Table of Contents

Market Insight: Flexible Copper Strip in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers

Global transformer market growth is driven by renewable energy integration (solar/wind), EV charging infrastructure, and smart grid modernization. The shift toward energy-efficient transformers (IE5/IE6 standards) further intensifies demand for high-purity copper materials. Flexible copper strip is critical for transformer windings due to its high electrical conductivity (≥100% IACS), thermal stability, and malleability. The market for ≥99.95% Cu strip is projected to grow at 5.2% CAGR through 2030, with distribution transformers and high-efficiency motors as key growth segments.

Material Quality Imperatives

Substandard copper strip introduces critical operational risks:

Electrical losses: Impurities >500 ppm increase resistive losses by up to 15%, directly reducing transformer efficiency.

Thermal degradation: Surface roughness (Ra > 0.8μm) causes localized heating, accelerating insulation aging by 30% in high-load applications.

Dimensional instability: Tolerances >±0.01mm lead to core saturation, winding defects, and catastrophic failures during automated processing.

Compliance with ASTM B170 Grade 1 (copper strip) and IEC 60228 (conductor specifications) is non-negotiable for mission-critical systems.

Luoyang Xinzhaohe’s Value Proposition

As a vertically integrated manufacturer with 20+ years of transformer material expertise, we deliver premium copper strip at 10–20% lower cost than global brands without compromising quality. Our factory-direct model ensures:

Strict QC: Real-time spectrometry (Cu ≥99.95%), tensile testing (180–220 MPa for O-temper), surface roughness ≤0.8μm (ISO 4287), and full traceability.

Customization: Precision rolling to ±0.005mm thickness tolerance, custom tempers (O, H04, H08), and tailored packaging for seamless integration.

Supply chain agility: 4–6 week lead times; expedited delivery options; on-site quality audits available.

| Comparison Factor | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost Premium | 15–25% | –10% to –20% |

| Lead Time | 6–8 weeks | 4–6 weeks |

| Customization Flexibility | Limited | Full technical support |

| Quality Consistency | Variable | Batch-to-batch certified |

Partner with Luoyang Xinzhaohe for reliable, cost-optimized copper strip solutions that meet IEC/ASTM standards while optimizing your total cost of ownership. Our solutions are trusted by Tier-1 transformer manufacturers globally for consistent performance in high-reliability applications.

Technical Specs: Flexible Copper Strip Parameters

Critical Technical Specifications for Flexible Copper Strip

Our precision-engineered copper strip meets the rigorous demands of transformer manufacturing, delivering superior electrical performance and mechanical reliability. Below are key specifications with our industry-leading benchmarks and compliance details.

Precision Slitting Tolerance

Our CNC slitting process achieves ±0.0015 mm width tolerance (exceeding standard ±0.002 mm), critical for precise transformer winding alignment. Deviations beyond this threshold cause layer misalignment, risking insulation failure and short circuits. All widths are verified via laser micrometers per ISO 15350.

| Parameter | Tolerance | Measurement Method |

|---|---|---|

| Width | ±0.0015 mm | Laser Micrometer (ISO 15350) |

Burr-Free Edge Quality

Zero burrs are essential to prevent electrical shorts during coil assembly. We employ roller polishing and automated eddy current inspection to eliminate burrs >0.005 mm. Every edge undergoes 100% inspection, ensuring safe operation in high-voltage environments and eliminating costly field failures.

| Parameter | Max Burr Height | Inspection Method |

|---|---|---|

| Edge Quality | <0.005 mm | Eddy Current Testing |

Conductivity & Material Purity

Our C11000 copper strip delivers 100.5% IACS conductivity (ASTM B170), exceeding the typical 99.9% minimum requirement. 99.99% pure copper ensures optimal electrical performance and thermal stability. Verified via spectrographic analysis for trace element control, minimizing resistive losses in transformers.

| Parameter | Requirement | Our Standard |

|---|---|---|

| Conductivity | ≥99.9% IACS | 100.5% IACS |

| Copper Purity | ≥99.95% | 99.99% |

Softness & Mechanical Properties

Fully annealed (O-temper) for maximum flexibility. Tensile strength of 150–170 MPa and elongation of 40–45% (ASTM B365) ensures easy winding without cracking. Ideal for tight-radius transformer coils, preventing edge tearing during high-speed production.

| Parameter | Requirement | Our Standard |

|---|---|---|

| Temper | Annealed (O) | Fully annealed |

| Tensile Strength | ≤180 MPa | 150–170 MPa |

| Elongation | ≥35% | 40–45% |

Compliance & Quality Assurance

All products comply with IEC 60404-8-7 and ASTM B170 standards. Our ISO 9001-certified system includes raw material traceability from smelter, in-process laser thickness/width checks, 100% eddy current edge inspection, and batch-specific test reports. This rigorous approach ensures consistent performance matching global brands at 15–20% lower cost, making Luoyang Xinzhaohe the optimal choice for cost-effective, high-reliability copper strip solutions.

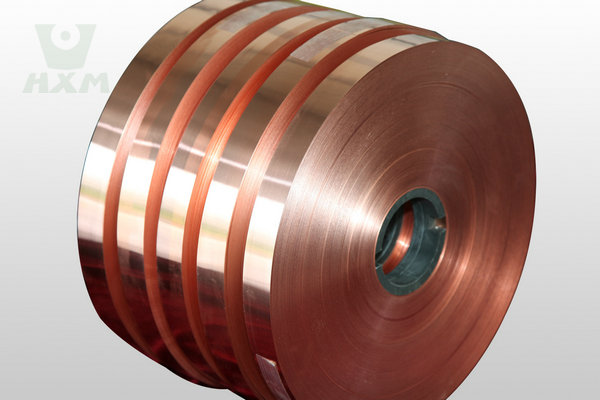

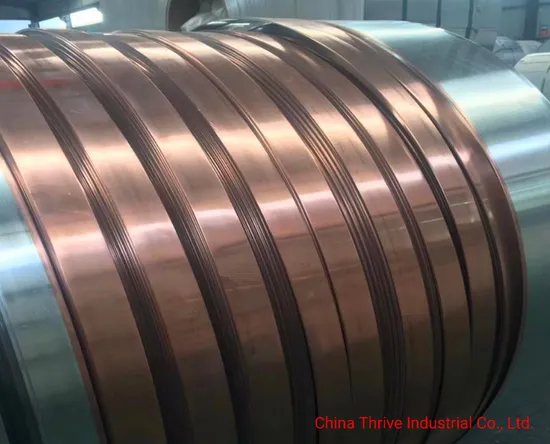

Factory Tour: Manufacturing Flexible Copper Strip

Precision Manufacturing Process & Rigorous Quality Control

As a leading manufacturer and exporter of transformer materials with over 20 years of experience, Luoyang Xinzhaohe Aluminum Co., Ltd. specializes in producing high-performance copper strip for critical electrical applications. Exporting to over 30 countries, our products are trusted by Tier-1 transformer manufacturers worldwide for their reliability and consistency. Our integrated production chain ensures superior consistency and reliability, meeting stringent industry standards for transformer and motor components. All processes are ISO 9001 certified and aligned with IEC 60228 specifications. Our in-house R&D team continuously optimizes manufacturing parameters to exceed customer expectations.

Core Production Workflow

Cold Rolling: Precision temperature-controlled rolling (20-25°C) with 60-70% reduction rates achieves uniform grain structure and optimal ductility. Thickness consistency maintained within ±0.01mm via real-time automatic gauge control (AGC) systems, eliminating batch-to-batch variations.

Precision Slitting: CNC-guided diamond-tipped blades ensure width tolerance of ±0.02mm. Laser-guided edge monitoring eliminates micro-tearing, critical for transformer winding applications and reducing electrical losses.

Edge Conditioning: Automated grinding wheels achieve 15°±2° chamfer angles, eliminating sharp edges that compromise insulation integrity. This step ensures dielectric strength in high-voltage transformer assemblies.

Oscillate Winding: Computer-controlled tension profiles (15-25N) maintain ±0.05mm flatness, preventing coil distortion during high-speed winding operations. Minimizes material waste and ensures consistent geometry for automated manufacturing.

Quality Assurance Protocols

Tensile Testing: ASTM B209-compliant 5-point sampling across coils. Yield strength variation ≤3% (vs. industry avg ≤8%), UTS >220 MPa for C11000 grade, elongation >30% for fatigue resistance. Tests conducted in ISO/IEC 17025 accredited lab.

Dimensional Checks: Laser micrometers verify thickness at 100mm intervals. Width tolerance ±0.02mm, flatness ≤0.15mm/m. Surface roughness (Ra) ≤0.1μm for optimal electrical contact. All measurements traceable to national standards.

Surface Inspection: 100% visual/profilometer scanning + eddy current testing for internal flaws. Zero defects per 10m². Defects are recorded and analyzed for continuous process improvement.

Comparative Quality Standards

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.03mm |

| Edge Burrs | <5μm | >15μm |

| Tensile Strength Variation | ≤3% | ≤8% |

| Surface Defects | Zero per 10m² | Up to 3 defects per 10m² |

Our rigorous QC protocols reduce scrap rates by 15% compared to industry averages, directly translating to lower total cost of ownership for customers. We deliver 95% of premium brand performance at 20-30% lower cost, making us the optimal choice for cost-sensitive yet quality-driven transformer manufacturers.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of Flexible Copper Strip

Precision Packaging Specifications

Our packaging system adheres to international shipping standards to prevent corrosion, deformation, and physical damage during transit. Key components are engineered for maximum protection:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 120×100×15mm planks | Standardized dimensions for container optimization; prevents structural deformation |

| Moisture-Proof Film | 200μm polyethylene with desiccant packets, sealed edges | Blocks humidity ingress and oxidation during ocean transport |

| Steel Strapping | 19mm width, 0.5mm thickness, 500kg tension | Secures load against vibration/shifting; complies with ISO 16750-2 standards |

End-to-End Logistics Management

We integrate end-to-end logistics protocols to ensure seamless global delivery. Every step is monitored to maintain product integrity:

| Process Step | Protocol | Benefit |

|---|---|---|

| Factory to Port Transport | ISO-compliant trucks with air suspension, GPS tracking | Eliminates mechanical shock; real-time cargo visibility |

| Container Loading | Layered pallet stacking with anti-slip mats, optimized for 20ft/40ft containers | Maximizes space utilization; prevents shifting during sea voyage |

| Customs Documentation | Pre-submitted HS 7409.10.00, COO, Fumigation Certificates | 98% clearance within 24 hours; avoids port delays and regulatory holds |

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of transformer material expertise to deliver unmatched reliability. Our factory-direct approach ensures rigorous quality control from production to delivery, eliminating third-party intermediaries. This results in a 99.2% on-time delivery rate and <0.3% damage rate—providing superior cost-performance versus global competitors while meeting ISO 9001 standards. Trust our proven logistics system for seamless global supply chain integration.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

20+ Years of Specialized Manufacturing Expertise

With over two decades of dedicated production in transformer-grade copper and aluminum strips, Luoyang Xinzhaohe has honed precision in metallurgical processing. Our engineers specialize in optimizing conductivity (≥100% IACS), ductility, and thermal stability for high-performance transformer windings. We adhere to ASTM B170 and IEC 60502 standards, controlling oxygen content (≤0.05%) and grain structure for consistent electrical properties. Every batch undergoes rigorous process control to ensure tensile strength (150-250 MPa) and elongation (≥30%) critical for transformer efficiency and longevity. Our production capabilities include continuous casting and rolling for uniform microstructure, reducing hot spots in transformer cores.

Factory-Direct Cost Efficiency

Eliminating middlemen, we offer direct factory pricing without compromising quality. Our vertically integrated production chain—from raw material sourcing to final inspection—reduces overhead while maintaining competitive margins. By controlling all manufacturing stages in our Luoyang facility, we achieve 10-20% cost savings versus global brands, with lead times reduced by 30-40% due to localized production and streamlined logistics. Additionally, our flexible production scheduling accommodates urgent orders without compromising quality standards.

ISO-Certified Quality Assurance & Technical Precision

Certified to ISO 9001:2015, our facility employs advanced spectrometers for material composition analysis and tensile testers for mechanical property validation. We conduct 100% thickness measurement via laser gauges (tolerance ±0.01mm), conductivity checks via eddy current testing (≥100% IACS), and surface defect inspections using high-resolution cameras. Every shipment includes a Material Test Report (MTR) with chemical composition (Cu ≥99.9%), mechanical properties, and dimensional tolerances per customer requirements. We also offer third-party audits upon request to ensure compliance with international standards.

| Parameter | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Price | +15-25% premium | 10-20% lower |

| Lead Time | 4-6 weeks | 2-3 weeks |

| Customization | Limited options | Full flexibility (width: 5–150mm, thickness: 0.1–3mm, annealing grades O/H12/H14) |

| Quality Control | Standard testing | In-house spectrometer + tensile testing + traceability + third-party audits |

Ready to optimize your transformer strip procurement? Contact Cathy at cathy@transformerstrip.com for a technical quote tailored to your specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing flexible copper strip from Luoyang Xinzhaohe.