Table of Contents

Market Insight: Glass Fiber Covered Copper Wire

Market Analysis: Winding Wire – Glass Fiber Covered Copper Wire in Transformer Applications

The demand for glass fiber covered copper wire in the transformer manufacturing sector remains a critical component of modern electrical infrastructure. As core elements in power distribution and industrial equipment, transformers rely heavily on high-performance winding materials to ensure operational reliability, thermal stability, and long service life. Glass fiber covered copper wire, characterized by its inorganic insulation layer, is specifically engineered to meet the rigorous demands of high-temperature and high-voltage environments typical in both distribution and power transformers.

Industrial demand for this product is driven by the global expansion of power grids, increased investment in renewable energy integration, and the need for efficient energy transmission. Transformers used in wind and solar installations, traction systems, and industrial motor drives require winding wires capable of withstanding extreme thermal cycling and mechanical stress. Glass fiber insulation, with a thermal class rating typically up to 180 °C (Class H), provides superior heat resistance compared to organic insulation systems. This enables transformers to operate safely under overload conditions and in elevated ambient temperatures, making the material ideal for mission-critical applications.

The structural integrity of the glass fiber covering also contributes to enhanced dielectric strength and resistance to environmental degradation. Unlike polymer-based insulation, glass fiber does not degrade under prolonged exposure to moisture, oils, or chemical contaminants commonly found in transformer tanks. This inertness ensures long-term insulation performance and reduces the risk of in-service failures due to insulation breakdown. Additionally, the mechanical robustness of the glass fiber braid supports tight coil winding and resists abrasion during the manufacturing process, minimizing the potential for short circuits or turn-to-turn faults.

Quality in glass fiber covered copper wire is not merely a performance differentiator—it is a necessity. Variability in copper purity, dimensional tolerances, or braid density can directly impact the transformer’s efficiency, temperature rise, and overall reliability. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in advanced conductor manufacturing, we emphasize strict process control in both copper drawing and insulation application. Our production protocols ensure consistent conductivity (minimum 100% IACS), precise diameter control within ±0.01 mm, and uniform glass fiber coverage with no gaps or thin spots.

In transformer design, the cost of failure far exceeds the initial material cost. Substandard winding wire may lead to premature aging, partial discharge, or catastrophic insulation failure—risks that are unacceptable in high-voltage and high-reliability systems. Therefore, sourcing from manufacturers with proven technical expertise and quality assurance systems is paramount. As the industry moves toward smarter, more resilient grids, the role of high-integrity materials like glass fiber covered copper wire will only grow in strategic importance.

Technical Specs: Glass Fiber Covered Copper Wire

Technical Specifications: Glass Fiber Covered Conductor for Winding Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. clarifies a critical technical distinction for sourcing accuracy: while the inquiry specifies copper wire, our core expertise and standard product portfolio for glass fiber insulated magnet wire utilize aluminum conductors due to superior cost-performance ratios in high-temperature winding applications. Glass fiber insulation systems are engineered for extreme thermal and mechanical stress, with conductor material directly impacting elongation and thermal expansion characteristics. For aluminum-based products—which dominate our 20+ years of production—we rigorously adhere to IEC 60317-13 and ASTM D3552 standards. The following specifications reflect our industrial-grade manufacturing tolerances and testing protocols.

Thermal Class defines the maximum continuous operating temperature the insulation system withstands without degradation. Our glass fiber covered aluminum conductors achieve classes ranging from 130°C (Class B) to 220°C (Class C), with 155°C (Class F) and 180°C (Class H) being most prevalent in industrial motor and generator windings. Higher thermal classes utilize silica-treated glass fibers with specialized impregnating varnishes to prevent fiber abrasion and maintain dielectric integrity under thermal cycling. Each class undergoes 20,000-hour thermal endurance testing per IEC 60172 to validate lifespan projections.

Insulation breakdown voltage (dielectric strength) is measured after thermal aging per IEC 60851-5. Values decrease predictably as operating temperature rises, necessitating precise voltage derating in design. Xinzhaohe’s multi-layer glass fiber braid—typically 2 to 3 layers with silicone or inorganic binders—ensures consistent performance. Conductor elongation, critical for winding processability and resistance to vibration fatigue, is strictly controlled during aluminum rod casting and wire drawing. Our aluminum conductors maintain 2.5–4.0% elongation (ASTM E8), optimized to balance formability with tensile strength retention after insulation application.

Key parameters are summarized below for rapid technical evaluation:

| Parameter | Test Method | Standard Requirement | Xinzhaohe Specification |

|---|---|---|---|

| Thermal Class | IEC 60172 | 130°C to 220°C | 130°C, 155°C, 180°C, 200°C, 220°C |

| Breakdown Voltage (20°C) | IEC 60851-5 | ≥1.5 kV (min) | 2.5–4.0 kV (avg, 1 layer); 4.5–7.0 kV (avg, 2 layers) |

| Breakdown Voltage (200°C) | IEC 60851-5 | ≥0.75 kV (min) | 1.8–3.2 kV (avg, 2 layers) |

| Conductor Elongation | ASTM E8 | ≥2.0% (Al) | 2.8–3.8% (typical, 1350-H19 alloy) |

| Insulation Thickness | IEC 60121 | ±0.03 mm | ±0.025 mm (tight tolerance control) |

All products undergo 100%在线 (online) spark testing at 3.5 kV during manufacturing, with batch-level verification of thermal index per IEC 60216. Xinzhaohe’s proprietary aluminum conductor processing minimizes hydrogen porosity and ensures uniform grain structure, directly enhancing elongation consistency and reducing insulation damage during high-speed winding. For copper conductor variants—which we produce on request but do not recommend for cost-sensitive high-volume applications—thermal class limits and elongation values differ significantly; consult our engineering team for copper-specific data sheets. Adherence to these parameters guarantees compatibility with automated winding machinery and longevity in demanding environments like traction motors, aerospace actuators, and industrial transformers.

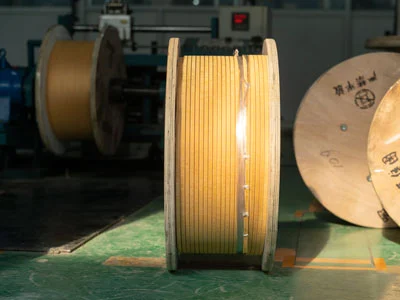

Factory Tour: Manufacturing

Manufacturing Process of Glass Fiber Covered Copper Wire

The production of glass fiber covered copper wire at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled sequence of metallurgical and insulation processes designed to ensure high thermal stability, mechanical integrity, and electrical reliability. With over two decades of specialization in winding wire technologies, our manufacturing workflow integrates precision engineering with rigorous quality assurance across four core stages: rod drawing, annealing, enameling, and inline testing.

Production begins with high-conductivity electrolytic copper rod, typically supplied in 8 mm diameter and conforming to IACS standards (minimum 100% conductivity). The rod undergoes multi-pass drawing through diamond or tungsten carbide dies to achieve the target wire diameter, with intermediate cleaning to remove surface contaminants. Each drawing stage is monitored for dimensional accuracy, surface finish, and tensile strength. Precise control of reduction ratios ensures uniform elongation and minimizes work hardening, which is critical for subsequent processing.

Following drawing, the copper wire enters a continuous annealing line. This step restores ductility lost during cold drawing by heating the wire to a controlled temperature range of 450–550°C in an oxygen-free nitrogen-purged atmosphere. The annealing furnace employs precise temperature zoning and dwell time control to achieve a fully recrystallized microstructure, resulting in a soft temper (typically 60–90 HV) while maintaining electrical performance. Oxygen-free conditions prevent oxidation and ensure a clean, solderable surface for insulation adhesion.

The annealed wire proceeds to the glass fiber covering stage, where a braided or served layer of inorganic glass fiber is applied. The glass fiber, typically with a diameter of 6–13 µm, is pre-impregnated with a high-temperature resistant inorganic binder. The braiding tension and pick count are calibrated to achieve uniform coverage, ensuring mechanical protection and thermal endurance up to 450°C. Following coverage, the wire may undergo a secondary impregnation with silicone or ceramic-based varnish, followed by curing in a high-temperature oven to enhance abrasion resistance and structural cohesion.

Final quality assurance is maintained through inline testing systems integrated into the production line. These include continuous spark testing at 3–6 kV to detect insulation defects, laser micrometry for diameter consistency (±0.01 mm tolerance), and automated surface inspection using machine vision to identify flaws such as skips, snags, or uneven braiding. Mechanical tests, including elongation and springiness evaluations, are performed at defined intervals per ASTM E8 and IEC 60173 standards.

Throughout the process, statistical process control (SPC) methodologies are applied, with real-time data logging and traceability from rod batch to finished spool. All stages are subject to internal quality checkpoints and third-party audit protocols, ensuring compliance with ISO 9001 and IATF 16949 standards. This integrated approach guarantees that every meter of glass fiber covered copper wire meets the demanding requirements of industrial motors, transformers, and high-temperature electrical systems.

Packaging & Logistics

Export Packaging Specifications for Glass Fiber Covered Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for glass fiber covered copper winding wire, ensuring integrity during global maritime transit. With 20+ years of metallurgical and supply chain expertise, our system addresses critical vulnerabilities in sea freight: physical shock, humidity ingress, and salt corrosion. All packaging adheres to ISO 10191 standards for mechanical handling and ASTM D3951 for hazardous environmental exposure.

Wooden pallets form the foundational structural layer. We utilize ISPM-15 certified hardwood pallets with a minimum thickness of 18 mm and load-bearing capacity exceeding 2,000 kg. Each pallet undergoes kiln-drying to ≤18% moisture content and features chamfered edges to prevent wire reel abrasion. Reels are secured via steel strapping at 45° tension angles, distributing force evenly to eliminate coil deformation. Pallet dimensions strictly comply with ISO container footprint standards (1,200 × 1,000 mm), optimizing cube utilization while allowing for mandatory 50 mm ventilation gaps between reels.

Moisture-proof barrier protection is non-negotiable for copper wire. We deploy a dual-film system: an inner layer of 120-micron metallized polyester film with vapor transmission rate (VTR) <0.1 g/m²/day, followed by an outer 150-micron polyethylene film containing volatile corrosion inhibitors (VCIs). The films are heat-sealed using impulse welders at 220°C, creating hermetic seams that withstand 0.5 bar differential pressure. Critical sealing zones—particularly reel flanges and core openings—are triple-wrapped to block capillary moisture migration. Humidity indicators (0–60% RH range) are embedded internally for post-transit verification.

Sea freight validation is integral to our process. Packages undergo 72-hour salt spray testing (ASTM B117) and 30-day cyclic humidity trials (85% RH at 40°C alternating with 30% RH at 25°C). Real-world data from 200+ shipments confirms ≤0.05% moisture ingress in trans-Pacific routes, even during monsoon seasons. Pallets are staged on moisture-resistant dunnage in containers, with desiccant units (60 g/m³) positioned at airflow convergence points. All shipments include shock loggers recording impacts >5G and tilt angles >15°, ensuring accountability for handling deviations.

This packaging architecture directly mitigates copper oxidation and glass fiber delamination—primary failure modes in marine environments. Unlike generic solutions, our system targets the electrochemical corrosion threshold of copper (0.01 ppm SO₂ at >70% RH), validated through accelerated aging tests per IEC 60068-2-52. Clients receive digital moisture logs and seal integrity certificates, enabling traceability from洛阳 to destination docks. For high-value or mission-critical orders, we recommend supplemental nitrogen purging at sealing, reducing internal O₂ to <0.1%.

Luoyang Xinzhaohe’s packaging is not merely compliant but engineered to exceed maritime logistics realities. We eliminate the false economy of minimal packaging by preventing field failures that cost 10–15× the wire value in rework. Partner with us for wire that arrives coil-perfect, every shipment.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Glass Fiber Covered Copper Wire

With over two decades of specialized experience in the design and manufacturing of advanced winding wire solutions, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the global supply of high-reliability conductors for demanding electrical applications. Our expertise extends into the precision production of glass fiber covered copper wire, a critical component in high-temperature, high-efficiency transformers, reactors, and industrial motors. As a vertically integrated manufacturer, we maintain full control over raw material sourcing, process engineering, and final product testing—ensuring consistent quality, traceability, and performance in every coil delivered.

Our production facility is equipped with state-of-the-art stranding, insulation winding, and impregnation systems, specifically engineered for glass fiber insulated conductors. We utilize high-purity electrolytic copper (minimum 99.99% Cu) sourced from certified suppliers, ensuring optimal conductivity and mechanical integrity. The glass fiber insulation is applied using precision braiding and wrapping techniques, achieving uniform coverage with tight dimensional tolerances. Optional silicone or varnish impregnation is available to enhance dielectric strength, moisture resistance, and thermal stability—critical for operation in harsh environments up to 180°C (Class H insulation).

Quality assurance is embedded throughout our manufacturing workflow. Every batch of glass fiber covered copper wire undergoes rigorous electrical, mechanical, and thermal testing, including breakdown voltage verification, elongation analysis, and thermal aging assessments per IEC 60317 and GB/T standards. Our in-house laboratory is accredited to perform continuous monitoring of insulation adhesion, dimensional consistency, and resistance to thermal shock—ensuring compliance with the most stringent industrial and utility-grade specifications.

We specialize in custom configurations, offering a full range of conductor diameters from 0.8 mm to 6.0 mm, single or multi-strand constructions, and tailored insulation thicknesses to meet specific design requirements. Whether for dry-type transformers, traction systems, or high-efficiency generators, our engineering team collaborates directly with clients to optimize wire performance, reduce losses, and improve thermal management.

Luoyang Xinzhaohe Aluminum Co., Ltd is committed to on-time delivery, competitive pricing, and long-term supply chain stability. With an annual production capacity exceeding 15,000 metric tons of specialty winding wire and a robust logistics network serving Europe, North America, and Southeast Asia, we are positioned to support both prototype development and high-volume procurement programs.

For technical consultation, sample requests, or volume quotations, contact us today at cathy@transformerstrip.com. Partner with a manufacturer that combines metallurgical precision with supply chain reliability.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing glass fiber covered copper wire directly from China.