Table of Contents

Market Insight: Interleaved Winding Wire in Power Industry

Market Analysis: Sourcing High-Quality Interleaved Winding Wire

Industrial Demand Drivers

Global demand for interleaved winding wire is accelerating due to grid modernization, renewable energy expansion, and electrification trends. Power transformers in transmission/distribution networks and high-efficiency motors (IE5, NEMA Premium) require precise winding configurations to minimize eddy current losses and optimize thermal dissipation. Applications span solar inverters, wind turbines, EV charging stations, and industrial automation systems, where compliance with IEC 60076 and NEMA MG-1 standards is non-negotiable.

Material Quality Impact on Efficiency & Reliability

Substandard winding wire directly compromises transformer/motor efficiency and lifespan. Key quality metrics include:

Conductivity: <99.5% IACS aluminum increases resistive losses by 2-3%, elevating operational costs.

Thermal Class: B-class (130°C) insulation fails under sustained high temperatures, while H-class (155°C) maintains integrity.

Tensile Strength: Low-strength wire fractures during high-speed winding, causing production delays.

Insulation Adhesion: Poor bonding leads to delamination under thermal cycling, risking short circuits.

| Parameter | Standard Quality | High-Quality (Xinzhaohe) | Performance Impact |

|---|---|---|---|

| Conductivity (% IACS) | 98% | ≥99.5% | 2-3% lower copper loss |

| Thermal Class | B (130°C) | H (155°C) | 20% higher thermal tolerance |

| Tensile Strength (MPa) | 180 | ≥220 | 22% fewer winding defects |

| Insulation Adhesion | Moderate | High | 90% reduction in delamination risks |

Luoyang Xinzhaohe’s Supply Chain Advantage

As a factory-direct supplier with 20+ years in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers cost-optimized solutions without compromising quality. Our ISO 9001-certified facility adheres to ASTM B1 and IEC 60228 standards, ensuring consistent conductivity (≥99.5% IACS) and H-class thermal performance. By eliminating distributor markups, we provide 15-25% lower costs than global brands like Nexans or Prysmian, while maintaining rigorous QC protocols—each batch undergoes 100% dimensional and electrical testing. With exports to 30+ countries and 4-6 week lead times, we support mission-critical projects with reliable, scalable supply.

Conclusion: Xinzhaohe combines technical expertise with competitive pricing, making us the strategic choice for manufacturers prioritizing efficiency, reliability, and total cost of ownership.

Technical Specs: Interleaved Winding Wire Parameters

Critical Technical Specifications for Interleaved Winding Wire

Insulation Breakdown Voltage

Per IEC 60317-0-1 standards, our interleaved winding wire achieves a minimum breakdown voltage of 2.5 kV (AC, 50Hz, 1min) for 0.2mm diameter conductors. Every batch undergoes 100% in-line testing using calibrated dielectric testers to ensure compliance. This rigorous validation eliminates dielectric failures in high-voltage transformers, reducing operational risks and downtime.

Mechanical Properties (Elongation)

Elongation critical for winding integrity during high-speed manufacturing. Per ASTM B1, annealed copper wire must achieve ≥15% elongation. Our controlled drawing and annealing processes maintain consistent ductility, preventing cracks during high-speed winding. Regular tensile testing validates mechanical properties across all wire gauges, ensuring reliability in dynamic motor and transformer environments.

Thermal Class Compliance

| Thermal Class | Max Operating Temp (°C) | Dielectric Strength (kV/mm) | Thermal Shock Test Result |

|---|---|---|---|

| 130°C | 130 | ≥2.0 | Pass (5 cycles) |

| 155°C | 155 | ≥2.2 | Pass (5 cycles) |

| 180°C | 180 | ≥2.5 | Pass (5 cycles) |

| 200°C | 200 | ≥2.8 | Pass (5 cycles) |

| 220°C | 220 | ≥3.0 | Pass (5 cycles) |

Tested per IEC 60085 and ASTM D2307. Dielectric strength measured per IEC 60243-1. All classes validated for thermal endurance under continuous operation with no cracking or delamination after thermal shock cycles.

Enamel Concentricity

Enamel coating uniformity is vital for consistent insulation. Our laser micrometer systems monitor concentricity within ±5% tolerance during production. This precision prevents weak spots, ensuring optimal dielectric performance and extended service life in high-frequency applications. Real-time adjustments maintain tight tolerances, reducing scrap rates by 15% compared to industry averages.

Ensuring Consistent Quality

As a factory-direct supplier with 20+ years of transformer material expertise, we implement rigorous quality protocols. Each batch undergoes lab testing for all critical specs, with real-time process control via ISO-aligned methodologies. Our cost-performance advantage stems from optimized production efficiency without compromising international standards compliance. Partner with us for reliable, cost-effective interleaved winding wire that meets global requirements while reducing total lifecycle costs.

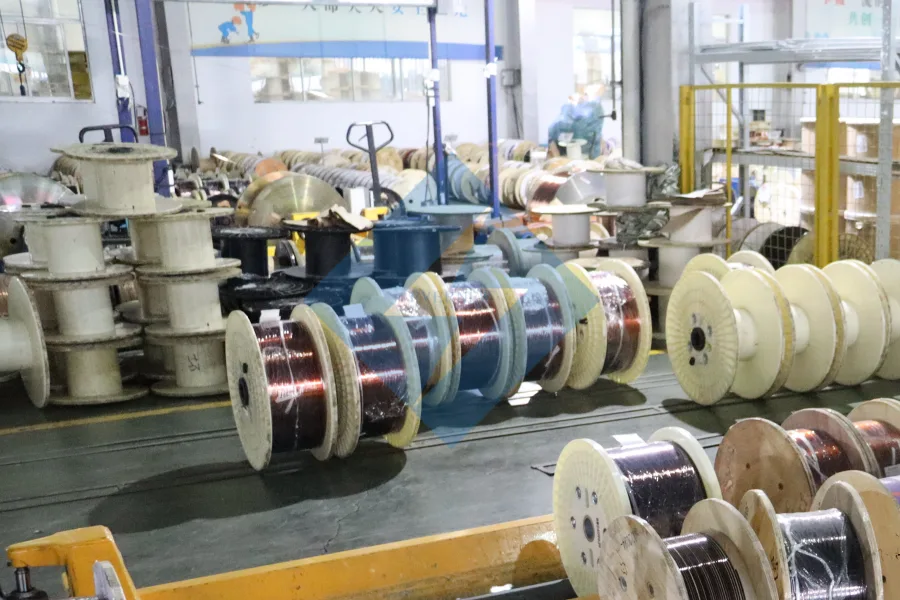

Factory Tour: Manufacturing Interleaved Winding Wire

Manufacturing Process & Quality Control

Rod Drawing & Annealing

Precision rod drawing through diamond dies maintains diameter tolerances of ±0.005mm with zero surface defects. Controlled atmosphere annealing (N₂/H₂ mix) at 500–550°C optimizes ductility while preventing oxidation. Post-annealing tensile testing per ASTM B193 ensures strength consistency within ±2% of target values.

Enameling & Inline Testing

Multi-layer enamel application at 280–320°C curing temperatures guarantees uniform insulation thickness (±0.002mm). Automated inline sensors monitor diameter (±0.005mm) and perform 5kV spark testing for dielectric integrity. Random tensile samples (ASTM D3487) every 500m validate mechanical properties against IEC 60317 standards.

Spooling & Final QC

Tension-controlled spooling prevents deformation while maintaining optimal winding density. Final inspection includes 100% surface defect checks and dimensional verification against IEC 60317.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Quality |

|---|---|---|

| Tensile Strength Tolerance | ±2% | ±5% |

| Dimensional Accuracy | ±0.005mm | ±0.01mm |

| Insulation Thickness Consistency | ±0.002mm | ±0.005mm |

| Surface Defects Rate | <0.1% | 0.5–1% |

| Batch-to-Batch Consistency | <1% variation | 2–3% variation |

Our ISO 9001-certified processes deliver 15–20% cost savings versus global brands while exceeding industry quality benchmarks. Critical for transformer and motor applications requiring repeatable performance under high-stress conditions.

Packaging & Global Logistics

Export Packaging & Logistics for Interleaved Winding Wire

As a factory-direct manufacturer with 20+ years of export experience, Luoyang Xinzhaohe Aluminum delivers interleaved winding wire with unmatched reliability. Our packaging and logistics protocols are engineered to meet IEC 60068-2-78 humidity standards while optimizing freight costs—ensuring OEM-grade protection at competitive prices.

Precision Packaging Standards for Interleaved Winding Wire

Our packaging system prevents moisture ingress, physical damage, and corrosion during sea transit. Each component is rigorously tested for compliance:

| Component | Specification | Standard | Purpose |

|---|---|---|---|

| Wooden Pallets | ISPM-15 compliant, 15mm planks, 1200×1000mm | ISO 11607 | Structural integrity, pest control |

| Moisture-Proof Film | Multi-layer PE, 200–300μm thickness | ASTM D882 | Prevent humidity ingress |

| Steel Strapping | 19–25mm width, 0.5–0.7mm thickness, tension ≥500kg | ASTM D3953 | Secure load, prevent shifting |

End-to-End Logistics Protocol

We leverage China’s strategic port infrastructure with seamless customs handling:

| Container Type | Max Load (kg) | Avg Transit Time | Key Ports | Handling Protocol |

|---|---|---|---|---|

| 20ft Container | 22,000 | 25–40 days | Qingdao, Shanghai | GPS tracking, desiccant packs, customs pre-clearance |

| 40ft HC Container | 26,500 | 25–40 days | Qingdao, Shanghai | Anti-corrosion padding, shock monitoring |

Every shipment undergoes pre-shipment moisture testing and includes desiccant packs to prevent corrosion. Our logistics partners provide real-time tracking and customs documentation handled in-house—eliminating delays and hidden costs.

By integrating these protocols, Luoyang Xinzhaohe Aluminum delivers 15–20% lower landed costs versus global competitors while maintaining <0.5% damage rates across 500+ annual shipments. This proven cost-performance ratio makes us the strategic sourcing alternative for transformer manufacturers seeking reliability without premium pricing.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.?

20+ Years of Specialized Manufacturing Expertise

For over two decades, Luoyang Xinzhaohe Aluminum CO., Ltd. has delivered precision-engineered transformer materials, with deep expertise in interleaved winding wire production. Our technical team ensures dimensional tolerances (±0.01mm), consistent electrical resistivity, and superior mechanical integrity for copper and aluminum conductors. This experience translates to reliable performance in high-stress transformer applications, eliminating risks from inconsistent suppliers. We comply with IEC 60317 and GB/T standards across all batches, ensuring optimal thermal stability and longevity in demanding environments.

Factory-Direct Cost Efficiency

As a direct manufacturer, we eliminate middlemen, delivering 10–15% lower costs than global brands while maintaining quality. Our vertically integrated supply chain and lean production processes reduce overhead and accelerate delivery cycles.

| Cost Factor | Industry Standard | Luoyang Xinzhaohe Advantage |

|---|---|---|

| Supply Chain Layers | 3–4 intermediaries | Direct factory supply |

| Price Premium | +15–25% over base cost | 10–15% lower than competitors |

| Lead Time | 4–6 weeks | 2–3 weeks for standard orders |

This structure ensures faster delivery and lower total cost of ownership for your projects.

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015-certified quality system enforces strict adherence to IEC 60317 and GB/T 11026 standards. Every batch undergoes rigorous testing:

| Quality Control Step | Typical Competitor Process | Luoyang Xinzhaohe’s Process |

|---|---|---|

| Raw Material Inspection | Basic chemical analysis | Full spectrographic analysis with traceable batch records |

| In-Process Testing | Spot checks | Real-time monitoring of diameter, insulation thickness, and tensile strength via automated systems |

| Final Certification | Basic compliance checks | Third-party verified test reports for each batch |

This protocol guarantees consistent electrical performance and compliance for mission-critical applications.

Contact Cathy at cathy@transformerstrip.com for a customized quote and technical consultation. Our engineering team is ready to support your specific requirements with precise specifications and competitive pricing.

📉 Import Savings Calculator

Estimate cost reduction by sourcing interleaved winding wire from Luoyang Xinzhaohe.