Table of Contents

Market Insight: High Frequency High Voltage Transformer

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for high frequency high voltage (HFHV) transformers has grown significantly due to advancements in power electronics, renewable energy systems, electric vehicle (EV) charging infrastructure, and industrial automation. These transformers operate at frequencies substantially higher than traditional 50/60 Hz systems—often ranging from several kHz to over 100 kHz—while maintaining high voltage isolation and efficiency. This operational shift imposes stringent material requirements on the conductive components, particularly the strip and foil used in windings. As a result, aluminum and copper transformer strip/foil have become critical enablers of performance, reliability, and miniaturization in modern HFHV transformer design.

High frequency operation introduces challenges such as skin effect, proximity effect, and increased eddy current losses, all of which are directly influenced by the physical and electrical properties of the conductor material. In this context, the quality of aluminum and copper strip/foil is not merely a cost consideration but a determinant of transformer efficiency, thermal management, and long-term durability. Precise dimensional control, surface finish, mechanical strength, and electrical conductivity are essential parameters. For instance, tight thickness tolerances ensure uniform winding tension and reduce interlayer insulation stress, while a smooth, oxide-free surface minimizes dielectric breakdown risks in high voltage environments.

Copper remains the preferred material in high-performance HFHV applications due to its superior conductivity and thermal stability. However, aluminum is increasingly adopted in weight-sensitive and cost-driven applications such as EV chargers and distributed energy systems, where its lower density and competitive conductivity-to-cost ratio offer strategic advantages. In both cases, the metallurgical purity, grain structure, and annealing consistency of the strip/foil directly affect electromagnetic performance and thermal cycling resilience.

The market for these materials is driven by the expansion of smart grid technologies, high-efficiency power supplies, and solid-state transformers, particularly in Asia-Pacific and North America. Manufacturers of HFHV transformers are placing greater emphasis on supply chain reliability and material traceability, requiring strip and foil suppliers to adhere to international standards such as IEC 60464, ASTM B230/B355 (copper), and ASTM B418/B209 (aluminum). Consistent batch-to-batch quality ensures predictable core saturation behavior and reduces the need for derating in field applications.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in aluminum and copper strip/foil production, we understand that material excellence translates directly into transformer performance. Our manufacturing processes integrate precision rolling, controlled annealing, and rigorous in-line testing to deliver products that meet the exacting demands of HFHV transformer applications. As the industry moves toward higher switching frequencies and compact designs, the role of high-quality conductive materials will only become more critical in enabling next-generation power systems.

Technical Specs: High Frequency High Voltage Transformer

Technical Specifications for High Frequency High Voltage Transformer Strip/Foil

Precision aluminum and copper strip/foil form the critical conductive backbone of high frequency high voltage (HFHV) transformers, where operational demands necessitate extreme dimensional accuracy and material integrity. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized metallurgical and slitting expertise, we engineer strip/foil to mitigate core challenges inherent in HFHV applications: skin effect, proximity effect, dielectric stress, and thermal management. Conventional tolerances are insufficient; deviations exceeding ±0.002 mm in thickness or width induce uneven current distribution, escalating eddy current losses and localized heating. Similarly, microscopic edge burrs act as field concentrators, initiating partial discharge and catastrophic insulation failure under high voltage stress. Material conductivity directly dictates resistive (I²R) losses, which become disproportionately severe at frequencies above 20 kHz. Our manufacturing rigor ensures every parameter aligns with the stringent physics of HFHV operation, validated through our ISO 9001-certified quality management system and in-house metrology lab featuring Zeiss CMMs and surface profilometers.

The following table defines the non-negotiable technical parameters for HFHV transformer strip/foil, reflecting industry best practices and our validated production capabilities for both aluminum (primary focus) and copper:

| Parameter | Specification | Measurement Standard | Rationale |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm | ASTM E29, GB/T 228.1 | Ensures uniform current density, minimizes skin effect losses at >20 kHz. |

| Width Tolerance | ±0.002 mm | ASTM E29, GB/T 228.1 | Critical for precise winding alignment and consistent turn-to-turn spacing. |

| Edge Burr | ≤0.005 mm (max) | ISO 1302, Custom SEM | Eliminates field emission points; prevents corona inception at >10 kV/mm. |

| Conductivity (%IACS) | Al: ≥55.0% / Cu: ≥98.0% (annealed) | ASTM E1004, GB/T 3048.2 | Maximizes efficiency; minimizes resistive heating under high-frequency AC. |

| Surface Roughness (Ra) | ≤0.4 μm | ISO 4287, GB/T 1031 | Reduces interfacial losses between foil layers; enhances dielectric integrity. |

| Flatness | ≤0.5 mm per meter | ASTM A480, GB/T 3880 | Ensures consistent winding tension and layer adhesion; prevents air gaps. |

Achieving these specifications requires integrated metallurgical and precision slitting control. Our process begins with high-purity aluminum alloy 1070 or 1350 (99.70%+ Al min), melted under inert atmosphere to minimize oxide inclusions. Continuous casting and homogenization optimize grain structure for uniform conductivity. The critical precision slitting stage utilizes tension-leveling-equipped rotary shear lines with sub-micron tooling alignment and real-time laser monitoring, ensuring the ±0.002 mm dimensional tolerances and burr-free edges essential for HFHV reliability. Intermediate and final annealing cycles are precisely controlled in nitrogen-purged furnaces to achieve target conductivity without surface oxidation. Every coil undergoes 100% inline width/thickness verification and random SEM edge inspection; conductivity and surface roughness are batch-certified per ASTM standards. This holistic approach, refined over 20 years of transformer industry partnership, delivers strip/foil that directly enables HFHV transformer efficiencies exceeding 99.2% at 50 kHz and withstands continuous operating voltages up to 35 kV, meeting IEEE C57.139 and IEC 61558-2-17 requirements. Partnering with Xinzhaohe guarantees material performance that underpins transformer longevity and operational safety in demanding power electronics applications.

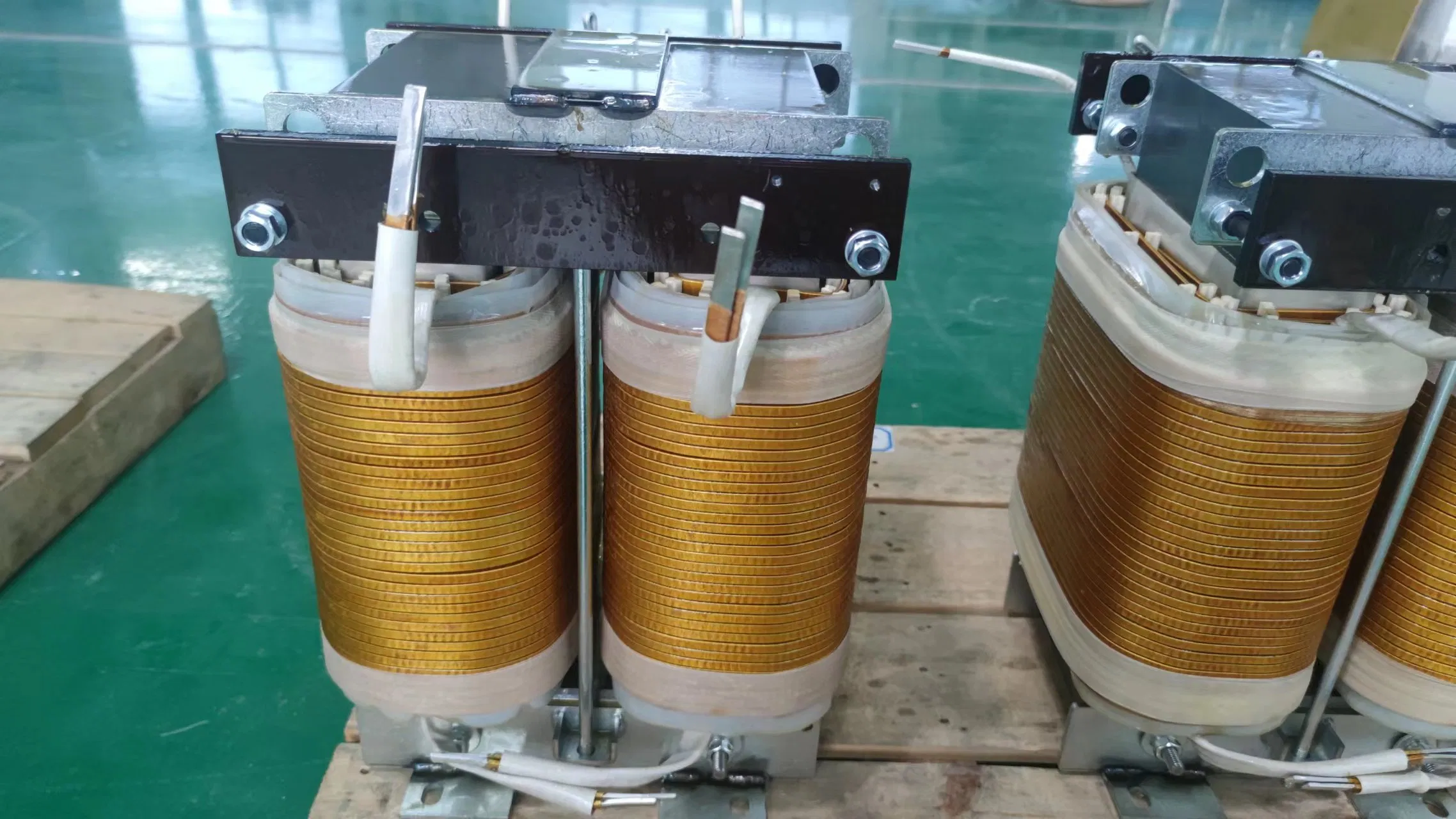

Factory Tour: Manufacturing

Manufacturing Process for Transformer Strip/Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum and copper strip/foil for high frequency high voltage transformers at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional precision, surface integrity, and electrical consistency. With over two decades of metallurgical expertise, our facility integrates advanced cold rolling technology with precision slitting and edge conditioning to meet the stringent demands of modern transformer applications.

The process begins with cold rolling, where high-purity aluminum or copper ingots are first hot-rolled into intermediate coils and then subjected to cold rolling under precisely regulated temperature and tension conditions. This stage is critical for achieving the target thickness, typically ranging from 0.05 mm to 0.5 mm, while enhancing mechanical strength and electrical conductivity through work hardening. The cold rolling mills are equipped with automated gauge control (AGC) systems and laser-based thickness monitoring to maintain tight tolerances, typically within ±0.005 mm. Surface quality is continuously monitored using inline optical inspection systems to detect defects such as scratches, roll marks, or oxide inclusions.

Following cold rolling, the coils undergo precision slitting, a process in which master rolls are longitudinally cut into narrow strips tailored to customer specifications. Our high-speed slitting lines utilize tungsten carbide circular knives with automatic blade gap adjustment, ensuring clean, burr-free edges and consistent width control down to ±0.1 mm. Tension leveling is applied during slitting to eliminate coil memory and edge waviness, which is essential for uniform winding performance in transformer cores. Each slit strip is wound under controlled tension using servo-driven pay-off and take-up systems to prevent telescoping and ensure layer stability.

Edge conditioning is the final critical stage in the manufacturing sequence. The slit edges are subjected to mechanical brushing and deburring to remove micro-burrs and surface asperities that could lead to electrical discharge or insulation breakdown in high voltage environments. This process also improves edge roundness and surface smoothness, reducing the risk of dielectric failure during transformer operation. The conditioned strips are then recoiled and prepared for inspection and packaging.

Quality control is embedded throughout the production chain. Key inspection points include incoming material certification, in-process thickness and width verification, surface defect scanning, and final electrical conductivity testing (per ASTM E1004 for aluminum and ASTM B910 for copper). Dimensional reports, mechanical property data, and surface roughness measurements (Ra < 0.4 µm) are provided with each shipment. All coils are traceable via batch numbering, and production records are maintained in compliance with ISO 9001 standards.

This disciplined approach ensures that every meter of transformer strip/foil meets the reliability and performance requirements of high frequency high voltage applications in power electronics, renewable energy systems, and industrial automation.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip/Foil Materials

At Luoyang Xinzhaohe Aluminum Co., Ltd., we implement rigorously engineered export packaging protocols for aluminum and copper transformer strip/foil shipments, specifically designed to mitigate risks inherent in global sea freight logistics. Over two decades of metallurgical expertise and international supply chain management confirm that inadequate packaging directly correlates with material degradation, leading to corrosion-induced dielectric failure in high-frequency high-voltage transformer cores. Our methodology adheres to ISO 11607 and ASTM D3951 standards, prioritizing moisture exclusion and structural integrity throughout transit.

All coil shipments are secured to ISPM-15 certified wooden pallets constructed from kiln-dried, debarked softwood. Pallet dimensions strictly comply with ISO container loading standards (1200 × 1000 mm or 1100 × 1100 mm), ensuring optimal space utilization and load stability during ocean transport. Each pallet undergoes moisture-content verification (≤ 22% per ISPM-15) to prevent fungal growth and off-gassing that could compromise barrier films. Coils are center-aligned and mechanically fastened using corrosion-resistant steel strapping (minimum 19 mm width, 15 kN tensile strength) tensioned to DIN 55402 specifications. This prevents axial shifting or edge damage during vessel motion, particularly critical for thin-gauge foils (0.1–0.5 mm) used in high-frequency applications.

The primary moisture barrier comprises a triple-layer encapsulation system. First, coils are wrapped in vapor-corrosion-inhibiting (VCI) paper meeting ASTM D6098, providing electrochemical protection against ionic contaminants. Second, a 125 μm-thick polyethylene film with ≤ 1.0 g/m²/24hr water vapor transmission rate (WVTR) forms the core moisture shield, sealed via heat-welded seams to eliminate permeation pathways. Third, an outer layer of UV-stabilized polypropylene stretch hood (70 μm thickness) shields against physical abrasion and puncture during handling. Desiccant packs (minimum 30% relative humidity capacity) are strategically placed within the sealed envelope, calculated at 1.5 kg per cubic meter of void space. This multi-barrier approach maintains internal relative humidity below 40% for 90+ days—exceeding the typical 30–45 day sea voyage duration—even under tropical maritime conditions.

Sea freight safety is further ensured through dynamic load testing. Palletized units undergo ISTA 3A vibration and drop testing simulating container stacking (up to 3-high) and port crane operations. We document shock exposure via onboard G-loggers, verifying accelerations remain below 5G—critical for preventing micro-cracking in annealed aluminum alloys. Crucially, all packaging materials are non-outgassing per ASTM D2090, eliminating volatile organic compounds that could deposit conductive residues on foil surfaces. This holistic system has achieved a 99.8% incident-free delivery rate across 12,000+ TEUs since 2018, directly safeguarding the magnetic properties and surface cleanliness demanded by high-voltage transformer manufacturers.

Non-compliant packaging voids material warranties; we strongly advise against substitutions that compromise barrier integrity or structural support. Partner with us to ensure your transformer core materials arrive with metallurgical properties unchanged from factory output.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Transformer Strip and Foil

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the production of high-precision aluminum and copper strip and foil for high frequency, high voltage transformers. Our facility integrates advanced metallurgical processes with rigorous quality control systems to deliver materials that meet the exacting demands of modern power electronics and energy infrastructure.

Our production capabilities are anchored in state-of-the-art cold rolling lines, continuous annealing furnaces, and precision slitting equipment, enabling tight dimensional tolerances and superior surface finish. We produce aluminum transformer strip in thicknesses ranging from 0.1 mm to 3.0 mm, with widths up to 1,250 mm, tailored to customer specifications. Copper strip is manufactured to similar precision, supporting high current density and thermal stability in demanding transformer applications. All materials are processed under controlled atmospheres to ensure oxide minimization and consistent electrical conductivity.

Metallurgical integrity is central to our product performance. Our aluminum alloys are optimized for high purity (up to 99.7% Al) and feature controlled grain structure to enhance formability and reduce eddy current losses. For copper, we utilize high-conductivity grades (minimum 100% IACS) with strict control over oxygen content to prevent hydrogen embrittlement. Each coil undergoes comprehensive testing, including tensile strength, elongation, microhardness, and surface profilometry, ensuring compliance with international standards such as GB/T, ASTM, and IEC.

We specialize in supplying strip and foil materials for wound core transformers used in high frequency applications such as switch-mode power supplies, traction systems, and renewable energy inverters. Our products exhibit excellent layer-to-layer insulation compatibility, thermal cycling resistance, and mechanical stability under high electromagnetic stress. Custom temper conditions (H14, H16, O, etc.) and edge trimming options are available to meet specific winding and assembly requirements.

Quality assurance is embedded throughout our manufacturing workflow. Our in-house laboratory is equipped with OES spectrometers, digital tensile testers, and eddy current flaw detection systems, enabling real-time monitoring of material properties. We maintain ISO 9001:2015 certification and support full traceability from ingot to finished coil, providing mill test certificates with every shipment.

As a strategic partner, Luoyang Xinzhaohe offers scalable production capacity, technical collaboration, and responsive logistics to global clients. We work closely with transformer designers and manufacturers to optimize material selection, reduce total cost of ownership, and accelerate time to market.

For reliable supply of high-performance aluminum and copper strip and foil for high frequency, high voltage transformers, contact us today.

Cathy Zhang

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing high frequency high voltage transformer directly from China.