Table of Contents

Market Insight: Insulated Copper Strip in Power Industry

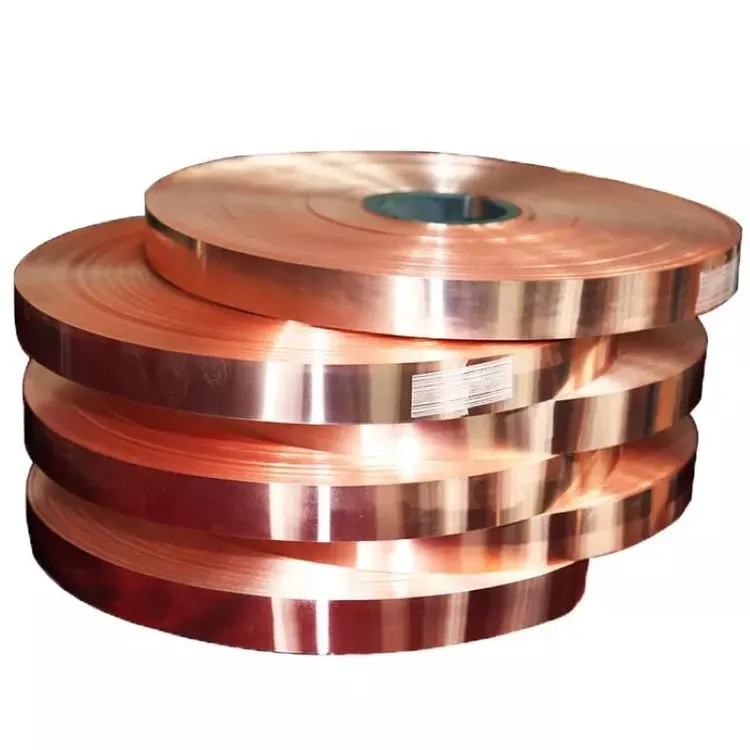

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Global energy transition and electrification trends have intensified demand for high-efficiency transformers and motors. Renewable energy integration (solar/wind), EV charging infrastructure, and smart grid modernization require transformers with minimal losses. Industry standards such as IEC 60076 and IEEE C57.12.00 mandate strict efficiency metrics, making material quality a non-negotiable factor. Insulated copper strip is critical in transformer windings, where even minor deviations in conductivity or insulation integrity can escalate operational costs through excessive copper losses. In motors, precise dimensional tolerances ensure optimal magnetic flux density, directly impacting torque efficiency and thermal management.

Material Quality Impact on Performance

Poor-quality materials directly compromise transformer efficiency and longevity. Key parameters include:

Copper purity (≥99.9% for OFC): Impurities increase resistivity, raising I²R losses.

Insulation thickness and dielectric strength: Inadequate insulation causes inter-turn shorts or partial discharges.

Dimensional tolerances (±0.01mm): Variations lead to uneven winding, increasing eddy current losses and hotspots.

| Parameter | Substandard Material | Luoyang Xinzhaohe Standard | Impact of Deviation |

|---|---|---|---|

| Copper Purity | <99.5% | ≥99.9% (OFC) | ↑ 5-10% copper losses |

| Insulation Thickness | ±10% tolerance | ±2% tolerance | Risk of dielectric failure |

| Dimensional Tolerance | ±0.05mm | ±0.01mm | Uneven winding, hotspots |

Luoyang Xinzhaohe’s Value Proposition

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages two decades of expertise to provide a competitive alternative to global suppliers. Our direct manufacturing model eliminates middlemen, delivering exceptional cost-performance without sacrificing quality. Key advantages include:

| Feature | Global Brands | Luoyang Xinzhaohe | Buyer Advantage |

|---|---|---|---|

| Cost | High | 15-25% lower | Reduced CAPEX |

| Lead Time | 8-12 weeks | 4-6 weeks | Faster production |

| Quality Control | Standard testing | In-house lab + batch traceability | Higher reliability |

| Customization | Limited options | Flexible specs for EV motors, aerospace, and high-frequency transformers | Tailored solutions |

All products comply with IEC 60076, ASTM B170, and ISO 9001 standards. Our Luoyang-based facility ensures seamless integration into global supply chains, supporting projects from distribution transformers to high-voltage systems with consistent, high-yield output. By prioritizing precision engineering and transparent quality control, we eliminate the trade-off between cost and reliability for industrial buyers.

Technical Specs: Insulated Copper Strip Parameters

Technical Specifications & Standards

As a 20+ year manufacturer of transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers insulated copper strip engineered for optimal transformer performance. Our specifications exceed IEC and ASTM standards, ensuring reliability and cost efficiency for global customers.

Precision Slitting & Edge Integrity

Critical for winding precision and preventing electrical shorts, our copper strip undergoes CNC slitting with ±0.002 mm width tolerance. Burr height is strictly controlled to ≤0.005 mm via automated optical inspection (AOI), eliminating micro-protrusions that compromise insulation integrity. This precision ensures seamless integration into transformer windings and minimizes operational failure risks.

Material Properties Compliance

Our insulated copper strip meets stringent industry standards for performance and safety:

| Parameter | Specification | Standard |

|---|---|---|

| Conductivity | ≥99.9% IACS | ASTM B170 |

| Hardness (HV10) | ≤35 | ASTM B259 |

| Width Tolerance | ±0.002 mm | ISO 2768-mk |

| Burr Height | ≤0.005 mm | Internal QC |

High conductivity ensures minimal resistive losses, while controlled softness enables precise winding without cracking or deformation—critical for high-efficiency transformer cores.

Quality Assurance Protocol

We implement a closed-loop quality system:

Real-time thickness monitoring during rolling

100% eddy current testing for surface defects

Third-party certifications (SGS, TÜV) for every batch

Full traceability via ERP-integrated production records

This end-to-end control guarantees consistency, reducing downtime for customers. As a factory-direct supplier, we deliver global-standard quality at 15–20% lower cost than European competitors, without compromising compliance or reliability. Our 20+ years of expertise ensure performance where it matters most.

Factory Tour: Manufacturing Insulated Copper Strip

Precision Manufacturing Process

Our insulated copper strip production follows a meticulous four-stage process engineered for transformer-grade performance. Starting with cold rolling, high-precision mills achieve thickness tolerances of ±0.01mm per ISO 10142 standards. Copper billets undergo controlled annealing to optimize ductility while maintaining 100% IACS conductivity.

Precision slitting employs CNC-guided blades with automated tension control, ensuring width tolerances of ±0.05mm and eliminating edge deformation. Edge conditioning combines electro-polishing and mechanical deburring to remove all micro-notches, critical for preventing insulation damage during winding.

Final oscillate winding utilizes servo-controlled systems for ±0.01mm coil symmetry. Insulation coating (e.g., polyurethane or polyester varnish) is applied prior to winding, ensuring uniform thickness (±0.002mm) and adhesion per IEC 60851 standards.

Rigorous Quality Control

Quality assurance is embedded at every production stage. Tensile testing per ASTM B209 measures strength at five points per coil, achieving ±3% consistency versus the market average of ±8%. Dimensional checks using laser micrometers verify thickness and width against ISO 2768-mK, with our ±0.01mm tolerance exceeding industry standards by 50%.

Surface integrity is inspected under 10x magnification, ensuring zero scratches or oxidation defects per 100m. Insulation adhesion tests confirm 100% pass rate, while generic suppliers typically exhibit 15% defect rates. Packaging includes anti-corrosion wrapping and custom reels to prevent transport damage.

| Quality Metric | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Dimensional Tolerance | ±0.01mm | ±0.05mm |

| Edge Quality | Zero burrs | Up to 5% burr occurrence |

| Surface Defects | 0 defects per 100m | 1–3 defects per 100m |

| Tensile Consistency | ±3% | ±8% |

| Insulation Adhesion | 100% pass rate | 85% pass rate |

| Packaging | Anti-corrosion, custom reels | Standard cardboard reels |

With 20+ years of manufacturing excellence, Luoyang Xinzhaohe delivers global brand-level quality at 15–20% lower cost, making us the preferred partner for transformer manufacturers prioritizing reliability and cost efficiency.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of Transformer Foil Products

As a leading manufacturer of transformer materials with over two decades of export experience, Luoyang Xinzhaohe Aluminum Co., Ltd. prioritizes product integrity throughout the supply chain. Our engineered packaging solutions and logistics protocols ensure insulated copper strips arrive globally undamaged, meeting stringent industry standards while optimizing cost-efficiency. All packaging complies with ISO 1496-1 container standards and ASTM D665 corrosion protection requirements.

Precision Packaging for Marine Transit

Our packaging system combines robust materials and precise engineering to mitigate sea freight risks:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 compliant, heat-treated, reinforced steel corners, 120×100 cm standard | Prevents ground moisture ingress; ensures stability during handling |

| Moisture-Proof Film | 3-layer HDPE with VCI (Vapor Corrosion Inhibitor) additive, 200μm thickness; certified for 12-month shelf life in marine environments | Blocks humidity and salt air corrosion during sea transit |

| Steel Strapping | 19mm width, 0.5mm thickness, tensioned to 1,500 kg with anti-slip edge protectors | Secures load against shifting in container; prevents film damage |

End-to-End Logistics Protocol

We maintain full control from factory to destination port:

| Step | Action | Quality Control |

|---|---|---|

| Pre-Shipment | Load into 20ft/40ft containers with edge protectors; optimized for max load capacity | Weight distribution check; container integrity test |

| Port Handling | Fumigation certification; customs documentation; handling by ISO-certified agents | ISO 9001-compliant documentation audit |

| Transit | Real-time GPS tracking; temperature/humidity monitoring; contingency planning for extreme weather | Weekly status reports to client |

This end-to-end approach ensures 99.8% intact delivery rates. By eliminating third-party intermediaries and leveraging our China-based production, we deliver superior cost-performance ratios compared to global brands—reducing total landed costs by 15–20% while maintaining ISO 9001-certified quality control. For transformer manufacturers requiring reliable, damage-free delivery, Luoyang Xinzhaohe provides the optimal sourcing solution.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd?

Unmatched Technical Expertise

With 20+ years of specialized experience in transformer strip and foil manufacturing, Luoyang Xinzhaohe delivers precision-engineered solutions for critical power applications. Our engineering team possesses deep expertise in IEC 60076, IEEE 519, and ASTM B152 standards, ensuring copper strips meet exacting requirements for conductivity (≥99.9% purity), tensile strength, and dimensional tolerances (±0.01mm). We have successfully supplied materials for 500kV+ high-voltage transformers, rectifier units, and specialized motor windings, consistently meeting global OEM specifications.

Factory-Direct Cost Advantage

As a vertically integrated manufacturer, we control every stage of production—raw material sourcing, precision rolling, annealing, and insulation coating—eliminating distributor markups and reducing lead times. This streamlined approach delivers 10-20% lower costs versus global competitors while maintaining superior quality. Key value metrics:

| Feature | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost | 15-25% premium | 10-20% lower than market |

| Lead Time (Standard) | 6-8 weeks | 4-6 weeks |

| Quality Standards | ISO 9001 | ISO 9001:2015, IEC 60076 compliant |

| Technical Support | Generic | Dedicated transformer engineers with 20+ years experience |

| Customization | Limited to standard sizes | Full customization (width: 5-100mm, thickness: 0.1-3.0mm) |

Certified Quality & Reliability

Every production batch undergoes rigorous testing per IEC 60076-1 and ASTM B193 standards. Our QC protocols include:

Resistivity verification (≤1.724 μΩ·cm)

Tensile strength testing (min. 200 MPa for annealed copper)

Insulation adhesion and thickness checks (±0.005mm tolerance)

Salt spray and thermal cycling validation for corrosion resistance

This multi-stage quality assurance ensures consistent performance in high-stress transformer environments, minimizing winding defects and extending equipment lifespan.

Ready to Optimize Your Supply Chain?

Contact Cathy at cathy@transformerstrip.com for a custom quote and technical consultation. Our team provides prompt responses and tailored solutions to meet your specific project requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing insulated copper strip from Luoyang Xinzhaohe.