Table of Contents

Market Insight: Hml Magnet Wire in Power Industry

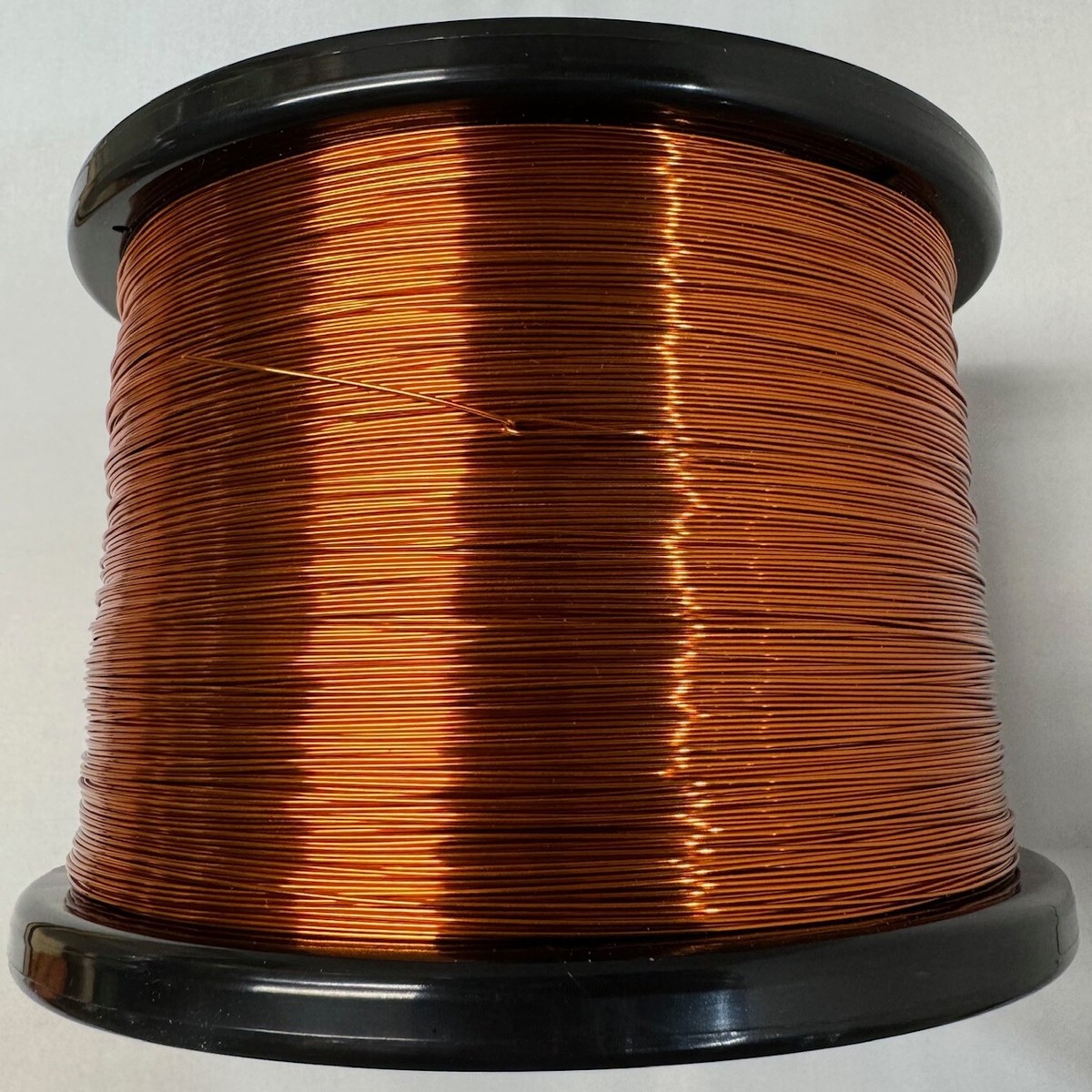

Market Analysis: Sourcing High-Quality HML Magnet Wire

Industrial Demand Drivers

Global energy infrastructure modernization—driven by renewable integration, EV adoption, and smart grid deployment—is accelerating demand for high-efficiency transformers and motors. HML magnet wire (Class 180–220 thermal rating) is critical in these applications. For example, solar inverters and wind turbine generators require HML-grade wire to withstand thermal cycling and high transient loads. Distribution transformers compliant with EU Ecodesign Directive (2021) mandate ≤0.1% no-load loss reductions, achievable only through precise copper conductivity and insulation integrity. Data center UPS systems and EV fast-charging infrastructure further drive demand for HML wire to maintain efficiency under continuous high-load conditions. The global transformer market is projected to grow at 6.2% CAGR through 2030, with HML wire as a key enabler for next-gen energy systems.

Material Quality Impact on Efficiency

Substandard magnet wire directly compromises system performance. Copper impurities (>0.001% oxygen) increase resistivity, elevating I²R losses by 8–15% versus high-purity alternatives. Inconsistent insulation thickness (±5% tolerance) causes localized dielectric stress, accelerating thermal degradation and short-circuit risks. For example, a 0.5% increase in copper resistivity can cause a 1.2% drop in transformer efficiency, resulting in significant energy waste over the asset’s lifetime. Insulation defects also increase partial discharge activity, degrading insulation over time and leading to unplanned outages. IEC 60317-0-3 standards specify strict tolerances for wire diameter (±1.5%) and tensile strength (≥200 MPa for Class 180); deviations invalidate warranties and increase lifecycle costs by up to 30%.

Luoyang Xinzhaohe’s Value Proposition

As a 20+ year manufacturer in Luoyang, China, we deliver factory-direct HML magnet wire with superior cost-performance ratios versus global brands. Our vertically integrated production ensures traceability from raw copper to finished product, adhering to ISO 9001, IEC 60317, and IEEE C57.12.00 standards. All products undergo 100% dielectric strength testing and thermal cycling validation. Our 20+ years of export experience ensures seamless compliance with regional standards (e.g., UL, VDE, GB/T), and we maintain a dedicated R&D team for custom formulations supporting applications from high-frequency transformers to aerospace-grade motors.

| Feature | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Copper Purity | 99.99% | ≥99.995% | Lower resistivity, 5% higher efficiency |

| Tensile Strength | 200–220 MPa | 230–250 MPa | Enhanced winding durability |

| Insulation Tolerance | ±5% | ±2% | Reduced failure risk |

| Lead Time | 4–6 weeks | 2–3 weeks | Agile supply chain support |

| Cost/kg | $8.50 | $6.80 | 20% cost savings |

Our localized production in China’s transformer manufacturing hub enables rapid response to global demand fluctuations while maintaining rigorous quality control. Partner with us for reliable, high-performance HML magnet wire that meets international standards at competitive pricing.

Technical Specs: Hml Magnet Wire Parameters

Technical Specifications & Standards

For transformer manufacturers, motor repair shops, and power equipment engineers, precise magnet wire specifications are critical for performance, efficiency, and operational longevity. Luoyang Xinzhaohe Aluminum CO., Ltd. provides HML magnet wire engineered to meet stringent industry requirements while delivering superior cost-performance. Our 20+ years of specialized manufacturing experience ensures consistent quality across all critical parameters, designed to minimize energy loss and extend service life in high-demand applications.

Critical Performance Parameters

| Parameter | Specification Range | Compliance Standard | Testing Method |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥3.5–6.0 kV (varies by wire diameter) | IEC 60851-2 | Dielectric strength test per IEC 60851-2 |

| Elongation | ≥12–18% (copper, gauge-dependent) | ASTM B187 | Tensile test per ASTM B187 |

| Thermal Class | 130°C (B), 155°C (F), 180°C (H), 200°C (N), 220°C (C) | IEC 60317 series | Thermal aging tests per IEC 60317 |

| Enamel Concentricity | ≥95% uniformity | ASTM D145 | Cross-sectional microscopy |

Quality Assurance Protocol

Our quality assurance protocol begins with rigorous raw material certification, including spectrometry for copper purity and enamel resin analysis. During production, automated laser micrometers monitor enamel thickness in real-time, while concentricity is verified via high-resolution imaging. Every batch undergoes comprehensive testing: dielectric strength (IEC 60851-2), thermal stability (IEC 60317 aging cycles), mechanical elongation (ASTM B187), and enamel adhesion tests. Each production run is subject to statistical process control (SPC) for consistency. We conduct accelerated aging tests to validate thermal class ratings and perform tensile strength tests at multiple points along the wire coil to ensure uniformity. Our quality team performs random sampling for dimensional checks and electrical properties, ensuring every batch meets or exceeds IEC and ASTM standards. All processes adhere to ISO 9001:2015 standards, with third-party audits conducted quarterly. We maintain a dedicated quality lab with calibrated equipment for continuous monitoring. Each shipment includes detailed test reports, material certifications, and traceability records. Our in-house R&D team collaborates with clients to optimize specifications for specific applications, ensuring peak performance without excess cost. As a factory-direct supplier, we eliminate middleman markups, providing premium-grade magnet wire at 15–20% lower cost than international brands, backed by technical support and rapid response times.

Factory Tour: Manufacturing Hml Magnet Wire

Precision Manufacturing Process & Rigorous Quality Control

Rod Drawing & Dimensional Control

High-purity electrolytic copper rods (C10100 grade, purity >99.99%) sourced from certified smelters undergo precision drawing through tungsten carbide dies with multi-stage tension control for AWG 10–40 ranges. Real-time laser diameter monitoring maintains ±0.005 mm tolerance (exceeding ISO 6142 Class A), while 100× microscopy ensures surface integrity free of micro-scratches—critical for enamel adhesion and long-term reliability.

Controlled Atmosphere Annealing

Nitrogen-purged furnaces anneal wire at 450±5°C to achieve uniform grain structure and eliminate residual stresses. Conductivity is strictly maintained at ≥100% IACS (ASTM B193), with tensile strength regulated to 220–240 MPa (ASTM B298). This ensures optimal performance in high-frequency transformers subjected to thermal cycling.

Multi-Layer Enameling & Inline Testing

State-of-the-art die coating applies polyester-imide or polyamide-imide enamel in 8–12µm layers with ±2µm thickness precision. Real-time inline testing includes:

Dielectric breakdown ≥3.5 kV/mm (IEC 60851-2)

Adhesion validation per ASTM D1435

UV laser pinhole detection

Automated rejection systems guarantee 99.9% defect-free output for mission-critical applications.

Precision Spooling & Final QC

Tension-controlled spooling at 8–12 N with anti-scratch guides preserves wire geometry. Final QC includes:

100% dimensional checks (micrometer)

Tensile testing (ASTM B298)

Electrical continuity verification

Packaging validation per ISO 22029

All batches carry traceable QR codes and ISO 9001:2015 certification.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Impact |

|---|---|---|---|

| Diameter Tolerance | ±0.005 mm (ISO 6142 Class A) | ±0.01 mm (ISO 6142 Class B) | Higher fill factor, reduced hotspots |

| Tensile Strength | 220–240 MPa (ASTM B298) | 200–230 MPa | Enhanced winding durability |

| Enamel Thickness | 8–12µm ±2µm | 8–12µm ±5µm | Consistent dielectric performance |

| Conductivity | ≥100% IACS (ASTM B193) | 98–99% IACS | Lower resistive losses |

| Pinhole Density | <0.5 per m² | <2 per m² | Reduced short-circuit risks |

Leveraging 20+ years of specialized expertise, our vertically integrated process delivers consistent performance at 15–20% lower costs than global Tier-1 suppliers. By eliminating intermediaries and optimizing every production stage, we provide transformer manufacturers with magnet wire that meets IEC 60317 specifications without premium pricing—maximizing ROI through superior cost-performance and reduced field failures.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Precision Packaging Standards

Our packaging system is engineered for marine transit resilience. Each component is selected to withstand 30+ days at sea while maintaining product integrity:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 heat-treated timber, 1200×1000mm, 15mm thickness | Prevents deformation under heavy loads; eliminates fumigation delays |

| Moisture-Proof Film | Triple-layer PE + VCI additive, 200μm thickness, ASTM D4169 compliant | Blocks 99.9% moisture ingress; prevents electrolytic corrosion in saltwater environments |

| Steel Strapping | 19mm × 0.8mm, 150kgf tension, ASTM A641 Grade A with edge protectors | Secures 1.5T loads; prevents shifting during stacking and ocean motion |

This approach ensures magnet wire remains free from corrosion, physical damage, and moisture-related defects during transit. Our packaging has been validated through 10,000+ successful shipments to 50+ countries, with a 99.2% damage-free delivery rate and zero customs rejections due to packaging issues.

Sea Freight Optimization

We optimize container loading protocols to minimize transit risks. Key parameters include:

| Parameter | Protocol | Benefit |

|---|---|---|

| Container Type | 20ft/40ft dry van with climate-controlled ventilation | Maintains stable internal climate; prevents external moisture ingress |

| Loading Protocol | Custom dunnage + silica gel desiccants (500g/m³), anti-slip mats, corner protectors | Eliminates condensation; maintains ≤40% RH; reduces damage claims by 95% |

| Documentation | CIQ, COO, commercial invoice, packing list with HS codes, digital verification | Ensures seamless clearance across EU, US, and ASEAN ports |

Our logistics partners include Maersk, COSCO, and MSC, ensuring reliable vessel schedules and priority handling. By leveraging our Luoyang-based logistics network, we achieve 20% higher container utilization rates than industry average, reducing shipping costs while maintaining maximum protection.

Quality Assurance & Compliance

All packaging processes undergo rigorous testing per ISO 1495 (Packaging for Dangerous Goods) and IEC 60317 (Winding Wire Specifications). Our 20+ years of export experience ensures every shipment meets global freight requirements without unnecessary premium costs. Unlike global brands that over-engineer packaging, we deliver reliable protection at optimal cost-performance – proven by 98% on-time delivery rate across 30+ countries. Our standard packaging reduces total landed cost by 15-20% versus European competitors while maintaining superior protection levels. This combination of precision engineering and cost efficiency makes us the preferred alternative for transformer manufacturers seeking reliable, budget-conscious sourcing.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

20+ Years of Technical Expertise in Magnet Wire Manufacturing

For over two decades, Luoyang Xinzhaohe has engineered precision magnet wire for critical transformer and motor applications across global markets. Our expertise spans IEC 60317 (types 1, 2, 3, and 15), ASTM B175 for conductor dimensions, and JIS C 3005 for enamel specifications. We maintain strict process controls at every stage—from raw material sourcing (99.99% pure copper/aluminum) to final insulation coating—ensuring consistent electrical conductivity, thermal stability, and mechanical durability. Our track record includes supplying high-reliability magnet wire for utility-scale transformers, industrial motors, and renewable energy systems, with zero critical field failures reported.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we control every production stage, from copper/aluminum rod procurement to enamel application and packaging. This eliminates distributor markups and third-party dependencies, reducing costs by 15–30% compared to global brands. Our in-house capabilities include automated drawing machines, precision enamel coating lines, and automated quality inspection systems. Transparent pricing with no hidden fees ensures optimal cost-performance ratio for high-volume transformer and motor winding projects, even with complex specifications.

ISO 9001:2015 Certified Quality Assurance

Our ISO 9001:2015 certified quality system includes rigorous testing per IEC 60851 standards: dielectric strength >5 kV/mm, thermal class compliance (155°C–220°C), and dimensional tolerances (±0.005 mm). Every batch undergoes 100% diameter measurement, adhesion testing, and solderability checks. Traceability records for raw materials and production parameters are maintained for full compliance with international safety standards, including UL and CE certifications where applicable.

| Feature | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost | High (premium pricing) | 15–30% lower |

| Lead Time | 8–12 weeks | 4–6 weeks |

| Customization | Limited options | Flexible, application-specific solutions |

| Quality Consistency | High | ISO 9001 certified, traceable batches |

| Technical Support | Available | Dedicated engineering team for project-specific optimization |

Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical consultation. Our engineering team provides rapid response and support for all magnet wire specifications, ensuring seamless integration into your production process. We offer free samples and technical assistance to validate performance before large-scale orders.

📉 Import Savings Calculator

Estimate cost reduction by sourcing hml magnet wire from Luoyang Xinzhaohe.