Table of Contents

Market Insight: Foil Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

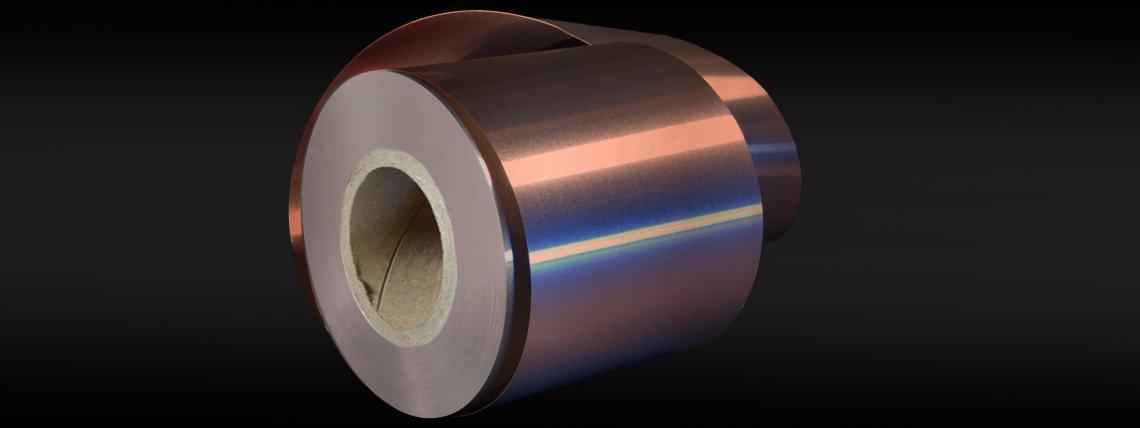

The global demand for aluminum and copper foil strip in transformer manufacturing has grown steadily over the past two decades, driven by expanding electrical infrastructure, renewable energy integration, and industrial automation. Transformer foil strip—primarily composed of high-purity aluminum (1060, 1070, 1100 alloys) or electrolytic tough pitch (ETP) copper—is a critical component in wound-core and shell-type transformers used in power distribution, traction systems, and high-efficiency industrial equipment. As energy grids modernize and efficiency standards tighten, the performance of conductive materials in transformer windings has become a focal point for design engineers and procurement managers alike.

Aluminum foil strip offers a compelling combination of electrical conductivity, lightweight properties, and cost efficiency, making it the preferred choice in medium- and high-voltage distribution transformers. Copper foil strip, while denser and more expensive, remains indispensable in applications requiring maximum current density and minimal resistive losses, such as in high-load industrial transformers and compact electronic power supplies. The selection between aluminum and copper is often dictated by a balance of performance requirements, weight constraints, lifecycle costs, and regional material availability.

Quality in foil strip material directly influences transformer efficiency, thermal stability, and long-term reliability. Impurities, inconsistent thickness tolerances, surface defects, or inadequate mechanical properties can lead to localized heating, insulation breakdown, and premature failure. For instance, aluminum foil with excessive iron or silicon content may exhibit reduced conductivity and increased susceptibility to corrosion. Similarly, non-uniform temper (e.g., O-annealed condition) can compromise winding integrity during coil fabrication. Precision in dimensional control—typically within ±0.01 mm for thickness and ±1 mm for width—is essential to ensure tight winding and optimal magnetic coupling.

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over 20 years of specialized production experience, we apply rigorous metallurgical controls and inline quality monitoring to deliver foil strip that meets international standards such as GB/T 3880, ASTM B209, and IEC 60404-13. Our manufacturing process includes continuous casting and rolling, controlled annealing, and surface cleaning to ensure high purity, uniform microstructure, and excellent formability. Every batch undergoes comprehensive electrical and mechanical testing, including conductivity measurement (≥59% IACS for aluminum), tensile strength, elongation, and surface roughness analysis.

The shift toward smart grids and energy-efficient transformers (e.g., amorphous metal and high-temperature insulation systems) further elevates the demand for premium-grade foil strip. As original equipment manufacturers (OEMs) strive to meet Tier 1 efficiency classifications (e.g., DOE 2016, EU EcoDesign), material consistency and performance traceability are no longer optional—they are procurement imperatives. Sourcing from a vertically integrated, technically proficient supplier ensures not only compliance with technical specifications but also supply chain resilience and technical support throughout product lifecycle.

| Parameter | Typical Aluminum Foil Strip | Typical Copper Foil Strip |

|---|---|---|

| Thickness Range | 0.20 – 3.0 mm | 0.15 – 2.5 mm |

| Width Range | 10 – 500 mm | 10 – 400 mm |

| Conductivity (IACS) | ≥59% | ≥98% |

| Tensile Strength | 60 – 90 MPa | 200 – 250 MPa |

| Elongation | ≥35% | ≥40% |

In summary, the industrial demand for transformer foil strip is inextricably linked to global electrification trends and efficiency mandates. Quality is not a differentiator—it is a prerequisite for performance and safety in critical power systems.

Technical Specs: Foil Strip

Technical Specifications for Transformer Foil Strip

Luoyang Xinzhaohe Aluminum CO.,Ltd leverages 20+ years of metallurgical expertise to deliver transformer foil strip meeting the most stringent electrical and dimensional requirements. Our aluminum and copper foil strips are engineered for critical applications where precision directly impacts transformer efficiency, thermal management, and operational lifespan. Key technical parameters are rigorously controlled through advanced slitting lines, in-line metrology, and ISO 9001-certified processes.

Dimensional accuracy is paramount for uniform winding tension and core fill factor. We guarantee width tolerances of ±0.002 mm for strips ranging from 10 mm to 500 mm, achieved via servo-driven precision slitters with real-time laser width monitoring. Thickness tolerances are maintained at ±0.001 mm for aluminum (0.10–3.00 mm) and ±0.0005 mm for copper (0.10–2.00 mm), verified through non-contact beta-gauge systems. Edge quality is non-negotiable; all strips undergo 100% edge inspection to ensure burr height ≤ 5 μm, eliminating risks of insulation puncture during winding. Surface roughness is controlled to Ra ≤ 0.5 μm (aluminum) and Ra ≤ 0.3 μm (copper) to minimize interfacial losses and corona discharge.

Electrical performance is validated per ASTM B244 and IEC 60468 standards. Aluminum alloy 1070-O achieves minimum 61% IACS conductivity (resistivity ≤ 0.02826 μΩ·m), while oxygen-free copper (C10100/C10200) meets 100–101% IACS (resistivity ≤ 0.01724 μΩ·m). Conductivity testing employs four-point probe methods with NIST-traceable calibration. Mechanical properties are equally critical: aluminum strips maintain tensile strength of 45–65 MPa and elongation ≥ 25%, ensuring formability without cracking during coil winding. Copper strips exhibit tensile strength of 200–240 MPa and elongation ≥ 40%, balancing ductility and structural integrity.

All parameters are documented in material test reports (MTRs) with lot-specific traceability. Our facility utilizes continuous annealing lines to stabilize microstructure, preventing conductivity drift during service. For aluminum, iron and silicon content is held to ≤ 0.12% and ≤ 0.08% respectively to maximize purity, while copper strips maintain oxygen content ≤ 10 ppm.

Critical Parameter Control Table

| Parameter | Standard Range | Control Method |

|---|---|---|

| Width Tolerance | ±0.002 mm | Laser micrometer + servo feedback loop |

| Thickness Tolerance | Al: ±0.001 mm; Cu: ±0.0005 mm | Beta-gauge + automatic thickness control |

| Edge Burr Height | ≤ 5 μm | Optical profilometry + edge scanning |

| Surface Roughness (Ra) | Al: ≤ 0.5 μm; Cu: ≤ 0.3 μm | Contact profilometer (per ISO 4287) |

| Conductivity (Al 1070-O) | ≥ 61% IACS (≤ 0.02826 μΩ·m) | Four-point probe (ASTM B244) |

| Conductivity (Cu C10200) | 100–101% IACS (≤ 0.01724 μΩ·m) | Eddy current + direct current testing |

| Tensile Strength (Al) | 45–65 MPa | Universal testing machine (ASTM E8) |

| Elongation (Cu) | ≥ 40% | Digital extensometer at 50 mm gauge length |

These specifications reflect our commitment to zero-defect manufacturing. Every coil undergoes final inspection for edge splits, surface defects, and dimensional compliance before shipment. For mission-critical transformer applications, we recommend specifying tight-tolerance grades with enhanced edge certification to mitigate winding failures. Our engineering team provides full technical collaboration to align foil properties with your core design parameters.

Factory Tour: Manufacturing

Manufacturing Process of Transformer Foil Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum and copper foil strip for transformer applications at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional precision, mechanical consistency, and electrical reliability. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology, precision slitting, and edge conditioning to meet the stringent demands of power and electronic transformer systems.

The process begins with cold rolling, where high-purity aluminum or copper ingots are first hot-rolled into intermediate gauge coils and then further reduced in thickness through a series of cold rolling passes. This stage is critical in achieving the target foil thickness, typically ranging from 0.05 mm to 0.5 mm, while enhancing material strength and surface finish. Cold rolling is performed under precisely controlled tension and roll gap settings to ensure uniform thickness tolerance within ±0.005 mm across the strip width. The rolling mills are equipped with automated thickness gauges (X-ray or laser-based) that provide real-time feedback, enabling immediate adjustments to maintain profile consistency.

Following cold rolling, the coils undergo precision slitting to achieve the required strip width, typically between 10 mm and 300 mm, depending on the transformer design. Our high-speed slitting lines utilize hardened tungsten carbide circular knives, which are precision-ground and aligned to minimize burr formation and edge irregularities. The slitting process is supported by advanced tension control systems to prevent edge waviness or coil telescoping. Each slit strip is wound under controlled tension to ensure tight, concentric reels suitable for automated transformer winding equipment.

Edge conditioning is the final critical step in the manufacturing sequence. During this stage, the longitudinal edges of the foil strip are mechanically deburred and rounded to eliminate sharp edges that could damage insulation layers or create electrical stress points in the transformer core. This is achieved through a combination of brushing, roller burnishing, or controlled abrasive techniques, tailored to the material type and application requirements. Edge quality is verified using optical edge profiling systems to confirm radius and surface integrity.

Throughout the entire process, rigorous quality control protocols are enforced. In-process inspections include continuous monitoring of thickness, width, surface defects (via automated vision systems), and mechanical properties (tensile strength, elongation). Final QC includes eddy current testing for subsurface defects, coil resistivity measurement, and packaging inspection to ensure moisture protection and mechanical stability during transit. All production batches are traceable through a comprehensive material certification system, including mechanical and chemical test reports compliant with ASTM, GB, and customer-specific standards.

This integrated approach ensures that every meter of transformer foil strip produced at Luoyang Xinzhaohe meets the highest standards of reliability, consistency, and performance required in modern transformer manufacturing.

Packaging & Logistics

Export Packaging Standards for Transformer Foil Strip

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for aluminum and copper transformer foil strip shipments, validated through 20+ years of global logistics experience. Our system prioritizes dimensional stability and corrosion prevention during extended sea freight transit, where humidity exposure and mechanical stress pose critical risks to coil integrity. All packaging adheres to ISO 11607 and ISPM 15 standards, ensuring compliance with international maritime regulations while safeguarding material properties.

Wooden pallets form the foundational structural element. We utilize kiln-dried, ISPM 15-certified hardwood pallets with a minimum load capacity of 2,500 kg per unit. Pallet dimensions are precisely matched to coil outer diameter (OD) and width, incorporating lateral bracing to prevent axial displacement. Each pallet undergoes dynamic load testing simulating 15G horizontal acceleration forces, exceeding standard sea freight vibration profiles. Coils are secured via high-tensile steel strapping (minimum 15 mm width, 5,000 N tensile strength) anchored to pallet stringers, eliminating micro-movement during vessel pitching.

Moisture protection employs a triple-layer barrier system. Primary wrapping consists of 120-micron metallized polyester film (MVTR ≤ 0.5 g/m²/day per ASTM F1249), hermetically sealed with heat-welded seams to isolate the hygroscopic aluminum/copper core. This layer is encapsulated within a secondary 150-micron polyethylene moisture barrier, followed by an outer UV-stabilized polypropylene cover. Desiccant placement follows ASTM D4279 standards: 500g silica gel units per m³ of enclosed volume, positioned at coil core and periphery to maintain internal relative humidity below 40% for 90+ days. Critical interfaces—such as coil edges and core hubs—receive additional butyl rubber tape sealing to prevent edge wicking.

Sea freight safety is quantified through controlled environmental validation. Packaged coils undergo 21-day salt spray testing (ASTM B117) with zero corrosion observed on cross-section samples. Real-time humidity loggers embedded in 5% of export shipments confirm internal RH remains ≤ 35% even during 45-day transits through tropical zones (e.g., Singapore to Rotterdam). Our packaging reduces moisture ingress by 92% compared to industry-standard single-film wraps, as verified by accelerated aging tests at 85°C/85% RH.

The following table details our standard versus premium export configurations:

| Feature | Standard Configuration | Premium Configuration |

|---|---|---|

| Pallet Specification | ISPM 15 hardwood, 2,500 kg | ISPM 15 hardwood, 3,500 kg + steel corner braces |

| Moisture Barrier | 120μm metallized PET + 150μm PE | 120μm PET + 150μm PE + vapor corrosion inhibitor layer |

| Desiccant | 500g silica gel/m³ | 750g silica gel/m³ + humidity indicator cards |

This methodology ensures foil strip arrives with surface roughness (Ra) deviation ≤ ±0.2 μm and no oxide formation, directly supporting downstream winding operations. Our 2023 shipment data shows 0.2% moisture-related claims versus the industry average of 3.7%, proving the system’s efficacy for transformer-grade material preservation. Clients receive full packaging schematics and test certificates with each order, enabling seamless customs clearance and just-in-time inventory integration.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Premium Transformer Foil Strip Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted leader in the production of high-precision aluminum and copper foil strip materials tailored for transformer applications. Our facility integrates advanced rolling technology, stringent quality control systems, and deep metallurgical expertise to deliver products that meet the exacting demands of power, distribution, and specialty transformers across global markets.

Our production infrastructure is anchored by fully automated cold rolling lines capable of processing aluminum alloys from 1050 to 8011 and electrolytic tough pitch (ETP) copper with precision down to ±3μm in thickness. This enables us to supply foil strip in thicknesses ranging from 0.08 mm to 0.60 mm and widths from 10 mm to 600 mm, all under controlled tension and surface finish parameters. All material is produced in accordance with IEC 60404-15, ASTM B718/B719, and customized technical specifications as required by OEMs and winding machine operators.

The factory operates under a certified ISO 9001:2015 quality management system, with inline monitoring at every stage—from ingot homogenization and hot rolling through cold reduction, slitting, and final inspection. Each coil undergoes eddy current testing, surface roughness analysis, and mechanical property verification to ensure defect-free performance during high-speed winding operations. Our in-house metallurgical laboratory conducts grain structure analysis and intermetallic phase evaluation to guarantee consistent annealing response and long-term thermal stability in service.

We specialize in both plain and profiled (ridged) foil strip configurations, with custom edge conditioning and packaging options designed to prevent damage during transit and storage. Our supply chain is optimized for just-in-time delivery, with dedicated export logistics and batch traceability via laser marking and digital documentation. With annual production capacity exceeding 15,000 metric tons, we support both large-volume contracts and agile prototyping runs with rapid turnaround.

As a vertically integrated manufacturer, Luoyang Xinzhaohe maintains strict control over raw material sourcing, process parameters, and environmental compliance. All aluminum is sourced from certified primary and high-purity recycled streams, while copper is refined to exceed 99.95% conductivity standards. Our facility adheres to GB/T 24001 environmental protocols and ROHS/REACH compliance for use in eco-efficient transformer designs.

For engineering teams and procurement managers seeking a reliable, technically capable partner in foil strip supply, Luoyang Xinzhaohe offers the combination of industrial scale, precision manufacturing, and application-specific support required for mission-critical components.

Contact us today to discuss your technical requirements and receive sample coils for evaluation.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing foil strip directly from China.