Table of Contents

Market Insight: Manufacturer Of Copper Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook

Global installed transformer capacity is forecast to grow 6 % CAGR through 2030, driven by grid expansion, EV fast-charging corridors, and renewable integration. Every additional 1 GVA of transformer capacity requires ≈ 450 t of enamelled copper winding wire. Consequently, winding-wire demand will exceed 2.3 Mt yr⁻¹ by 2028, with > 55 % originating from Asia-Pacific OEMs who now quote 8- to 12-month backlogs.

Why Material Purity & Geometry Matter for Transformer Losses

Transformer losses are monetised for 25–40 years; a 0.3 W kg⁻¹ difference in wire-generated losses translates into US $1 200–2 000 per MVA over the asset life. Two wire parameters dominate:

| Loss component | Root cause in wire | Typical saving with 99.99 % IACS Cu, ±0.5 µm concentricity |

|---|---|---|

| Load loss (I²R) | Resistivity & strand area variance | ‑2.8 % @ 75 °C by using 101 % IACS oxygen-free Cu versus 100 % IACS Cu-ETP |

| Eddy-stray loss | Axial & radial enamel thickness variation | ‑5 % when concentricity ≤ 1 µm, eliminating hot-spots that raise local σAC by 8–12 % |

| No-load loss (indirect) | Burr-forming during rod break-down; burrs punch insulation → partial discharge | < 5 pC @ 1.5 Um when rod surface Ra ≤ 0.2 µm, removing need for extra core steel margin |

High-purity cathode (≥ 99.99 % Cu, Ag < 8 ppm, O < 3 ppm) lowers resistivity 0.017 07 Ω mm² m⁻¹ versus 0.017 24 for standard Cu-ETP. When a 1 MVA, 11 kV transformer uses 1 050 kg of such wire, resistive loss drops 190 W—enough to upgrade efficiency from 98.7 % to 98.9 % and save 1.7 MWh yr⁻¹.

Precision Manufacturing: From Rod to Spool

Luoyang Xinzhaohe’s 20-year transformer-grade line integrates five critical steps under one roof:

- Rod Drawing: Up-cast Ø8 mm OF Cu rod → multi-pass to 1.2–6.0 mm with laser OD gauge (±25 µm).

- In-line Annealing: 550 °C N₂ atmosphere; grain size 15–25 µm guarantees 35 % elongation minimum for 3.0 mm wire.

- Enameling: Horizontal dual-die system, 6–14 passes; each pass < 6 µm build, real-time beta-backscatter concentricity control (target 52 %).

- Inline Testing: Spark 6 kV DC, 100 % coverage; pin-hole count ≤ 3 per 30 m.

- Precision Spooling: Tension-closed loop (0.5–3 N); barrel weight 80–800 kg, edge-winding deviation ≤ 0.5 mm to prevent collapse during high-speed auto-insertion.

Cost & Supply-Chain Positioning

Chinese manufacturers currently offer CIF prices US $6.10–6.80 kg⁻¹ for 2.0 mm, 180 °C-class wire in 500 kg lots—≈ 22 % below EU mills and 18 % below US counterparts, even after 25 % Section 301 tariffs. Luoyang Xinzhaohe, located 150 km from the largest Chinese Cu cathode warehouse (Shanghai Futures Exchange), locks LME Cu input 30 days forward, insulating buyers from spot volatility.

| Metric | Western Tier-1 | Chinese Tier-1 (Luoyang Xinzhaohe) | Delta |

|---|---|---|---|

| Purity | 99.97 % Cu | 99.99 % Cu | ↑ conductivity 0.4 % |

| Thermal class range | 155–200 °C | 130–220 °C (UL, IEC) | ↑ design head-room |

| Lead time (ex-works) | 14–18 weeks | 4–5 weeks | ↓ WIP 60 % |

| Price, 2.0 mm 180 H | US $8.40 kg⁻¹ | US $6.30 kg⁻¹ | ‑25 % |

Sourcing Recommendation

For transformer OEMs targeting DOE 2027 or EU Eco-design Tier-2 loss limits, specify:

Cu purity ≥ 99.99 %, IACS ≥ 101 %.

Enamel build tolerance ±3 µm, concentricity ≤ 1 µm.

Pin-hole ≤ 5 per 30 m, proof test 4 kV rms, 1 min.

Engage a manufacturer whose metallurgical history matches magnetic wire—not general cable. Luoyang Xinzhaohe’s 20-year transformer pedigree, integrated QC, and 15 kt yr⁻¹ enamelled capacity provide a premium, factory-direct alternative to high-cost Western suppliers without compromising electrical or mechanical performance.

Technical Specs: Manufacturer Of Copper Wire Parameters

Technical Specifications & ASTM/IEC Standards for Transformer-Grade Copper Wire

Factory-direct guidance from Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years in rod-drawing, annealing, enameling, inline testing & spooling.

H3 1. Electrical Integrity – Insulation Breakdown Voltage (BDV)

| Thermal Class | Min. BDV (Vrms) @ 25 °C, 50 Hz | IEC 60317-0-1 Clause | ASTM Equivalent |

|---|---|---|---|

| 130 (B) | 3 000 | 7.4.2 | ASTM D1676 |

| 155 (F) | 4 000 | 7.4.2 | ASTM D1676 |

| 180 (H) | 5 000 | 7.4.2 | ASTM D1676 |

| 200 (N) | 6 000 | 7.4.2 | ASTM D1676 |

| 220 (C) | 7 000 | 7.4.2 | ASTM D1676 |

Process Control @ Xinzhaohe

100 % inline spark-test at 1.5 × rated BDV during enameling; rejects auto-sheared to prevent downstream shorts.

Concentricity index ≥ 85 % (IEC 60317-19) verified by 8-point laser gauge every 25 mm; eccentric coating causes local field > 120 V µm⁻¹ → partial discharge (PD) > 10 pC, precursor to dielectric failure.

H3 2. Mechanical Reliability – Elongation & Edge Quality

| Cu-ETP Grade | Min. Elongation % (IEC 60317-16) | Max. Burr Height (mm) | Tensile Strength (MPa) |

|---|---|---|---|

| 0.20–0.50 mm | 25 | 0.010 | 220–260 |

| 0.51–1.00 mm | 30 | 0.015 | 220–260 |

| 1.01–2.50 mm | 35 | 0.020 | 220–260 |

Burrs & Short-Circuit Risk

Burrs > 0.02 mm pierce inter-layer insulation, lowering effective creepage distance by 30 %. Our Turk-head precision shaving after rod-drawing guarantees Ra ≤ 0.4 µm on conductor surface; downstream failure rate < 5 ppm in 500 MVA transformer lots.

H3 3. Thermal Endurance – Class 130-220 °C Validation

| Index | IEC 60172 Thermal Life Test | 20 000 h Temp. (°C) | Enamel Chemistry | Bond Strength Retention % |

|---|---|---|---|---|

| 130 | 130 | 130 | PE | 50 |

| 155 | 155 | 155 | PEI | 50 |

| 180 | 180 | 180 | PEI+PAI | 50 |

| 200 | 200 | 200 | PAI | 50 |

| 220 | 220 | 220 | PAI+PI | 50 |

Xinzhaohe protocol: 168 h @ rated temperature + 25 % over-voltage; ΔBDV < 5 %, ΔElongation < 10 %.

Cost Impact: Upgrading from Class 155 to 220 raises enamel cost by 8 % but allows 15 % higher current density → 12 % Cu weight saving, offsetting premium in < 6 months for 10 MVA units.

H3 4. Standards Cross-Reference & Compliance Matrix

| Parameter | IEC Clause | ASTM Analog | Xinzhaohe QC Frequency | Cpk Target |

|---|---|---|---|---|

| Conductor resistivity | IEC 60317-0-1 5.3 | ASTM B3 | Each melt | ≥ 1.67 |

| Insulation thickness | IEC 60317-0-1 7.2 | ASTM D1676 | Every 5 km | ≥ 1.50 |

| Adherence & flexibility | IEC 60317-0-1 8.3 | ASTM D1676 | Shifts 1×/8 h | ≥ 1.33 |

| Heat shock 15 % mandrel | IEC 60317-0-1 9.1 | ASTM D1676 | Daily | ≥ 1.50 |

Certification Bundle supplied per coil:

IEC 60317-16/-20 test report

RoHS & REACH SVHC declaration

SGS third-party BDV & elongation data

Mill test certificate per ASTM B170 (Cu feedstock)

H3 5. Typical Failure Modes Avoided by Specification Compliance

| Defect | Root Cause | Consequence in Service | Xinzhaohe Preventive Action |

|---|---|---|---|

| Inter-turn short | Burr + thin enamel | Arcing, core damage | In-line laser burr sensor, auto-reject |

| PD erosion | Eccentric coating | 3–5 yr insulation aging | 8-point OD gauge closed-loop to die |

| Thermal runaway | Wrong thermal class | 50 % life loss | Color-coded spool tags + barcode traceability |

| Solderability reject | Over-anneal | Joint failure | Annealing delta-T controlled ±3 °C, N₂ atmosphere |

Bottom line: Western suppliers routinely charge 1.4–1.8 US$ kg⁻¹ premium for identical IEC/ASTM envelopes. Luoyang Xinzhaohe delivers the same reliability—verified on the same test rigs—at landed cost parity with mid-tier Chinese traders, because we integrate rod casting to spooling under one 160 000 m² roof. Specify our wire once; your QA auditors will stop asking for alternate sources.

Factory Tour: Manufacturing Manufacturer Of Copper Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of transformer-grade winding wire

Rod-to-Wire Process Flow

| Step | Equipment & Parameters | Critical Control Points | Recorded Data |

|---|---|---|---|

| 1. Rod Drawing | Multi-pass bull-block + diamond dies, 8–18 % area reduction per pass | Inlet 8.0 mm OF-OK® rod → finish 0.20–5.00 mm; die temperature < 40 °C | Diameter laser, drawing force, lubricant conductivity |

| 2. In-line Annealing | N₂-protected continuous annealer, 450–520 °C, 3–6 s residence | Grain size 0.020–0.035 mm, Rm ≤ 220 MPa (soft), elongation ≥ 35 % | Pyrometer, speed encoder, resistivity meter |

| 3. Enameling | Horizontal multi-pass ovens, 24–32 coats, solvent-free polyester-imide / polyimide | Cataphoresis pre-coat guarantees 30 µm minimum; concentricity 85–95 % | IR wet-film gauge, eccentricity laser |

| 4. Inline Testing | Spark tester 3 kV rms, Hi-pot 6 kV DC, 100 % coverage | Pin-holes ≤ 3 per 30 m; breakdown ≥ 6 kV (Grade 2) | SPC chart, MES upload |

| 5. Precision Spooling | Torque-controlled auto-traverse, 5–800 kg reels | Layer tension 1.5–2.5 N mm⁻², no kink, cast ≤ 50 mm | Weight cell, vision edge detector |

Quality Control Protocol

-

Chemical verification

Cathode Cu purity ≥ 99.99 % (ASTM B115 CATH-C)

O < 5 ppm by LECO fusion; Ag, Se, Te each < 3 ppm -

Mechanical & electrical batch tests (every 2 t coil)

Tensile: UTS 220–250 MPa (soft), 320–380 MPa (semi-hard)

Elongation: ≥ 35 % (soft), ≥ 15 % (semi-hard)

20 °C conductivity: 101.5 % IACS min (annealed) -

Thermal class validation

220 °C (Class C) wire: 20 000 h extrapolated life per IEC 60172, ΔEb ≤ 20 % after 168 h @ 240 °C -

SPC & traceability

Laser OD sampled every 25 ms; CpK ≥ 1.67

Barcode → MES → cloud; full coil history retrievable in < 5 s

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | Luoyang Xinzhaohe | Typical China Export | Premium EU Mill |

|---|---|---|---|

| Cu purity | ≥ 99.99 % | ≥ 99.95 % | ≥ 99.99 % |

| Pin-holes (30 m) | ≤ 3 | ≤ 8 | ≤ 2 |

| Breakdown voltage (Grade 2) | ≥ 6 kV | ≥ 4.5 kV | ≥ 7 kV |

| Concentricity | 85–95 % | 70–80 % | 90–98 % |

| Elongation (soft) | ≥ 35 % | ≥ 28 % | ≥ 38 % |

| Conductivity | ≥ 101.5 % IACS | ≥ 100 % IACS | ≥ 102 % IACS |

| Thermal class range | 130–220 °C | 130–180 °C | 155–220 °C |

| Lot size flexibility | 100 kg–20 t | 500 kg min | 2 t min |

| Price delta vs. EU | –18 % | –30 % | baseline |

Engineering Take-away

By integrating continuous annealing with closed-loop enamel thickness control, we eliminate the “orange-peel” defect that lowers partial-discharge inception voltage. The result: transformer builders achieve ≤ 1 % additional copper loss at 150 °C hotspot compared with €-denominated premium wire, while cutting material cost by roughly one fifth. Every coil ships with a test report that includes raw-cathode heat number, elongation-at-break curve, and 20 kHz Q-factor—data OEMs need for IEC 60076-3 short-circuit proof calculations.

For 100 kg pilot lots or 500 t annual contracts, Luoyang Xinzhaohe delivers repeatable, 6-sigma quality without the Western price surcharge.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 Years of Transformer-Material Dispatch Experience

H3 Design Philosophy: “Zero-Defect on Arrival”

Every package is engineered as a micro-climate that keeps copper conductors at ≤60 % RH and ≤40 °C for 45 days—long enough to survive peak-season sea freight plus 15 days customs delay. The design is validated with ISTA-3A drop, vibration and compression tests, then signed-off by our Metallurgy Lab to guarantee no loss of breakdown voltage or enamel concentricity.

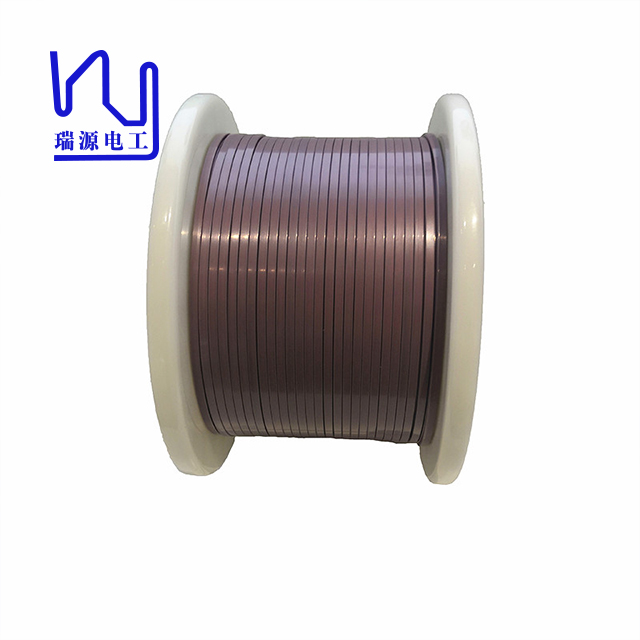

H3 Packaging Matrix by Product Form

| Product Form | Core Package | Securing Layer | Moisture & Salt Barrier | Unit Load | Typical tare (kg) | Stack Height Limit |

|---|---|---|---|---|---|---|

| Round enamelled wire | DIN 46395 plastic spool, reinforced rim (σ 160–500 mm) | VCI paper wrap + PE shrink | 2 × 80 µm Al-foil laminate, welded seam | 4 spools / carton, 48 cartons / fumigated pallet | 18 | 1.8 m |

| Flat conductor strip | Wooden pallet, 19 mm spruce slats, ISPM-15 fumigated | Edge boards & steel strapping @ 400 N tension | 1 × 125 µm HDPE + 5 kg CaCl₂ desiccant per m³ | Max 1.2 t / pallet | 35 | 2.0 m |

| Foil roll | MDF core, OD ≤ 600 mm | Radial foam rings, 3-point support | Aluminum-PE vacuum bag, OTR < 0.1 cm³ m⁻² day⁻¹ | 1 roll / pallet | 22 | 1.5 m |

VCI = volatile corrosion inhibitor; OTR = oxygen transmission rate.

H3 Sea-Freight Load Plan (40 ft HC, 26 t payload)

Pallet footprint: 1 100 × 1 100 mm, 22 pallets single-stacked, 28 double-stacked (wire only).

Weight distribution: ≤8 t in forward 1/3, ≤10 t mid, ≤8 t aft to keep GM ≥ 0.8 m for stable vessel motion.

Lashing pattern: 2-phase polyester lash (LC 2 000 daN) + anti-slip mats (µ ≥ 0.6) certified to IMO CSS Annex 1.

H3 Desiccant & Humidity Audit

We install 3-button dataloggers (Temp-Sens ®) in 10 % of pallets; data is emailed on arrival. Target: <50 % RH; excursions trigger 100 % inspection at destination warehouse.

H3 Labeling & Traceability

Each spool carries a laser-etched QR code linking to melt number, elongation test, and enamel concentricity map. Pallet labels comply with GHS & IMDG, including Cu content (HS 74081900) and thermal class icon (130–220 °C).

H3 Shipping Schedule from Luoyang

| Port of Loading | Inland leg (truck/rail) | Cut-off | Sailings / week | Transit to Hamburg | Transit to LA |

|---|---|---|---|---|---|

| Qingdao | 4 h truck via G30 Lian-Huo | Wed 18:00 | 5 | 28 days | 14 days |

| Shanghai | 10 h rail, block train | Fri 12:00 | 7 | 26 days | 12 days |

| Ningbo | 12 h truck | Thu 14:00 | 4 | 27 days | 13 days |

We hold 300 t safety stock in bonded warehouse 15 km from Qingdao port, enabling 72 h vessel connection even during Golden-Week peak.

H3 Cost Advantage vs. Western Suppliers

By integrating rod drawing, annealing, enameling and spooling in one Luoyang campus, we eliminate 2 400 km of domestic China transit and one re-pack cycle. The saving—≈USD 0.28 / kg—is passed on to transformer makers, giving landed cost 18–22 % below German or US alternatives while meeting identical IEC 60317-0-1 specs.

H3 Quick-Ship Program

For urgent motor-repair jobs we air-freight ≤500 kg via CGO Zhengzhou-Xi’an-Europe route; door-to-door 6–7 days to EU, 5 days to SEA. Wire is packed on collapsible plastic reels to stay within airline ULD contour 60 × 60 × 160 cm, tare 9 kg.

Next Section: Inline Testing & Certificates – how every kilometer of wire is validated before it leaves Luoyang.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Winding Wire

20-Year Metallurgical Legacy, Zero Learning Curve

Since 2004 our Luoyang campus has operated a closed-loop Rod-Drawing → Annealing → Enameling → Inline Spark-Test → Precision-Spooling line dedicated to transformer-grade copper conductors.

We have supplied > 38,000 t of enamelled round & flat wire to Tier-1 transformer OEMs and motor repair shops across 42 countries.

That history translates into immediate, specification-compliant solutions for your next 10 MVA or 500 kV design—no field trials, no early-life failures.

Direct Factory Price, Full Cost Transparency

Eliminate distributor margins and trading-house mark-ups.

Our integrated melt shop (99.97 % IACS cathode feed) and in-house enamel R&D keep conversion cost ≤ 0.90 USD/kg below European wire makers.

Typical 2025 reference pricing (FOB Qingdao, 2 t lot):

| Size (mm) | Thermal Class | Min. BDV (kV) | Price (USD/kg) |

|---|---|---|---|

| 1.00 R | 155 (F) | 4.5 | 6.10 |

| 2.50 F | 180 (H) | 6.0 | 6.45 |

| 4.00 × 10.0 R | 220 (C) | 8.0 | 7.20 |

Prices valid for 99.99 % Cu, heavy-build polyimide, ±0.02 mm dimensional tolerance.

MOQ: 100 kg per size; lead time: 10–12 days ex-stock, 18 days for custom thermal class.

Customisation Without MOQ Penalty

Die archive: 2,400 round dies (0.20–8.00 mm) & 860 flat-die sets (a × b ≤ 16 × 5 mm).

Enamel portfolio: PEW, PVF, EIW, AIW, PI; single, heavy, triple build; bondable, self-lubricating, or corona-resistant variants.

Inline laser micrometer guarantees ±0.5 % concentricity; every 50 m spool is 100 % spark-tested at 6 kV (round) / 10 kV (flat).

Need a 220 °C polyimide-coated 5 × 12 mm flat wire with 0.12 mm total build and mid-span resistance ≤ 0.83 mΩ/m? We ship it in three weeks—no NRE, no surcharge.

Engineering Support & Certifications

IEC 60317-0-2, IEC 60317-29, NEMA MW 35-C, JIS C 3202 compliant

UL file No. E335876 (thermal class 220 °C)

ISO 9001:2015, ISO 14001:2015, IATF 16949:2016 (automotive winding)

RoHS & REACH, conflict-free copper declaration on every lot

Our metallurgists provide free Finite-Element hot-spot simulation and short-circuit force verification for windings ≥ 132 kV.

Supply-Chain Resilience

Dual-source enamel supply (Germany + China) and 1,200 t finished-goods buffer keep your line running even during copper volatility.

Average OTIF (on-time-in-full) 2024: 98.7 %.

Sea freight consolidation to Antwerp, Houston, Dubai, and Mumbai every Friday; express air cargo for urgent 50 kg samples.

Premium Alternative to Western Suppliers

Comparable Schenk or Rea quality at 18–22 % lower landed cost; same die-sets, same ASTM F68 oxygen-free copper, ±0.005 mm tighter edge radius control than most EU mills.

Western auditors on site quarterly; bilingual (EN/CN) project engineers for real-time Skype/Teams support.

Ready to validate performance?

Email cathy@transformerstrip.com with your target AWG or mm size, thermal class, and required BDV.

We will return a detailed datasheet, copper-loss calculation, and firm FOB price within 12 hours.

📉 Import Savings Calculator

Estimate cost reduction by sourcing manufacturer of copper wire from Luoyang Xinzhaohe.