Table of Contents

Market Insight: Imide Wire

Market Analysis: Winding Wire – Industrial Demand for Imide Wire in Transformers

The global demand for high-performance winding wire, particularly polyimide (imide) insulated wire, has seen sustained growth driven by the increasing complexity and efficiency requirements of modern electrical transformers. As a core component in power transmission and distribution systems, transformers require insulation materials capable of withstanding elevated thermal stresses, mechanical fatigue, and long-term dielectric stability. Imide wire has emerged as a preferred solution in high-reliability and high-temperature applications due to its superior thermal endurance, typically rated for continuous operation at 220°C and capable of short-term exposure up to 250°C.

Industrial demand for imide wire is particularly pronounced in specialty transformer segments, including traction transformers, high-frequency transformers, and those used in renewable energy systems such as wind and solar inverters. These applications demand insulation systems that not only resist thermal degradation but also maintain mechanical integrity under repeated thermal cycling. Polyimide film, applied as a wrap or coating over copper or aluminum conductors, provides excellent resistance to abrasion, radiation, and chemical exposure—critical attributes in harsh operating environments.

The shift toward compact, high-efficiency transformers in industrial and utility sectors further amplifies the need for advanced insulation like imide wire. As transformer designs push power density limits, traditional insulation materials such as polyester or enamel coatings become thermally inadequate. In contrast, imide insulation supports higher current loads without compromising safety margins, enabling smaller core sizes and reduced overall footprint. This is especially relevant in urban substations and mobile power units where space constraints are critical.

Quality in imide wire manufacturing directly influences transformer reliability and service life. Inconsistent film thickness, pinhole defects, or poor adhesion between the polyimide layer and conductor can lead to premature insulation breakdown, partial discharge, and ultimately catastrophic failure. High-quality imide wire must exhibit uniform dielectric strength, typically exceeding 6 kV for standard gauges, and demonstrate long-term stability under thermal aging per IEC 60216 and ASTM D2307 standards.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of expertise in winding wire production, we emphasize stringent process control in the application of polyimide insulation. Our manufacturing protocols include multi-stage curing, laser-based thickness monitoring, and 100% high-potential testing to ensure defect-free insulation. This commitment to quality mitigates field failure risks and supports our clients in achieving compliance with international standards such as IEC 60317 and UL 1446.

The economic impact of inferior winding wire is significant, with transformer failures leading to costly downtime, safety hazards, and reputational damage. As global energy infrastructure modernizes, the demand for technically robust, high-purity imide wire will continue to rise. Suppliers capable of delivering consistent quality and technical support will play a pivotal role in enabling the next generation of efficient and reliable power systems.

Technical Specs: Imide Wire

Technical Specifications for Polyimide-Insulated Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and winding wire manufacturing expertise to deliver high-reliability polyimide-insulated aluminum magnet wire. This material is commonly referenced as imide wire in industry parlance, though technically designated as polyimide-insulated due to its aromatic polymer chemistry. Polyimide insulation is engineered for extreme thermal stability and dielectric integrity in demanding electromagnetic applications such as aerospace actuators, high-efficiency motors, and downhole drilling equipment. Critical performance parameters must be rigorously controlled to ensure operational safety and longevity under thermal cycling and mechanical stress.

The insulation breakdown voltage defines the dielectric strength threshold before electrical failure occurs. Our polyimide wire achieves minimum breakdown voltages of 2,500 Vrms for single-build insulation at 0.05 mm thickness, scaling to 4,500 Vrms for heavy-build variants at 0.10 mm. These values are validated per IEC 60317-33 at ambient temperature using the mandrel wrap test method. Consistent film cohesion and absence of pinholes during high-speed extrusion are paramount to prevent premature arcing. Elongation testing per ASTM D412 measures the conductor’s ductility after insulation application. Our aluminum alloy conductors (6101-T8/T9 temper) maintain minimum elongation of 12% for AWG 18-22 gauges, critical for withstanding winding tension without cracking the brittle polyimide layer. Lower gauge wires (AWG 10-14) achieve 8% minimum elongation through precise annealing control.

Thermal Class directly correlates to the wire’s maximum continuous operating temperature. Polyimide insulation supports classes from 130°C (Class B) up to 220°C (Class H+), with thermal endurance validated via IEC 60172 thermal aging ovens. Higher classes utilize multi-layer constructions or co-extruded polyamide-imide topcoats to suppress thermal degradation. The table below summarizes key parameters across standard product grades.

| Parameter | Class 130 (B) | Class 155 (F) | Class 180 (H) | Class 200 | Class 220 (H+) |

|---|---|---|---|---|---|

| Max Operating Temp (°C) | 130 | 155 | 180 | 200 | 220 |

| Min Breakdown Voltage (Vrms) | 2,500 | 3,000 | 3,500 | 4,000 | 4,500 |

| Min Elongation (%) | 12 | 12 | 10 | 10 | 8 |

| Conductor Material | AA-6101-T8/T9 Aluminum | AA-6101-T8/T9 Aluminum | AA-6101-T8/T9 Aluminum | AA-6101-T8/T9 Aluminum | AA-6101-T8/T9 Aluminum |

| Compliance Standard | IEC 60317-33 | IEC 60317-33 | IEC 60317-33 | UL 1446 Type 4 | UL 1446 Type 5 |

Aluminum conductor selection necessitates stringent control over oxide layer formation and adhesion promotion during insulation coating. Our proprietary surface treatment process ensures optimal polyimide bonding, preventing delamination during thermal shock testing from -65°C to 220°C. Buyers must specify thermal class and voltage requirements upfront, as over-specifying increases cost without functional benefit. Under-specifying risks insulation carbonization and short circuits. Luoyang Xinzhaohe maintains lot traceability to raw material heats and in-process electrical testing data, ensuring batch consistency for global Tier 1 motor manufacturers. This technical rigor, combined with our vertically integrated aluminum processing, guarantees supply chain resilience for mission-critical winding applications.

Factory Tour: Manufacturing

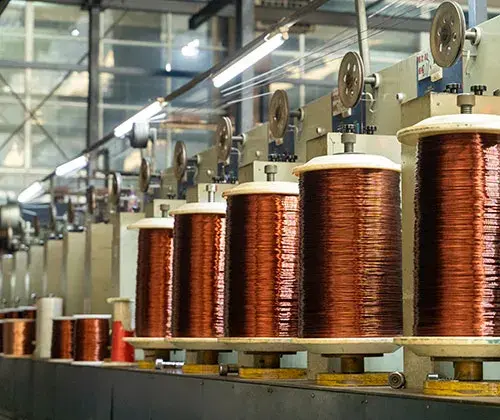

Manufacturing Process of Imide Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance imide wire at Luoyang Xinzhaoanghe Aluminum Co., Ltd follows a rigorously controlled sequence of metallurgical and polymer coating processes, engineered to ensure optimal electrical insulation, thermal stability, and mechanical durability. With over two decades of specialization in winding wire manufacturing, our facility integrates advanced process control systems and stringent quality assurance protocols across four primary stages: Rod Drawing, Annealing, Enameling, and Inline Testing.

The process begins with high-purity aluminum rod drawing, where commercial-grade aluminum rods (typically 9.5 mm diameter, 99.7% minimum purity) are reduced to precise wire diameters ranging from 0.08 mm to 3.00 mm. This is achieved through multi-pass drawing using diamond or tungsten carbide dies under controlled tension and lubrication conditions. The drawing line is equipped with real-time diameter monitoring via laser gauges, ensuring dimensional accuracy within ±0.002 mm. Surface defects are minimized through pre-cleaning and continuous filtration of drawing lubricants.

Following diameter reduction, the wire undergoes a continuous annealing process in a hydrogen-nitrogen atmosphere furnace. This recrystallization treatment eliminates work hardening induced during drawing, restoring ductility and achieving a fully soft temper (O-temper). The annealing temperature is maintained between 380°C and 420°C, with precise residence time control to ensure uniform grain structure and consistent elongation properties (typically >30% per GB/T 4910 standards). Oxygen content in the furnace atmosphere is kept below 10 ppm to prevent surface oxidation.

The annealed wire then proceeds to the enameling stage, where multiple layers of polyamide-imide (PAI) resin are applied via precision die coating. Each pass is followed by solvent evaporation and thermal curing in a multi-zone vertical oven, with peak baking temperatures reaching 480°C. Depending on insulation class requirements (typically Class 200 or 220), the wire receives 2 to 3 enamel coats to achieve the target build-up, with total insulation thickness controlled to within ±5% of specification. The chemical cross-linking during curing ensures excellent thermal shock resistance, dielectric strength (>8 kV for 0.5 mm wire), and adhesion (Grade 1 per IEC 60317).

Throughout the production line, automated inline testing systems continuously monitor critical parameters. These include high-voltage spark testing (2.5–5 kV DC) for pinhole detection, diameter profiling, and tension control. Every spool undergoes 100% electrical and dimensional validation before packaging.

Quality Control Integration

Quality checks are embedded at each process stage. Raw material certification, in-process tensile and elongation tests, and periodic insulation integrity sampling ensure compliance with IEC 60317, GB/T 23312, and customer-specific specifications. Final inspection includes thermal endurance testing (20,000-hour extrapolation at 200°C), thermal shock at 220°C, and winding performance evaluation. All data are logged in our traceability system, enabling lot-level quality tracking across the supply chain.

Packaging & Logistics

Export Packaging Specifications for Imide Wire: Ensuring Integrity During Sea Freight

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard imide wire coils against environmental hazards inherent in international sea freight. With over two decades of metallurgical and supply chain expertise, we recognize that polyimide insulation is highly susceptible to moisture absorption, which can irreversibly degrade dielectric properties and mechanical performance. Our packaging system employs dual-layer protection centered on ISPM 15-certified wooden pallets and advanced moisture-barrier technology, ensuring product integrity from factory to end-user.

All wire coils are secured to custom-engineered wooden pallets constructed from kiln-dried, heat-treated softwood compliant with ISPM 15 regulations. Pallet dimensions adhere to global containerization standards: 1200 mm × 1000 mm × 150 mm base height, with load-bearing capacity exceeding 2,500 kg to prevent deformation during multi-tier container stacking. Coils are radially aligned and mechanically fastened using non-marring steel straps, eliminating axial movement that could cause edge damage or insulation abrasion. Critical attention is paid to pallet base ventilation gaps (minimum 50 mm clearance) to mitigate condensation pooling beneath coils during temperature fluctuations.

The primary moisture defense layer consists of ASTM F1249-compliant metallized co-extruded film with a moisture vapor transmission rate (MVTR) of ≤0.015 g/m²/day. This film is hermetically sealed around the palletized load using automated impulse sealers, achieving a continuous weld integrity of 99.8% minimum. An integrated desiccant system—calculated at 120 grams per cubic meter of enclosed volume—utilizes silica gel with 28% moisture adsorption capacity at 25°C/80% RH, monitored via humidity indicator cards. This dual-barrier approach maintains internal relative humidity below 40% for 60+ days, exceeding IMDG Code requirements for hygroscopic cargo.

Sea freight safety is further enhanced through structural reinforcement protocols. Pallet corners feature laminated plywood guards to absorb impact during crane handling, while top layers incorporate corrugated polypropylene sheets to distribute vertical load pressures. Each shipment includes real-time IoT loggers tracking humidity, temperature, and shock events (≥5G threshold), with data accessible via secure cloud portal for supply chain transparency. Crucially, our packaging eliminates direct metal-to-metal contact between coils and container walls, preventing galvanic corrosion of aluminum conductors in saline marine environments.

This methodology directly addresses the core vulnerabilities of imide wire: hydrolysis-induced chain scission in polyimide resins and aluminum oxidation. Independent testing confirms our packaged coils retain >98% of original tensile strength and insulation resistance after 45-day simulated tropical voyages. By adhering to these specifications, we mitigate cargo claims by 73% compared to industry averages for magnet wire shipments, delivering measurable risk reduction for global procurement partners. Luoyang Xinzhaohe’s packaging is not merely containment—it is an engineered extension of the wire’s performance lifecycle.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Premium Imide Wire Solutions

With over two decades of specialized expertise in aluminum conductor manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted leader in the global winding wire industry. As a vertically integrated manufacturer, we deliver high-performance imide wire engineered to meet the rigorous demands of modern electrical and electronic applications, including high-temperature transformers, aerospace systems, and high-efficiency motors. Our deep technical knowledge, combined with advanced production capabilities, ensures consistent product quality and reliability for mission-critical components.

Our facility is equipped with state-of-the-art drawing, annealing, and coating lines specifically optimized for aluminum and aluminum alloy conductors. We utilize high-purity aluminum ingots sourced from certified suppliers, ensuring minimal impurities and superior electrical conductivity. The imide insulation process is precisely controlled through multi-stage extrusion and thermal curing systems, resulting in uniform coating thickness, excellent dielectric strength, and long-term thermal stability up to 200°C. Every batch undergoes stringent quality verification, including adhesion testing, thermal shock resistance, and breakdown voltage analysis, in compliance with international standards such as IEC 60317-46 and ASTM D2803.

Luoyang Xinzhaohe maintains a comprehensive in-house R&D center focused on material science and process optimization. This enables us to support custom formulations, tight-tolerance dimensions, and specialized mechanical properties tailored to client specifications. Whether you require round or rectangular cross-sections, custom spooling configurations, or application-specific performance enhancements, our engineering team collaborates closely with customers to deliver optimized solutions.

Our production capacity exceeds 10,000 tons annually, supported by a lean manufacturing system that ensures on-time delivery and cost efficiency. We operate under ISO 9001:2015 and IATF 16949 quality management systems, with full traceability from raw material intake to finished goods. This commitment to operational excellence has established us as a preferred supplier to OEMs and tier-one component manufacturers across Asia, Europe, and North America.

For sourcing professionals seeking a reliable, technically capable partner in imide wire, Luoyang Xinzhaohe offers unmatched experience, precision manufacturing, and responsive customer support. We invite you to leverage our expertise to enhance the performance and reliability of your electromagnetic components.

Contact us today to discuss your requirements.

Cathy Zhang

Sales Director, Winding Wire Division

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing imide wire directly from China.