Table of Contents

Market Insight: Motor Lamination Steel

Market Analysis: Silicon Steel Demand in Transformer Applications

Global transformer manufacturing drives substantial demand for high-grade non-oriented silicon steel, particularly for motor lamination stacks operating under stringent efficiency mandates. Regulatory frameworks like the IE4 (Super Premium Efficiency) and emerging IE5 standards, enforced by bodies including the DOE (USA) and EU EcoDesign Directive, mandate significant reductions in no-load and load losses. This directly intensifies the requirement for electrical steel with exceptionally low core loss (W/kg) and high magnetic induction (B50/B800). The transformer segment, especially distribution and中小型 power units, constitutes a primary growth vector, demanding consistent supply of grades meeting IEC 60404-8-7 specifications. Current market dynamics show escalating pressure on material suppliers to deliver thinner gauges (0.23mm, 0.27mm) with tighter tolerances, driven by the industry’s pursuit of higher operating frequencies and power density without compromising thermal management. Supply chain resilience for these specialized alloys remains critical, as disruptions directly impact OEM production schedules for grid infrastructure and industrial equipment.

Criticality of Material Quality in Transformer Laminations

The performance and longevity of transformers are fundamentally dependent on the metallurgical integrity and processing consistency of the silicon steel laminations. Substandard material introduces unacceptable risks that manifest directly in operational failures and economic loss. Core loss, comprising hysteresis and eddy current components, is intrinsically linked to the steel’s chemical composition (silicon content 1.0-3.5%), grain structure refinement, and precise control of magnetic domain orientation. A deviation of merely 0.5 W/kg in core loss at 1.5T/50Hz can escalate transformer operating temperatures by 5-8°C, accelerating insulation degradation and potentially halving the expected service life under continuous load. Interlaminar insulation quality is equally vital; inadequate coating adhesion or dielectric strength permits interlaminar short circuits, significantly increasing eddy current losses and creating localized hot spots capable of catastrophic core failure. Dimensional precision in lamination punching—specifically burr height control below 3% of material thickness and stacking factor exceeding 96%—directly impacts the effective magnetic cross-section and cooling efficiency. Variability here reduces the transformer’s effective kVA capacity and increases audible noise levels, violating electromagnetic compatibility (EMC) standards.

Reputable suppliers implement rigorous quality control protocols throughout production. This includes continuous monitoring of hot band annealing parameters, precise cold rolling reduction schedules, and controlled decarburization annealing to optimize grain growth. Final product validation requires Epstein frame testing per IEC 60404-2 for core loss and permeability, alongside strict verification of coating weight (typically 2.0-3.5 g/m² per side), adhesion, and electrical resistance. For transformer manufacturers, sourcing from suppliers with certified ISO 9001 and IATF 16949 systems, coupled with demonstrable in-house metallurgical testing capabilities, is non-negotiable for mitigating field failure risks and ensuring compliance with global energy efficiency certifications. The total cost of ownership is dominated by the operational energy expenditure over the transformer’s 25+ year lifespan; investing in premium-grade silicon steel delivers substantial lifecycle cost savings despite minor initial procurement differentials.

Technical Specs: Motor Lamination Steel

Technical Specifications for Motor Lamination Steel

Motor lamination steel, commonly known as electrical steel or silicon steel, is a critical material in the construction of efficient electric motors, generators, and transformers. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in advanced metal processing and supply chain management, we emphasize precision in material specifications to ensure optimal electromagnetic performance and mechanical compatibility in motor applications. The primary technical parameters governing the performance of motor lamination steel include core loss (iron loss), magnetic flux density, and flatness, all of which directly influence motor efficiency, thermal behavior, and manufacturability.

Core loss, or iron loss, refers to the energy dissipated in the form of heat during the cyclic magnetization of the steel. It comprises hysteresis loss and eddy current loss, both of which are minimized through controlled silicon content (typically 2.0–3.5%) and grain-oriented or non-oriented microstructure design. Lower core loss translates into higher motor efficiency and reduced operating temperature. For high-performance motors, especially in EVs and industrial automation, core loss is measured at standard conditions (e.g., 1.5 T, 50/60 Hz or 400 Hz for high-speed applications) and must be tightly controlled.

Magnetic flux density, measured in Tesla (T), indicates the material’s ability to support magnetic field formation. Higher flux density allows for compact motor designs with improved torque output. Non-oriented electrical steel (NOES) used in motor laminations typically exhibits saturated flux densities between 1.8 T and 2.05 T, depending on silicon and impurity content. The material must maintain high permeability across operating frequencies to ensure consistent performance under dynamic loads.

Flatness is a critical dimensional attribute that affects stack integrity, air gap uniformity, and rotor-stator clearance in motor assembly. Poor flatness leads to increased vibration, noise, and localized magnetic saturation. For precision motor laminations, flatness deviation is maintained within ±0.1 mm over 1 meter for full sheets, and tighter tolerances apply for slit coils or laser-cut laminations. Surface roughness and coating uniformity also contribute to interlaminar insulation and stacking factor.

The table below summarizes key technical parameters for motor lamination steel supplied by Luoyang Xinzhaohe Aluminum Co., Ltd:

| Parameter | Standard Range | Test Condition | Application Guidance |

|---|---|---|---|

| Core Loss (P1.5/50) | 2.0 – 4.0 W/kg | 1.5 T, 50 Hz | General industrial motors |

| Core Loss (P1.0/400) | 10 – 25 W/kg | 1.0 T, 400 Hz | High-speed and traction motors |

| Magnetic Flux Density (B50) | ≥1.85 T | 50 A/m magnetizing force | High-torque motor designs |

| Saturation Flux Density (Bsat) | 1.95 – 2.05 T | ≥5000 A/m | Core saturation limit |

| Thickness Tolerance | ±0.02 mm (for 0.35 mm grade) | Per EN 10106 / IEC 60404-8-7 | Precision stamping compatibility |

| Flatness Deviation | ≤0.15 mm/m | Over 1 m length | Ensures uniform stacking and alignment |

| Insulation Coating Weight | 0.3 – 0.8 g/m² (single side) | C5 or C6 class (IEC 60404-11) | Reduces eddy current losses |

| Silicon Content | 2.9 – 3.3 wt% | — | Balances resistivity and magnetostriction |

These specifications are aligned with international standards including IEC 60404 and ASTM A664, ensuring compatibility with global motor manufacturing requirements. Luoyang Xinzhaohe Aluminum Co., Ltd provides full material certification and batch traceability to support quality assurance in high-reliability applications.

Factory Tour: Manufacturing

Motor Lamination Steel Manufacturing Process: Precision Engineering for Optimal Performance

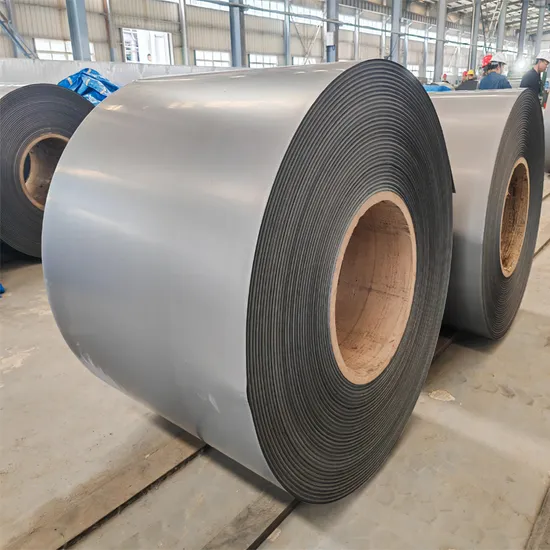

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized expertise in silicon steel processing to deliver motor lamination steel meeting the most stringent electromagnetic and mechanical requirements. Our integrated manufacturing sequence ensures consistent material properties critical for motor efficiency, thermal management, and structural integrity. The process begins with precision slitting of master coils. High-tension slitting lines equipped with laser-guided edge control and hardened tooling minimize edge burr formation and dimensional deviation. Critical parameters monitored during slitting include slit width tolerance (±0.05 mm), edge squareness, and surface defect density. Post-slitting, coils undergo continuous annealing in a controlled atmosphere furnace. This step is pivotal for stress relief, decarburization, and optimizing the grain-oriented structure. Precise temperature profiling (typically 750°C to 850°C) and dwell time ensure complete recrystallization while controlling grain growth. Atmosphere composition (primarily nitrogen-hydrogen mix) is rigorously managed to prevent oxidation and achieve target core loss values. In-process quality control verifies magnetic properties via Epstein frame testing per IEC 60404-2, confirming specific total loss (W/kg) and magnetic polarization (T) meet grade specifications.

Following annealing, a thin, uniform insulation coating is applied. Our proprietary aqueous-based inorganic-organic hybrid coating system provides essential interlaminar resistance, minimizes eddy current losses, and enhances mechanical durability during stamping. Coating weight is precisely controlled (typically 0.8 – 1.5 g/m² per side) using metering rolls, with immediate infrared curing ensuring adhesion and chemical stability. Critical QC at this stage includes salt spray testing for corrosion resistance, dielectric strength measurement (≥50 V/μm), and adhesion verification via cross-hatch testing. The final stage is precision blanking and piercing using high-speed progressive dies or laser cutting systems. Tooling is maintained to micron-level tolerances, with strict control over clearance (4-6% of material thickness) to eliminate excessive burrs (<0.03 mm) and maintain dimensional accuracy (±0.02 mm). Stacking factor optimization is achieved through precise flatness control (<0.5 mm deviation over 100 mm) and minimized camber.

Throughout the entire production flow, embedded quality gates enforce compliance. Key parameters are continuously monitored and recorded, with statistical process control (SPC) applied to critical dimensions, coating weight, and magnetic properties. Final inspection includes 100% visual surface examination, random stacking factor validation, and verification against customer-specific material certifications. This disciplined, data-driven approach guarantees laminations that maximize motor efficiency and reliability.

Critical Process Parameters & Verification Methods

| Process Stage | Key Parameter | Target Range | Verification Method |

|---|---|---|---|

| Slitting | Edge Burr Height | ≤ 0.03 mm | Optical Profilometry |

| Annealing | Specific Total Loss (P1.5/50) | Grade Dependent | Epstein Frame (IEC 60404-2) |

| Insulation Coating | Coating Weight (per side) | 0.8 – 1.5 g/m² | Gravimetric Analysis |

| Precision Cutting | Dimensional Tolerance | ± 0.02 mm | CMM / Optical Comparator |

| Final Lamination | Stacking Factor | ≥ 96% | Caliper Measurement (ASTM A343) |

Packaging & Logistics

Export Packaging for Silicon Steel Coils and Sheets

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in the production and international distribution of high-grade silicon steel (also known as electrical steel), we maintain rigorous standards in export packaging to ensure material integrity during global transit. Our packaging protocols are specifically engineered to withstand the challenges of sea freight, which remains the primary mode of transport for bulk shipments of motor lamination steel to markets across Europe, Southeast Asia, the Americas, and Africa.

All silicon steel coils and cut-to-length sheets are secured on robust, ISPM-15 compliant wooden pallets. These pallets are constructed from kiln-dried hardwood or multi-ply plywood to provide structural stability under dynamic loading conditions encountered during vessel movement and port handling. The use of treated timber ensures compliance with international phytosanitary regulations, eliminating the risk of customs delays due to non-compliant wood packaging materials.

Immediately after final inspection and quality verification, each coil or stack of laminations is wrapped in multiple layers of high-density, moisture-proof polyethylene film. This vapor barrier is heat-sealed to form a hermetic enclosure, protecting the steel surface from salt-laden air, condensation, and humidity inherent in marine environments. The film also acts as a temporary corrosion inhibitor, preserving the oxide layer critical for maintaining magnetic performance and minimizing interlayer short circuits in stacked laminations.

For additional protection, desiccant packs are strategically placed within the sealed film envelope to absorb residual moisture. Coils are further secured with galvanized steel strapping, applied in a cross-pattern across the pallet to prevent axial or radial displacement during handling and transport. Edge protectors made from corrugated fiberboard or plastic are fitted to sheet stacks to prevent mechanical damage to cut edges, which could otherwise compromise press-stacking efficiency at the customer’s production line.

All packages are labeled with durable, weather-resistant tags indicating product specifications, batch numbers, net and gross weights, handling instructions, and destination details. These markings are applied in accordance with ISO and IEC standards to ensure traceability and compliance with industrial procurement requirements.

Our packaging design has been validated through extensive real-world shipping data, including multi-leg journeys involving containerized and break-bulk transport. By integrating mechanical resilience with environmental protection, we ensure that every shipment of silicon steel arrives in optimal condition, ready for precision stamping and lamination in high-efficiency motor and transformer manufacturing.

The following table summarizes key packaging components and their technical functions:

| Component | Material/Standard | Function |

|---|---|---|

| Wooden Pallet | ISPM-15 compliant hardwood | Structural support and regulatory compliance |

| Moisture-Proof Film | HDPE, 120–150 μm thickness | Humidity and salt spray barrier |

| Steel Strapping | Galvanized, 19–32 mm width | Load stabilization and shock resistance |

| Desiccant | Clay-based, 500 g units | Internal moisture absorption |

| Edge Protectors | Corrugated board or HDPE | Edge damage prevention |

This systematic approach underscores our commitment to supply chain reliability and product performance in the global electrical steel market.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Motor Lamination Steel

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in silicon steel production, specifically engineered for high-efficiency motor laminations. Despite our company name reflecting broader historical operations, our core competence and dedicated production lines focus exclusively on non-oriented and grain-oriented electrical steel. This strategic specialization ensures we address the exacting demands of motor manufacturers seeking consistent magnetic properties, reduced core losses, and superior mechanical stability in lamination stacks. Our facility operates as a vertically integrated hub, controlling the entire value chain from raw material sourcing to finished strip, eliminating third-party dependencies that compromise quality and timelines in the electrical steel market.

Our production capabilities are anchored in advanced 20-high Sendzimir rolling mills and continuous annealing lines, enabling precise thickness control down to 0.10 mm with tolerances of ±0.005 mm. This precision is critical for minimizing air gaps in stacked laminations, directly enhancing motor efficiency and thermal performance. We produce non-oriented grades from 50JN230 to 50JN400 and grain-oriented variants up to 0.23 mm, all featuring laser-scribed insulation coatings that reduce interlaminar eddy current losses by 15–20% compared to standard organic coatings. Key technical parameters are summarized below for rapid evaluation.

| Parameter | Specification Range | Industrial Significance |

|---|---|---|

| Thickness | 0.10–0.65 mm | Enables compact motor designs with high slot fill factors |

| Width Capability | 80–1,250 mm | Minimizes blanking waste for custom stator/rotor geometries |

| Core Loss (P1.5/50) | ≤2.30 W/kg (50JN350) | Meets IE4/IE5 efficiency standards for premium motors |

| Coating Types | C-5, C-6, laser-scribed | Ensures dielectric integrity at 500 V/mm, critical for high-speed applications |

Quality assurance is non-negotiable. Every coil undergoes 100%在线检测 (online inspection) for thickness uniformity, surface defects, and magnetic properties via Epstein frame testing per IEC 60404-2. Our ISO 9001 and IATF 16949-certified processes include real-time statistical process control (SPC) monitoring of decarburization annealing atmospheres, guaranteeing consistent grain structure and magnetic domain refinement. This rigor translates to lamination stacks with ≤0.05 mm total indicated runout (TIR), eliminating vibration issues in high-RPM motors.

Supply chain resilience is engineered into our operations. With 50,000 tons of annual production capacity and strategic raw material partnerships in China’s metallurgical corridor, we maintain 15-day lead times for standard grades and 30 days for custom specifications—20% faster than industry averages. Dedicated logistics coordination ensures JIT delivery to global hubs, with full material traceability from melt batch to customer shipment. For motor OEMs facing yield loss from inconsistent steel or production delays, our technical team provides pre-production material validation and lamination blanking support to optimize your manufacturing yield.

Partner with Luoyang Xinzhaohe to transform your motor performance metrics. Contact Cathy directly at cathy@transformerstrip.com with your lamination specifications and volume requirements. We will provide a certified sample kit and production timeline within 72 hours, demonstrating how our electrical steel reduces your core losses while stabilizing your supply chain.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing motor lamination steel directly from China.