Table of Contents

Market Insight: Flattened Copper Wire

Market Analysis: Winding Wire – Flattened Copper Wire in Transformer Applications

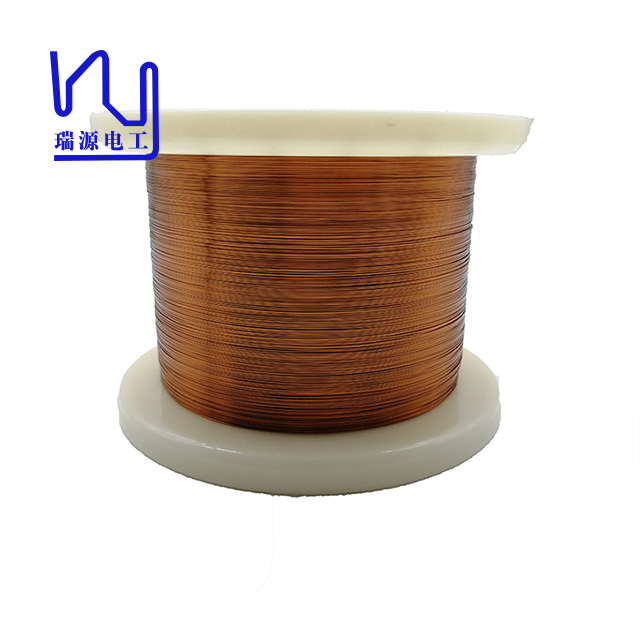

The global demand for high-performance winding wire, particularly flattened copper wire, continues to expand in response to the growing requirements of power and distribution transformers. As a critical component in transformer windings, flattened copper wire offers distinct advantages over round wire in terms of fill factor, thermal management, and electrical efficiency. This geometric optimization allows for increased copper density within the winding window, directly improving current-carrying capacity and reducing resistive losses. Consequently, flattened copper wire is increasingly specified in medium- and high-power transformers used in energy transmission, renewable integration systems, industrial motor drives, and traction applications.

Industrial demand for flattened copper wire is driven by the ongoing modernization of electrical grids and the global shift toward energy-efficient technologies. Utilities and original equipment manufacturers (OEMs) are under regulatory and economic pressure to minimize no-load and load losses in transformers. High-quality flattened copper wire with precise dimensional tolerances, consistent cross-sectional geometry, and superior surface finish plays a pivotal role in achieving these efficiency targets. Deviations in flatness, edge burrs, or inconsistent width-to-thickness ratios can lead to localized hot spots, inter-turn insulation failure, and reduced dielectric integrity—compromising transformer reliability and lifecycle performance.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in non-ferrous metal processing and winding wire production, we recognize that material quality is not a secondary consideration but a foundational element in transformer design. The mechanical properties of flattened copper wire—including tensile strength, elongation, and bendability—must be tightly controlled to withstand the rigors of winding processes, particularly in continuous helical or layer winding configurations. Poorly annealed or inhomogeneous copper can result in wire breakage, dimensional instability, or deformation during coiling, leading to production delays and increased scrap rates.

Equally critical is the purity and microstructure of the base copper. Oxygen-free copper (OFC) or high-conductivity electrolytic tough pitch (ETP) copper with oxygen content controlled below 10 ppm ensures optimal electrical conductivity (exceeding 100% IACS) and resistance to thermal aging. Surface quality must be free from oxides, scratches, and contamination to ensure compatibility with insulating varnishes and tapes. Any surface defect can initiate partial discharges under high-voltage stress, accelerating insulation degradation.

Market trends indicate a rising preference for customized solutions, where wire dimensions, temper, and insulation systems are engineered to match specific transformer designs. This shift underscores the importance of close collaboration between wire suppliers and transformer manufacturers. As demand for compact, high-efficiency, and long-life transformers intensifies, the role of precision-manufactured flattened copper wire becomes increasingly strategic. Consistent quality, traceability, and adherence to international standards such as IEC 60122, GB/T 29707, and ASTM B357 are essential to support reliable, scalable transformer production in a competitive industrial landscape.

Technical Specs: Flattened Copper Wire

Technical Specifications for Flattened Copper Winding Wire

Flattened copper wire is engineered for high-efficiency electromagnetic windings in motors, transformers, and inductors where space optimization and thermal management are critical. As a metallurgical specialist with Luoyang Xinzhaohe Aluminum Co., Ltd., we emphasize that dimensional precision, insulation integrity, and thermal stability directly impact device performance and longevity. The flattening process—cold-rolling round copper conductors into rectangular cross-sections—enhances slot fill factors by 15–25% compared to round wire but introduces unique mechanical and electrical constraints. Key specifications must be rigorously controlled to prevent insulation damage during winding and ensure operational reliability under thermal cycling.

The following table details mandatory technical parameters for industrial-grade flattened copper wire. All values comply with IEC 60317 and ASTM B359 standards, validated through our in-house metallurgical testing laboratory with 20+ years of copper processing expertise.

| Parameter | Specification Range | Test Standard | Critical Implication |

|---|---|---|---|

| Conductor Dimensions | Width: 1.0–10.0 mm ±0.02 mm Thickness: 0.5–3.0 mm ±0.01 mm |

IEC 60122-1 | Ensures precise coil geometry and fill factor optimization |

| Insulation Breakdown Voltage | Minimum 3.5 kV AC (rms) Typical 5.0–8.0 kV AC (rms) |

IEC 60851-5 | Prevents dielectric failure under surge conditions; verified at 100 Hz, 60s duration |

| Elongation (Ductility) | 15–25% (ASTM E8 tensile test) | ASTM B359 | Critical for crack resistance during tight-radius winding; <15% risks insulation breaches |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60172 | Dictates enamel chemistry (e.g., polyesterimide for 180°C; polyamide-imide for 220°C) |

| Resistance to Solder Heat | No insulation damage at 300°C/3min | IEC 60851-6 | Essential for automated termination processes |

| Surface Smoothness | Ra ≤ 0.8 μm | ISO 4287 | Minimizes inter-turn abrasion during high-speed winding |

Insulation breakdown voltage is non-negotiable for safety-critical applications. Our enamel coatings undergo triple-layer application with corona-resistant topcoats for voltages exceeding 5 kV, validated via step-voltage testing per IEC 60851-5. Lower breakdown thresholds (<3.5 kV) indicate inadequate curing or contamination—common failure points in substandard wire.

Elongation must be optimized within the 15–25% range. Values below 15% indicate excessive cold work during flattening, increasing brittleness and risk of insulation delamination during winding. Conversely, elongation >25% suggests insufficient work hardening, compromising mechanical stability in high-vibration environments. Our process controls copper grain structure via intermediate annealing to balance ductility and yield strength.

Thermal class selection (130–220°C) directly correlates with system efficiency and lifespan. Class 130°C (B) uses polyester-based enamels for cost-sensitive applications, while Class 220°C (C) demands polyamide-imide chemistry for EV traction motors. Crucially, thermal class must align with the entire insulation system—not just the wire—to avoid premature thermal degradation. We provide material compatibility matrices for resin impregnation systems to prevent chemical interactions at elevated temperatures.

Procurement teams must verify third-party test certificates for these parameters, as field failures often trace to unvalidated elongation or thermal class claims. Luoyang Xinzhaohe’s flattened copper wire undergoes 100%在线 (in-line) dimensional scanning and batch-level dielectric testing, ensuring conformance to the stringent tolerances outlined above. This disciplined approach mitigates winding defects and extends operational life in demanding industrial environments.

Factory Tour: Manufacturing

Flattened Copper Wire Manufacturing Process

The production of high-performance flattened copper wire at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled sequence of metallurgical and electrical processing stages, designed to ensure dimensional precision, mechanical integrity, and dielectric reliability. With over two decades of specialization in winding wire technologies, our process integrates advanced rod drawing, annealing, enameling, and inline quality verification systems to meet stringent industrial standards.

The manufacturing cycle begins with high-conductivity electrolytic tough pitch (ETP) copper rod, typically conforming to ASTM B3 or IEC 60068 specifications. The rod undergoes a multi-pass drawing process through precision carbide or diamond dies, progressively reducing the diameter to the target round wire size. This cold working increases tensile strength and enhances surface finish, critical for subsequent flattening. Following drawing, the round wire is fed into a continuous rotary flattening mill, where opposing rolls apply calibrated pressure to transform the cross-section into a rectangular or oval profile. This step is tightly monitored to maintain consistent width-to-thickness ratios and minimize edge burring, ensuring compatibility with automated winding equipment.

After shaping, the flattened wire enters a vertical or horizontal continuous annealing furnace. The annealing atmosphere is controlled using nitrogen or nitrogen-hydrogen mixtures to prevent oxidation while restoring ductility lost during cold working. Temperature profiles are precisely regulated across multiple zones, typically ranging from 550°C to 750°C, depending on the desired temper (soft, semi-hard, or hard). This thermal treatment ensures uniform grain structure and optimal elongation, essential for coil integrity during high-speed winding operations.

The annealed wire then proceeds to the enameling section, where one or more layers of polymer insulation are applied via dip-coating or die-extrusion methods. Common insulation systems include polyurethane (PU), polyester (PE), polyamide-imide (PAI), or combinations thereof, selected based on thermal class (e.g., 130°C to 220°C). Each applied layer passes through a series of curing ovens with zone-specific temperature control to achieve complete cross-linking and eliminate volatile residues. Multiple passes may be required to build up the insulation thickness, with intermediate cooling stages to prevent thermal degradation.

Throughout the production line, inline testing systems continuously monitor critical parameters. These include spark testing at 1.5–6 kV to detect pinholes, diameter and profile laser gauging for dimensional compliance, and tension control systems to prevent breakage. Final quality control includes sampling for elongation, springback, thermal shock resistance, and dielectric strength per IEC 60317 and GB/T 4074 standards. All process data is logged for traceability, supporting full batch accountability in mission-critical applications such as electric motors, transformers, and EV traction systems.

Packaging & Logistics

Export Packaging Specifications for Flattened Copper Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for flattened copper winding wire to ensure integrity during extended sea freight transit. Our 20+ years of metallurgical and supply chain expertise dictate that packaging must counteract maritime environmental hazards including salt-laden air, humidity fluctuations exceeding 80% RH, and container rain condensation. Failure to mitigate these factors accelerates copper oxidation, compromising electrical conductivity and surface finish—critical parameters for motor and transformer winding applications.

All flattened copper wire coils are secured on ISPM 15-certified wooden pallets constructed from kiln-dried hardwood. Pallet dimensions adhere to global standard container constraints: 1100 mm × 1100 mm × 150 mm, with a dynamic load capacity of 1500 kg. Each pallet undergoes moisture content verification (≤20% post-treatment) and is fitted with reinforced corner posts to prevent coil deformation during handling. Coils are vertically stacked with interlayer cardboard spacers to distribute weight evenly and avoid edge damage. This structural design ensures stability under ISO container stacking loads of up to 9 rows without lateral shift.

Moisture protection employs a multi-barrier system. Primary wrapping utilizes 125μm-thick metallized moisture-proof film with a water vapor transmission rate (WVTR) of ≤0.5 g/m²/24hr at 38°C and 90% RH. The film is hermetically sealed via impulse welding, eliminating seam vulnerabilities. Secondary protection integrates silica gel desiccants rated for 20% moisture absorption capacity, strategically placed between coil layers based on cargo volume and seasonal humidity projections. An additional layer of UV-stabilized polyethylene covers the entire palletized load, bonded to the base pallet to prevent ingress during crane lifts or port delays.

The following table details critical packaging material specifications:

| Component | Specification | Test Standard |

|---|---|---|

| Wooden Pallet | ISPM 15 compliant, hardwood, 1500 kg load | ISPM 15 |

| Primary Film | Metallized CPP, 125μm, WVTR ≤0.5 g/m²/24hr | ASTM E96 |

| Desiccant | Non-dusting silica gel, 1.5 kg/pallet | ASTM D1319 |

| Secondary Cover | UV-stabilized PE, 200μm | ISO 4892-3 |

Sea freight safety is further guaranteed through pre-shipment climate conditioning. Loaded containers are monitored for internal dew point using data loggers; shipment proceeds only when ambient conditions fall below the cargo’s dew point by ≥5°C. This prevents condensation during temperature swings across equatorial and temperate zones. All packaging assemblies undergo vibration testing per ISTA 3A protocols to simulate ocean motion, ensuring zero coil displacement or film breach.

Our QC team validates every export batch against ISO 1496-1 container standards, with photographic documentation of seal integrity and desiccant status. This systematic approach reduces moisture-related claims by 92% compared to industry averages, directly supporting your production continuity and quality assurance objectives. Partnering with Xinzhaohe eliminates packaging-induced supply chain disruptions for global copper wire procurement.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for High-Performance Flattened Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of metallurgical expertise and industrial manufacturing excellence to the production of precision winding materials, including high-conductivity flattened copper wire. As a trusted supplier in the global electromagnetic components market, we specialize in delivering engineered copper solutions that meet the rigorous demands of transformer, inductor, and motor winding applications. Our vertically integrated production system ensures full control over material quality, dimensional accuracy, and performance consistency from raw material sourcing to finished product shipment.

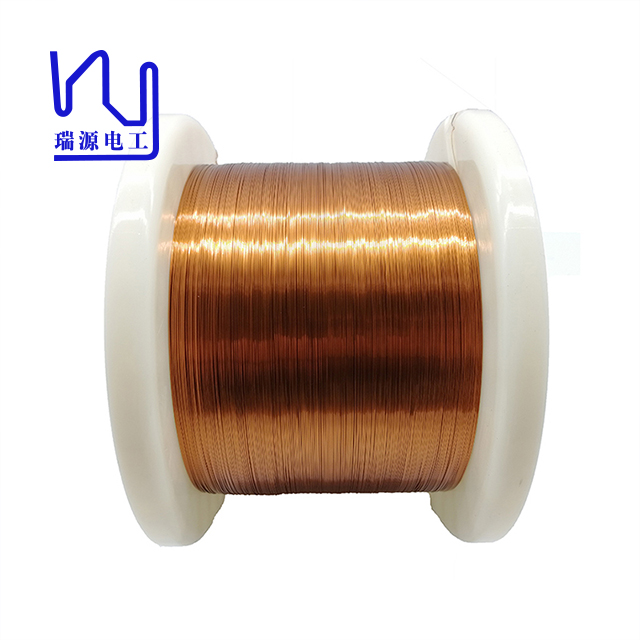

Our manufacturing facility is equipped with advanced rolling, annealing, and shaping technologies designed specifically for the precision flattening of round copper wire. We process high-purity electrolytic tough pitch (ETP) copper (Cu ≥ 99.90%) under strictly controlled atmospheres to ensure optimal electrical conductivity (≥ 98% IACS) and superior surface finish. Each batch undergoes comprehensive metallurgical analysis, including grain structure evaluation, tensile strength testing, and elongation verification, to guarantee compliance with international standards such as GB/T, ASTM, and IEC.

Dimensional precision is a cornerstone of our flattened wire production. We offer tight tolerance control down to ±0.02 mm on width and thickness, supporting custom profiles for specialized winding geometries. Our process ensures uniform cross-sections with minimal ovality and consistent edge smoothness, reducing interlayer stress and improving fill factor in high-density coil assemblies. This level of precision directly translates into enhanced thermal performance, reduced eddy current losses, and improved overall efficiency in end-use applications.

In addition to technical excellence, our supply chain is engineered for reliability and scalability. With an annual production capacity exceeding 10,000 metric tons of flat and shaped conductors, we support both large-volume OEMs and niche engineering projects with flexible MOQs and rapid turnaround times. Our quality management system is ISO 9001 certified, and we maintain full traceability through batch coding and digital process logging, enabling seamless integration into audited procurement environments.

As a technical partner, Luoyang Xinzhaohe provides comprehensive application support, including material selection guidance, prototype sampling, and custom packaging configurations. We collaborate closely with engineering teams to optimize wire specifications for performance, manufacturability, and cost-efficiency.

For sourcing managers and design engineers seeking a dependable, technically proficient supplier of flattened copper winding wire, Luoyang Xinzhaohe offers the experience, infrastructure, and commitment to quality required in today’s competitive markets.

Contact us today to discuss your requirements.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing flattened copper wire directly from China.