Table of Contents

Market Insight: Foil Transformer

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

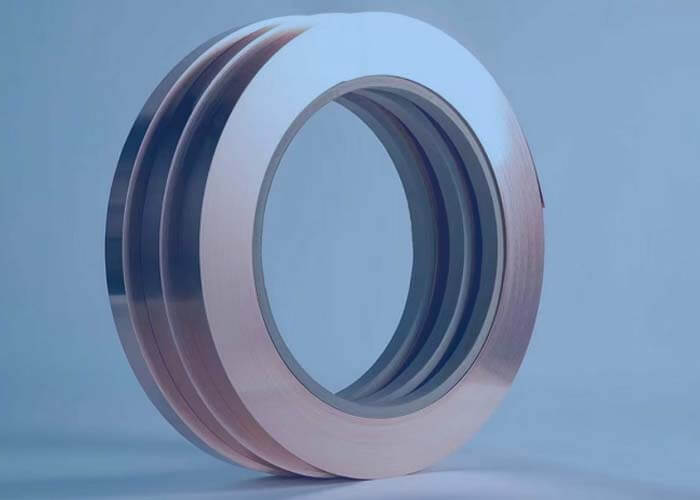

The global demand for transformer strip and foil—fabricated from high-purity aluminum and copper—has experienced sustained growth, driven by the expansion of power infrastructure, renewable energy integration, and industrial electrification. Transformer foil, specifically, serves as the core conductive material in low-voltage (LV) windings of dry-type and oil-immersed distribution and power transformers. Its application extends to high-efficiency transformers used in commercial buildings, data centers, and utility-scale substations, where electrical performance, thermal stability, and mechanical reliability are paramount.

Aluminum transformer foil has gained significant market share due to its favorable conductivity-to-weight ratio, corrosion resistance, and cost efficiency compared to copper. Modern aluminum alloys, particularly 1060, 1070, and 1350 grades, are engineered to meet ASTM B418 and IEC 60164 standards, ensuring minimum electrical conductivity of 61% IACS and tight compositional control. Copper foil, while denser and more expensive, remains critical in high-current applications where maximum conductivity (≥98% IACS) and compact winding geometry are required. The selection between aluminum and copper is often dictated by design specifications, lifecycle cost analysis, and regional material availability.

Industrial demand is further amplified by regulatory mandates promoting energy-efficient transformers (e.g., DOE 2016 in the U.S., EU Ecodesign Directive). These standards necessitate reduced no-load and load losses, directly influencing the quality and consistency of conductor materials. Transformer foil with non-uniform thickness, edge defects, or surface oxidation can lead to localized hotspots, increased eddy current losses, and premature insulation breakdown. Therefore, precision in foil dimensions—typically ranging from 0.2 mm to 6.0 mm in thickness and up to 1,250 mm in width—is essential to ensure uniform current distribution and optimal magnetic coupling.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized production experience, we emphasize metallurgical purity, dimensional accuracy, and surface integrity in every coil. Our transformer foil undergoes continuous casting and rolling processes under controlled atmospheres to minimize hydrogen content and inclusions. Each batch is tested for tensile strength, elongation, grain structure, and electrical resistivity to meet or exceed international quality benchmarks. Consistent foil quality directly impacts transformer efficiency, reducing total ownership costs through lower energy dissipation and extended service life.

The supply chain for transformer foil is increasingly sensitive to material traceability and process control. Leading transformer manufacturers require certified material test reports (MTRs), lot tracking, and compliance with ISO 9001 and IATF 16949 standards. As global grid modernization accelerates, particularly in Asia, Africa, and South America, the demand for reliable, high-performance foil will continue to rise. Suppliers capable of delivering consistent quality, technical support, and scalable production capacity will play a pivotal role in enabling next-generation transformer systems.

| Parameter | Aluminum Foil (Typical) | Copper Foil (Typical) |

|---|---|---|

| Thickness Range | 0.2 – 6.0 mm | 0.2 – 5.0 mm |

| Conductivity | ≥61% IACS | ≥98% IACS |

| Tensile Strength | 90 – 120 MPa | 200 – 250 MPa |

| Elongation | ≥30% | ≥4% |

| Standard Compliance | ASTM B418, IEC 60164 | ASTM B3, IEC 60164 |

Technical Specs: Foil Transformer

Technical Specifications for Transformer Foil Sourcing

As a metallurgical specialist with Luoyang Xinzhaohe Aluminum CO., Ltd., we emphasize that transformer foil performance hinges on stringent dimensional and material property control. Our two decades of focused production for power and electronic transformers mandate specifications exceeding generic strip standards. Precision slitting accuracy directly impacts winding integrity and core loss; we achieve a consistent thickness tolerance of ±0.002 mm through state-of-the-art tension-controlled slitting lines equipped with real-time laser micrometry. This precision minimizes interlayer air gaps during coil winding, critical for thermal management and electromagnetic efficiency in high-frequency applications. Edge quality is non-negotiable. Burr formation during slitting introduces insulation puncture risks and localized heating. Our process guarantees burr heights ≤ 2 μm, verified by profilometry and optical edge inspection per IEC 60404-9 protocols. This burr-free condition ensures clean layer stacking and long-term dielectric reliability.

Electrical conductivity, measured per ASTM E1004, is fundamental to minimizing resistive losses. Aluminum transformer foil must meet a minimum 59.5% IACS (International Annealed Copper Standard) for grade 1070/1060, achieved through strict melt chemistry control and optimized annealing. Copper foil targets ≥100% IACS for C11000 grade, requiring oxygen-free processing and absence of interstitial impurities. Surface roughness (Ra) significantly influences interfacial capacitance and partial discharge inception voltage. We maintain Ra ≤ 0.4 μm for aluminum and ≤ 0.3 μm for copper, controlled via precision rolling and surface conditioning. Flatness deviation must not exceed 5 mm/m to prevent winding defects; this is secured through multi-stage tension leveling. Mechanical properties require a narrow tensile strength range (Al: 40-60 MPa, Cu: 180-220 MPa) with minimum elongation of 1.5% to ensure handling robustness without compromising formability during winding. Consistent coil geometry, including precise inner diameter control (±0.1 mm) and secure packaging, prevents edge damage during transit and handling.

The following table details critical parameters for sourcing qualification:

| Critical Parameter | Aluminum Foil Specification | Copper Foil Specification | Measurement Standard |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm | ±0.002 mm | ASTM E29, ISO 11562 |

| Edge Burr Height | ≤ 2 μm | ≤ 2 μm | IEC 60404-9, Profilometry |

| Electrical Conductivity | ≥ 59.5% IACS (1070/1060) | ≥ 100% IACS (C11000) | ASTM E1004 |

| Surface Roughness (Ra) | ≤ 0.4 μm | ≤ 0.3 μm | ISO 4287 |

| Tensile Strength | 40-60 MPa | 180-220 MPa | ASTM E8/E8M |

| Minimum Elongation | 1.5% | 1.5% | ASTM E8/E8M |

| Flatness Deviation | ≤ 5 mm/m | ≤ 5 mm/m | Internal Optical Method |

| Coil Inner Diameter Tolerance | ±0.1 mm | ±0.1 mm | ISO 6646 |

These specifications represent the baseline for reliable transformer operation under thermal and electromagnetic stress. Deviations in slitting tolerance or edge quality directly correlate with increased core losses and reduced transformer lifespan. Luoyang Xinzhaohe implements 100% inline thickness monitoring and statistical process control for all critical parameters, supported by quarterly third-party lab validation. Sourcing decisions must prioritize certified conformance to these metrics, not merely nominal alloy grades, to ensure optimal transformer efficiency and field reliability. Documentation of mill test reports with actual measured values per coil lot is essential for traceability and quality assurance in critical power applications.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Foil and Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

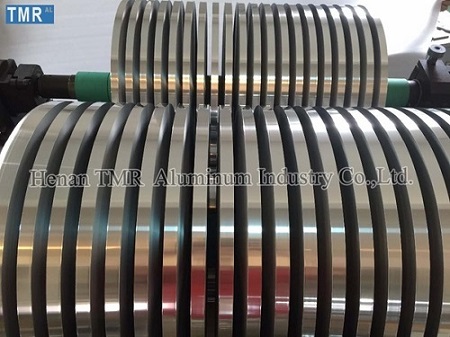

The production of high-performance aluminum and copper transformer foil and strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to meet the stringent electrical, mechanical, and dimensional requirements of modern transformer applications. With over two decades of metallurgical expertise, our process ensures consistent material integrity, surface quality, and edge precision critical for efficient magnetic performance and winding reliability.

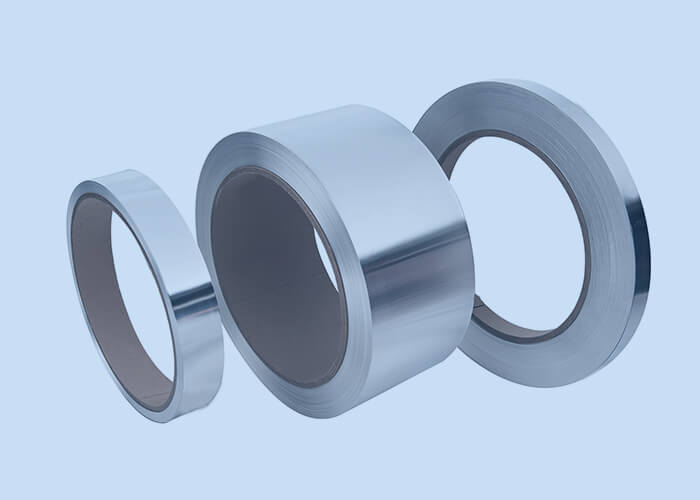

The process begins with cold rolling, where high-purity aluminum or copper ingots are first homogenized and hot rolled into intermediate gauges. These are then fed into precision cold rolling mills equipped with advanced gauge control systems. Cold rolling reduces the material to the final specified thickness, typically ranging from 0.10 mm to 3.0 mm for transformer applications. This stage is critical for achieving uniform thickness tolerance (±0.005 mm or tighter), optimal microstructure, and enhanced mechanical properties such as yield strength and elongation. The rolling parameters—including roll force, tension, and speed—are continuously monitored and adjusted in real time using automated process control systems to maintain consistency across batches.

Following cold rolling, the material undergoes precision slitting. This operation converts master coils into narrow strips or foils of exact widths as required by transformer winding designs. Our high-speed slitting lines utilize hardened, ground, and polished rotary knives with micro-adjustable alignment to ensure burr-free cuts and parallel edges. Width tolerances are maintained within ±0.1 mm, with edge straightness held to less than 0.5 mm per meter. The slitting process is performed under controlled tension to prevent edge wave or center buckle, preserving flatness essential for automated winding operations.

Edge conditioning is the final critical step in the manufacturing sequence. All slit edges are subjected to mechanical brushing or edge rounding to remove micro-burrs and sharp asperities that could damage insulation during coil winding. This process significantly reduces the risk of dielectric breakdown in the finished transformer. Edge profile is verified using optical edge inspection systems to ensure smooth, uniform contours.

Throughout the production flow, rigorous quality control measures are implemented. Incoming billets are spectrometrically analyzed for alloy composition. During rolling, online laser micrometers monitor thickness profile, while surface inspection systems detect defects such as scratches, pits, or inclusions. Final coils undergo comprehensive testing, including tensile strength, elongation, electrical conductivity, and surface roughness measurements. All test data is documented and available with material certification.

This integrated approach—combining precision engineering, metallurgical control, and systematic quality validation—ensures that every coil of transformer foil or strip delivered by Luoyang Xinzhaohe meets the highest industrial standards for performance and reliability.

Packaging & Logistics

Export Packaging Specifications for Transformer Foil Shipments

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard aluminum and copper transformer strip and foil during international maritime transit. With over two decades of metallurgical and supply chain expertise, we recognize that packaging integrity is non-negotiable for maintaining the precise dimensional tolerances, surface finish, and electrical properties critical to transformer foil performance. Our system addresses the dual threats of mechanical damage and environmental corrosion inherent in sea freight.

All transformer foil coils are systematically secured onto robust, ISPM 15 certified wooden pallets. These pallets utilize heat-treated, kiln-dried lumber meeting global phytosanitary standards, preventing pest infestation and structural degradation during extended voyages. Pallet dimensions and load-bearing capacity are precisely calculated based on coil weight, outer diameter, and core size to ensure zero movement or deformation under dynamic shipping stresses. Edge protectors fabricated from high-density polyethylene are mandatorily applied to all coil edges prior to palletization, distributing pressure and eliminating cut-through risks during strapping.

The primary moisture and contaminant barrier consists of multi-layer, metallized moisture-proof film. This specialized film incorporates a minimum 0.2mm thickness with an aluminum oxide barrier layer and integrated Vapor Corrosion Inhibitor (VCI) technology. The VCI molecules actively migrate to the foil surface, forming a molecular layer that disrupts electrochemical corrosion processes even under sustained high-humidity conditions. Film application follows a validated sequence: coils are individually wrapped with heat-sealed seams, then palletized units receive a secondary overwrap creating a hermetically sealed environment. Critical seal integrity is verified via pressure decay testing, ensuring the package maintains internal relative humidity below 40% for durations exceeding 120 days – significantly beyond typical ocean transit times.

This packaging methodology directly mitigates key sea freight hazards. Salt-laden atmospheres, temperature fluctuations causing condensation (cargo sweat), and prolonged exposure to marine humidity are neutralized by the film’s dual barrier: the physical metallized layer blocks moisture vapor transmission, while the VCI provides active electrochemical protection. Pallet construction prevents coil buckling during container stacking and absorbs shock from vessel motion. Our protocols exceed IMO and IACS guidelines for non-hazardous cargo, with documented validation through accelerated salt spray testing and real-world shipment monitoring using onboard hygrothermal loggers.

Compliance with international shipping regulations is inherent. ISPM 15 certification documentation accompanies every shipment, and film composition adheres to REACH and RoHS directives. Each packaged unit bears clear handling labels indicating moisture sensitivity, orientation requirements, and gross/net weights. This engineering-driven approach, refined through 20+ years of global logistics experience, ensures transformer foil arrives at destination facilities in as-processed condition, ready for immediate slitting and core winding without surface remediation. For procurement teams, this packaging specification represents a quantifiable reduction in supply chain risk and a direct contributor to downstream manufacturing yield.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Transformer Strip and Foil

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd has established itself as a leading supplier of precision aluminum and copper transformer strip and foil for global power and electronics industries. Our facility integrates advanced metallurgical processing, stringent quality assurance, and scalable production capacity to meet the exacting demands of transformer manufacturers worldwide. As a vertically integrated producer, we maintain full control over raw material sourcing, rolling, annealing, slitting, and packaging, ensuring consistent product integrity from ingot to finished coil.

Our production infrastructure is centered on high-precision cold rolling mills equipped with automated thickness control (AGC) and surface inspection systems, enabling us to produce transformer foil with tolerances as tight as ±0.005 mm. We specialize in both aluminum (1000, 3000, and 8000 series) and electrolytic tough pitch (ETP) copper strips, tailored to customer specifications for conductivity, mechanical strength, and surface finish. All materials are processed under controlled atmospheres to minimize oxidation and ensure optimal performance in dry-type and oil-immersed transformer applications.

Quality is systemically embedded in our manufacturing philosophy. Our facility operates under ISO 9001-certified quality management protocols, with in-line and final product testing conducted using state-of-the-art equipment including eddy current testers, tensile testers, micro-ohmmeters, and surface profilometers. Each batch is traceable through batch numbers and comprehensive material test reports (MTRs), supporting compliance with international standards such as IEC 60404, ASTM B209, and GB/T 3880.

We offer standard and custom slit widths ranging from 20 mm to 1,250 mm, with coil weights up to 5,000 kg, optimized for high-speed winding operations in transformer production lines. Our annealing processes are precisely controlled to achieve fully soft (O-temper) conditions with uniform grain structure, ensuring excellent ductility and low core loss characteristics. For specialized applications, we provide anti-corrosion coatings, edge trimming, and customized core types to enhance handling and performance.

Supply chain reliability is a cornerstone of our service model. With an annual production capacity exceeding 30,000 metric tons and strategic warehousing in Zhengzhou and Shanghai, we support just-in-time delivery schedules across Asia, Europe, and North America. Our export experience spans over 30 countries, backed by DDP, CIF, and FOB trade term flexibility.

Partnering with Luoyang Xinzhaohe means securing a long-term, technically capable supplier committed to material excellence and operational transparency. Whether you require high-volume standard foil or engineered strip solutions, our engineering team collaborates directly with clients to optimize specifications, reduce waste, and improve manufacturability.

For technical consultations or to request sample reels and pricing, contact us at cathy@transformerstrip.com. Let us become your trusted partner in transformer material supply.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing foil transformer directly from China.