Table of Contents

Market Insight: Isolation Transformer Winding Wire

Market Analysis: Winding Wire for Isolation Transformers

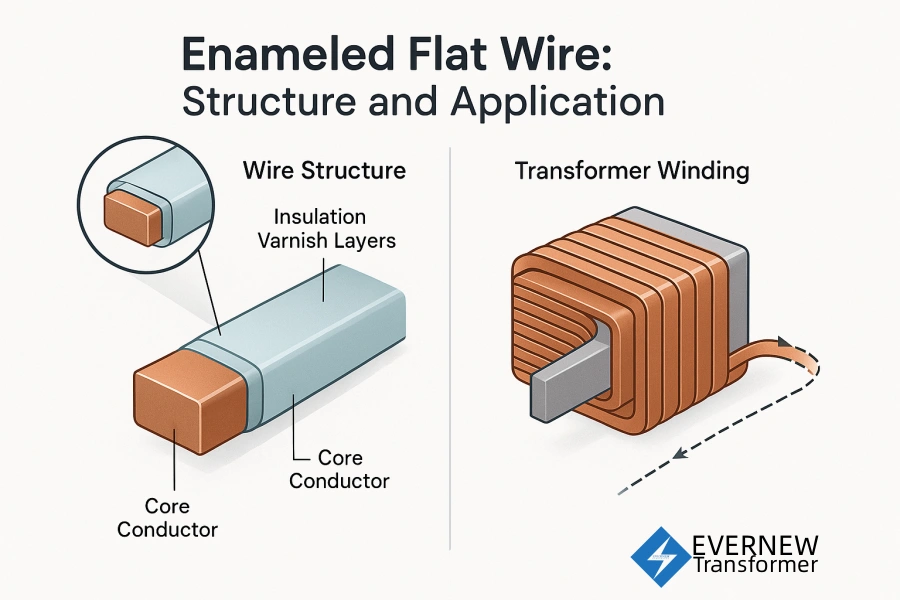

The global industrial demand for isolation transformer winding wire continues to grow, driven by the expansion of power infrastructure, renewable energy integration, and the increasing need for electrical safety in commercial and industrial applications. Isolation transformers serve a critical function in electrical systems by decoupling primary and secondary circuits, thereby minimizing electrical noise, suppressing voltage spikes, and enhancing operator safety through galvanic isolation. The performance and reliability of these transformers are directly influenced by the quality of the winding wire used in their construction.

Copper and aluminum are the predominant conductive materials used in winding wire, with copper offering superior conductivity and thermal stability, while aluminum provides a cost-effective, lightweight alternative suitable for specific applications. In isolation transformers, where electrical integrity and thermal management are paramount, the selection of high-purity conductive material with consistent mechanical and electrical properties is essential. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical and wire manufacturing expertise, we emphasize the importance of material homogeneity, precise dimensional tolerances, and dielectric coating integrity to ensure optimal transformer performance.

Quality in winding wire directly impacts transformer efficiency, thermal endurance, and long-term reliability. Poor-quality wire with impurities, inconsistent diameter, or compromised insulation can lead to localized hotspots, inter-turn short circuits, and premature transformer failure. In high-voltage or high-frequency applications, such as in medical equipment, data centers, or industrial automation systems, even minor deviations in wire quality can result in system instability or safety hazards. The enamel insulation system—typically composed of polyurethane, polyester, or polyamide-imide—must exhibit excellent dielectric strength, thermal class compliance (e.g., Class B, F, or H), and resistance to thermal aging and mechanical stress during winding and operation.

The market trend reflects a shift toward higher efficiency standards, such as IEC 60076 and IEEE C57, which place stringent demands on no-load and load losses. This necessitates the use of winding wire with minimized DC resistance and reduced skin effect, particularly in high-frequency isolation transformers. Additionally, environmental and sustainability considerations are influencing material choices, with increased interest in recyclable conductors and lead-free insulation systems.

As a trusted supplier in the winding wire segment, Luoyang Xinzhaohe Aluminum Co., Ltd adheres to rigorous quality control protocols, including continuous annealing,在线 tension control, and automated diameter monitoring, to ensure product consistency. Our aluminum winding wire solutions are engineered to meet or exceed international standards, offering customers a reliable alternative where weight and cost are critical factors without compromising electrical performance.

In summary, the industrial demand for isolation transformer winding wire is shaped by the need for safety, efficiency, and durability in modern electrical systems. The quality of the winding wire is not a peripheral concern but a foundational element that determines the operational lifespan and reliability of the transformer. Selecting a supplier with proven technical expertise and process control is essential for achieving performance consistency in demanding applications.

Technical Specs: Isolation Transformer Winding Wire

Technical Specifications for Isolation Transformer Winding Wire

Isolation transformers demand exceptional electrical insulation integrity and mechanical reliability to ensure safety and longevity in critical applications. At Luoyang Xinzhaohe Aluminum Co., Ltd., our aluminum winding wire is engineered to exceed standard requirements for isolation duty, with rigorous control over three core parameters: Insulation Breakdown Voltage, Elongation, and Thermal Class. These specifications directly impact dielectric safety margins, winding process yield, and operational lifespan under thermal stress.

Insulation Breakdown Voltage is non-negotiable for isolation transformers, where failure risks catastrophic equipment damage or personnel hazard. Industry standards typically mandate a minimum 3.0 kV AC breakdown, but Xinzhaohe implements a 4.5 kV AC minimum threshold during routine 100% testing per IEC 60317. This elevated margin accommodates voltage transients and manufacturing variances, ensuring consistent performance even under grid instability. Our dual-layer polyester-imide/polyamide-imide insulation system achieves this through precise extrusion control and void-free polymer adhesion, eliminating weak points at conductor edges.

Elongation governs wire ductility during high-tension winding processes. Substandard elongation causes microfractures in the conductor or insulation, leading to premature failure. Aluminum’s inherent ductility requires optimized annealing; Xinzhaohe maintains elongation between 18% and 28% (per ASTM B355), significantly above the 15% industry baseline. This range prevents work hardening during automated winding while retaining tensile strength for layer stability. Critical to this is our proprietary annealing profile, which homogenizes grain structure without oxide formation—verified via in-line mechanical testing every 500 kg.

Thermal Class defines the insulation system’s continuous operating temperature, directly correlating to transformer service life. Xinzhaohe wires support classes from 130°C (Class B) to 220°C (Class C), with thermal indices validated per NEMA MW 1000. Higher classes (e.g., 180°C/Class H) utilize ceramic-filled polyimide coatings to suppress thermal aging, extending operational life by 4× compared to 130°C alternatives under identical load cycles. Crucially, thermal class must align with the transformer’s entire insulation system; mismatched components accelerate degradation regardless of wire performance.

The following table summarizes critical parameters against industry benchmarks and Xinzhaohe’s controlled ranges:

| Parameter | Standard Requirement | Xinzhaohe Performance Range | Test Standard |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 3.0 kV AC | 4.5 – 6.0 kV AC | IEC 60317-0-8 |

| Elongation (Al conductor) | ≥ 15% | 18% – 28% | ASTM B355 |

| Thermal Class | 130°C – 180°C | 130°C – 220°C | NEMA MW 1000, IEC 60085 |

| Conductor Resistivity | ≤ 0.028264 Ω·mm²/m | 0.02800 – 0.02820 Ω·mm²/m | ASTM B230 |

Metallurgical integrity underpins these specifications. Our aluminum alloy (EC Grade, 99.7% min purity) undergoes triple-refining to minimize iron/silicon inclusions, ensuring uniform current distribution and reducing localized heating. Combined with precision diameter tolerances (±0.003 mm), this minimizes hot spots during overload conditions. For isolation transformers, where safety isolation is paramount, Xinzhaohe’s adherence to these technical parameters eliminates compromise between electrical performance and mechanical robustness. All batches include full traceability to melt chemistry and process logs, enabling root-cause analysis if required. Partnering with a supplier that rigorously controls these variables is essential to mitigate field failure risks in mission-critical power systems.

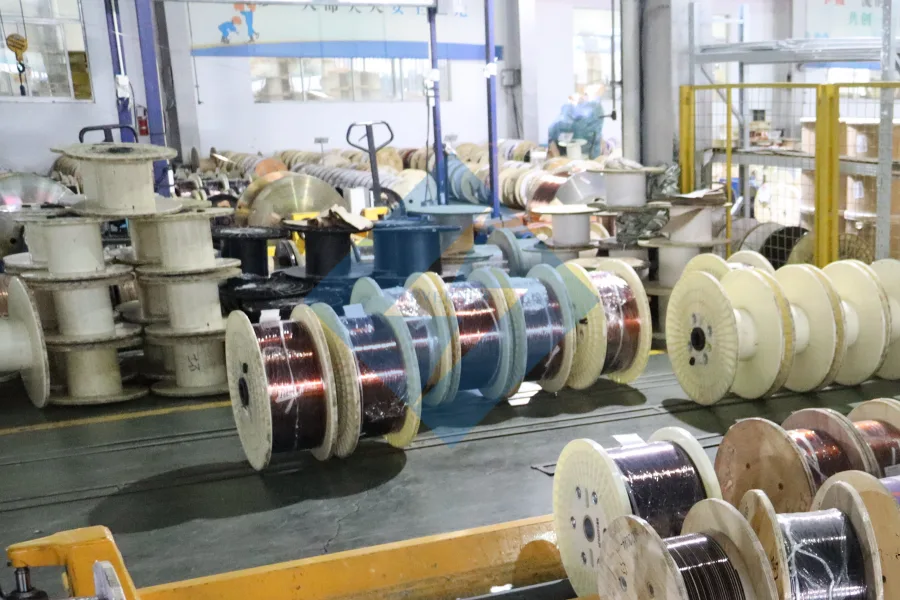

Factory Tour: Manufacturing

Manufacturing Process of Isolation Transformer Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance isolation transformer winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a rigorously controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, electrical integrity, and long-term reliability under demanding operating conditions. With over two decades of metallurgical and wire processing expertise, our facility integrates advanced equipment with stringent quality control protocols across each phase: rod drawing, annealing, enameling, and inline testing.

The process begins with high-purity aluminum rod (typically 99.7% Al or higher), sourced from certified suppliers and verified through incoming material inspection. The rod undergoes continuous rod drawing, where it is pulled through a series of precision tungsten carbide or diamond dies to achieve the target wire diameter. This cold working process reduces the cross-section incrementally, with intermediate cleaning to remove lubricants and surface contaminants. Dimensional consistency is maintained through laser micrometer monitoring, ensuring tolerances within ±0.005 mm.

Following drawing, the wire enters a controlled atmosphere annealing furnace. This step is critical for restoring ductility and electrical conductivity lost during cold working. The annealing process employs an inert nitrogen-hydrogen atmosphere to prevent oxidation, with precise temperature profiling (typically 450–550°C) and dwell time calibrated to the wire gauge. Post-annealing, the wire is rapidly cooled to stabilize the recrystallized microstructure, ensuring uniform elongation (typically 25–35%) and tensile strength suitable for tight coil winding without breakage.

The annealed wire then proceeds to the enameling line, where multiple layers of thermosetting polymer insulation are applied via precision die coating. Common insulation systems include polyurethane (PU), polyester (PE), or polyamide-imide (PAI), selected based on thermal class requirements (up to Class 200). Each coat is cured in a series of high-temperature ovens, with film thickness monitored in real time using beta-gauge measurement systems. Layer uniformity and adhesion are validated through scratch and winding tests at defined intervals.

Throughout the entire production line, inline quality control systems continuously monitor key parameters. These include diameter variation, insulation thickness, continuity (hi-pot testing at 3–5 kV), and surface defects via optical inspection. Data from these systems are logged for traceability and process optimization.

Final quality verification includes off-line testing per IEC 60317 and ASTM B700 standards, covering breakdown voltage, thermal shock resistance, and solderability. Every production lot is accompanied by a material test report, ensuring full compliance with customer specifications and international electrical safety requirements. This end-to-end control framework ensures that each spool of winding wire delivered meets the exacting demands of isolation transformer applications in industrial, medical, and power electronics sectors.

Packaging & Logistics

Export Packaging Specifications for Isolation Transformer Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. implements rigorously engineered export packaging protocols for isolation transformer winding wire to ensure absolute product integrity during global maritime transport. With over two decades of metallurgical and supply chain expertise, we recognize that aluminum conductor wire—particularly thin-gauge enameled or insulated grades—is highly susceptible to moisture ingress, mechanical stress, and salt-air exposure during extended sea freight. Our packaging system is designed to mitigate these risks through material science and structural engineering principles, adhering strictly to international shipping regulations and client quality expectations.

All winding wire reels are secured on custom-engineered wooden pallets compliant with ISPM-15 standards for international phytosanitary safety. These pallets utilize kiln-dried, knot-free hardwood with a minimum compressive strength of 1,200 psi to withstand stacking loads up to 4,000 kg in containerized cargo holds. Each pallet undergoes thermal treatment at 56°C for 30 minutes to eliminate biological contaminants, followed by laser-etched certification marking. Reels are mechanically fastened to the pallet base using corrosion-resistant steel strapping at 800 kg tensile strength, preventing axial displacement during vessel motion or crane handling. Critical edge protection is applied to reel flanges using polyethylene corner guards to eliminate abrasion damage to delicate conductor insulation layers during intermodal transit.

Moisture protection constitutes the core defense against conductor degradation. We deploy a triple-layer barrier system:

First, reels receive an initial wrap of 100-micron metallized polyester film with a water vapor transmission rate (WVTR) of ≤0.1 g/m²/day per ASTM F1249.

Second, a desiccant layer comprising silica gel packets (50g/unit, 30% moisture absorption capacity) is distributed at reel core and periphery, calculated at 15% of total wire mass per ISO 11469.

Finally, the entire assembly is hermetically sealed in 150-micron co-extruded polyethylene film with ethylene-vinyl alcohol (EVOH) barrier resin, achieving WVTR <0.05 g/m²/day. All sealing employs industrial heat-welding at 180°C to eliminate micro-perforations, with humidity indicator cards (0–100% RH range) affixed internally for post-transit verification.

This methodology directly addresses the hygroscopic properties of aluminum and organic insulation materials during sea freight. Containerized cargo experiences extreme humidity fluctuations (up to 95% RH) and temperature swings (−25°C to 60°C) across shipping lanes, inducing “container rain” condensation. Our packaging maintains internal relative humidity below 40% RH for 120+ days—validated through accelerated climate testing per ISO 12103-1—preventing conductor oxidation, enamel delamination, or dielectric strength reduction. All packages undergo drop testing (1.2m height) and vibration simulation (5–55 Hz, 0.75g) per ISTA 3A protocols prior to shipment.

For clients, this translates to zero moisture-related quality claims and immediate production line readiness upon arrival. We provide full packaging compliance documentation, including material certificates, desiccant load calculations, and ISPM-15 validation—all critical for customs clearance and end-customer acceptance. This engineered approach exemplifies our commitment to metallurgical excellence beyond the wire itself, safeguarding your supply chain from factory gate to transformer winding cell.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Isolation Transformer Winding Wire

With over two decades of specialized expertise in metallurgical engineering and precision wire manufacturing, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted industrial partner for high-reliability isolation transformer winding wire. Our vertically integrated production system, anchored in advanced aluminum processing and strict quality control, ensures consistent delivery of conductive materials engineered to meet the demanding electrical and thermal requirements of modern transformer applications.

Our manufacturing facility is equipped with state-of-the-art continuous casting and rolling lines, enabling precise control over aluminum purity, grain structure, and mechanical properties. We produce high-conductivity aluminum rod (EC grade, 99.7% minimum Al) as the foundational material for our winding wire, ensuring low resistivity and superior ampacity. This raw material integrity translates directly into enhanced transformer efficiency and reduced I²R losses—critical performance metrics for isolation transformers used in industrial, medical, and renewable energy systems.

All winding wire is drawn under controlled atmosphere conditions to minimize oxidation and maintain surface cleanliness, which is essential for uniform enamel insulation adhesion. We offer a full range of aluminum winding wire from 1.0 mm to 5.0 mm diameter, compatible with standard magnet wire enameling processes. Our wire exhibits excellent elongation (≥25%), tensile strength (90–110 MPa), and bendability, meeting or exceeding IEC 60208 and GB/T 23312 standards for magnet wire performance.

Quality assurance is embedded at every stage of production. Our in-house laboratory conducts routine testing on electrical conductivity, dimensional tolerance, thermal aging resistance, and dielectric breakdown strength. Each batch is traceable through a digital quality management system compliant with ISO 9001:2015, providing full documentation for audit and certification purposes.

As a strategic supplier, we understand the importance of on-time delivery and supply chain resilience. Our facility maintains a monthly production capacity of 3,000 metric tons of aluminum winding wire, supported by dedicated logistics coordination for both domestic and international clients. We work closely with transformer OEMs to optimize material specifications, reduce total cost of ownership, and accelerate time to market.

For sourcing managers and engineering teams seeking a technically capable, reliable partner in winding wire supply, Luoyang Xinzhaohe offers the combination of metallurgical precision, industrial scale, and customer-focused service.

Contact us today to discuss your isolation transformer material requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing isolation transformer winding wire directly from China.