control over cost, lead time, and quality consistency. We utilize high-purity electrolytic tough pitch (ETP) copper (Cu ≥ 99.90%) as the base material, ensuring minimal impurities and excellent conductivity. The continuous nickel electroplating line is equipped with real-time monitoring systems to maintain plating uniformity and adhesion integrity across the entire strip length. Our in-house R&D team continuously optimizes process parameters to meet evolving customer specifications, including customized temper (soft, half-hard, or full-hard), thickness tolerance (±0.01 mm), and width precision (±0.1 mm).

Luoyang Xinzhaohe maintains a robust quality management system certified to ISO 9001:2015, with full traceability from coil to shipment. Every production lot is documented with material test reports (MTRs), ensuring compliance with project-specific requirements. Our facility has an annual production capacity exceeding 15,000 metric tons for copper-based products, supported by automated warehousing and global logistics partnerships for reliable on-time delivery.

We serve a diverse client base across Asia, Europe, and North America, supplying to OEMs, transformer manufacturers, and electrical component fabricators who demand precision, consistency, and technical support. Our engineering team provides application-specific guidance, including strip selection, handling recommendations, and compatibility assessments for integration into high-current systems.

For sourcing nickel plated copper strip that meets the highest industrial standards, partner with Luoyang Xinzhaohe Aluminum Co., Ltd. Contact us today at cathy@transformerstrip.com to discuss your technical requirements, request samples, or obtain a competitive quotation.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing nickel plated copper strip directly from China.