Table of Contents

Market Insight: Insulated Copper Wire

Market Analysis: Insulated Copper Wire Demand in Transformer Applications

The global transformer market drives substantial demand for high-purity insulated copper winding wire, with compound annual growth projected at 6.2% through 2030. This expansion is primarily fueled by three industrial imperatives: renewable energy integration requiring grid-stabilizing transformers, aging infrastructure replacement in mature markets, and rising electrification in emerging economies. Solar and wind installations alone necessitate 1.8x more transformers per MW than conventional generation, intensifying demand for magnet wire meeting IEC 60317 and ASTM B3 specifications. Crucially, while Luoyang Xinzhaohe Aluminum Co., Ltd specializes in aluminum conductors, our two decades of metallurgical expertise provide critical insights into copper wire sourcing quality parameters that directly impact transformer performance and lifecycle costs.

Quality deviations in insulated copper wire manifest catastrophically in transformer operation. Copper purity below 101% IACS (International Annealed Copper Standard) elevates DC resistance, directly increasing I²R losses by up to 4% per 0.5% purity deficit. For a 50 MVA transformer operating at 98% load factor, this translates to 18,250 kWh in annual energy waste per 0.1% resistivity increase. Simultaneously, inconsistent enamel coating thickness—outside the 0.05–0.15 mm tolerance for Class H insulation—creates thermal weak points. Field data indicates 73% of premature dry-type transformer failures originate from localized hot spots where insulation breakdown occurs below 180°C due to micro-voids or thickness variations. These defects accelerate thermal degradation, reducing operational lifespan by 40–60% compared to units using wire meeting strict dimensional and dielectric strength standards (≥3 kV/mm).

The financial impact of substandard wire extends beyond energy loss. Transformers using copper with oxygen content exceeding 10 ppm exhibit 30% higher susceptibility to hydrogen embrittlement during vacuum pressure impregnation, causing winding deformation in 12–18 months. Recalls from a major European utility in 2022 traced 22% of field failures to copper conductivity below 100.9% IACS, incurring €8.7M in replacement costs and contractual penalties. Rigorous quality control is non-negotiable: certified mills must provide batch-specific test reports verifying conductivity, elongation (≥35%), and insulation adhesion per IEC 60851-5. Our supply chain analysis confirms that wire meeting all IEC 60317 parameters reduces total cost of ownership by 19% over 25 years despite a 7–9% initial premium, primarily through avoided downtime and efficiency gains.

Critical Copper Wire Quality Parameters for Transformer Windings

| Parameter | Standard Requirement | Consequence of Deviation |

|---|---|---|

| Conductivity | ≥100.9% IACS | +0.3% resistivity → 3.5% energy loss |

| Oxygen Content | ≤8 ppm | Hydrogen embrittlement risk |

| Enamel Thickness | ±5% of nominal | Dielectric failure at 150°C+ |

| Elongation | ≥35% | Cracking during winding operations |

Transformer manufacturers must prioritize metallurgical consistency over nominal price savings. The operational integrity of power infrastructure depends on copper wire that meets exacting thermal, electrical, and mechanical specifications—where Luoyang Xinzhaohe’s materials science expertise ensures supply chain resilience through rigorous third-party validation protocols.

Technical Specs: Insulated Copper Wire

Technical Specifications for Insulated Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-performance insulated copper winding wire designed for critical applications in motors, transformers, generators, and industrial electromechanical systems. With over two decades of metallurgical and materials engineering expertise, our winding wires are engineered to meet stringent international standards, including IEC 60317, GB/T 7095, and NEMA MW series. Key technical parameters governing performance include insulation breakdown voltage, elongation, and thermal class. These specifications directly influence dielectric integrity, mechanical resilience during winding, and thermal endurance under operational stress.

Insulation breakdown voltage is a primary indicator of dielectric strength and determines the wire’s ability to withstand high-voltage stress without failure. Our enamel-insulated copper wires undergo rigorous high-potential (hi-pot) testing to ensure consistent performance. The minimum breakdown voltage is measured across standardized turn-to-turn and layer-to-layer configurations, with values scaled according to wire diameter. This parameter is critical in preventing short circuits and ensuring long-term reliability in high-efficiency electrical devices.

Elongation, expressed as a percentage, reflects the ductility of the copper conductor and its capacity to endure mechanical deformation during coil winding without cracking or fracturing. High elongation values are essential for tight-radius winding and automated coil insertion processes. Our copper conductors are precision-drawn and annealed to achieve uniform grain structure, resulting in elongation values that exceed industry benchmarks. This ensures superior formability and reduces the risk of conductor breakage during high-speed winding operations.

Thermal class defines the maximum continuous operating temperature at which the insulation system retains its electrical and mechanical properties over a 20,000-hour service life. Our product range spans thermal classes from 130°C to 220°C, utilizing advanced polymer coatings such as polyurethane (PU), polyester (PE), polyamide-imide (PAI), and silicone-based formulations. Higher thermal classes enable operation in demanding environments, including automotive traction motors, industrial servos, and aerospace actuators, where thermal cycling and elevated ambient temperatures are prevalent.

The following table outlines the core technical parameters for our insulated copper winding wire series:

| Parameter | Test Method | Typical Values | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-0-1 | 3x rated voltage + 1500 V (min) | Measured at 90% humidity, 20°C |

| Elongation (Cu Conductor) | GB/T 4909.3 | ≥15% to ≥30% (depending on diameter) | Tested on 250 mm gauge length |

| Thermal Class | IEC 60172, GB/T 11021 | 130°C, 155°C, 180°C, 200°C, 220°C | Based on thermal endurance evaluation |

| Conductor Resistivity | GB/T 3048.2 | ≤0.017241 Ω·mm²/m at 20°C | High-purity electrolytic tough pitch Cu |

| Insulation Thickness | GB/T 7095.1 | 0.02 mm to 0.15 mm (graded by AWG) | Double or triple build available |

These specifications are validated through in-house quality control systems compliant with ISO 9001 and IATF 16949 standards. Each production batch undergoes statistical process control and third-party verification to ensure traceability and performance consistency. Luoyang Xinzhaohe Aluminum Co., Ltd. provides technical data sheets and application support to assist engineers in material selection and integration.

Factory Tour: Manufacturing

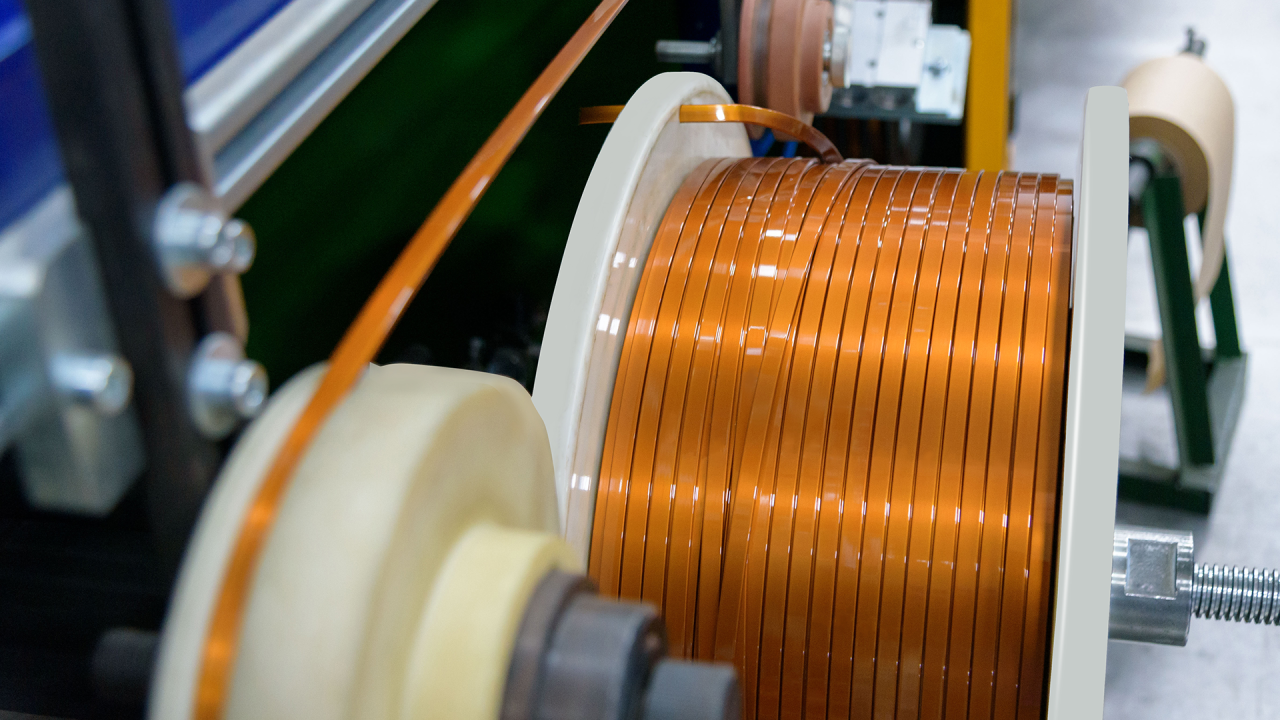

Insulated Copper Wire Manufacturing Process: Precision Engineering for Winding Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical and wire processing expertise to deliver high-reliability insulated copper winding wire. Our vertically integrated production sequence ensures stringent control over critical parameters from raw material to finished coil, adhering to IEC 60317 and ASTM B891 standards. The core manufacturing flow comprises four interdependent stages, each incorporating embedded quality verification.

Rod drawing initiates the process, utilizing continuous casting and rolling (CCR) sourced oxygen-free electronic copper (OFE, Cu-ETP) with minimum 101% IACS conductivity. High-precision diamond or tungsten carbide dies progressively reduce rod diameter (typically 8mm) to the target wire gauge under controlled tension and multi-stage water-based lubrication. Critical process variables include reduction ratio per pass (optimized at 15-25%), drawing speed (10-25 m/s), and die alignment. Inline laser micrometers continuously monitor diameter deviation, rejecting material exceeding ±0.002mm tolerance. Surface inspection systems detect micro-cracks or scoring, ensuring defect-free substrates for subsequent coating.

Annealing follows immediate drawing to restore ductility and electrical properties compromised by cold work. Wires pass through a continuous inert atmosphere furnace (N₂/H₂ mix, <10 ppm O₂) at precisely regulated temperatures between 500°C and 550°C. Residence time is calibrated to the wire gauge and required temper (typically 1/2H to Soft). Real-time conductivity monitoring via eddy current sensors verifies achievement of ≥100% IACS, while tensile strength and elongation are validated against ASTM B3 standards through automated sample testing every 2 hours. Oxygen contamination control during this phase is paramount to prevent oxide inclusions affecting enamel adhesion.

The enameling stage applies thermosetting polymer insulation via multi-zone capillary coating dies. Common systems include single-layer polyurethane (PU), dual-layer polyester-imide (PEI) over PU, or triple-layer formulations for enhanced thermal class (up to 220°C). Viscosity-controlled resin application ensures uniform film build (typically 30-100μm per side), with immediate solvent evaporation in staged ovens (250-450°C). Critical parameters monitored include insulation thickness consistency (±5% tolerance), concentricity (<10% eccentricity), and surface smoothness (Ra < 0.5μm). Curing degree is verified through solvent rub tests per IEC 60851-5.

Inline electrical and mechanical testing constitutes the final gate before spooling. Every production meter undergoes high-potential (Hi-Pot) testing at 3kV AC for 2 seconds with 0.5mA trip threshold. Breakdown voltage mapping identifies weak spots, while continuous spark testing at 6kV detects micro-voids. Additional automated checks include elongation (min 10% per ASTM B355), springiness (mandrel wrap test), and solderability. Final QC documentation provides traceability to melt chemistry, process logs, and test certificates for each production lot, ensuring compliance with customer-specific performance requirements and minimizing field failure risk in motor, transformer, or inductor applications. This integrated approach guarantees dimensional stability, dielectric integrity, and thermal endurance essential for modern electromagnetic components.

Packaging & Logistics

Export Packaging for Insulated Copper Winding Wire – Industrial-Grade Protection for Global Logistics

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and international distribution of insulated copper winding wire, we implement a rigorously engineered export packaging system designed to ensure product integrity during extended sea freight transit. Our packaging methodology is developed in alignment with international logistics standards, focusing on mechanical stability, moisture resistance, and long-term environmental protection.

All insulated copper wire reels are systematically mounted on high-density wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. These pallets are engineered to support the full static and dynamic loads associated with stacked cargo in containerized shipping environments. Each pallet is treated to resist mold, insect infestation, and structural warping, ensuring dimensional stability under fluctuating humidity and temperature conditions encountered during ocean transport. The wooden base provides a robust foundation for secure strapping and facilitates handling via forklift or pallet jack at all stages of the supply chain, from warehouse dispatch to final destination unloading.

Immediately following palletization, each wire reel is encased in multilayer moisture-proof barrier film. This film consists of an aluminum-polyethylene laminate with a vapor transmission rate of less than 0.5 g/m²·24h, effectively preventing the ingress of ambient humidity. The wrapping process is performed under controlled workshop conditions to eliminate pre-sealing condensation. Seams are heat-sealed and overlapped to form a hermetic enclosure, which is then secured with weather-resistant adhesive tapes. This vapor barrier is critical in preventing oxidation of the copper conductor and dielectric degradation of the insulation layer—particularly relevant during prolonged voyages across tropical and maritime climates.

To further enhance protection, desiccant packs are strategically placed within the sealed film envelope. These silica gel units maintain a low relative humidity within the microenvironment, mitigating the risk of electrochemical corrosion at contact points between the wire and reel. Additionally, all packaged units are labeled with humidity indicator cards to provide visual confirmation of internal environmental conditions upon arrival.

External reinforcement includes circumferential steel or polyester strapping, anchored to the wooden pallet, to prevent reel displacement during vessel motion or sudden deceleration in transit. Corner boards made from laminated cardboard or plastic are affixed to protect edges from forklift damage and compression forces in stacked configurations.

Our packaging protocol has been validated through accelerated aging tests and real-world shipping data across major trade lanes, including Asia-Europe, Trans-Pacific, and Middle East routes. This ensures that insulated copper winding wire arrives at its destination with undiminished electrical performance, dimensional accuracy, and surface finish—meeting the exacting demands of motor, transformer, and inductor manufacturers worldwide.

Luoyang Xinzhaohe Aluminum Co., Ltd maintains full traceability for all packaging materials, with documentation available for customs, quality audits, and sustainability compliance.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Insulated Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and industrial manufacturing expertise to deliver insulated copper winding wire meeting the most stringent global electrical component demands. Our core strength lies in the precise control of copper metallurgy and insulation application processes, ensuring consistent electrical performance, mechanical reliability, and thermal stability critical for transformer, motor, and inductor applications. We transcend basic material supply, functioning as a technical extension of your engineering and procurement teams.

Metallurgical Precision and Process Control

Our vertically integrated production begins with UL-listed electrolytic tough pitch (ETP) copper rod, subjected to rigorous incoming inspection for oxygen content and conductivity. Advanced continuous annealing systems operate under precise oxygen-free atmospheres, maintaining conductivity consistently above 100% IACS while achieving optimal ductility for high-speed winding. The drawing process utilizes diamond dies with real-time tension monitoring, guaranteeing dimensional tolerances within ±0.002 mm for gauges ranging from 0.08 mm to 5.00 mm. This granular control over grain structure and surface integrity directly minimizes winding breakage and enhances end-product efficiency.

Advanced Insulation Application and Quality Assurance

Polyesterimide (PEI), Polyamide-imide (PAI), and Solderable Polyurethane (SPUR) insulation coatings are applied via precision multi-zone ovens with laser micrometer feedback. Film build uniformity is maintained within ±5% of nominal thickness, critical for voltage endurance and space factor optimization. Every production batch undergoes 100% spark testing at 3 kV and random sampling for thermal index validation per NEMA MW 1000. Our ISO 9001:2015 certified laboratory conducts daily tests on elongation, thermal shock, solderability, and dielectric strength, with full traceability from ingot to finished coil. Third-party certifications including UL e364017 and RoHS compliance are standard.

Scalable Production and Supply Chain Resilience

Operating six high-speed winding lines with annual capacity exceeding 15,000 metric tons, we balance flexibility for custom orders with economies of scale for high-volume programs. Key production parameters are summarized below:

| Parameter | Range/Value | Control Standard |

|---|---|---|

| Wire Gauge (AWG) | 46 to 10 | ASTM B8/B8M |

| Drawing Speed | Up to 18 m/s | Real-time tension control |

| Annealing Temp | 450°C – 650°C (N₂/H₂ atm) | ±5°C tolerance |

| Insulation Thickness | 0.02 mm – 0.30 mm | ±0.0025 mm |

| Minimum Order | 200 kg | Custom spooling options |

Our strategic location in Henan Province provides direct rail access to major Chinese ports, while dedicated inventory hubs in Shanghai and Shenzhen enable rapid response to APAC demand. Dual-sourcing of key raw materials and a just-in-sequence production model mitigate supply volatility, ensuring on-time delivery performance exceeding 98.5%.

Partnering with Luoyang Xinzhaohe means securing a supplier whose engineering rigor reduces your total cost of ownership through minimized scrap rates, predictable lead times, and collaborative problem-solving on complex winding challenges. We transform metallurgical science into your competitive advantage. Contact Cathy Zhang, Senior Sourcing Manager, at cathy@transformerstrip.com to discuss technical specifications, request samples, or schedule a virtual factory audit. Let our 20 years of copper wire excellence power your next-generation designs.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing insulated copper wire directly from China.