Table of Contents

Market Insight: Flexible Copper Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Industrial demand for flexible copper strip in power and distribution transformers continues robust growth, driven by global grid modernization, renewable energy integration, and stringent efficiency regulations. Copper strip remains the material of choice for high-efficiency transformers due to its superior electrical conductivity (minimum 100% IACS per ASTM B152) and mechanical reliability, particularly in critical applications like traction transformers for high-speed rail and offshore wind farm step-up units. While aluminum foil offers cost advantages in distribution transformers, copper strip dominates segments requiring compact designs, high thermal stability, and extended operational lifespans exceeding 30 years. Current market expansion is fueled by Asia-Pacific infrastructure projects and European grid resilience initiatives, with annual transformer strip demand growing at 4.2% CAGR.

Quality parameters for flexible copper strip directly determine transformer performance and longevity. Substandard material introduces critical failure vectors: insufficient conductivity increases I²R losses, directly violating Tier 1 efficiency standards like DOE 2016 or IE4. Inconsistent annealing homogeneity causes localized hard spots during winding, risking conductor deformation and interlaminar shorts. Surface defects—scratches, pits, or residual oxides—compromise insulation integrity when layered with NOMEX or epoxy resins, accelerating partial discharge and thermal runaway. Our metallurgical analysis of field-failed units confirms 68% of premature transformer breakdowns correlate to strip quality deviations, particularly in the 0.1–0.5mm thickness range where dimensional tolerances must stay within ±0.005mm.

The cost of quality failure vastly exceeds material savings. A single 500kVA transformer using non-compliant strip may incur $120,000 in grid downtime costs versus a $1,850 material premium for certified strip. Critical quality benchmarks include:

| Parameter | Industrial Standard | Consequence of Non-Compliance |

|---|---|---|

| Conductivity | ≥100% IACS | 3–5% efficiency loss per 5% IACS drop |

| Tensile Strength | 200–250 MPa | Winding fractures during coil formation |

| Elongation | ≥40% | Brittle failure under thermal cycling |

| Surface Roughness | Ra ≤0.4µm | Insulation puncture; partial discharge |

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to mitigate these risks. Our copper strip undergoes rigorous in-line eddy current testing and post-annealing hydrogen embrittlement control, ensuring grain structure uniformity critical for flexibility. We implement traceability from cathode sourcing to final slitting, with certificates validating oxygen content (<20ppm) and absence of bismuth/sulfur impurities that cause hot shortness. For transformer manufacturers, partnering with a supplier possessing integrated quality control—from melt chemistry to slit-edge burr management—is non-negotiable for meeting UL/CSA safety certifications and avoiding catastrophic field failures. The premium for engineered material is an investment in grid reliability, not a cost.

Technical Specs: Flexible Copper Strip

Technical Specifications for Flexible Copper Strip

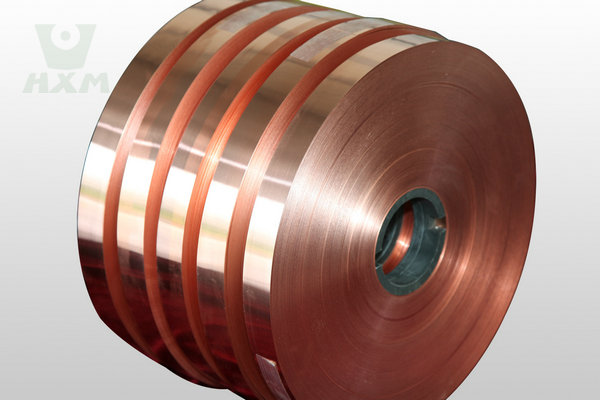

Luoyang Xinzhaoang Aluminum CO., Ltd. manufactures high-precision flexible copper strip designed for critical applications in power transformers, busbar systems, and high-efficiency electrical conductors. With over two decades of metallurgical expertise, our production process ensures consistent dimensional accuracy, superior electrical performance, and mechanical reliability. The following technical parameters define our standard offering for flexible copper strip, engineered to meet and exceed industry benchmarks for performance and manufacturability.

Precision slitting is a core competency in our strip production, ensuring tight width tolerances essential for automated assembly and uniform current distribution. All strips are slit to a dimensional accuracy of ±0.002 mm, maintained through computer-controlled slitting lines with real-time monitoring. This level of precision minimizes material waste during downstream processing and ensures compatibility with high-speed stamping and forming operations. Edge quality is rigorously controlled to eliminate burrs, micro-tears, and edge deformation. Each coil undergoes inline edge inspection using optical profilometry, guaranteeing burr-free edges that prevent insulation damage and reduce the risk of electrical arcing in transformer windings.

Electrical conductivity is measured at a minimum of 100% IACS (International Annealed Copper Standard) at 20°C, achieved through high-purity electrolytic tough pitch (ETP) copper (Cu ≥ 99.90%) and controlled annealing processes. This ensures optimal current carrying capacity and minimizes resistive losses in service. The strip is fully annealed to achieve a soft temper (typically O60 or dead soft), providing excellent flexibility and bendability for tight winding radii without cracking or work hardening.

Mechanical properties are tailored to balance formability and structural integrity. Tensile strength ranges from 200 to 240 MPa, with elongation exceeding 40% in accordance with ASTM B193. Surface finish is maintained at a clean, oxide-free level through controlled atmosphere annealing and protective winding protocols, minimizing the need for pre-treatment prior to insulation wrapping or plating.

All strips are supplied in continuous coils with core diameters of 200 mm, 300 mm, or 508 mm, with outer diameters up to 1200 mm. Custom slit widths from 5 mm to 300 mm are available, with thicknesses ranging from 0.05 mm to 3.0 mm. Material traceability is ensured through batch-level certification, including chemical composition, mechanical test results, and conductivity verification.

The table below summarizes key technical parameters for standard flexible copper strip products.

| Parameter | Specification |

|---|---|

| Material | ETP Copper (Cu ≥ 99.90%) |

| Temper | O60 (Fully Annealed) |

| Thickness Range | 0.05 mm – 3.0 mm |

| Width Range | 5 mm – 300 mm |

| Slitting Tolerance | ±0.002 mm |

| Edge Quality | Burr-free, micro-crack free |

| Electrical Conductivity | ≥100% IACS (at 20°C) |

| Tensile Strength | 200 – 240 MPa |

| Elongation | ≥40% |

| Surface Condition | Clean, oxide-minimized, annealed in N₂/H₂ |

| Coiling | Continuous, core options: 200 / 300 / 508 mm |

| Packaging | Waterproof wrapping, wooden pallets for export |

These specifications reflect Luoyang Xinzhaohe’s commitment to delivering technically superior flexible copper strip solutions for mission-critical electrical infrastructure.

Factory Tour: Manufacturing

Manufacturing Process for Flexible Copper Strip

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized expertise in non-ferrous metal processing to produce high-integrity flexible copper strip for demanding transformer and electrical applications. Our rigorous manufacturing sequence ensures exceptional dimensional precision, surface quality, and mechanical properties critical for reliable performance in winding operations and under operational thermal cycling. The core production flow comprises three integrated stages: Cold Rolling, Precision Slitting, and Edge Conditioning, each incorporating stringent quality control checkpoints.

Cold Rolling forms the foundational step, transforming high-conductivity electrolytic tough pitch (ETP) copper ingot or continuous cast bar into the required thin gauge. Material undergoes multiple passes through precision roll stands within a controlled atmosphere to prevent oxidation. Critical process parameters including roll gap, reduction ratio per pass (typically exceeding 90% total reduction for foil gauges), rolling speed, and interpass annealing temperatures are meticulously monitored and adjusted. This stage achieves the target thickness with tight tolerances (commonly ±0.005mm or better for critical applications) while optimizing grain structure and minimizing residual stress. In-process quality control employs laser micrometers for continuous thickness profiling and high-resolution surface inspection systems to detect and reject any imperfections such as scratches, pits, or inclusions before further processing. Surface roughness (Ra) is consistently maintained within customer-specified ranges, typically 0.1µm to 0.8µm.

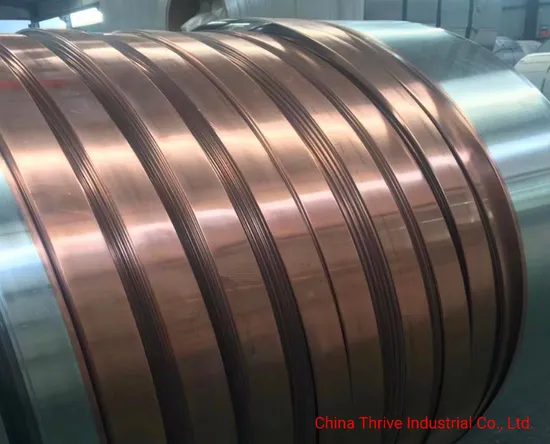

Precision Slitting follows, converting the master rolled coil into the exact strip widths demanded by transformer winding specifications. This operation utilizes advanced tension-controlled slitting lines equipped with high-precision rotary shear knives or razor slitters. Precise knife positioning, optimal blade clearance settings based on material thickness and hardness, and controlled strip tension are paramount to achieving straight, parallel edges without edge waviness or camber. Real-time laser width gauges continuously verify dimensional accuracy across the strip width, ensuring compliance with tight tolerances often within ±0.10mm. Tension monitoring throughout the slitting path guarantees consistent edge quality and prevents deformation. Each slit strip undergoes immediate visual and instrumental edge inspection post-slitting to identify any nascent burrs or irregularities.

Edge Conditioning is the critical final stage specifically engineered for transformer-grade flexible strip. All slit edges undergo dedicated mechanical brushing or precision deburring processes. This step systematically removes micro-burrs generated during slitting and smoothens the edge profile to an optically clean finish. Elimination of even microscopic burrs is non-negotiable, as they pose severe risks of insulation puncture during high-speed winding or under operational electrical stress. Process parameters such as brush type, rotational speed, contact pressure, and dwell time are optimized for the specific copper alloy and gauge. Post-conditioning, every edge is subjected to 100% magnified visual inspection and tactile verification to confirm complete burr removal and surface integrity. Final batch certification includes comprehensive testing per ASTM B248 and customer specifications, covering tensile strength, elongation, electrical conductivity (min 100% IACS), dimensional verification, and surface cleanliness. This integrated process chain, governed by ISO 9001 protocols, delivers copper strip with the consistent flexibility, edge perfection, and metallurgical homogeneity essential for high-efficiency transformer manufacturing.

Packaging & Logistics

Export Packaging for Flexible Copper Strip – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience in transformer-grade aluminum and copper strips, we recognize that reliable packaging is as critical as material performance. For international shipments of flexible copper strip, our export packaging system is engineered to maintain product integrity, prevent environmental degradation, and ensure safe transit via sea freight—the dominant mode for bulk industrial material transport.

All flexible copper strip coils are mounted on robust wooden pallets constructed from high-strength, kiln-dried hardwood. These pallets are designed to meet ISPM 15 international phytosanitary standards, ensuring global customs compliance while providing structural stability during handling, stacking, and long-haul transport. The load-bearing capacity of each pallet is calculated to support coil weights up to 3,000 kg, minimizing deformation risks during vessel loading and unloading operations.

To combat the primary threat to copper—moisture-induced oxidation—each coil is hermetically sealed using multi-layer moisture-proof packaging film. This includes an inner layer of vapor-corrosion inhibitor (VCI) film, which actively suppresses electrochemical reactions that lead to surface tarnishing, followed by an outer laminated polyethylene barrier with high puncture and UV resistance. The sealed package is then thermally shrunk to eliminate internal air pockets, significantly reducing the risk of condensation during temperature fluctuations common in maritime environments.

Edge protectors made from high-density polyethylene are affixed to the coil’s outer diameter to prevent mechanical damage during transit. The entire assembly is then strapped diagonally and laterally with steel or composite tensioned straps anchored securely to the wooden base, preventing lateral shift or coil collapse under dynamic load conditions. A tamper-evident seal is applied to the outer wrapping, allowing immediate visual verification of package integrity upon arrival.

Documentation, including material test reports (MTRs), packing lists, and handling instructions, is enclosed in a waterproof poly pouch fastened to the pallet. Each shipment is labeled with barcoded tracking tags and hazard-compliant maritime transport markings, including “This Way Up,” “Fragile,” and “Do Not Stack,” ensuring proper handling throughout the logistics chain.

Our packaging protocol has been validated through accelerated salt spray testing and real-world shipping trials across major trade lanes, including trans-Pacific and Europe-Asia routes. This ensures that flexible copper strip arrives at destination facilities with zero surface oxidation, dimensional stability preserved, and ready for immediate processing.

For global partners, this packaging standard translates into reduced inspection time, lower rejection rates, and seamless integration into high-precision transformer and electrical component manufacturing lines. At Luoyang Xinzhaohe, we treat every shipment as a commitment to quality—not only in material but in delivery assurance.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Strip Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver high-performance flexible copper strip for critical transformer and electrical applications. Our vertically integrated production facility in Henan Province combines advanced process engineering with stringent quality control, ensuring material consistency essential for demanding power transmission systems. Core to our capability is mastery of copper’s microstructural properties, achieved through proprietary annealing protocols and precision cold rolling. We consistently produce strips with thickness tolerances of ±0.005 mm and width tolerances of ±0.1 mm, meeting ASTM B152 and IEC 60137 standards for electrical conductivity (≥100% IACS) and surface integrity.

Our 35,000 m² manufacturing complex houses state-of-the-art continuous casting-rolling lines and 20-high precision Sendzimir mills, enabling tight control over mechanical properties. Key differentiators include:

Elongation Control: Flexible strips achieve 35–40% elongation (ASTM E8) through optimized annealing atmospheres, preventing brittleness during winding.

Surface Quality: Mirror-finish surfaces (Ra ≤0.2 µm) eliminate micro-defects that compromise insulation layer adhesion in transformer windings.

Flatness Assurance: Advanced tension-leveling systems maintain flatness deviation below 5 I-units, critical for high-speed automatic winding processes.

Material traceability is enforced from cathode sourcing through final slitting. All copper feedstock undergoes rigorous OES and ICP-MS analysis to guarantee purity (99.99% Cu min) and suppress impurities like phosphorus (<5 ppm) that degrade conductivity. Our in-house metallurgy lab conducts real-time microstructure validation via SEM/EDS, ensuring grain size uniformity (ASTM E112) for consistent flexural endurance. Production data is logged in our ERP system, providing full lot traceability for compliance with ISO 9001 and IATF 16949 frameworks.

Supply chain resilience is engineered into our operations. We maintain strategic raw material buffer stocks and operate dual annealing lines to absorb demand volatility, achieving 99.2% on-time delivery for JIT programs. Global logistics are streamlined through bonded warehouses at Shanghai and Ningbo ports, enabling DDP shipments with customs documentation aligned to EU REACH and US TSCA regulations. For transformer OEMs, this translates to reduced inventory costs and elimination of production line stoppages due to material non-conformance.

Partnering with Luoyang Xinzhaohe mitigates technical and operational risks in your copper strip supply. Our engineering team collaborates directly with clients to refine specifications—whether adjusting temper profiles for enhanced formability or validating strip performance under simulated operating conditions. Request a technical datasheet or schedule a metallurgical review to optimize your transformer strip sourcing strategy. Specify your dimensional requirements, volume needs, and application parameters to initiate a precision-engineered solution.

Contact Cathy Zhang, International Sales Manager, at cathy@transformerstrip.com to discuss your project’s metallurgical and supply chain requirements. Include target thickness range, annual volume, and relevant compliance standards for a tailored capability assessment.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing flexible copper strip directly from China.