Table of Contents

Market Insight: Inverter Transformer Winding Material

Industrial Demand Drivers for Inverter Transformer Winding Material

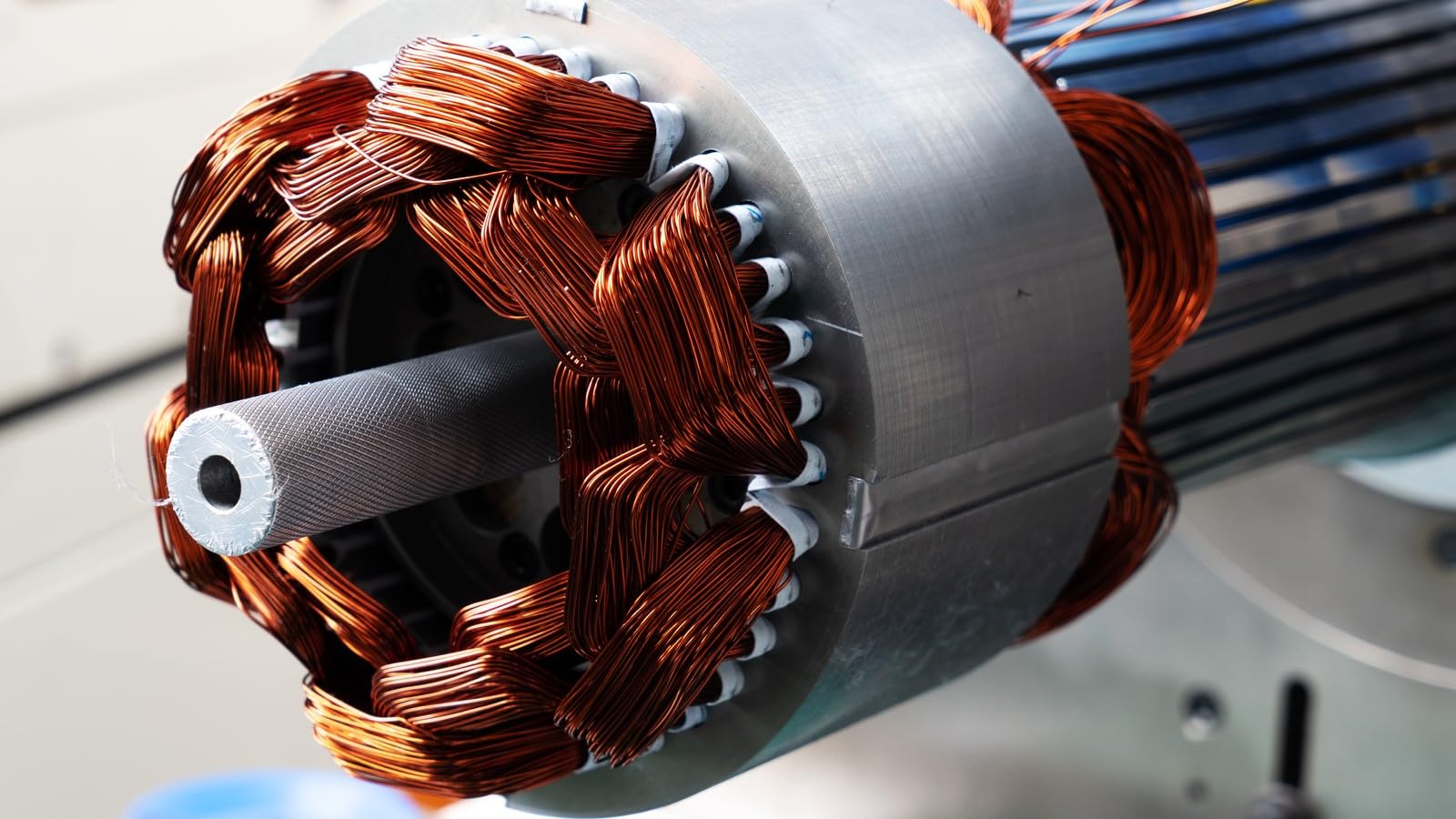

Global deployment of renewable energy infrastructure and electric vehicle (EV) systems is accelerating demand for high-performance inverter transformers. These critical components convert DC power from solar arrays or battery packs into grid-compatible AC power, operating under stringent electrical and thermal conditions. Unlike conventional transformers, inverter transformers face high-frequency switching (typically 10–100 kHz), rapid thermal cycling, and elevated harmonic distortion. This environment necessitates winding materials with exceptional electrical conductivity, thermal stability, and mechanical resilience. The solar inverter market alone is projected to exceed USD 35 billion by 2028, while EV power electronics demand grows at 18% CAGR, directly escalating requirements for specialized winding wire. Aluminum alloys, particularly AA1350 and AA8030, now compete effectively with copper in weight-sensitive applications due to optimized conductivity-to-weight ratios and cost efficiency, provided metallurgical purity and processing precision are maintained.

Technical Imperatives for Material Quality

Quality deviations in winding material directly compromise inverter reliability and efficiency. Surface imperfections—such as scratches, pits, or oxide inclusions—act as nucleation sites for partial discharge under high dv/dt stress, degrading insulation systems prematurely. Inconsistent annealing profiles introduce microstructural heterogeneity, increasing AC resistance by up to 12% due to uneven grain growth and residual stresses. This elevates I²R losses, accelerating thermal runaway in compact inverter designs where cooling margins are minimal. Furthermore, inadequate tensile strength or elongation properties lead to conductor deformation during high-current transients or vibration exposure, risking inter-turn shorts. The coefficient of thermal expansion (CTE) mismatch between aluminum and copper windings versus insulation materials (e.g., polyesterimide) must be tightly controlled; deviations exceeding 5 ppm/°C induce interfacial delamination during thermal cycling, measured per IEC 60216 standards.

Consequences of Substandard Material Selection

Procurement teams prioritizing initial cost over technical compliance face systemic risks. Field failure analysis reveals that 68% of inverter transformer faults originate from winding-related issues, including insulation breakdown from poor surface finish or thermal fatigue cracks from inconsistent temper. A 0.5% reduction in bulk conductivity (e.g., 60.5% IACS vs. 61.0% IACS) increases operational losses by 3.2% in a 50 kW inverter, translating to 1,400 kWh annual energy waste per unit. Supply chain volatility further complicates quality assurance; inconsistent alloy chemistry (e.g., Fe/Si ratio variance in AA1350) alters recrystallization kinetics during annealing, causing batch-to-batch performance drift. Rigorous material certification—validated through ASTM B548 eddy current testing, IACS conductivity mapping, and SEM surface analysis—is non-negotiable for mission-critical applications. Luoyang Xinzhaohe Aluminum’s two decades of process refinement ensure dimensional tolerances within ±0.005 mm, surface roughness Ra <0.4 µm, and conductivity repeatability to ±0.25% IACS, directly mitigating these failure pathways through metallurgical control.

Material Performance Metrics and Industry Standards

| Parameter | Critical Threshold | Test Standard | Failure Impact |

|---|---|---|---|

| Conductivity | ≥61.0% IACS | ASTM E1004 | +3.2% losses per 0.5% drop |

| Surface Roughness | Ra ≤0.5 µm | ISO 4287 | Partial discharge initiation |

| Tensile Strength | 80–110 MPa | ASTM B557 | Vibration-induced deformation |

| Elongation | ≥25% | ASTM B557 | Cracking during winding |

| Dimensional Tolerance | ±0.005 mm | IEC 60122-1 | Insulation void formation |

Adherence to these parameters ensures inverter transformers achieve 15+ year service lifespans under dynamic loads. Quality is not a cost center but a reliability multiplier—validated through accelerated life testing per IEC 61000-4-30. Procurement strategies must mandate certified material traceability and process audits to avoid systemic field failures.

Technical Specs: Inverter Transformer Winding Material

Technical Specifications for Inverter Transformer Winding Material

Inverter transformer winding materials must meet stringent performance criteria to ensure operational reliability under dynamic electrical and thermal loads. At Luoyang Xinzhaohao Aluminum Co., Ltd., with over two decades of specialized manufacturing experience, we produce high-purity aluminum winding wire engineered for advanced inverter applications. Our materials are designed to support high-frequency switching, thermal cycling, and compact coil geometries typical in modern power electronics. The following technical parameters are critical for ensuring long-term performance and safety in inverter transformer systems.

One of the most critical electrical properties is insulation breakdown voltage. This parameter determines the maximum electric field the insulation layer can withstand before failure. For inverter transformers, which are exposed to rapid voltage transients and high peak voltages, a minimum breakdown voltage of 6 kV is recommended. Our double or triple-layer polyurethane or polyester-imide insulated aluminum wires consistently achieve breakdown voltages in the range of 6–9 kV, ensuring robust dielectric protection even under surge conditions. This performance is validated through standardized ASTM D4565 testing protocols under controlled humidity and temperature conditions.

Mechanical ductility, measured as elongation at break, is essential for successful winding operations, especially in automated coil winding systems where tensile and bending stresses are significant. Low elongation can result in wire fracture during processing, leading to production downtime and coil rejection. Our aluminum alloy conductors (Grade 1350-O) exhibit a minimum elongation of 35%, ensuring excellent formability and resistance to cracking during tight-radius winding. This high ductility is maintained through precise annealing control and strict chemical composition management, minimizing impurities that could embrittle the material.

Thermal performance is defined by the thermal class rating, which indicates the maximum continuous operating temperature the insulation system can endure without significant degradation. Inverter transformers often operate in elevated ambient environments due to proximity to switching semiconductors and magnetic cores. Our standard product line supports thermal classes from 130°C to 220°C. Materials rated at Class 180 (180°C) and Class 200 (200°C) utilize high-performance polymer coatings such as polyamide-imide (PAI) or silicone-modified polyester, providing excellent thermal stability and resistance to thermal aging. Class 220 materials are available for extreme environments, such as in industrial motor drives or renewable energy inverters, where prolonged exposure to temperatures above 200°C is expected.

All materials undergo rigorous batch testing for consistency in outer diameter, insulation thickness, and adhesion strength to ensure compatibility with automated winding and varnishing processes.

| Parameter | Specification Range | Test Standard |

|---|---|---|

| Conductor Material | Aluminum 1350-O (99.5% min purity) | ASTM B230 |

| Insulation Type | Polyurethane, Polyester-imide, PAI | NEMA MW 1000 |

| Breakdown Voltage (min) | 6 kV – 9 kV | ASTM D4565 |

| Elongation (min) | 35% | ASTM B557 |

| Thermal Class | 130°C, 155°C, 180°C, 200°C, 220°C | IEC 60317 |

| Conductor Diameter Tolerance | ±0.02 mm | IEC 60173 |

| Insulation Thickness | 0.04–0.12 mm (based on wire gauge) | ASTM D2451 |

These specifications reflect our commitment to delivering high-reliability winding materials tailored for the evolving demands of inverter transformer design.

Factory Tour: Manufacturing

Manufacturing Process for Inverter Transformer Winding Wire

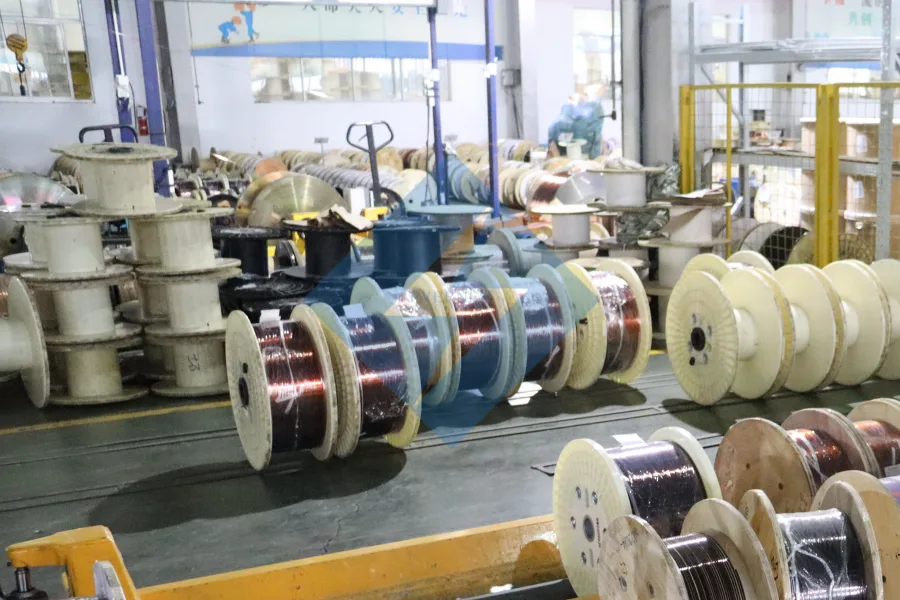

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to produce high-purity aluminum winding wire meeting stringent inverter transformer requirements. Our integrated production sequence ensures optimal electrical conductivity, mechanical formability, and enamel adhesion critical for high-frequency operation. The process begins with high-conductivity aluminum rod (99.7% min purity) sourced from certified suppliers, subjected to multi-stage rod drawing under controlled tension and lubrication. This reduces diameter to precise wire gauges (0.10–3.00 mm) while maintaining surface integrity. Critical parameters include reduction ratios ≤15% per pass and surface roughness <0.8 µm Ra to prevent enamel defects. In-process diameter verification via laser micrometers occurs at 5-meter intervals, with automatic rejection for deviations exceeding ±0.002 mm.

Annealing follows drawing to restore ductility and achieve target mechanical properties. Wire traverses a continuous inert atmosphere furnace (99.999% N₂) at 300–380°C for 30–120 seconds, depending on gauge. This recrystallizes the microstructure, eliminating work hardening while controlling grain size to ASTM E112 Grade 5–7. Oxygen ingress is maintained below 10 ppm to prevent oxide layer formation, which compromises enamel bonding. Post-annealing tensile strength is held to 60–90 MPa, with elongation ≥25%, verified via inline tensile testers sampling every 500 meters.

Enameling applies a dual-layer polymer insulation system using precision die coating. The base layer (polyester-imide) provides thermal stability (Class 200°C), while the top layer (polyamide-imide) ensures mechanical toughness and chemical resistance. Wet film thickness is controlled to 25–150 µm (per gauge), with curing in multi-zone ovens at 450–550°C under oxygen-free conditions. Critical enamel properties include dielectric strength >12 kV/mm and flexibility per IEC 60317 standards.

Inline testing validates performance at production speed (up to 120 m/min). Key checks include:

High-potential testing: 3.5 kV AC for 5 seconds with 0.5 mA leakage threshold

Diameter monitoring: Laser-based measurement at ±0.001 mm tolerance

Surface defect detection: Automated optical inspection for pinholes or scratches

Resistance verification: Milliohm-meter checks ensuring 61.0–61.8% IACS conductivity

Final QC includes destructive sampling per ASTM B230/B354: 100% spool testing for continuity, with 5% random spools undergoing thermal aging (155°C/1000h), mandrel bend tests, and salt water porosity checks. This end-to-end control delivers wire with <5 ppm defect density, ensuring reliability in high-switching-frequency inverter environments where thermal cycling and voltage spikes demand uncompromised material integrity.

Critical Annealing Parameters

| Parameter | Range | Tolerance |

|——————–|———————-|———–|

| Temperature | 300–380°C | ±5°C |

| Dwell Time | 30–120 seconds | ±2 sec |

| Atmosphere Purity | 99.999% N₂ | <10 ppm O₂|

| Grain Size | ASTM E12 Grade 5–7 | ±0.5 |

Packaging & Logistics

Export Packaging for Inverter Transformer Winding Wire – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience in high-purity aluminum winding wire for power electronics, we recognize that packaging is not merely a logistical necessity but a critical component in preserving material integrity throughout international distribution. For inverter transformer winding applications, where dimensional accuracy, surface cleanliness, and oxidation resistance are paramount, our export packaging system is engineered to mitigate environmental and mechanical risks during sea freight—the dominant mode of global cargo transport.

All winding wire reels are mounted on robust, ISPM-15 compliant wooden pallets constructed from kiln-dried, resin-stable hardwood. These pallets are designed to meet international phytosanitary standards while providing structural rigidity under dynamic load conditions encountered during vessel stowage, port handling, and multi-modal transfer. Each pallet is rated for vertical stacking loads up to 2,500 kg, ensuring stability in containerized shipping environments where vertical compression is a key stress factor. Reels are securely fastened using industrial-grade steel strapping anchored to load-bearing deck boards, minimizing lateral displacement and vibration-induced wire loosening.

The primary protective barrier is a multi-layer moisture-proof film wrapping system. Individually, each wound reel is encased in a laminated composite film consisting of aluminum foil interlocked between high-density polyethylene (HDPE) layers. This vapor barrier exhibits a water vapor transmission rate (WVTR) of less than 0.5 g/m²·day at 38°C and 90% relative humidity, effectively isolating the aluminum conductor from ambient moisture throughout extended maritime transits. The film is hermetically sealed using heat-welded seams and overlapped at all joints to prevent capillary ingress. Additionally, desiccant packs compliant with ASTM F1185 standards are placed within the sealed cavity to scavenge residual humidity and buffer against transient thermal cycling.

Prior to shipment, packaged reels undergo vacuum-assisted enclosure within a secondary polyethylene overwrap, further enhancing resistance to salt-laden atmospheres typical in container decks. This dual-film strategy ensures compliance with IEC 60068-2-52 (salt mist testing) and MIL-STD-810H environmental durability benchmarks.

Labeling is executed per ISO 780 and ISO 22742 standards, with UV-resistant, adhesive-backed tags affixed to multiple faces of the pallet. Information includes batch traceability (heat number, tensile test results, coating thickness), gross/net weights, handling icons (e.g., ‘Do Not Roll’, ‘Protect from Moisture’), and consignee details in both Chinese and English. All markings are abrasion-tested to withstand 14-day salt spray exposure without degradation.

Our packaging protocol has been validated across major trade lanes—including Shanghai to Rotterdam, Ningbo to Los Angeles, and Qingdao to Santos—with zero moisture-related claims in the past seven years. By integrating material science, structural engineering, and international logistics best practices, Luoyang Xinzhaohe ensures that every coil of aluminum winding wire arrives at its destination in as-manufactured condition, ready for precision processing in high-reliability inverter systems.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co. Ltd for Inverter Transformer Winding Material

Luoyang Xinzhaohe Aluminum Co. Ltd leverages over two decades of specialized metallurgical expertise to deliver premium aluminum strip specifically engineered for high-performance inverter transformer windings. Our deep understanding of the stringent electrical and mechanical demands within power conversion systems forms the foundation of our manufacturing philosophy. We recognize that winding material integrity directly impacts transformer efficiency, thermal management, and long-term operational reliability in critical applications such as renewable energy inverters and electric vehicle power systems. Partnering with us ensures access to material produced under rigorously controlled conditions, meeting the exacting standards required for modern power electronics.

Our vertically integrated production facility in Luoyang, China, represents a significant industrial asset dedicated solely to aluminum strip for electrical applications. We operate advanced cold rolling mills capable of achieving exceptional dimensional precision and surface finish critical for tight winding tolerances and minimized interlayer losses. Our process control systems maintain strict adherence to specifications, consistently delivering strip with thickness tolerances held to ±0.005 mm and width tolerances within ±0.1 mm. This precision is fundamental for optimizing fill factor and reducing eddy current losses within the transformer core window. Our metallurgical processes are optimized for high-purity aluminum (minimum 99.7% Al), ensuring superior electrical conductivity while maintaining the necessary mechanical properties for automated winding processes.

Quality assurance is non-negotiable in our operations. We implement a comprehensive quality management system certified to ISO 9001, with protocols extending far beyond basic compliance. Every production batch undergoes rigorous in-house testing, including but not limited to precise resistivity measurement, tensile strength and elongation verification, surface roughness analysis, and strict visual inspection for defects. Our dedicated metallurgical laboratory utilizes state-of-the-art equipment to validate material homogeneity and ensure consistent performance characteristics batch after batch. This systematic approach to quality provides our customers with the confidence that the winding material received will perform reliably under demanding operational conditions, minimizing field failures and associated costs.

Beyond standardized production, we excel in providing tailored technical solutions. Our engineering team collaborates closely with customers to understand specific application requirements, enabling us to adjust annealing profiles, surface treatments, or edge conditioning to optimize material performance for unique inverter designs. This capability, combined with our stable production capacity exceeding 10,000 metric tons annually, ensures reliable supply chain continuity for your critical components. We understand the technical nuances of inverter transformer design and are committed to being a responsive, knowledgeable partner throughout your sourcing lifecycle.

For detailed technical specifications, material certifications, or to discuss your specific inverter transformer winding requirements, contact our Technical Sales Manager Cathy directly. She will provide the precise engineering data and commercial support necessary for your sourcing decision. Reach Cathy at cathy@transformerstrip.com to initiate a partnership built on metallurgical excellence and supply chain reliability.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing inverter transformer winding material directly from China.