Table of Contents

Market Insight: Hv Winding Material

Market Analysis: High Voltage Winding Material in Transformer Applications

The global demand for high voltage (HV) winding materials, particularly aluminum and copper conductors used in power and distribution transformers, continues to grow in alignment with expanding electrical infrastructure, renewable energy integration, and grid modernization initiatives. As a key component in transformer windings, HV winding materials must meet stringent performance criteria to ensure long-term reliability, thermal stability, and electrical efficiency. Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in aluminum conductor manufacturing, recognizes the critical role of material integrity in meeting the evolving demands of the power transmission and distribution sector.

Industrial demand for HV winding materials is primarily driven by utility-scale transformer manufacturing, industrial power systems, and renewable energy installations such as wind and solar farms, where step-up transformers require robust winding conductors capable of handling high voltages and variable load conditions. Aluminum-based winding wires have gained significant market share due to their favorable conductivity-to-weight ratio, corrosion resistance, and cost efficiency compared to copper, particularly in large power transformers. However, the performance of aluminum conductors is highly dependent on metallurgical quality, dimensional precision, and surface finish—factors that directly influence winding integrity, current carrying capacity, and thermal performance.

Quality in HV winding material is not a secondary consideration—it is a fundamental engineering requirement. Substandard conductors can lead to increased resistive losses, localized hot-spot formation, mechanical deformation under electromagnetic stress, and ultimately, premature transformer failure. At Luoyang Xinzhaohe, we emphasize strict control over alloy composition (typically 1350-O or equivalent), tensile strength, elongation, and ovality to ensure consistency across production batches. Our manufacturing process includes continuous annealing, precision drawing, and surface cleaning to achieve the required soft temper (annealed state) and defect-free surface morphology essential for tight coil winding and insulation compatibility.

Another critical factor is adherence to international standards such as IEC 60164, ASTM B355, and GB/T 23308, which define electrical, mechanical, and dimensional specifications for transformer winding wires. Compliance ensures interoperability, safety, and long service life under continuous electrical stress. Furthermore, with the increasing deployment of smart grids and high-efficiency transformers (e.g., amorphous metal cores), the synergy between core design and winding performance becomes even more pronounced, necessitating conductors with minimal skin effect and optimized cross-sectional uniformity.

In summary, the industrial demand for HV winding materials is shaped by the need for reliable, efficient, and scalable power systems. As transformer manufacturers face tighter performance margins and longer warranty expectations, the quality of winding wire directly impacts system uptime, maintenance costs, and total cost of ownership. Luoyang Xinzhaohe Aluminum Co., Ltd is committed to delivering aluminum winding conductors that meet the highest technical standards, supporting the global transition toward resilient and efficient energy infrastructure.

Technical Specs: Hv Winding Material

Technical Specifications for High Voltage Aluminum Winding Material

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to deliver aluminum winding wire engineered for critical high-voltage (HV) transformer and reactor applications. Our HV winding material adheres to stringent international standards, ensuring reliability under extreme electrical and thermal stress. Key specifications focus on dielectric integrity, mechanical resilience, and thermal stability, directly impacting equipment lifespan and safety. Insulation breakdown voltage is non-negotiable for HV systems; our materials consistently exceed 15 kV RMS at 50 Hz for 1 mm nominal thickness, validated per IEC 60317-0-5. This performance is achieved through proprietary polymer insulation formulations and precision extrusion processes, eliminating voids or inclusions that could initiate partial discharges. Impulse withstand testing at 1.2/50 μs waveforms further certifies resilience against transient overvoltages common in grid operations.

Elongation properties are critical for winding manufacturability and in-service ductility. Our aluminum alloy conductors (typically 1350 or 1370 grade) achieve minimum 25% elongation after final annealing, per ASTM B230/B231. This ensures the wire withstands high-tension winding without microcracking while accommodating thermal cycling stresses during operation. Rigorous in-line tensile testing at 0.5-meter intervals guarantees batch uniformity, preventing localized weak points that compromise structural integrity.

Thermal classification defines operational limits for insulation systems. Xinzhaohe supplies materials rated from Class 130°C (B) to Class 220°C (C), aligned with IEC 60085 and NEMA MW 1000. Class 180°C (F) and 200°C (H) variants are most prevalent for HV power transformers, balancing cost and longevity. Each thermal class undergoes 1,000+ hours of thermal aging at maximum rated temperature, with post-aging elongation retention >50% and dielectric strength degradation <15%. Continuous conductor temperature limits are strictly enforced; exceeding these accelerates insulation embrittlement and hydrolysis.

The following table summarizes critical technical parameters for our standard HV aluminum winding wire:

| Parameter | Minimum Value | Test Standard | Measurement Condition |

|---|---|---|---|

| Insulation Breakdown Voltage | 15 kV RMS | IEC 60317-0-5 | 50 Hz, 1 mm nominal thickness |

| Impulse Withstand Voltage | 45 kV peak | IEC 60243-1 | 1.2/50 μs waveform |

| Elongation | 25% | ASTM B230/B231 | After final annealing |

| Thermal Class Rating | 130°C to 220°C | IEC 60085 | Based on insulation system |

| Thermal Aging Retention | >50% | IEC 60216-2 | After 1,000 hrs at max temp |

| Conductor Resistivity | ≤0.028264 Ω·mm²/m | ASTM B230 | 20°C, annealed condition |

All materials undergo 100% spark testing during production and batch-level verification of dimensional tolerances (±0.02 mm for round wire). Xinzhaohe’s vertically integrated production—from molten aluminum casting to insulation coating—ensures traceability and consistency. For mission-critical HV infrastructure, these specifications mitigate risks of insulation failure, thermal runaway, and mechanical fatigue, directly supporting grid reliability. Partner with us to define application-specific tolerances beyond standard benchmarks.

Factory Tour: Manufacturing

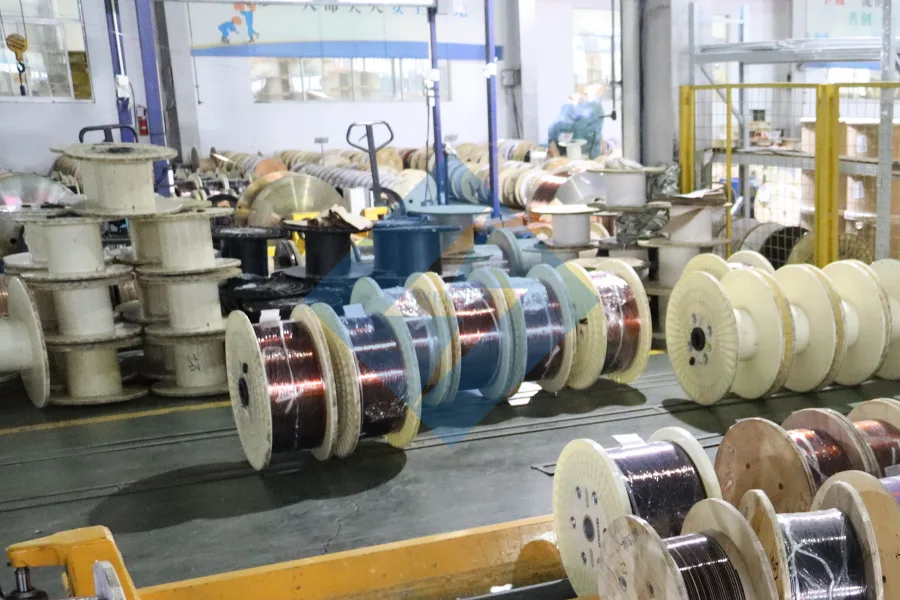

Manufacturing Process of HV Winding Material at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-voltage (HV) winding material at Luoyang Xinzhaohe Aluminum Co., Ltd follows a rigorously controlled, multi-stage manufacturing process designed to ensure superior electrical performance, mechanical integrity, and long-term reliability in demanding applications. With over two decades of metallurgical and process engineering expertise, our facility integrates precision equipment and real-time quality monitoring to deliver aluminum winding wire that meets stringent international standards.

The process begins with rod drawing, where high-purity aluminum rods (typically 99.7% Al or higher) are fed into a multi-die continuous drawing machine. The rods are reduced in diameter through a series of precision tungsten carbide or diamond dies, achieving the target wire gauge with tight dimensional tolerances (±0.01 mm). Lubrication with water-soluble drawing oil ensures surface smoothness and minimizes work hardening. The drawn wire is wound onto precision spools under constant tension to prevent deformation and ensure uniform layering.

Following drawing, the wire undergoes a controlled annealing process in a continuous inert atmosphere furnace. This step is critical for restoring ductility and eliminating residual stresses induced during drawing. The annealing profile—carefully calibrated for temperature (typically 300–450°C), dwell time, and cooling rate—ensures a fully recrystallized microstructure with consistent elongation (>15%) and tensile strength (80–100 MPa). The nitrogen-purged environment prevents oxidation and maintains surface integrity.

The annealed wire then proceeds to the enameling line, where multiple layers of thermosetting polymer insulation are applied via precision die coating. For HV applications, a dual-layer system is standard: a base layer of polyamide-imide (PAI) for thermal stability and adhesion, followed by an outer layer of polyesterimide (PEI) for dielectric strength and chemical resistance. Each coat is cured in-line through a series of high-temperature ovens (up to 550°C), ensuring complete cross-linking and insulation cohesion. Total insulation thickness is maintained within ±0.005 mm, with precise control over concentricity.

Inline testing is performed continuously throughout the enameling and curing stages. Key parameters monitored include dielectric breakdown voltage (tested at 3–5 kV AC for standard gauges), conductor continuity, and dimensional consistency. Spark testing detects pinholes or insulation defects, while laser micrometers provide real-time diameter feedback. All data is logged for traceability.

Final quality control includes batch sampling for thermal class verification (typically 180°C or 200°C), thermal shock resistance, and solderability. Each production lot is certified to IEC 60317, GB/T 23311, and customer-specific specifications. This integrated approach ensures that every meter of HV winding material from Xinzhaohe delivers consistent performance in transformers, reactors, and high-efficiency motors.

Packaging & Logistics

Export Packaging Specifications for HV Winding Material

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for high-voltage (HV) winding material to ensure absolute integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, our system addresses the critical vulnerabilities of aluminum conductor coils: mechanical stress, saltwater exposure, and atmospheric humidity. Sea freight presents unique hazards including container condensation (“cargo sweat”), prolonged vibration, and temperature fluctuations; our packaging mitigates these risks through material science and structural design.

All HV winding coils are secured on custom-engineered wooden pallets constructed from kiln-dried spruce or pine. These pallets comply strictly with ISPM 15 phytosanitary standards for international wood packaging, featuring heat-treated certification to prevent pest transmission. Pallet dimensions are optimized for coil geometry and container utilization, with key specifications as follows:

| Parameter | Specification | Technical Rationale |

|---|---|---|

| Wood Moisture | ≤12% (ASTM D4442) | Prevents mold growth and dimensional instability |

| Load Capacity | ≥3,000 kg per pallet | Accommodates coil weights up to 2,500 kg with safety margin |

| Base Height | 150 mm minimum | Elevates coils above container floor moisture |

| Treatment | Non-chemical heat treatment only | Eliminates chemical residue contamination risk |

Coils are wrapped in a multi-layer moisture barrier system comprising 120-micron polyethylene film with aluminum foil lamination. This composite structure achieves a water vapor transmission rate (WVTR) of ≤0.5 g/m²/24hr (ASTM F1249), creating a hermetic seal against humidity ingress. The film is heat-sealed at all seams using industrial-grade impulse sealers, with weld strength exceeding 80 N/15mm (ISO 11339) to withstand handling stresses. An additional layer of anti-corrosion VCI (Vapor Corrosion Inhibitor) paper is interposed between the coil layers, releasing non-toxic inhibitors that form a molecular barrier on aluminum surfaces for 24 months.

Palletized units undergo vacuum consolidation to eliminate air pockets before final overwrapping. The entire assembly is then strapped with steel tension straps (minimum 15 mm width, 15 kN tensile strength) anchored to pallet stringers at 300 mm intervals. This prevents coil shifting during vessel motion, addressing ISO 133-1997 maritime vibration profiles. Corner boards of 12 mm marine-grade plywood protect edges from forklift impact, while top covers feature UV-stabilized polypropylene to resist solar degradation during port storage.

Our packaging protocol has been validated through 500+ successful container shipments across Pacific and Atlantic routes, with zero moisture-related claims in the past five years. This reliability stems from integrating metallurgical knowledge of aluminum’s susceptibility to hygroscopic degradation with supply chain physics. Clients receive digital moisture logs from IoT sensors placed within sample shipments, providing real-time RH/temperature data throughout transit. For HV applications where conductor purity and dimensional stability are non-negotiable, this packaging system is not merely protective—it is a prerequisite for maintaining the material’s dielectric performance upon delivery.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for High-Voltage Winding Material Excellence

With over two decades of specialized expertise in aluminum winding materials, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted manufacturer and supplier for high-voltage (HV) winding applications in the transformer and electrical equipment industries. Our dedicated focus on precision aluminum strip and foil products has positioned us as a strategic partner for global OEMs, winding wire producers, and transformer manufacturers seeking consistent quality, technical reliability, and scalable supply.

Our manufacturing facility integrates advanced rolling, annealing, and slitting technologies to produce aluminum materials that meet the stringent demands of HV winding systems. We specialize in producing 1000-series and 8000-series aluminum alloys, with precise control over mechanical properties such as tensile strength, elongation, and electrical conductivity. Our aluminum strips are engineered to achieve minimum resistivity of 0.028264 Ω·mm²/m (IACS ≥ 61%) and are available in thicknesses ranging from 0.2 mm to 6.0 mm, with widths from 10 mm to 1,250 mm, tailored to customer-specific winding configurations.

All production processes are governed by a certified quality management system (ISO 9001:2015), with in-line monitoring and laboratory testing for dimensional accuracy, surface finish, edge quality, and metallurgical consistency. Our coil-to-coil uniformity ensures minimal variation in winding tension and layer stability, critical for high-voltage insulation integrity and long-term operational reliability.

We operate a fully integrated production line that includes hot rolling, cold rolling, intermediate and final annealing, tension leveling, and precision slitting. This vertical control enables us to maintain tight tolerances—down to ±0.01 mm in thickness and ±0.1 mm in width—and deliver materials with defect-free surfaces, essential for preventing partial discharge in HV transformer windings.

Our R&D team collaborates closely with customers to optimize material specifications for specific dielectric requirements, thermal performance, and mechanical robustness. Whether supplying bare aluminum strip for continuous disc windings or surface-treated material for enhanced adhesion in resin-impregnated systems, we ensure compatibility with industry-standard insulation materials and varnishing processes.

As a supplier, Luoyang Xinzhaohe combines technical depth with operational agility. We support low-volume prototyping and high-volume production runs, with an annual capacity exceeding 30,000 metric tons. Our logistics network ensures timely delivery to international markets, supported by comprehensive documentation including mill test certificates (MTCs), RoHS compliance reports, and custom packaging solutions.

For engineers and procurement teams sourcing high-performance HV winding materials, partnering with Luoyang Xinzhaohe means access to metallurgical expertise, process stability, and a commitment to on-time, defect-free delivery.

Contact us today to discuss your technical requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing hv winding material directly from China.