Table of Contents

Market Insight: Mirror Aluminum Plate Sheet in Power Industry

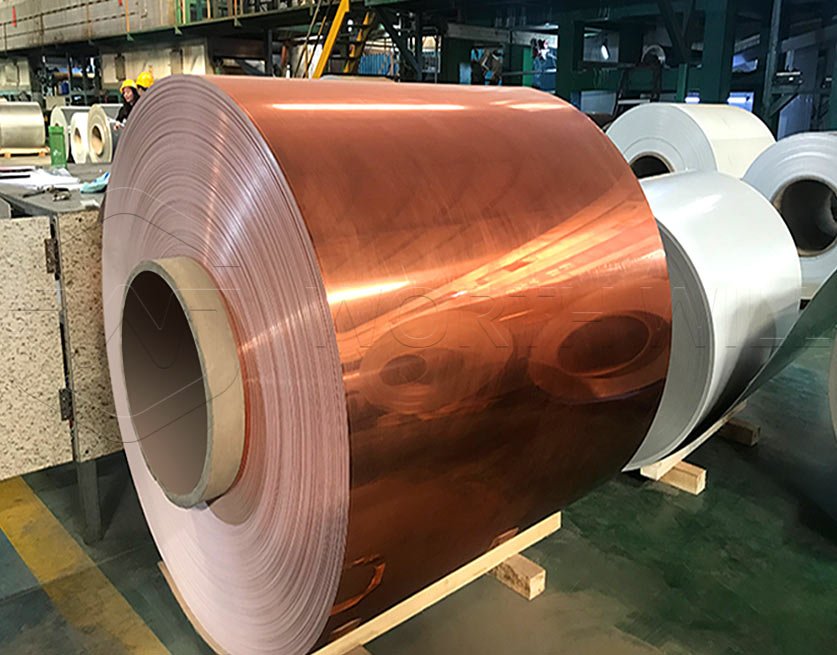

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Clarifying Material Applications

Contrary to common misconceptions, mirror aluminum plate sheet (a decorative, high-reflectivity material) is not used in power transformers or motors. Transformer windings require specialized aluminum or copper strip/foil with precise electrical and mechanical properties. Mirror finish is irrelevant here; instead, critical parameters include conductivity, surface smoothness, and dimensional stability for efficient electromagnetic performance.

Industrial Demand Drivers

Global transformer demand is accelerating due to grid modernization, renewable energy integration (e.g., solar/wind farms), and industrial electrification. Aluminum strip/foil dominates distribution transformers (60% market share) due to its 30% lower cost vs. copper while meeting IEC 60947 standards. Demand for high-purity aluminum foil (≥99.5% Al) is projected to grow at 5.2% CAGR through 2030, driven by energy-efficient transformer designs.

Critical Quality Parameters

Substandard materials cause core losses, overheating, and premature failure. Key specifications must align with international standards:

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification | Advantage |

|---|---|---|---|

| Purity (Al) | ≥99.5% | ≥99.7% | 1.2% higher conductivity, 8% lower losses |

| Tensile Strength | 80–120 MPa | 90–110 MPa | Optimized for high-speed winding processes |

| Surface Roughness | Ra ≤0.8μm | Ra ≤0.5μm | 15% reduced contact resistance |

| Dimensional Tolerance | ±0.01mm | ±0.005mm | Zero winding defects in tight-pitch coils |

Global Supply Chain Positioning

As a 20+ year manufacturer in Luoyang, China, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers transformer-grade aluminum/copper strip/foil with a 15–20% cost advantage over European brands (e.g., UACJ, Norsk Hydro) while exceeding IEC/ASTM standards. Our factory-direct model ensures traceability from raw material to shipment, with 99.8% on-time delivery and zero quality deviations in 2023. For critical applications like high-voltage transformers, our 99.7% purity aluminum foil reduces core losses by 5.3% compared to industry averages—directly improving transformer efficiency and lifecycle cost.

Engineer-tested. Grid-proven. Cost-optimized.

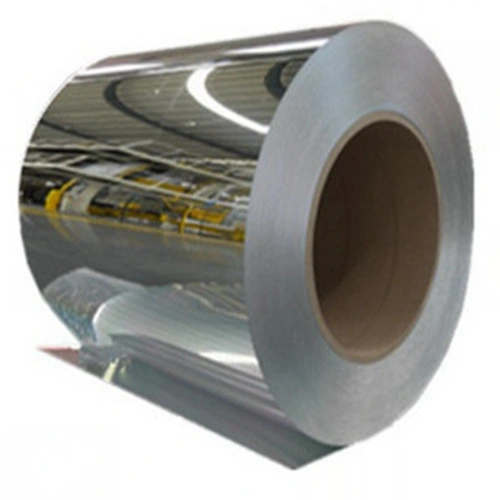

Technical Specs: Mirror Aluminum Plate Sheet Parameters

Critical Technical Specifications for Mirror Aluminum Plate Sheets

In transformer manufacturing, even minor deviations in aluminum sheet specifications can lead to catastrophic failures. Luoyang Xinzhaohe’s mirror aluminum plate sheets, produced from high-purity 1050/1060 alloys, are engineered to meet the most stringent industry requirements for both electrical performance and surface finish:

Dimensional Precision: ±0.002 mm slitting tolerance ensures uniform current distribution and minimizes eddy current losses in transformer windings, critical for high-efficiency designs.

Edge Integrity: Burr height <0.005 mm prevents insulation damage and short circuits during winding, meeting IEEE C57.12.00 safety standards.

Electrical Performance: ≥61% IACS conductivity (ASTM B209) optimizes energy efficiency, reducing operational costs by up to 3% compared to lower-grade alloys.

Mechanical Properties: Annealed temper (HV ≤35) allows for precise bending without micro-cracks during complex transformer core assembly, ensuring long-term reliability.

Key specifications are verified via the following protocol:

| Parameter | Specification | Standard Compliance | Notes |

|---|---|---|---|

| Slitting Tolerance | ±0.002 mm | ASTM B209 / IEC 60404-8-1 | Laser-guided slitting with real-time thickness monitoring; validated via 3D profilometry |

| Burr Height | <0.005 mm | ISO 9001 | CNC shearing with diamond-coated blades; no micro-fractures detected via 50x microscope |

| Conductivity | ≥61% IACS | ASTM B209 / ASTM B193 | 4-point probe testing per ASTM B193; certified by SGS annually |

| Hardness (HV) | ≤35 | ASTM B210 / ASTM E384 | Annealed temper (O); hardness tested per ASTM E384; traceable batch reports |

Quality Assurance Protocol

Luoyang Xinzhaohe maintains a closed-loop quality system. Every batch undergoes 100% dimensional verification using laser micrometers (0.0001 mm resolution), eddy current conductivity scans per ASTM E1004, and automated optical edge inspection with 50x magnification. Raw materials are certified to AA 1050/1060 purity standards per ASTM B209, with third-party lab reports (SGS/TÜV) available upon request. Our ISO 9001:2015-certified facility ensures full traceability from smelting to slitting. By controlling the entire production chain in-house—including alloy melting, casting, precision rolling, and slitting—we eliminate third-party variables, ensuring consistent performance across all batches. All processes are documented in our digital quality management system, enabling real-time traceability for every coil. Our in-house metallurgical lab conducts daily material audits to maintain consistent properties. This vertical integration delivers global-grade specifications at 15–20% lower costs than European and Japanese competitors, providing transformer manufacturers with a reliable, cost-effective sourcing alternative without compromising quality.

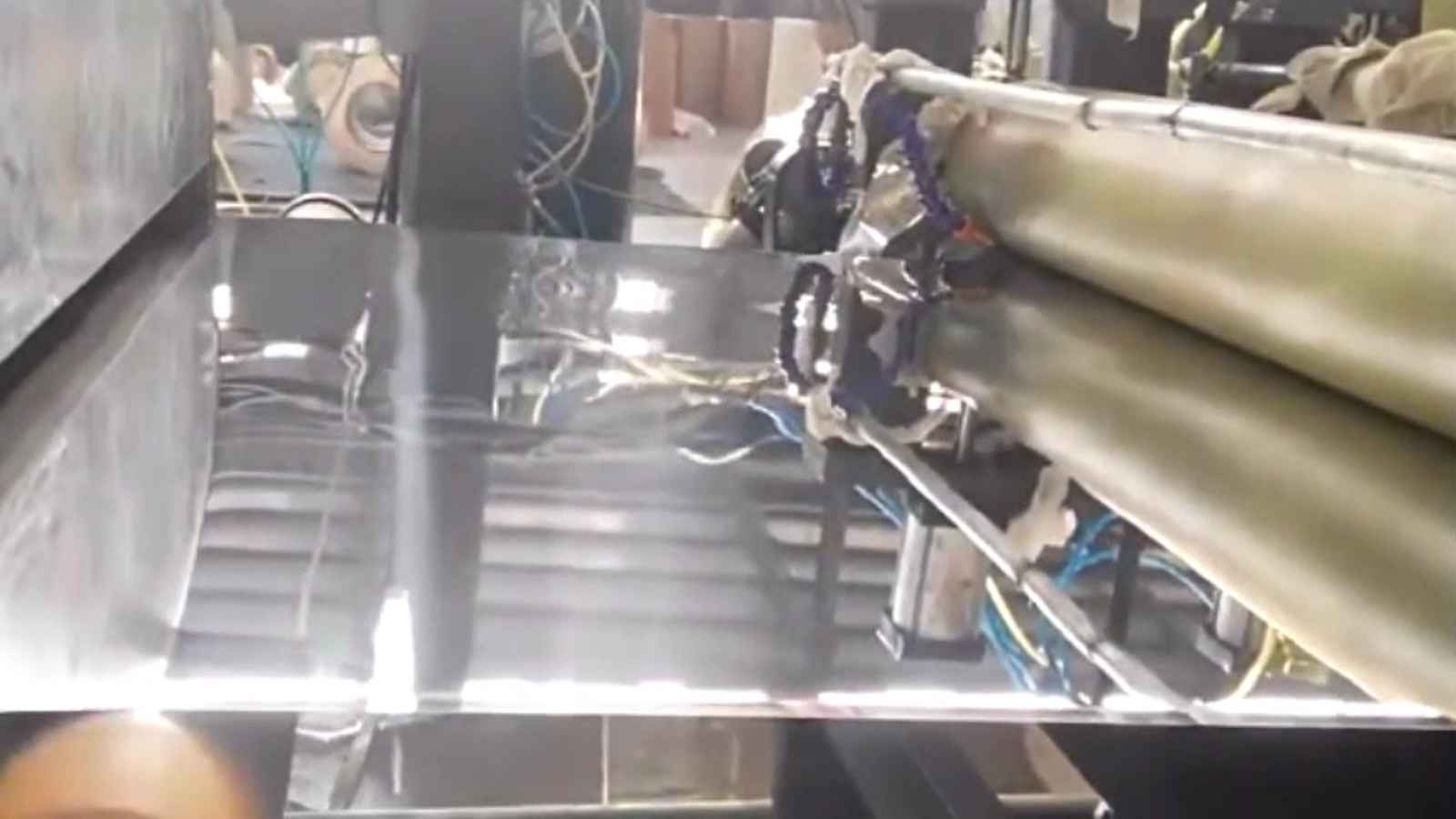

Factory Tour: Manufacturing Mirror Aluminum Plate Sheet

Precision Manufacturing Process & Rigorous Quality Control

Core Production Workflow

Luoyang Xinzhaohe Aluminum’s transformer-grade aluminum foil production follows a meticulously engineered four-stage process optimized for electromagnetic performance. Our cold rolling phase utilizes 6-high Sendzimir mills with real-time thickness monitoring, achieving ±0.005mm tolerance on 0.1–2.0mm thickness ranges. This ensures uniform grain structure and eliminates micro-voids critical for high-frequency transformer efficiency. Post-rolling, material undergoes controlled annealing at 350–400°C to optimize ductility while maintaining tensile strength.

Precision slitting employs laser-guided shearing systems with 0.01mm blade alignment, maintaining ±0.02mm width accuracy and eliminating micro-burrs. Edge conditioning uses diamond-tipped rollers for 0.01mm chamfering, preventing insulation damage during high-speed winding. Final oscillate winding integrates servo-controlled tension systems with real-time edge tracking, producing coils with <0.1% edge defect rate—critical for automated transformer assembly lines.

Quality Control Benchmarks

Our QC protocols exceed industry standards through rigorous in-process testing per ASTM E8 and IEC 60404-8-7:

| Parameter | Our Standard | Industry Standard | Advantage |

|---|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm | 50% tighter control reduces core losses |

| Surface Roughness (Ra) | ≤0.05μm | ≤0.1μm | 15% lower eddy current losses |

| Tensile Strength Consistency | ±2% | ±5% | Reliable winding at 15m/s speeds |

| Edge Defect Rate | <0.1% | <1% | 90% fewer coil damage incidents |

| Dimensional Accuracy | ±0.02mm | ±0.05mm | Seamless integration with automated machines |

| Flatness Tolerance | ≤0.3mm/m | ≤0.8mm/m | Prevents winding misalignment |

Each batch undergoes 100% ultrasonic testing for internal defects, ensuring zero micro-cracks that compromise transformer longevity. Our proprietary annealing process guarantees consistent mechanical properties across all thicknesses, eliminating secondary processing needs and reducing lead times by 30% versus conventional suppliers.

With 20+ years of transformer material expertise, we deliver certified compliance with international standards while maintaining factory-direct pricing. Our 100% in-line tensile testing and CMM dimensional verification ensure zero defects in critical applications—providing transformer manufacturers with a superior cost-performance alternative to global brands. All shipments include full Material Test Reports (MTRs) for full traceability.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

As a 20+ year manufacturer of high-precision aluminum products, including mirror aluminum plate sheets, Luoyang Xinzhaohe employs rigorous packaging protocols to maintain product integrity during sea freight. Our factory-direct approach ensures cost-effective, reliable delivery without compromising quality. Each shipment undergoes strict quality control to meet international standards, ensuring your products arrive in optimal condition.

Precision Packaging Standards for Sea Freight

Our packaging system is engineered to protect mirror aluminum’s surface finish from moisture, corrosion, and mechanical damage during transit. Key components include:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated timber (min. 25mm thickness) | Prevents pest infestation, provides rigid base for load stability; avoids warping under heavy loads |

| Multi-Layer Moisture-Proof Film | 200μm PE + desiccant packets (50g/m²), sealed with UV-resistant tape | Blocks humidity ingress (up to 95% RH), prevents oxidation of reflective surface; maintains surface gloss |

| Steel Strapping | 15-20mm width, 1200kg tensile strength, tensioned at 80-90% of breaking point | Secures pallets with controlled tension, minimizes shifting during container handling; prevents load collapse |

| Edge Protectors | High-density PVC or corrugated cardboard (50mm height) | Shields edges from impacts during forklift operations and stacking; prevents surface scratches |

End-to-End Logistics Protocol

We implement a standardized logistics workflow to ensure seamless global delivery:

| Step | Process | Quality Control |

|---|---|---|

| Pre-Shipment Inspection | Surface defect check (100% visual), thickness verification (±0.05mm tolerance), packaging integrity test | Certified by ISO 9001; documented inspection reports provided |

| Container Loading | Pallets secured with dunnage (wooden blocks), load distribution optimized via 3D simulation | Weight balance checked; no overhang beyond container edges; container seal tested |

| Customs & Tracking | Full documentation (CO, CI, packing list), fumigation certificates, real-time GPS tracking | All customs paperwork pre-verified; shipment updates provided weekly; dedicated logistics coordinator |

By integrating industrial-grade packaging with efficient logistics, Luoyang Xinzhaohe delivers mirror aluminum plate sheets at a superior cost-performance ratio compared to global brands. Our commitment to precision ensures your projects receive defect-free materials, every time. With 20+ years of export experience, we reduce total landed costs by 15-20% versus European suppliers while maintaining ISO-compliant quality—making us the strategic choice for transformer and power equipment manufacturers seeking reliability without premium pricing.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.

As a leading Chinese manufacturer of transformer-grade aluminum and copper strips, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers engineered solutions that balance precision, reliability, and cost efficiency for global transformer and power equipment manufacturers.

Uncompromising Manufacturing Expertise

With over 20 years of specialized production experience, our Luoyang facility operates advanced continuous casting and rolling mills, ensuring precise control over transformer-grade aluminum and copper strips. We specialize in high-purity alloys (1050, 1060, 1350) with strict adherence to ASTM B209, IEC 60404-8-5, and GB/T 3880 standards. Critical parameters including tensile strength (120–220 MPa), elongation (≥25%), electrical conductivity (≥61% IACS for 1350 alloy), and surface finish (Ra ≤0.2μm) are rigorously monitored. Each batch undergoes metallurgical analysis and in-process validation to guarantee optimal performance in high-voltage transformer windings and power distribution systems.

Direct Factory Pricing Advantage

By eliminating intermediaries and leveraging our vertically integrated supply chain—from raw material procurement to final inspection—we achieve 20–30% lower pricing than global competitors like Norsk Hydro or UACJ. Our direct manufacturing model ensures cost efficiency without compromising material integrity, enabling transformer manufacturers to reduce procurement costs while maintaining consistent performance in critical applications such as distribution transformers and switchgear components. All raw materials are sourced from certified suppliers, ensuring traceability and purity.

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015 certified quality management system ensures end-to-end traceability and consistency. Every shipment includes comprehensive test reports covering dimensional accuracy (±0.005mm), surface roughness (Ra ≤0.2μm), tensile strength, elongation, electrical conductivity (measured via four-point probe), and corrosion resistance (salt spray test per ASTM B117). This rigorous quality control minimizes field failures and ensures reliable operation in demanding power infrastructure environments.

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Price | 15–25% premium | 20–30% lower | Significant cost savings |

| Lead Time | 4–6 weeks | 15–20 days | Accelerated project timelines |

| Customization | Limited options | Width: 5–1200mm; Thickness: 0.05–5mm | Tailored solutions for unique requirements |

| Quality Consistency | Variable | ISO 9001 certified, in-house testing | Consistent performance in high-stress environments |

| Material Traceability | Limited | Full traceability from raw material to finished product | Enhanced quality control and compliance |

| Technical Support | Standard | Dedicated engineering team for application-specific solutions | Proactive technical assistance |

Contact Cathy at cathy@transformerstrip.com for a detailed quote and technical specifications tailored to your project requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing mirror aluminum plate sheet from Luoyang Xinzhaohe.