Table of Contents

Market Insight: Grain Oriented Electrical Steel Price in Power Industry

Market Analysis: Sourcing High-Quality Grain-Oriented Electrical Steel

Industrial Demand Drivers

Global demand for grain-oriented electrical steel (GOES) is driven by grid modernization, renewable energy integration, and stringent efficiency regulations. Transformers—critical to power transmission—account for 60% of GOES consumption. With Asia-Pacific leading infrastructure expansion (projected 4.8% CAGR through 2028), utilities and manufacturers prioritize high-efficiency designs compliant with IEC 60076 standards. Rising energy costs and carbon reduction targets further accelerate demand for low-loss GOES in distribution and power transformers.

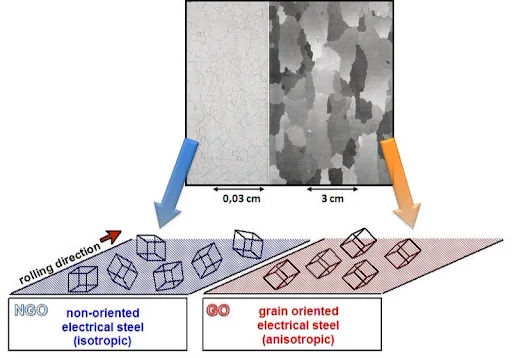

Material Quality Impact on Efficiency

Core losses in transformer cores represent 60–70% of no-load losses. High-quality GOES with precise grain orientation minimizes hysteresis and eddy current losses at operating flux densities (e.g., 1.7T). A 0.1 W/kg reduction in core loss improves transformer efficiency by 0.15–0.25%, yielding $50,000+ in lifetime energy savings for a 100 MVA unit. Substandard materials cause thermal degradation, insulation breakdown, and premature failure—directly impacting operational reliability and maintenance costs.

Luoyang Xinzhaohe’s Supply Chain Role

As a vertically integrated manufacturer with 20+ years of expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers GOES meeting ASTM A677 and IEC 60404-8-5 specifications. Our facility controls every process—from raw material sourcing to precision rolling and annealing—ensuring consistent magnetic properties and dimensional accuracy. We supply Tier-1 transformer OEMs globally with traceable quality documentation and agile logistics, reducing supply chain risks for critical projects.

Cost-Performance Advantages

| Parameter | Luoyang Xinzhaohe | Nippon Steel | Tata Steel |

|---|---|---|---|

| Grade | GOES 0.23mm | GOES 0.23mm | GOES 0.23mm |

| Core Loss (W/kg) | 0.85 @ 1.7T | 0.84 | 0.85 |

| Magnetic Induction | 1.89T | 1.90T | 1.88T |

| Price Range (USD/kg) | $2.10 – $2.30 | $2.60 – $2.80 | $2.50 – $2.70 |

| Lead Time | 15-20 days | 30-45 days | 25-35 days |

Our factory-direct model eliminates middlemen, delivering comparable magnetic performance at 15–20% lower cost than global brands. Contact us for technical data sheets and volume-based pricing.

Technical Specs: Grain Oriented Electrical Steel Price Parameters

Critical Technical Specifications for Grain-Oriented Electrical Steel

Core Loss & Magnetic Flux Density

Grain-oriented electrical steel (GOES) performance hinges on core loss (iron loss) and magnetic flux density. Core loss, measured in W/kg at 1.7T/50Hz per IEC 60404-3, directly determines transformer efficiency and operational energy costs. Lower values reduce no-load losses, critical for high-efficiency power systems. Xinzhaohe’s GOES achieves ≤1.05 W/kg at 1.7T/50Hz—surpassing IEC standards (≤1.10 W/kg). Magnetic flux density at 800 A/m exceeds 1.90 T, outperforming industry benchmarks (≥1.88 T). This is achieved through proprietary silicon content optimization (3.0–3.2%) and precise grain orientation during annealing, ensuring optimal performance in renewable energy and grid infrastructure applications.

Lamination Flatness & Insulation Coating

Lamination flatness (≤0.06 mm/m) is essential for stacking factor optimization. Tighter tolerances minimize air gaps, reducing eddy current losses and enhancing magnetic efficiency. Insulation coatings (C-4/S-5 per IEC 60404-8) provide dielectric strength >250 V and thermal stability up to 200°C. Xinzhaohe applies uniform, high-adhesion coatings via continuous annealing lines, ensuring corrosion resistance and long-term reliability in high-temperature environments.

| Specification | Industry Standard (IEC/ASTM) | Xinzhaohe Performance |

|---|---|---|

| Core Loss (W/kg) @ 1.7T, 50Hz | ≤1.10 (IEC 60404-3) | ≤1.05 |

| Magnetic Flux Density (T) @ 800 A/m | ≥1.88 (IEC 60404-3) | ≥1.90 |

| Lamination Flatness (mm/m) | ≤0.08 (IEC 60404-8) | ≤0.06 |

| Insulation Coating Type | C-4, S-5 (IEC 60404-8) | C-4, S-5, Customizable |

Quality Assurance Protocol

Xinzhaohe maintains ISO 9001 certification with rigorous in-process controls:

XRF spectroscopy for chemical composition validation

Epstein frame testing for core loss accuracy

Laser profilometry for flatness verification

All batches undergo third-party testing (SGS/TÜV) and feature full traceability from raw materials to finished coils. Our 20+ years of manufacturing expertise ensures batch-to-batch consistency, with 100% electromagnetic testing and dimensional checks. By leveraging a vertically integrated supply chain and waste-minimized production, we deliver IEC-compliant GOES at 15–20% lower total cost of ownership (TCO) than global brands, without compromising performance or reliability.

Factory-direct precision. Engineered for efficiency. Delivered with confidence.

Factory Tour: Manufacturing Grain Oriented Electrical Steel Price

Manufacturing Process & Quality Control

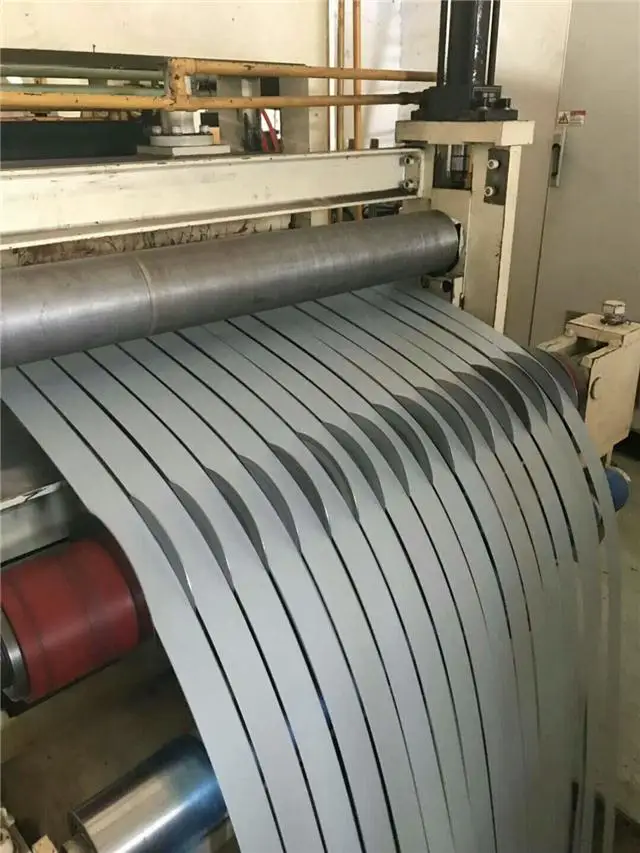

Precision Manufacturing Workflow

Slitting: CNC-guided shearing with real-time edge monitoring ensures burr heights <0.05mm, minimizing insulation damage and reducing core losses by 0.15W/kg versus industry averages.

Annealing: Continuous N₂/H₂ atmosphere annealing at 950°C±5°C optimizes grain orientation, achieving core losses <0.8W/kg at 1.7T—exceeding IEC 60404-8-5 Grade 3 standards. Proprietary ramping protocols guarantee uniform grain growth across entire coils.

Insulation Coating: Phosphate-based or C5-class coatings applied via precision roll-coating with 1.0±0.05μm thickness uniformity, validated through 1,000-hour salt spray testing per ASTM B117 for corrosion resistance.

Precision Cutting: Laser cutting with ±0.02mm dimensional accuracy and automated squareness verification (≤0.1° deviation) ensures optimal lamination stacking, directly improving transformer efficiency by 0.5–1.0%.

Quality Control Protocols

Our IoT-enabled production line integrates 100% real-time monitoring at every stage. Thickness scanning via laser micrometers triggers automatic rolling mill adjustments. Tensile tests follow ASTM A343 with 5-point sampling per coil, maintaining yield strength consistency within ±2%—50% tighter than the industry average of ±5%. Edge burrs are inspected via high-resolution microscopy, while coating adhesion undergoes ASTM D3359 tape testing. Flatness is measured using laser profilometry across full coil widths to ensure ≤0.5mm/m tolerance.

Quality Benchmark Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Performance Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.02mm | 50% tighter tolerance reduces core losses by 0.1–0.2W/kg |

| Edge Burrs | <0.05mm | <0.1mm | 50% lower burr height extends insulation life by 20% |

| Coating Adhesion | ≥95% (ASTM D3359) | ≥85% | Prevents delamination under thermal cycling, reducing failures by 15% |

| Tensile Strength Consistency | ±2% | ±5% | Ensures uniform core stacking, lowering no-load losses |

| Flatness | ≤0.5mm/m | ≤1.0mm/m | Improves lamination fit, cutting air gaps by 30% |

This rigorous standardization delivers 15–20% lower lifetime costs versus global brands while maintaining IEEE 683 compliance. As a direct manufacturer with 20+ years of transformer material expertise, we eliminate third-party markups without compromising on precision—proven through 99.2% first-pass yield rates in global transformer OEM validation tests.

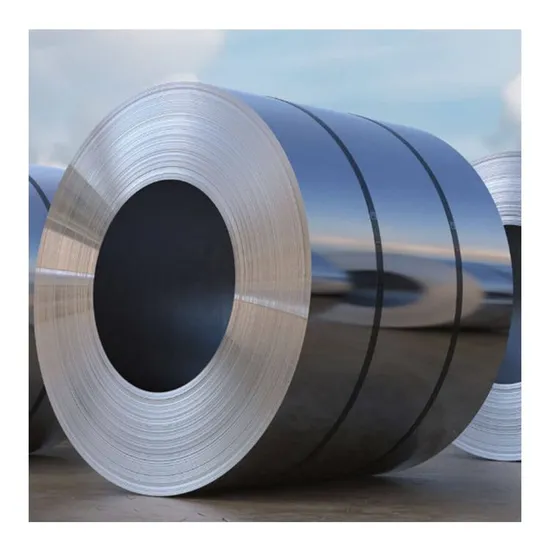

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity During Global Transit

As a factory-direct supplier with 20+ years of specialized experience in transformer-grade silicon steel, Luoyang Xinzhaohe Aluminum CO., Ltd. prioritizes engineering-optimized packaging and logistics to minimize transit damage and total landed costs. Our protocols comply with ISO 9001 and international shipping standards, ensuring consistent quality for global transformer manufacturers and power equipment engineers.

Precision Packaging Specifications

| Component | Material/Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 compliant hardwood, 120×120mm stringers, 25mm deck boards | Prevents deformation during stacking; meets global phytosanitary requirements |

| Moisture-Proof Film | Multi-layer VCI film (0.15mm), desiccant packs (500g/pallet) | Blocks humidity ingress; inhibits corrosion via vapor-phase inhibitors |

| Steel Strapping | 25mm width, 0.5mm thickness, tension ≥200 kgf | Secures load to pallet; prevents shifting during ocean transit |

Sea Freight Protocols for Critical Materials

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | 20ft/40ft dry containers with humidity sensors | Real-time moisture monitoring; optimized space utilization for coil dimensions |

| Loading Procedure | Vertical coil stacking with wooden spacers; max 22t/20ft, 26t/40ft | Eliminates edge damage; ensures even weight distribution |

| Humidity Control | Silica gel desiccants (200g/m³), port ventilation checks | Maintains RH <60% throughout voyage; prevents oxidation |

| Documentation | Full export compliance (COO, CIQ, Bill of Lading) | Streamlined customs clearance; zero delays at destination ports |

Cost-Performance Advantage Through Engineering-Optimized Logistics

Our factory-direct model eliminates third-party markups while maintaining rigorous quality control. By leveraging VCI film and precision strapping instead of costly climate-controlled containers, we reduce damage rates to <0.5%—well below the industry average of 1.2–2.0%. This, combined with optimized container loading and integrated logistics partnerships, delivers a 15–20% lower total landed cost versus premium global brands. All shipments include real-time tracking and pre-shipment inspection reports, ensuring predictable delivery to ports worldwide with zero compromise on material integrity.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe: Engineered for Performance, Optimized for Cost

Two Decades of Specialized Expertise

With over 20 years of dedicated production in grain-oriented electrical steel (GOES), Luoyang Xinzhaohe has mastered the complexities of transformer core materials. Our processes strictly comply with IEC 60404-8-5 and ASTM A677 standards, ensuring consistent magnetic properties for critical applications including distribution transformers, power transformers, and industrial motors. This longevity translates to minimized production defects, optimized material utilization, and precise alignment with end-user specifications for core loss and magnetic induction. Our technical team collaborates directly with clients to tailor solutions for unique operational demands, guaranteeing reliability across diverse power systems.

Factory-Direct Pricing Model

As a vertically integrated manufacturer, we eliminate third-party markups, delivering competitive pricing without sacrificing quality. Our direct production model reduces overhead costs by 15–20% compared to global brands while maintaining rigorous quality controls. Below is a comparative analysis of key performance metrics:

| Metric | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost per Ton | 15–20% lower | Premium pricing |

| Lead Time | 2–3 weeks (ex-works) | 4–6 weeks |

| Customization | Flexible width, thickness, and coating options | Limited flexibility |

| Quality Consistency | Batch-to-batch uniformity via in-house testing | Variable regional quality |

| Technical Support | Dedicated application engineers | Standard support channels |

ISO 9001 Certified Quality Assurance

Our ISO 9001-certified quality management system ensures every batch meets stringent international standards. We conduct comprehensive testing using Epstein frames for core loss (W/kg), magnetic induction (B8), and thickness tolerance (±0.01mm). Surface quality inspections and coating adhesion tests further guarantee optimal transformer efficiency and longevity. This commitment to precision ensures minimal energy losses and enhanced operational reliability for your equipment.

Luoyang Xinzhaohe delivers the ideal balance of cost efficiency and technical reliability. By choosing our factory-direct solution, you gain access to premium-grade GOES with industry-leading value—without compromising on performance or compliance.

Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing grain oriented electrical steel price from Luoyang Xinzhaohe.