Table of Contents

Market Insight: High Wire Transformers

Market Analysis: Winding Wire Demand for High Wire Transformers

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and supply chain expertise to address the critical demands of the high wire transformer sector. This segment, encompassing high-voltage and high-efficiency power transformers essential for transmission and distribution networks, represents a significant and growing market driver for precision aluminum winding wire. Global electrification initiatives, renewable energy integration requiring robust grid infrastructure, and stringent efficiency regulations under frameworks like DOE 2016 and IEC 60076-20 are primary catalysts. These factors necessitate transformers operating at higher voltages and sustained loads, placing unprecedented demands on the electrical and mechanical integrity of the conductor material. Aluminum alloy winding wire, particularly grades meeting ASTM B398/B398M and IEC 60122 specifications, has become the dominant solution due to its optimal balance of conductivity, weight, cost, and formability compared to copper, especially in larger power units.

The operational environment of high wire transformers dictates uncompromising wire quality. Continuous thermal cycling, intense electromagnetic forces, and long design lifespans exceeding 30 years demand conductors with exceptional electro-thermal stability and mechanical resilience. Substandard aluminum wire introduces critical failure vectors. Inconsistent electrical conductivity directly increases I²R losses, reducing transformer efficiency and escalating operational costs over the asset lifecycle. Poor mechanical properties, such as inadequate tensile strength or elongation, lead to conductor deformation under short-circuit forces, potentially causing inter-turn faults or catastrophic cascade failures. Surface imperfections or oxide inclusions act as initiation points for partial discharges, degrading insulation systems prematurely and risking unplanned outages. Furthermore, inconsistent dimensional tolerances impede precise winding processes, compromising coil integrity and thermal management.

Quality parameters extend beyond basic conductivity. Precise control of alloy composition (typically 1350 or 6101 series) is paramount to achieve target conductivity within tight tolerances, often ±0.5% IACS. Homogeneous microstructure, achieved through proprietary annealing processes, ensures uniform mechanical properties and stress relief critical for winding stability. Surface finish must be flawless, free from scratches, pits, or excessive oxide, to prevent insulation damage during winding and ensure reliable dielectric performance. Dimensional accuracy, including diameter tolerance within ±0.01mm and precise ovality control, is non-negotiable for achieving optimal fill factors and thermal conductivity within the winding structure. Rigorous batch traceability and adherence to international quality management systems like ISO 9001 are fundamental for mitigating supply chain risk in this safety-critical application.

For transformer manufacturers, the total cost of ownership is intrinsically linked to winding wire quality. Initial material cost savings from subpar suppliers are invariably outweighed by increased energy losses, higher warranty claims, potential grid penalties for inefficiency, and the immense financial and reputational damage of field failures. Luoyang Xinzhaohe Aluminum’s vertically integrated production, advanced process control, and deep metallurgical understanding ensure winding wire consistently meets the extreme performance thresholds required by modern high wire transformers, directly supporting grid reliability and operational economics.

Technical Specs: High Wire Transformers

Technical Specifications for Aluminum Winding Wire in High Voltage Transformers

Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience, provides high-performance aluminum winding wire engineered for use in high voltage transformers. These transformers demand materials capable of enduring extreme electrical and thermal stresses, where reliability and dielectric integrity are paramount. The aluminum conductor, combined with advanced polymer insulation systems, is formulated to meet or exceed international standards such as IEC 60317, GB/T 23311, and NEMA MW 1000. Key technical parameters—insulation breakdown voltage, elongation, and thermal class—are rigorously controlled during production to ensure consistent performance in demanding applications.

Insulation breakdown voltage is a critical parameter that determines the dielectric strength of the wire’s coating under high electric field stress. For high voltage transformers, the insulation must prevent arcing and short circuits under operating voltages that may exceed several kilovolts. Our aluminum winding wires are manufactured with multi-layer polyurethane, polyester, or polyamide-imide insulation systems, achieving breakdown voltages ranging from 4,000 V to 12,000 V depending on wire diameter and insulation build. This ensures robust protection against dielectric failure, especially in tightly wound coils where inter-turn voltage gradients are significant.

Elongation, measured as a percentage during tensile testing, reflects the ductility of the aluminum conductor. High elongation values are essential to withstand the mechanical stresses of winding processes, particularly on sharp radii or complex core geometries. Our aluminum alloy conductors achieve elongation values between 18% and 28%, depending on temper (typically O or H14). This ductility minimizes the risk of cracking or necking during coil formation, ensuring structural integrity and long-term reliability.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. For high voltage transformers, thermal classes range from 130°C to 220°C. Our product line includes wires rated at Class B (130°C), Class F (155°C), Class H (180°C), and up to Class C (>220°C, inorganic or glass-based insulation). The thermal endurance index is validated through thermal aging tests per IEC 60216, ensuring that the insulation retains mechanical and dielectric properties over extended service life under thermal cycling.

The following table summarizes the key technical specifications for our aluminum winding wire series designed for high voltage transformers:

| Parameter | Typical Value Range | Test Standard | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | 4,000 V – 12,000 V | IEC 60317-003 | Depends on AWG and insulation type |

| Conductor Elongation | 18% – 28% | GB/T 4909.3 | Measured on 250 mm gauge length |

| Thermal Class | 130°C (B) to 220°C+ (C) | IEC 60216, NEMA MW 1000 | Based on insulation system |

| Conductor Material | 1350-O, 8030-O | ASTM B233, GB/T 3955 | High purity, low resistivity |

| Insulation Material | Polyurethane, Polyester, Polyamide-imide | IEC 60317 | Single or multi-coat options |

| Temperature Index (TI) | 130 – 240 | IEC 60216 | Determined by thermal life testing |

These specifications reflect Luoyang Xinzhaohe’s commitment to delivering technically superior winding wire solutions for high voltage transformer applications, where performance under electrical, thermal, and mechanical stress is non-negotiable.

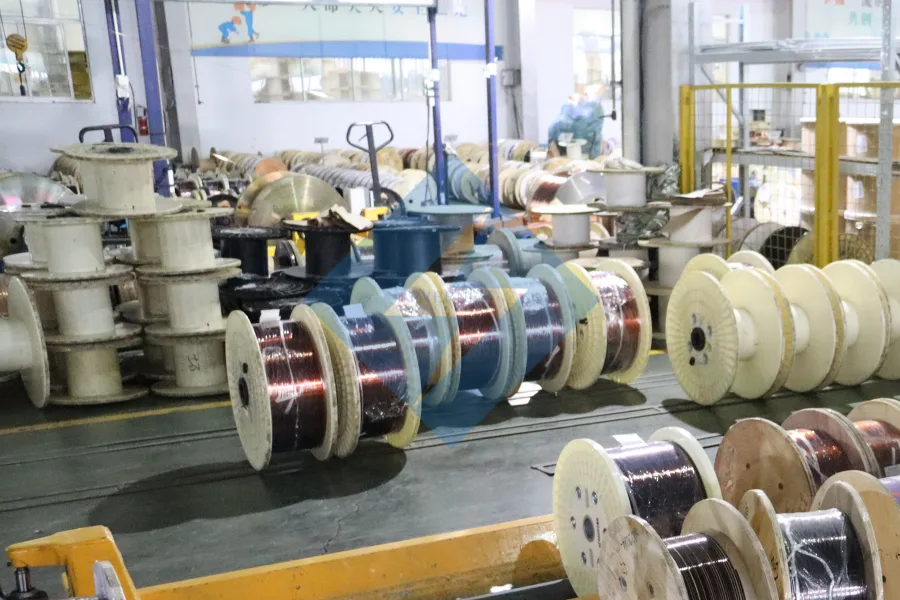

Factory Tour: Manufacturing

Manufacturing Process for High Performance Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of metallurgical expertise to produce aluminum winding wire meeting stringent high-voltage transformer specifications. Our vertically integrated process begins with high-purity aluminum rod (99.99% min) subjected to precision rod drawing. This stage employs multi-die reduction sequences under controlled tension, achieving diameters from 1.0mm down to 0.3mm with tolerances held to ±0.01mm. Critical surface integrity is maintained via diamond-coated dies and continuous lubricant filtration, eliminating micro-cracks or scoring that could compromise insulation adhesion. In-process diameter verification uses laser micrometers with real-time feedback to drawing speed controls, ensuring dimensional consistency essential for uniform winding density.

Annealing for Optimal Electrical and Mechanical Properties

Following drawing, wire undergoes continuous annealing in a hydrogen-nitrogen atmosphere furnace. Temperature profiles are precisely calibrated between 350°C and 420°C based on alloy composition and final gauge requirements. This recrystallization step restores ductility (target elongation: 25–30%) while optimizing electrical conductivity to 61.0–61.8% IACS. Oxygen ingress is maintained below 10 ppm to prevent oxide formation, verified through inline oxygen sensors and post-anneal conductivity spot checks. Mechanical property validation includes tensile strength testing (80–100 MPa range) at 15-minute intervals per ASTM B557.

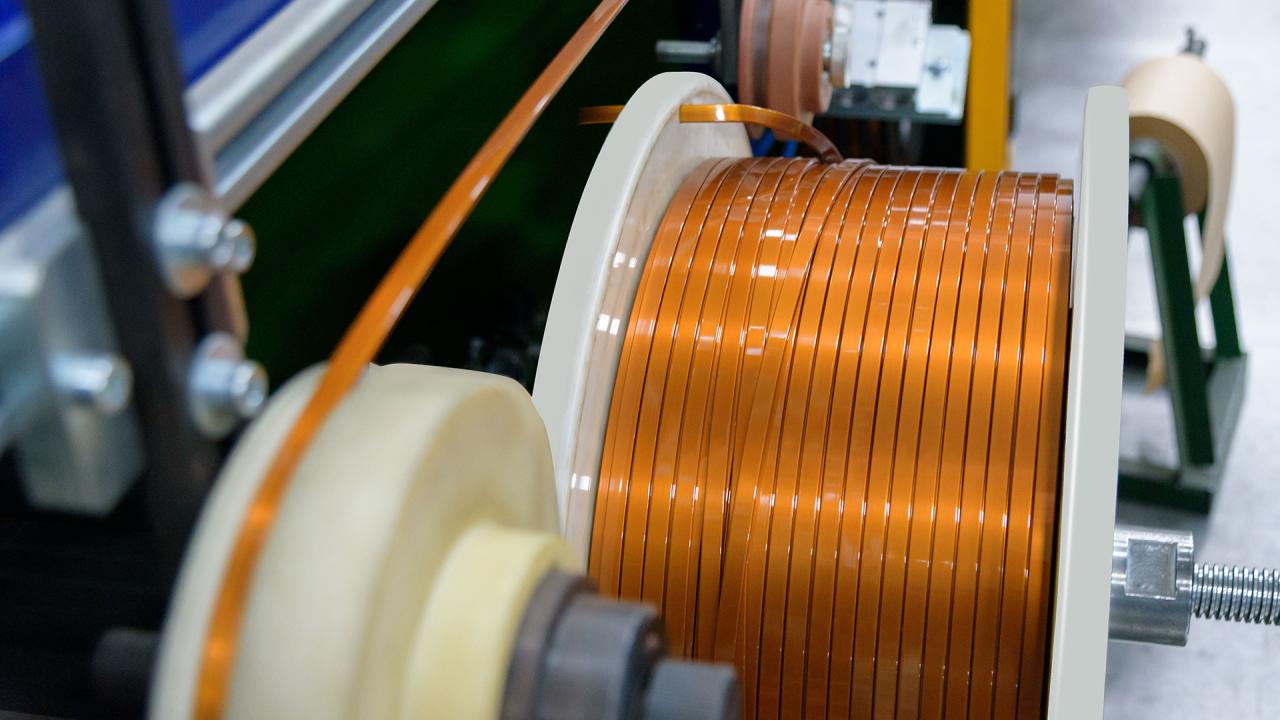

Multi-Layer Enameling System

The annealed wire enters our automated enameling line where a triple-coat system is applied. Base and intermediate layers utilize modified polyurethane resins for thermal stability (Class 155), followed by a topcoat of polyamide-imide for chemical resistance. Viscosity is controlled to ±0.5 seconds (DIN 4mm cup) with automated resin replenishment. Curing occurs in staged ovens at 380–450°C under nitrogen purge, ensuring complete polymerization without thermal degradation. Coating thickness is monitored via beta-ray gauges, targeting 35–45μm for 0.8mm wire with ±3μm tolerance. Adhesion testing per IEC 60851-5 is performed hourly using mandrel wrap procedures.

Integrated Inline Quality Control and Final Testing

Quality assurance is embedded throughout production. Key inline tests include:

| Parameter | Method | Frequency | Acceptance Criteria |

|---|---|---|---|

| Spark Test | 3.5 kV DC | Continuous | Zero defects per 10km |

| Diameter | Laser Micrometer | Real-time | ±0.01mm tolerance |

| Coating Thickness | Beta-ray Gauge | Continuous | ±3μm of target |

| Elongation | Tensile Tester (ASTM B557) | Hourly | 25–30% |

Final inspection comprises 100% spark testing at elevated voltage (4.5 kV), visual surface examination under 10x magnification, and batch sampling for thermal shock resistance (200°C/30s quench). All data is logged to batch-specific traceability records, enabling root-cause analysis for any non-conformance. This closed-loop manufacturing system ensures our aluminum winding wire delivers the dielectric integrity, thermal resilience, and dimensional precision required for high-efficiency transformer windings operating under extreme electromagnetic stress.

Packaging & Logistics

Export Packaging for High Wire Transformers – Aluminum Winding Wire

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in aluminum conductor manufacturing, we recognize that the integrity of winding wire—particularly for high wire transformers—is not only determined by material quality but also by the robustness of export packaging. Given the sensitivity of aluminum winding wire to environmental exposure and mechanical stress during transit, our export packaging system is engineered to ensure maximum protection, especially under the demanding conditions of sea freight logistics.

All aluminum winding wire shipments destined for international markets are mounted on high-strength wooden pallets constructed from kiln-dried, ISPM-15 certified hardwood. This standard ensures compliance with global phytosanitary regulations, preventing the unintentional transfer of pests or pathogens through raw wood materials. The pallets are designed with structural reinforcement to support coil weights ranging from 500 kg to 3,000 kg, minimizing deformation or shifting during loading, unloading, and long-haul transport. Each coil is securely fastened to the pallet using corrosion-resistant steel straps and locking tensioners, providing lateral and vertical stability throughout the shipment cycle.

Immediately after palletization, the entire assembly is wrapped in multiple layers of industrial-grade moisture-proof film. This multilayer polyethylene barrier is heat-sealed to form a hermetic enclosure that prevents ingress of humidity, salt spray, and atmospheric contaminants—critical safeguards during maritime transport where relative humidity can exceed 90% and condensation (cargo sweat) is a persistent risk. The film also acts as a protective shield against dust, grease, and minor mechanical abrasion that may occur during handling in port facilities or transshipment hubs.

For added protection in extended sea voyages, desiccant packs are strategically placed within the sealed film envelope to absorb residual moisture and maintain a low dew point inside the package. This proactive moisture management system prevents oxidation of the aluminum surface, preserving the conductor’s electrical conductivity and surface finish—key performance parameters for high-efficiency transformer windings.

All packaged coils are labeled with UV-resistant, tamper-evident identification tags containing batch numbers, alloy specifications (e.g., 1350-O), dimensions, and handling instructions. These labels are affixed to both the coil flange and the wooden pallet to ensure traceability, even if the outer wrapping is compromised.

Our packaging protocol is validated through internal simulation testing, including vibration, tilt, and humidity exposure trials that mirror real-world shipping conditions. This rigorous approach ensures that every shipment arrives at its destination with undiminished product quality, supporting seamless integration into our clients’ transformer production lines.

By integrating structural integrity, moisture resistance, and regulatory compliance, Luoyang Xinzhaohe’s export packaging system delivers a reliable, industrial-grade solution tailored to the global supply chain demands of high wire transformer manufacturers.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver mission-critical aluminum winding wire for high-voltage transformers. Our vertically integrated manufacturing ecosystem, centered on advanced melt processing and precision wire drawing, ensures unparalleled consistency in the electrical and mechanical properties demanded by modern transformer design. We understand that conductor performance directly impacts transformer efficiency, thermal stability, and long-term reliability; our processes are engineered to eliminate variability at the source.

Our 85,000-ton annual production capacity is anchored by state-of-the-art continuous casting and rolling lines, coupled with multi-stage wire drawing systems featuring laser-guided diameter control. This infrastructure guarantees strict adherence to dimensional tolerances essential for automated winding operations. Critical process parameters, including melt degassing levels, homogenization profiles, and annealing atmospheres, are continuously monitored via integrated SCADA systems, ensuring optimal electrical conductivity and mechanical formability. The resulting product exhibits exceptional surface smoothness (Ra < 0.4 µm) and precise roundness, minimizing interlayer friction and insulation damage during high-speed winding – a non-negotiable requirement for high-voltage applications.

Quality assurance is embedded within our operational DNA. We maintain IATF 16949 and ISO 9001 certified systems with dedicated in-line testing at every process stage. Our metallurgical laboratory employs OES for real-time alloy verification, four-point probe systems for conductivity validation per ASTM E1004, and advanced tensile testing to confirm mechanical properties. Statistical process control (SPC) with capability indices (Cpk > 1.67) is rigorously applied to critical characteristics. This systematic approach delivers wire with guaranteed minimum 61.0% IACS conductivity, tensile strength within ±5 MPa of target, and elongation controlled to ±1.5%, providing transformer manufacturers with predictable performance and reduced scrap rates.

Supply chain resilience is a core strategic pillar. Our strategic partnerships with primary aluminum suppliers and proprietary scrap reclamation processes ensure stable material availability and traceability from cathode to coil. Dedicated logistics coordination, including JIT delivery scheduling and VMI options, minimizes customer inventory risk while maintaining seamless production continuity. We proactively manage geopolitical and market volatility through diversified sourcing and buffer stock strategies for critical alloys.

Partnering with Luoyang Xinzhaohe means securing a supplier whose technical depth matches your engineering rigor. We translate metallurgical science into tangible manufacturing advantages for your transformer programs. For detailed specifications, process capability data, or to discuss your specific high-wire transformer requirements, contact Cathy Wang, International Sales Manager, directly at cathy@transformerstrip.com. Let us provide the conductor foundation for your next-generation transformer performance.

| Key Production Specifications | Typical Range | Test Standard |

|---|---|---|

| Alloy Grades | 1350, 1370, Custom High-Purity | ASTM B233 |

| Diameter Range | 1.0 mm – 6.0 mm | ASTM B244 |

| Conductivity | ≥ 61.0% IACS | ASTM E1004 |

| Tensile Strength | 60 – 100 MPa (Customizable) | ASTM B557 |

| Elongation | 15% – 35% | ASTM B557 |

| Surface Roughness (Ra) | ≤ 0.4 µm | ISO 4287 |

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing high wire transformers directly from China.