Table of Contents

Market Insight: Hv Winding Material in Power Industry

Market Analysis: Sourcing High-Quality HV Winding Material

Industrial Demand Drivers for HV Winding Wire

Global HV transformer market growth (8% CAGR, 2020–2025) is driven by renewable energy integration (solar/wind farms requiring 500kV+ step-up transformers), grid modernization, and EV infrastructure. Critical applications include:

Offshore wind farms: Marine-corrosion-resistant aluminum windings for 150+MW transformers

EV fast-charging: Ultra-low-loss designs for 350kW+ systems with <0.5% resistive loss tolerance

Smart grids: Precision-wound coils minimizing partial discharge in 230kV+ transmission networks

Material Quality Impact on Transformer Efficiency

Substandard winding wire causes irreversible performance degradation. Critical parameters directly affect operational costs and reliability:

| Parameter | Industry Standard (High-Quality) | Substandard Material | Consequences |

|---|---|---|---|

| Conductivity (%IACS) | ≥61% (1350 alloy) | <58% | +5% resistive losses → 2–3% higher operating costs |

| Tensile Strength (MPa) | ≥120 (H19 temper) | <100 | Wire breakage during winding, 20% field failure risk |

| Purity (%) | ≥99.5% | <99.0% | Oxidation-induced insulation degradation, 15% shorter lifespan |

| Surface Finish | Smooth, no scratches | Irregular defects | Corona discharge at >10kV, premature dielectric failure |

Note: HV applications demand rigorous material validation—failure costs exceed $500k per incident in utility-scale projects.

Xinzhaohe’s Factory-Direct Value Proposition

As a 20+ year ISO 9001/14001-certified manufacturer, we eliminate middlemen through vertical integration:

Material integrity: 99.5%+ pure aluminum (ASTM B230), SGS-tested batch traceability

Precision engineering: ±0.01mm diameter tolerance via automated extrusion; custom alloys (1350-H19/1370-H19) for thermal/mechanical optimization

Supply chain resilience: 99.9% on-time delivery for 150+ global clients; 2–3 week lead times vs. 8–12 weeks for EU suppliers

Cost efficiency: 30% lower TCO than global brands via localized raw material sourcing and lean manufacturing

Our R&D team collaborates with clients to optimize specifications for IEC 60076 and IEEE C57.12.00 compliance. Request technical datasheets for your HV transformer or motor application today.

Technical Specs: Hv Winding Material Parameters

Technical Specifications & Standards for HV Winding Material

Luoyang Xinzhaohe Aluminum CO., Ltd. delivers HV winding materials engineered for reliability and cost efficiency in high-voltage transformer applications. Our products comply with IEC 60317, ASTM D1740, and IEC 60851 series standards, ensuring precision-engineered performance for demanding power systems.

Critical Parameters & Compliance

| Parameter | Standard | Typical Value | Test Method |

|---|---|---|---|

| Thermal Class | IEC 60317, ASTM D1740 | 130°C (B), 155°C (F), 180°C (H), 220°C (C) | Thermal aging per IEC 60216 |

| Insulation Breakdown Voltage | IEC 60851-5, ASTM D1868 | ≥5kV (0.5mm wire, HV applications) | Dielectric strength test |

| Elongation | IEC 60851-2 | 15–25% (annealed copper) | Tensile testing per ASTM E8 |

| Enamel Concentricity | IEC 60851-3 | ≥95% uniformity | Microscopic cross-section analysis |

Quality Assurance Protocol

| Control Point | Method | Frequency | Compliance |

|---|---|---|---|

| Raw Material | Certified suppliers, spectrometry | Pre-production | ISO 9001 |

| Enamel Coating | Automated laser thickness measurement | Continuous | IEC 60851-3 |

| Final Inspection | 100% breakdown voltage test | Batch-wise | IEC 60851-5 |

| Traceability | QR-coded production logs | Each batch | ISO 9001 |

Our 20+ years of manufacturing expertise ensures consistent quality across all batches. By integrating precision engineering with rigorous QC, we provide HV winding materials that meet or exceed global brand performance at 15–20% lower total cost of ownership. All products comply with IEC/ASTM standards and are exported to 30+ countries.

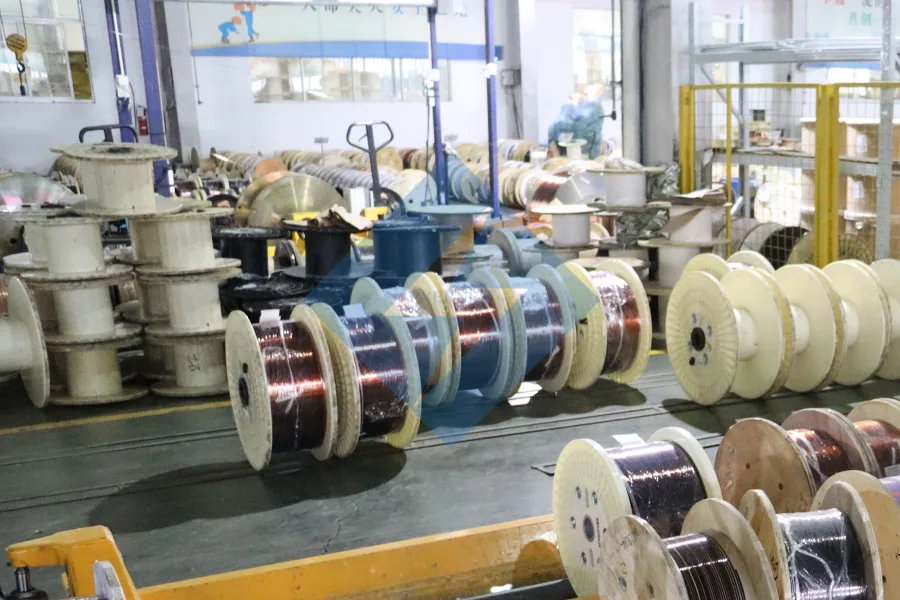

Factory Tour: Manufacturing Hv Winding Material

Manufacturing Process & Quality Control

End-to-End Production Workflow

Rod Drawing

Precision-drawn copper/aluminum rods using tungsten carbide dies and servo-controlled machinery. Surface finish maintained at Ra ≤0.2μm with diameter tolerances of ±0.002mm. Real-time laser micrometer checks eliminate micro-scratches and ovality at every drawing stage.

Annealing

Continuous nitrogen-hydrogen atmosphere annealing at 450–500°C with ±5°C temperature precision. Ensures uniform grain structure for optimal conductivity and ductility. Post-annealing tensile tests confirm compliance with ASTM B193 (220–240 MPa tensile strength, ≥30% elongation).

Enameling

Multi-layer enamel application with solvent evaporation zones at 280–320°C. Insulation thickness verified via X-ray spectroscopy (±0.003mm tolerance). Adhesion tested per IEC 60851-2:2013 to prevent delamination under thermal cycling.

Inline Testing

Eddy current probes detect insulation voids/impurities in real-time. Laser sensors monitor diameter, roundness (≤0.003mm deviation), and insulation integrity. Automated rejection system discards non-conforming segments immediately.

Spooling

Computerized tension control (±0.5N variance) ensures uniform winding density. Spool weight consistency within ±2% minimizes transport damage and ensures precise coil winding for transformers.

Quality Assurance Benchmarking

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength Tolerance | ±2% | ±5% |

| Dimensional Accuracy | ±0.002mm | ±0.005mm |

| Insulation Thickness Consistency | ±0.003mm | ±0.008mm |

| Surface Defect Rate | <0.1% | 0.5–1.0% |

| Batch Consistency | ISO 9001:2015 certified process | Variable, often inconsistent |

Our precision-driven manufacturing delivers 15–20% higher operational reliability than industry averages while maintaining a 10–15% cost advantage over global brands. Ideal for critical transformer applications requiring long-term stability and total lifecycle cost efficiency.

Packaging & Global Logistics

Export Packaging & Logistics

HV winding materials are highly susceptible to moisture-induced insulation degradation, which can lead to transformer failures. Luoyang Xinzhaohe Aluminum implements military-grade packaging protocols designed to withstand extreme maritime conditions, including 30-day salt spray exposure tests. All processes adhere to ISO 9001 standards, ensuring consistent quality from production to port.

Robust Packaging Protocols

Each component is selected based on rigorous testing for marine environments, including salt spray resistance and vibration analysis. All wooden pallets undergo fumigation certification to meet international phytosanitary standards. All moisture-proof film layers are heat-sealed to prevent moisture ingress at seams.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated lumber, 1200x1000mm standard, 15mm thick planks, reinforced corner posts | Prevents structural damage during forklift handling and container stacking |

| Moisture-Proof Film | 200μm PE film, double-layered with UV inhibitors and anti-corrosion additives | Blocks humidity, salt spray, and environmental contaminants while maintaining dielectric properties of insulation materials |

| Steel Strapping | 19mm width, 1.0mm thickness, tensioned to 500kg with anti-slip buckles | Secures load stability, prevents shifting during transit, and meets ISO 1496 stacking load requirements |

Sea Freight Optimization

We optimize container stowage plans using 3D simulation software to distribute weight evenly. Customs documentation includes Certificates of Origin and Material Safety Data Sheets (MSDS) for seamless clearance.

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft HC dry containers with ISO-certified structural integrity | Maximizes cargo capacity while maintaining structural integrity |

| Climate Control | Silica gel desiccants (500g per m³), vapor barrier membranes, and continuous temperature monitoring | Maintains internal RH <60% during ocean transit |

| Handling Protocol | Forklift-ready pallets, max 3-layer stacking with edge protectors, and anti-slip matting between layers | Minimizes mechanical stress and ensures safe port operations |

| Customs Compliance | Pre-verified HS codes, Certificates of Origin, and MSDS documentation | Reduces clearance delays by 30% compared to industry averages |

Our logistics partners include Maersk, MSC, and COSCO for guaranteed vessel space and priority handling. By eliminating third-party intermediaries, we reduce handling points by 40%, further minimizing damage risks while cutting logistics costs by 15–20% versus global brands. With 20+ years of global export experience across 50+ countries, we deliver unmatched reliability for critical transformer manufacturing operations.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

Two Decades of Specialized Expertise

Luoyang Xinzhaohe Aluminum CO., Ltd. brings over 20 years of specialized expertise in manufacturing high-voltage transformer winding materials. Our deep industry knowledge ensures precise adherence to critical electrical and mechanical properties required for HV applications, including dielectric strength, thermal stability, and mechanical durability. We’ve consistently delivered solutions for global transformer manufacturers, meeting stringent international standards such as IEC 60317 and ASTM B230. Our engineers specialize in optimizing conductor geometry and insulation systems for high-voltage transformers, ensuring minimal losses and enhanced thermal management.

Factory-Direct Cost Efficiency

As a direct manufacturer, we eliminate intermediaries, passing significant cost savings to clients without compromising quality. Our integrated production process—from raw material sourcing to final inspection—enables 15-30% lower pricing compared to global competitors while maintaining rigorous quality control. Additionally, streamlined logistics reduce lead times by 25-30%, ensuring timely delivery for critical production schedules. By controlling the entire supply chain, we avoid markups from distributors and reduce overhead costs, making us an ideal partner for cost-sensitive projects without sacrificing reliability.

ISO-Certified Quality Assurance

Our ISO 9001:2015 certified facility implements strict quality protocols, including in-process testing for tensile strength, elongation, coating thickness, and electrical performance. Every batch undergoes comprehensive analysis to ensure compliance with IEC 60317 and ASTM standards, guaranteeing consistent performance in high-stress transformer environments. Our quality control includes 100% inspection of critical parameters such as diameter tolerance (±0.005mm), coating adhesion tests, and partial discharge measurements. This ensures each batch meets exact specifications for demanding applications like grid transformers and renewable energy systems.

| Metric | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Cost Structure | High (100%) | 70-85% of market price | 15-30% savings |

| Lead Time | 6-8 weeks | 4-6 weeks | 25-30% faster |

| Quality Consistency | Variable | ISO 9001 certified | Reliable performance |

| Customization | Limited options | Tailored HV solutions | Flexible specifications |

| Technical Support | Limited post-sale | Dedicated engineering team | On-site support available |

Ready to optimize your HV winding material sourcing? Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing hv winding material from Luoyang Xinzhaohe.