Table of Contents

Market Insight: Interleaved Winding Wire

Market Analysis: Interleaved Winding Wire for Transformer Applications

Global demand for interleaved aluminum winding wire continues robust growth, driven by accelerating power grid modernization, renewable energy integration, and rising electricity consumption in emerging economies. The International Energy Agency (IEA) projects global electricity demand will increase by over 3% annually through 2026, necessitating substantial expansion and reinforcement of transmission and distribution infrastructure. High-voltage and extra-high-voltage power transformers represent the critical backbone of this infrastructure, where interleaved winding wire is indispensable. This specific configuration—integrating precision-wound aluminum conductor with interleaved insulating paper layers—provides the essential dielectric strength and thermal management required for reliable operation under extreme electrical and thermal stresses. The shift towards sustainable energy sources further intensifies demand, as solar and wind farms require dedicated step-up transformers with stringent performance and longevity requirements, directly increasing procurement volumes for certified interleaved wire globally.

Quality in interleaved winding wire is non-negotiable due to the catastrophic consequences of failure within power transformers. The aluminum conductor must meet exacting metallurgical specifications, primarily ASTM B418 Grade 1350-O or equivalent, with impurity levels strictly controlled below 0.15% total. Even minor deviations in electrical conductivity (requiring minimum 61.0% IACS) or mechanical properties significantly compromise thermal performance and mechanical stability during short-circuit events. Crucially, the interleaving process demands micron-level precision in paper placement and tension control. Inconsistent paper wrap density or misalignment creates voids or uneven insulation thickness, becoming initiation points for partial discharge under operational voltage stress. Partial discharge progressively degrades solid insulation, ultimately leading to dielectric failure. Field data indicates that over 65% of premature transformer failures in the 69kV+ range correlate directly to insulation system defects originating in the winding structure, often traceable to substandard wire or improper interleaving.

The operational environment imposes severe demands. Transformers experience continuous thermal cycling, dynamic electromagnetic forces during load fluctuations, and transient overvoltages. High-quality interleaved wire maintains dimensional stability and adhesion between conductor and paper under these conditions. Inferior wire exhibits paper migration, conductor oxidation at micro-voids, or delamination, accelerating aging and reducing the transformer’s operational lifespan from the designed 30-40 years to potentially less than 15 years. This directly impacts total cost of ownership through unplanned outages, costly replacements, and lost revenue. Luoyang Xinzhaohe Aluminum leverages two decades of specialized production experience to deliver wire meeting IEC 60204-1 and IEEE C57.12.00 standards. Our process integrates rigorous aluminum melt purification, continuous annealing for optimal ductility, and proprietary interleaving technology ensuring consistent paper coverage and minimal air entrapment. This technical precision, validated through routine partial discharge testing and accelerated aging protocols, provides the foundational reliability demanded by transformer OEMs serving critical power infrastructure. Procurement decisions must prioritize certified material traceability and proven manufacturing competence over marginal cost savings to ensure grid resilience.

Technical Specs: Interleaved Winding Wire

Technical Specifications for Interleaved Winding Wire

Interleaved winding wire is a specialized type of magnet wire engineered for high-performance electrical applications, particularly in transformers, reactors, and high-current inductors where thermal stability, mechanical resilience, and dielectric strength are critical. Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical and wire manufacturing expertise, provides interleaved aluminum winding wire solutions that meet stringent international performance benchmarks. This technical section outlines key parameters essential for reliable integration into industrial systems.

A defining characteristic of interleaved winding wire is its layered insulation system, designed to withstand high electrical stress and thermal cycling. The insulation breakdown voltage is a primary performance indicator, reflecting the dielectric integrity of the wire under operational loads. Our standard interleaved winding wires achieve a minimum breakdown voltage of 3,000 V RMS, with high-grade variants reaching up to 6,000 V RMS depending on insulation thickness and material composition. This ensures robust protection against short circuits and partial discharges in high-voltage environments.

Elongation is another critical mechanical property, directly influencing the wire’s formability and resistance to cracking during coiling and winding operations. Our aluminum-based interleaved wires exhibit a controlled elongation range of 18% to 28%, optimized through precise annealing processes. This balance between ductility and tensile strength allows for tight winding configurations without compromising structural integrity, particularly under thermal expansion and contraction cycles.

Thermal performance is evaluated through the Thermal Class rating, which defines the maximum continuous operating temperature the insulation system can endure without significant degradation. Luoyang Xinzhaohe offers interleaved winding wires across a broad thermal spectrum, from Class 130°C to Class 220°C. These ratings are achieved using advanced polymer insulation systems, including polyimide, polyester-imide, and aromatic polyamide coatings, applied in multiple interleaved layers to enhance thermal endurance and mechanical toughness.

The following table summarizes the key technical parameters of our interleaved aluminum winding wire product line:

| Parameter | Standard Range | Test Method | Notes |

|---|---|---|---|

| Conductor Material | Aluminum (EC Grade, 99.7%+) | GB/T 3954 | High purity for optimal conductivity |

| Insulation Type | Multi-layer Polyimide/Polyester-Imide | IEC 60317-0-8 | Interleaved for enhanced dielectric |

| Breakdown Voltage (min) | 3,000 – 6,000 V RMS | IEC 60172 | Measured at 1.5x nominal thickness |

| Thermal Class | 130°C to 220°C | IEC 60172 / NEMA MW 1000-C | Continuous operating temperature |

| Elongation | 18% – 28% | GB/T 4909.4 | Controlled annealing for consistency |

| Conductor Diameter | 1.0 – 6.0 mm | Customizable | Tolerance ±0.02 mm |

| Flexibility (Pin Test) | No cracking after 8 cycles | IEC 60851-5 | Mandrel diameter = 4x wire diameter |

| Temperature Index (TI) | Up to 220 | ASTM D2307 | Based on thermal aging life tests |

These specifications are validated through rigorous in-house and third-party testing, ensuring compliance with IEC, GB, and NEMA standards. The interleaved construction not only improves dielectric performance but also enhances resistance to abrasion, solvents, and thermal shock—key factors in extending the service life of electromagnetic components. Luoyang Xinzhaohe Aluminum Co., Ltd maintains full traceability and quality control throughout production, enabling reliable supply for mission-critical industrial applications.

Factory Tour: Manufacturing

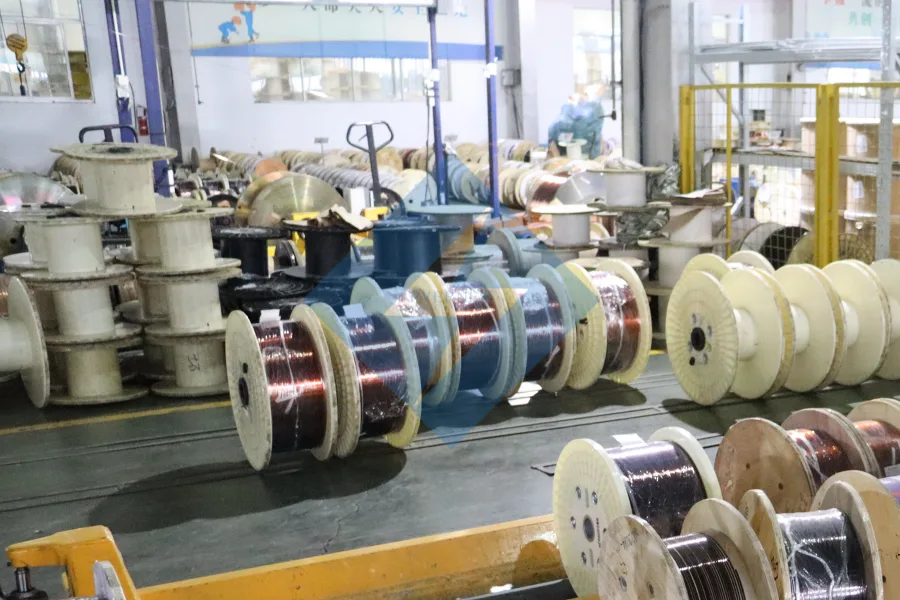

Manufacturing Process for Interleaved Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd employs a rigorously controlled, continuous production line for interleaved aluminum winding wire, ensuring optimal electrical, mechanical, and thermal properties demanded by motor and transformer manufacturers. This integrated process begins with high-purity aluminum rod and progresses through critical stages: Rod Drawing, Annealing, Enameling, and Inline Testing, each incorporating stringent quality control measures.

The process initiates with precision Rod Drawing. High-conductivity aluminum rod (typically 9.5mm diameter) undergoes multi-pass cold drawing through tungsten carbide or diamond dies within a continuous, water-lubricated drawing block system. This reduces the diameter to the precise final gauge required (e.g., 0.8mm to 2.5mm), work-hardening the metal. Critical process parameters include controlled reduction ratios per pass, die geometry, lubricant temperature and concentration, and capstan speeds to prevent surface defects or dimensional instability. In-process gauging using laser micrometers occurs continuously, verifying diameter tolerance adherence (typically ±0.005mm) and surface smoothness. Any deviation triggers immediate line stoppage for correction.

Subsequently, the drawn wire enters a continuous Annealing furnace under controlled inert atmosphere (N2/H2 mix). Precise temperature profiles (typically 300°C to 450°C) and residence times are maintained to relieve drawing-induced stresses and restore optimal electrical conductivity (targeting ≥61% IACS) while achieving the required temper (e.g., Soft or 1/2 Hard). Oxygen ingress is meticulously prevented to avoid oxidation. Post-anneal, conductivity is verified via eddy current testing, and tensile strength/elongation is sampled per ASTM E8, ensuring mechanical properties meet specification before proceeding.

The annealed wire then undergoes Enameling. A precisely metered application of high-temperature polymer resin (commonly polyester-imide or polyamide-imide) is applied via ceramic die or nozzle. For interleaved wire, multiple thin enamel layers are applied in sequence with controlled drying/curing between coats, achieving the specified total build thickness (e.g., Class 155, 180, or 200). The interleaving effect is achieved through the precise layering and curing process, enhancing thermal dissipation and voltage endurance. Solvent content, viscosity, oven temperature gradients, and line speed are tightly regulated. Critical inline QC includes spark testing at 3kV to detect pinholes and continuous diameter monitoring post-cure to ensure coating uniformity and thickness tolerance (±0.01mm).

The final stage is comprehensive Inline Testing. Every meter of wire undergoes 100% electrical integrity verification via high-voltage spark testing at elevated voltage levels. Thermal endurance is assessed through rapid thermal shock testers simulating thermal cycling. Additional automated checks include continuous diameter measurement, surface defect scanning via optical systems, and tension monitoring. All test data is logged in real-time against predefined pass/fail thresholds. Only wire batches passing all sequential QC checkpoints, documented through traceable batch records including raw material certs and process parameter logs, are approved for spooling, packaging, and shipment. This integrated approach guarantees the consistent performance and reliability essential for demanding electromagnetic applications.

Key Inline QC Parameters Summary

| Process Stage | Critical Parameter | Measurement Method | Typical Tolerance/Target |

|---|---|---|---|

| Rod Drawing | Wire Diameter | Laser Micrometer | ±0.005 mm |

| Surface Defects | Visual/Optical Scanner | Zero visible defects | |

| Annealing | Electrical Conductivity | Eddy Current Tester | ≥61% IACS |

| Tensile Strength | Destructive Sampling | Per ASTM B355 Spec | |

| Enameling | Enamel Thickness | Laser Micrometer | ±0.01 mm |

| Dielectric Strength (Pinholes) | Continuous Spark Tester | Pass 3kV DC | |

| Final Testing | High Voltage Integrity | HV Spark Tester | Pass Specified kV Level |

| Thermal Shock Resistance | Thermal Cycling Tester | Pass Specified Cycles |

Packaging & Logistics

Export Packaging for Interleaved Winding Wire – Luoyang Xinzhaohe Aluminum CO., Ltd

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized experience in the production and global distribution of high-performance winding wire, we maintain rigorous standards in export packaging to ensure product integrity throughout international logistics. Our packaging methodology for interleaved winding wire is engineered to address the unique vulnerabilities of aluminum and copper conductors during sea freight, particularly exposure to moisture, mechanical stress, and environmental contaminants.

All export shipments of interleaved winding wire are secured on robust wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. These pallets are designed to support the substantial weight of coiled conductors while maintaining structural stability during containerized transport. The use of treated timber ensures resistance to biological degradation and compliance with global phytosanitary regulations, eliminating the risk of customs delays or rejection at port of entry. Each coil is precisely positioned and anchored to the pallet using high-tensile steel strapping, minimizing lateral movement and preventing deformation during transit.

A critical component of our packaging protocol is the application of multi-layer moisture-proof film. Each coil is individually wrapped in heat-sealed, aluminum-laminated moisture barrier film, providing a vapor transmission rate of less than 0.1 g/m²/day under standard conditions. This encapsulation effectively isolates the conductor surface from ambient humidity, salt-laden air, and condensation commonly encountered in maritime environments. The film is further augmented with desiccant packs placed within the sealed envelope to scavenge residual moisture and maintain internal dew points below -40°C.

For added protection, outer layers of corrugated waterproof kraft paper are applied over the moisture barrier, shielding the film from punctures during handling. The entire palletized unit is then stretch-wrapped with UV-stabilized, marine-grade polyethylene to form a secondary environmental shield. This multi-tiered approach ensures that surface oxidation, fretting corrosion, and insulation degradation are mitigated over extended shipping durations, which may exceed 30 days for intercontinental routes.

Our packaging design has been validated through accelerated climatic testing, including 96-hour salt spray exposure and cyclic humidity trials (85°C/85% RH), confirming sustained electrical and mechanical performance post-storage. This methodology supports compliance with IEC 60280 and ASTM B356 standards for conductor preservation during transport.

Luoyang Xinzhaohe Aluminum CO., Ltd prioritizes reliability in every shipment. By integrating engineered wooden pallets with advanced moisture-proofing systems, we deliver interleaved winding wire to global clients with guaranteed material integrity, ensuring seamless integration into downstream manufacturing processes upon arrival.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Interleaved Winding Wire Excellence

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and precision manufacturing expertise to deliver interleaved winding wire solutions meeting the most stringent demands of transformer and inductor manufacturers. Our dedicated production ecosystem is engineered specifically for the complex requirements of interleaved conductor systems, where aluminum strip performance is critical to final component efficiency and reliability. Partnering with us provides direct access to vertically integrated capabilities ensuring consistent material integrity from billet to finished coil.

Advanced Production Capabilities for Critical Interleaving

Our facility operates fully automated, climate-controlled production lines exclusively configured for interleaved winding wire assembly. We utilize high-precision cold rolling mills capable of producing aluminum strip with thickness tolerances held to ±0.005 mm across widths up to 150 mm, essential for uniform current distribution and minimized eddy current losses. The interleaving process employs servo-driven tension control systems maintaining strip flatness within 0.1 mm/m and ensuring precise layer registration during continuous winding. This technical precision is supported by an annual production capacity exceeding 20,000 metric tons, enabling us to reliably support high-volume OEM programs without compromising on lead times.

Metallurgical Integrity and Rigorous Quality Assurance

Material purity and structural consistency form the foundation of our interleaved wire performance. We source primary aluminum meeting 99.99%+ (4N) purity standards, processed through our proprietary homogenization and annealing protocols to achieve optimal electrical conductivity (≥61.0% IACS) and mechanical properties. Every production batch undergoes comprehensive inline and offline testing per ASTM B230/B231 and IEC 60122 standards. Our ISO 9001-certified laboratory utilizes OES for elemental analysis, profilometry for surface roughness measurement (Ra ≤ 0.5 μm), and tensile testing to verify yield strength (40-60 MPa) and elongation (≥2%). Real-time statistical process control (SPC) monitors critical parameters including thickness profile, edge camber, and oxide layer thickness, ensuring zero non-conforming material reaches customers.

Supply Chain Resilience and Technical Partnership

Beyond manufacturing, we provide strategic supply chain stability through dual-source raw material agreements and dedicated inventory buffers for key alloy grades. Our logistics network guarantees 99.95% on-time delivery performance via optimized multimodal routing from our Luoyang hub. Crucially, our engineering team collaborates directly with your design and procurement staff to resolve material compatibility issues, optimize strip specifications for your winding processes, and implement just-in-time delivery models. This technical partnership approach minimizes your inventory costs while ensuring seamless production continuity.

Optimize Your Transformer Performance with Verified Expertise

Interleaved winding wire is not a commodity; its metallurgical properties directly impact core losses, thermal management, and transformer lifespan. Luoyang Xinzhaohe’s 20+ years of focused R&D and process refinement deliver the dimensional accuracy, surface quality, and electrical characteristics required for next-generation energy-efficient magnetics. We invite you to validate our capabilities through material samples and production trial coordination. Contact Cathy directly to initiate a technical consultation and receive our full specification dossier.

Contact Cathy at cathy@transformerstrip.com to engineer your next-generation interleaved winding solution.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing interleaved winding wire directly from China.