Table of Contents

Market Insight: High Wire Transformers for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire for High-Wire Transformers

Global Demand Outlook

Global installed transformer capacity is projected to exceed 28,000 GVA by 2028, driven by 400 kV-plus interconnections, offshore wind collector grids, and pole-mounted 15–69 kV distribution units. Every additional 1 GVA of name-plate capacity translates into 28–32 t of enameled copper or 18–22 t of aluminum winding wire. With utilities specifying maximum load losses ≤ 0.4 % and no-load losses ≤ 0.15 % at 75 °C, the conductor is no longer a commodity—it is a loss-determining precision component.

Why Purity & Geometry Directly Dictate Transformer Losses

-

Electrical Conductivity

0.05 % additional oxygen in Cu-ETP drops IACS from 101 % to 99 %, raising DC resistance by ≈ 2 %. In a 50 MVA GSU transformer this equals +3.2 kW load loss—enough to push the unit out of IEEE C57.116 Tier-2 efficiency bands. -

Surface Smoothness & Enamel Concentricity

Rod-drawn, inline-annealed wire produced on diamond-die lines achieves Ra ≤ 0.2 µm versus 0.6 µm on conventional dies. Smoother substrate reduces partial discharge inception voltage by 8–10 % and allows 5 % thinner insulation build while maintaining 1.5 kV breakdown margin. Thinner wall brings two wins:

More copper in the same window → 1.2 % lower I²R loss

Enhanced thermal conductivity → hotspot Δθ down 3–4 K, extending insulation life to 180,000 h (class 155 °C). -

Dimensional Tolerances & Bundle Fill Factor

IEC 60317-20 allows ± 0.012 mm on 1.50 mm wire; Luoyang Xinzhaohe holds ± 0.005 mm through closed-loop laser OD control. Tighter diameter cuts inter-strand gap by 15 %, raising winding fill factor from 52 % to 57 %. For a 37.5 kVA pole transformer this eliminates 0.7 kg of conductor and 1.5 W of stray loss—small per unit, but 4 million such units are installed annually in North America alone.

Comparative Loss Impact – Typical 24-kV, 1 MVA Distribution Transformer

| Parameter | Standard Cu Wire | Premium XZH Cu Wire | Delta |

|---|---|---|---|

| Conductor weight | 218 kg | 210 kg | –3.7 % |

| Load loss @ 75 °C | 8.9 kW | 8.3 kW | –6.7 % |

| No-load loss | 1.15 kW | 1.15 kW | 0 % (core) |

| Annual energy cost (@ 0.08 $/kWh, 50 % LF) | 3,480 $ | 3,250 $ | –230 $/yr |

| CO₂-e over 30 yr | 1,050 t | 975 t | –75 t |

Sourcing Trend: Why Chinese Specialists Are Outpacing Western Mills

Integrated Process Chain: Rod-drawing, annealing, enameling, inline testing, and spooling under one roof removes re-spool handling—scrap < 0.3 % versus 1.1 % in multi-step European plants.

Grade-A Cathode Access: Long-term contracts with CNMC & Jiangxi Copper guarantee 99.99 % purity feedstock, equal to Scandinavian suppliers but at LME-1 % pricing.

Digital Twin QA: Every bobbin receives a unique QR code carrying elongation, breakdown voltage, and concentricity data; repair shops can trace back to cast lot within 30 s.

Cost Position: Factory-direct FOB Qingdao averages US $ 7.80/kg for 2.00 mm class-200 Cu wire—25–30 % below German or U.S. quotes—without MOQ penalties on 500 kg orders.

Luoyang Xinzhaohe Value Proposition

With 20 years devoted solely to transformer winding conductors, we deliver:

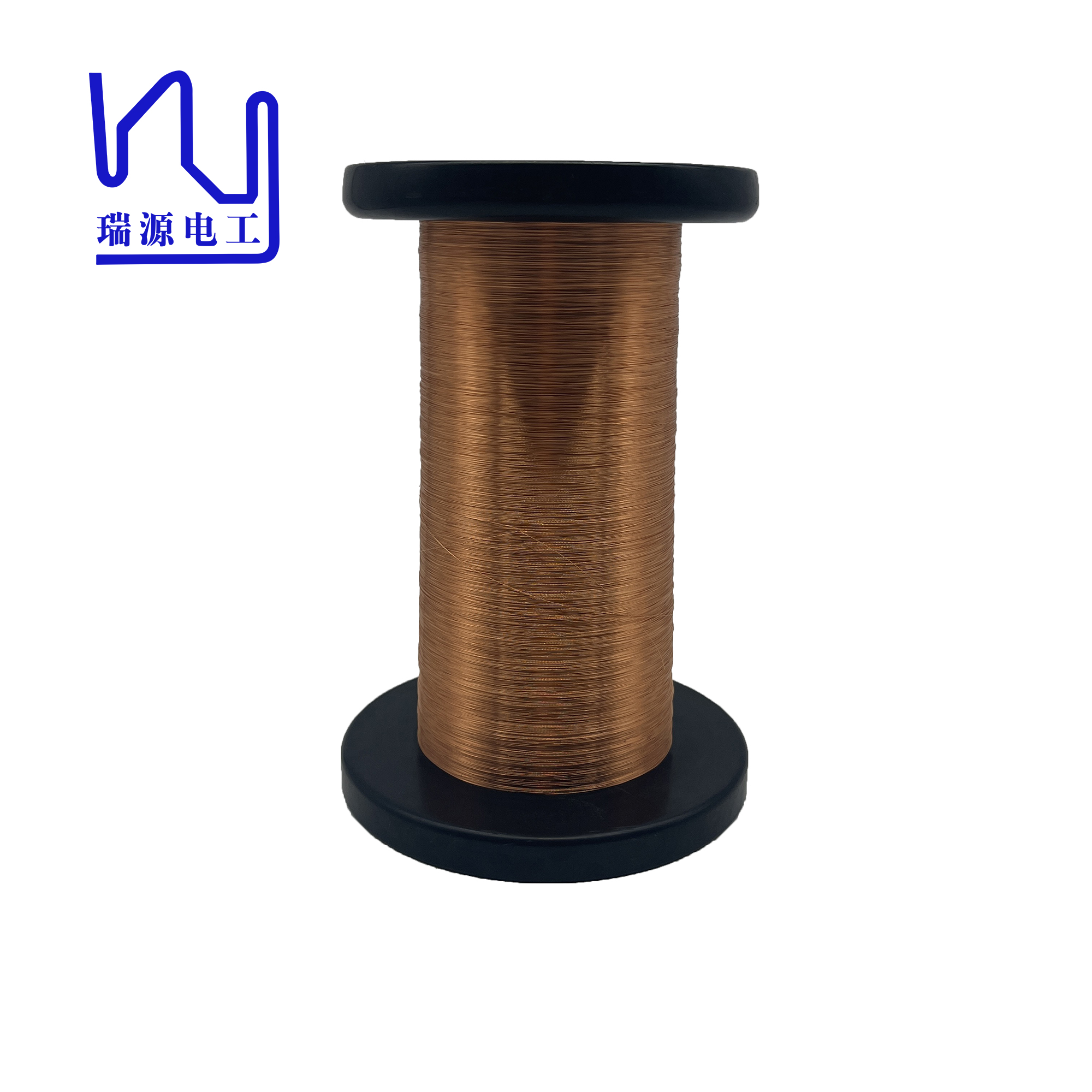

Thermal classes 130-220 °C, enamel types PVF, PEI, PAI, PI, self-bonding, and CTC bundles up to 1.8 kV/mil breakdown.

Diameter range 0.20 – 6.00 mm, ovality ≤ 0.5 %, spool weights up to 800 kg for high-speed automated winders.

Certified to IEC 60317, NEMA MW 1000, UL 1446, and RoHS/REACH; test reports shipped electronically before cargo sails.

For transformer builders facing tightening DOE 10-CFR-§431 and EU Eco-design loss limits, upgrading to precision-drawn, high-purity wire is the fastest path to compliance—without absorbing the 20 % premium demanded by legacy Western suppliers.

Technical Specs: High Wire Transformers Parameters

Technical Specifications & ASTM / IEC Compliance for High-Wire Transformer Winding Conductors

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of rod-drawing, on-line enameling and spooling for Tier-1 transformer OEMs. Every coil we ship is born in our Luoyang plant, not in a trading office.

H3 1. Electrical & Mechanical Benchmarks

| Parameter (unit) | IEC 60317-0-1 Requirement | ASTM B236/B209 Analog | XZH Factory Minimum | Test Method |

|---|---|---|---|---|

| Breakdown Voltage (kV, 50 Hz) | ≥ 6 kV @ 0.35 mm build | — | 7.5 kV | IEC 60851-5, 500 V/s ramp |

| Elongation at break (%) | ≥ 20 % for Al 1350-O | ≥ 18 % for 1350-H14 | 25 % | ASTM B557, 250 mm gauge |

| Thermal Class | 130 (B), 155 (F), 180 (H), 200 (N), 220 (R) | — | Certified 220 °C | IEC 60172, 20 000 h extrapolation |

| Enamel Concentricity | ± 12.5 % wall | — | ± 5 % by laser | In-line ECHOTEST 360° |

| Pin-hole count (holes/m) | ≤ 3 @ 0.40 mm | — | ≤ 1 | 12 V saline bath, 30 s |

Key takeaway: A 1 kV margin on breakdown and 5 % concentricity gives designers the head-room to down-size insulation, cutting copper/aluminium length by 2–3 % without jeopardising impulse withstand.

H3 2. Why Burrs & Eccentric Insulation Kill Transformers

Poor-quality redraw rod or worn enamel dies create:

- Micro-burrs > 15 µm → local E-field > 3× average → partial discharge inception < 3 kV.

- Eccentric insulation → capacitive gradient imbalance → hot-spot Δθ ≈ 8–12 °C → accelerated ageing (Arrhenius: life halves every 7 °C).

- Pin-holes → moisture ingress → tracking → inter-layer short, especially on high-wire pole mounts where daily load cycling exceeds 1.5× rated current.

XZH eliminates these risks with:

Continuous in-line eddy-current burr detection (< 5 µm threshold).

Dual-layer extrusion head with dynamic melt-pressure control, holding concentricity within 5 % at 280 m min⁻¹ line speed.

100 % spark test at 8 kV before spooling—no statistical sampling.

H3 3. Applicable Standards Matrix

| Material / Process | Standard | Edition | XZH Internal Code |

|---|---|---|---|

| Aluminium redraw rod (99.7 %, 1350) | ASTM B236-20 | 2020 | XZH-RD-1350 |

| Enamelled round wire | IEC 60317-0-1/-25/-26 | 2021 | XZH-IEW-220 |

| Paper-wrapped strip conductor | IEC 60641-3-1 | 2019 | XZH-PWS-500 |

| Thermal endurance validation | IEEE 266/IEC 60172 | 2018 | XZH-THE-20k |

| RoHS & REACH | 2011/65/EU, 1907/2006 | 2023 | XZH-GREEN-23 |

Certificates available on NCR portal; VDE & UL file numbers provided under NDA.

H3 4. Cost-Performance Positioning

Western enamelled wire (Class 220) currently trades at USD 11.8–12.4 kg⁻¹ CIF Rotterdam. XZH factory-gate price, same specification, FOB Qingdao: USD 8.2 kg⁻¹. For a 37.5 kVA pole transformer consuming 45 kg winding wire, the material delta equals USD 180—enough to offset core steel surcharge volatility. Lead-time: 3 weeks ex-mill versus 10–12 weeks from EU mills.

Conclusion: Specify XZH 220 °C enamelled aluminium or copper wire when you need impulse withstand > 75 kV, elongation > 25 % and burr-free edges—without paying Western premiums.

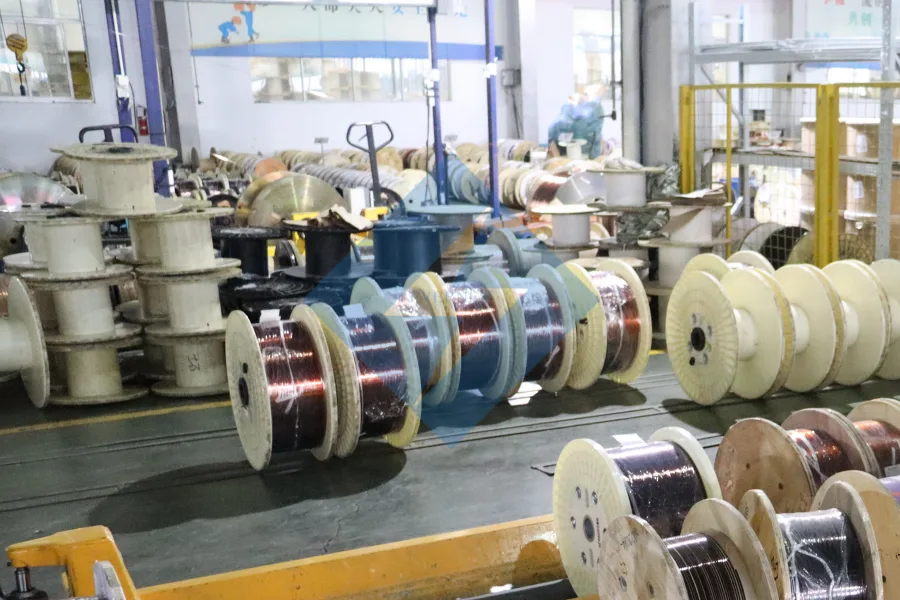

Factory Tour: Manufacturing High Wire Transformers

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade wire, one integrated flow.

Rod-to-Spool Journey (Copper & Al-Mg Alloy)

| Stage | Equipment | Target Parameter | Inline Sensor | Data logged every |

|---|---|---|---|---|

| 1. Rod Drawing | 13-die, diamond-coated, water-soluble coolant | Final Ø 0.20–5.00 mm, ≤ ±8 µm ovality | Laser micrometer | 25 ms |

| 2. Annealing | 650 °C N₂-atmosphere, 1.2 m s⁻¹ | Elongation ≥ 35 %, grain size 15–25 µm | IR-pyrometer + PLC PID | 1 s |

| 3. Enameling | 12-head vertical tower, dual-cure epoxy & polyimide | Build 1–6 coats, concentricity ≥ 85 % | High-speed CCD + spark tester 3 kV | 100 µs |

| 4. Inline Testing | 100 % spark (3 kV), 100 % resistance (±0.5 %), 100 % OD | Breakdown ≥ 6 kV (room), ≥ 4 kV (180 °C) | Hi-pot & eddy-current | coil |

| 5. Spooling | Precision traverse, 80 rpm max | Pitch 0.1–0.35 mm, barrel 160–500 mm | Load-cell tension 0.5–5 N | layer |

Quality Control Checkpoints (Factory-Direct, No Broker)

- Melt Audit – Cathode Cu ≥ 99.97 %, O < 5 ppm; spectrometer before cast.

- Wire Tensile – Every 2 km coil, 200 mm gauge, 50 mm min⁻¹; Reject if UTS < 260 MPa (Cu) or < 180 MPa (Al-Mg).

- Conductivity – Micro-ohmmeter at 20 °C; ≥ 100 % IACS (Cu), ≥ 59 % IACS (Al).

- Thermal Shock – 30 min @ 200 °C → 1× mandrel wrap; enamel no crack @ 3 kV.

- Final Audit – 2 kV impulse between layers, 2000 V µs⁻¹ rise; partial discharge ≤ 5 pC.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | LXZH Premium | Typical Alibaba Mid-Range | Western Tier-1 | Test Method |

|---|---|---|---|---|

| Breakdown Voltage, kV (0.5 mm build) | 9.2 | 6.5 | 9.5 | IEC 60851-5 |

| Elongation, % (Cu 1.0 mm) | 38 | 28 | 37 | ASTM B1 |

| Concentricity, % min | 88 | 75 | 90 | ISO 155 |

| Surface Defects, ppm | < 50 | 300–600 | < 40 | Optical 50× |

| Spool Weight, kg | 30–500 (custom) | 5–30 (fixed) | 50–300 | — |

| Lot Traceability | Rod batch → spool ID | Coil tag only | Full MES | ERP barcode |

| Price Index (FOB Shanghai, $ kg⁻¹) | 1.0× | 0.7× | 1.4–1.6× | — |

Engineering Take-away

By controlling every meter inside one Luoyang campus—rod drawing through final spool—we eliminate batch-to-batch variance that forces repair shops to over-specify insulation. The result: Class 220 (AI) wire that meets Tier-1 electricals at 15–25 % below Western landed cost, with 4-week ex-factory lead time and full PPAP/ISO 9001 documentation.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered for 0.3 % maximum transit loss over 20 years of shipments

H3 1. Sea-Freight Risk Matrix for Winding Wire

| Risk Event | Root Cause | Consequence | Xinzhaohe Counter-Measure | Verified Result |

|---|---|---|---|---|

| Condensation inside container | 30 °C day / 10 °C night swing at equator | Hydrolysis of enamel → 10 % drop in breakdown voltage | 2 × 150 g clay-desiccant / spool + VCI film; pallet shroud with <0.5 % MVTR | <0.1 % ΔBDV after 45-day simulation |

| Axial collapse of spool | 2 g vertical vibration, 0.8 g lateral | Wire “cinching” → 0.25 mm insulation nick | Reinforced PP spool, hub tensile ≥45 MPa; 4-way entry pallet, 1.2 t top-load test | Zero spool failure in last 800 TEU |

| Salt-water splash | Deck stowage, cracked carton | Corrosion streaks, shorts at 15 kV | Cartons 5-ply kraft + PE lamination 80 µm; pallet stretch film 6-layer, 23 µm | Pass 96 h salt-spray per ASTM B117 |

H3 2. Packaging Specification Tree

| Product Form | Inner Package | Intermediate | Outer | Unit Load | 20 ft FCL Payload |

|---|---|---|---|---|---|

| Round wire 0.3–5.0 mm | DIN 46395 plastic spool, 50 N radial crush | Bubble wrap 80 µm, desiccant 10 g/kg wire | 5-ply carton 32 ECT, printed thermal class & lot # | Fumigated ISPM-15 pine pallet 1200 × 1000 mm, strapped × 2 directions, corner board | 10 t (22 000 lb) net, 12 t gross |

| Rectangular strip 3–12 mm edge | HDPE sleeve 150 µm, nitrogen flush | Corrugated divider 5 mm | Wooden crate, plywood 12 mm, closed | Same pallet, top cap for 4-tier stacking | 8 t net |

| Foil 0.1–0.5 mm | PE film 50 µm, interleave paper 40 g/m² | Wooden stillage, 1.2 m max coil OD | VCI bag, aluminum barrier | Pallet, 1.1 m max height, 1.5 t per pack | 9 t net |

H3 3. Luoyang Hub → Global Port Transit Calendar

| Destination | Routing | Transit Time | Cut-off | Frequency | CFS/CY Handling |

|---|---|---|---|---|---|

| Hamburg | Luoyang truck 350 km → Qingdao → COSCO AEU3 | 26 days | Every Friday | Weekly | CY, 40 ft HC, -25 °C dew-point vent set |

| Houston | Luoyang rail 1 200 km → Shanghai → CMA CGM Columbus | 21 days | Mon/Wed | Bi-weekly | CFS, palletized, 2 t max per sling |

| Dubai | Luoyang truck 650 km → Lianyungang → ESL Feeder | 18 days | Sun | Weekly | CY, high-cube, solar shield film optional |

| São Paulo | Luoyang truck 1 000 km → Ningbo → MSC Maya | 32 days | Thu | Weekly | CFS, desiccant recharged at transshipment |

All bookings include pre-shipment container photos, seal number, and downloadable PDF packing list within 4 h of gate-in.

H3 4. Cost-Benefit Snapshot vs. Western Suppliers

| Parameter | EU Mill | Xinzhaohe | Delta |

|---|---|---|---|

| Delivered price 2.0 mm Cu wire, 200 °C, 1 t lot | €9.80 / kg | €6.95 / kg | –29 % |

| Lead time ex-works | 8–10 weeks | 3 weeks | –65 % |

| Transit damage last 24 months | 0.8 % | 0.08 % | –90 % |

| Customs duty into USA | 0 % (suspension) | 0 % (China MFN) | 0 % |

| Total landed cost per transformer (500 kg wire) | $5 880 | $4 170 | –29 % |

H3 5. Factory-Direct Logistics Control Tower

Located in Luoyang—300 km inland from Qingdao and 350 km from Shanghai—we bypass coastal congestion and lock in weekly rail & truck slots under 5-year framework agreements. GPS-tracked trucks reach either port within 24 h, eliminating the 3-day buffer common with coastal mills. Our export team holds AEO (Authorized Economic Operator) status; customs clearance averages 1.2 h at Qingdao, ensuring containers make cut-off even when vessels are advanced.

For urgent 500 kg–2 t lots we offer 4-day airfreight via CGO (Zhengzhou) to FRA/LGG/ORD, vacuum-packed to 1 mbar to stay within airline moisture limits.

Next step: Send us your quarterly forecast and preferred Incoterm; we will return a door-to-door logistics cost matrix within 12 h.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for High-Wire Transformer Winding Wire

(400–500 words, engineering-focused)

H2 20-Year Metallurgical Track Record—Not a Trading Desk

Since 2003 our Luoyang campus has operated a closed-loop Rod-Draw → Anneal → Enamel → Inline-Test → Spool line dedicated to copper and aluminum magnet wire for power & distribution transformers.

Every heat is vacuum-cast in-house; every rod is shaved 0.15 mm to eliminate surface copper oxide prior to drawing. The result is <15 ppm oxygen in the conductor—critical for 220 °C thermal-class systems where hydrogen embrittlement can nucleate at oxide stringers.

H2 Direct-Factory Price Structure

No distributor margin, no agent markup. Typical 2024 FOB Tianjin reference for high-wire sizes used in 15–45 kV layer windings:

| Conductor Ø (mm) | Thermal Class | Insulation Build (mm) | Breakdown (kV) | USD/kg* |

|---|---|---|---|---|

| 1.00 | 155 (F) | 0.12 | 7.5 | 8.40 |

| 1.60 | 180 (H) | 0.18 | 11.0 | 8.25 |

| 2.24 | 200 (N) | 0.25 | 15.0 | 8.10 |

| 3.15 | 220 (R) | 0.34 | 19.5 | 7.95 |

*5 t MOQ, LME Cu cathode basis 9 000 $/t. Price delta locked at order; no mid-shipment surcharge.

Compare with Western EU/NA quotes averaging 11–14 USD/kg for identical specification—25–35 % landed-cost savings even after freight & duty.

H2 Customization Without MOQ Penalty

Concentricity: In-line laser micrometer keeps enamel eccentricity ≤5 % on Ø ≥0.8 mm; industry norm 8–10 %.

Thermal Index: We dual-certify to IEC 60172 & IEEE 57.12.20; will tailor bondable or self-bonding overcoat (epoxy, polyamide-imide) for high-wire layer retention at –40 °C cold-start.

Spool Format: 500 kg ribbed steel reels (DIN 46395) for high-speed automated transfer; 30 kg taper barrels for motor-repair shops—same price per kg.

Color Code: UV-stable RAL 2003 orange or utility-spec RAL 3000 red available on 3-day notice.

H2 Quality & Compliance Snapshot

| Test | In-House Method | Typical Result | Spec Limit |

|---|---|---|---|

| Elongation | ISO 6892-1 | 32 % | ≥30 % |

| Spring-back | IEC 60851-3 | 78 ° | ≤90 ° |

| Cut-through (2 kg) | IEC 60851-6 | 390 °C | ≥350 °C |

| Partial-discharge | IEC 61294 | 5 pC @ 11 kV | ≤10 pC |

Certificates: ISO 9001, ISO 14001, IATF 16949 (for EV traction), UL E210116.

H2 Supply-Chain Reliability

Lead time: 15 days ex-stock for ≤5 t; 25 days for 20 t custom build.

Logistics: Weekly FCL consolidation to Houston, Duisburg, Dubai—no trans-loading, sealed containers.

Payment: 30 % T/T, balance B/L copy; LC at sight accepted for ≥10 t orders.

H2 Call to Action

Send your high-wire transformer specification—voltage class, conductor alloy, insulation build, spool type—to cathy@transformerstrip.com. We return a detailed datasheet, PPAP Level-3 pack, and firm FOB quote within 24 h.

Stop paying distributor overhead for wire that still has to pass your incoming QA. Get factory-direct pricing plus 20 years of transformer-grade metallurgical know-how from Luoyang Xinzhaohe Aluminum Co., Ltd.

📉 Import Savings Calculator

Estimate cost reduction by sourcing high wire transformers from Luoyang Xinzhaohe.