Table of Contents

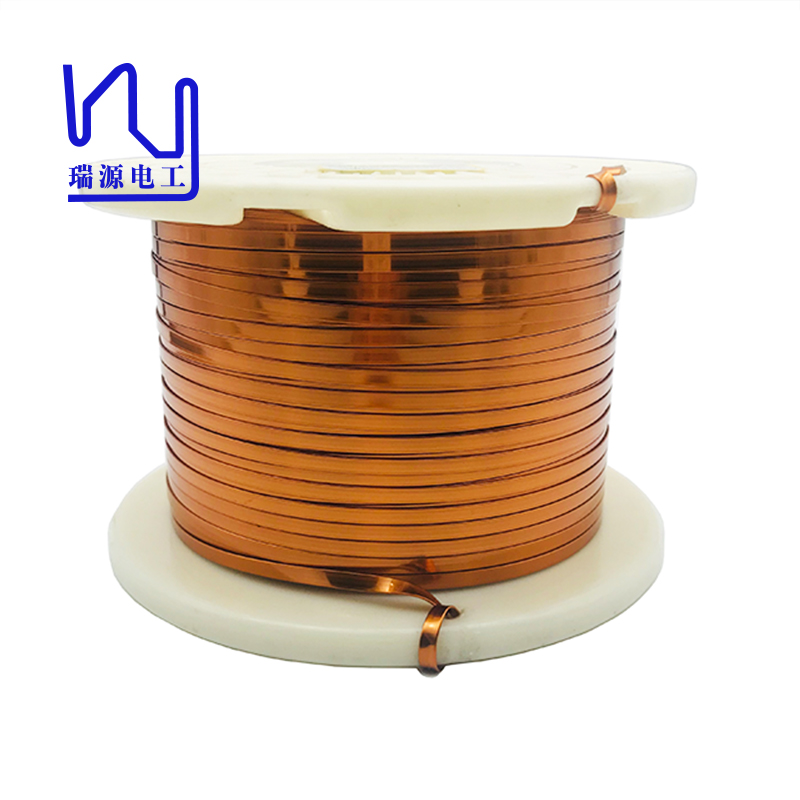

Market Insight: Flat Magnet Wire

Market Analysis: Winding Wire – Flat Magnet Wire in Transformer Applications

The global demand for flat magnet wire, particularly in power and distribution transformers, continues to grow in alignment with expanding electrical infrastructure, renewable energy integration, and industrial automation. Flat magnet wire, typically fabricated from either copper or aluminum, offers distinct advantages in transformer design due to its optimized cross-sectional geometry, which enhances fill factor and thermal dissipation in winding configurations. This geometric efficiency translates into higher power density and improved performance in both small-scale and utility-grade transformers.

Industrial demand for flat aluminum magnet wire has seen notable growth, driven by cost and weight considerations in medium-voltage distribution transformers. Aluminum offers a favorable conductivity-to-weight ratio and is approximately 60% lighter than copper, making it ideal for applications where transportation, handling, and structural support are critical. However, aluminum’s lower electrical conductivity (approximately 61% IACS compared to copper’s 100% IACS) necessitates careful design compensation through increased cross-sectional area. Despite this, its economic and logistical advantages have cemented aluminum as a strategic material in large-scale transformer manufacturing, especially in emerging markets and grid modernization projects.

Quality in flat magnet wire is paramount to transformer reliability, efficiency, and service life. Key quality parameters include dimensional consistency, surface finish, mechanical strength, and insulation integrity. Variations in thickness or width beyond tolerance can lead to uneven winding tension, localized hotspots, and reduced thermal performance. Surface defects, such as scratches or oxide inclusions, may compromise the enamel insulation layer during winding, increasing the risk of inter-turn short circuits. Moreover, aluminum’s susceptibility to creep and oxidation demands stringent process control during drawing, annealing, and insulation coating to ensure long-term stability under thermal cycling and electrical stress.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in aluminum-based winding wire production, we emphasize metallurgical purity, precise dimensional control, and advanced enamel coating technologies. Our flat magnet wires undergo rigorous testing for elongation, bendability, dielectric strength, and thermal class compliance (e.g., 130°C, 155°C, 180°C), ensuring compatibility with industry standards such as IEC 60317 and GB/T 2363. We supply customized solutions tailored to transformer OEMs requiring high-volume consistency and regulatory compliance across diverse operating environments.

As energy efficiency standards tighten—exemplified by DOE 2016 and EU Ecodesign Directive 2014—transformer manufacturers increasingly rely on high-quality magnet wire to meet no-load and load-loss targets. Substandard materials may yield short-term cost savings but often result in premature failure, higher maintenance costs, and non-compliance with environmental regulations. Therefore, sourcing from technically proficient and quality-focused suppliers is not merely a procurement decision but a strategic investment in system reliability and lifecycle performance.

| Parameter | Typical Specification for Flat Aluminum Magnet Wire |

|---|---|

| Conductivity | ≥ 58% IACS (min) |

| Tensile Strength | 80–120 MPa |

| Elongation | ≥ 15% |

| Insulation Thermal Class | 130°C, 155°C, or 180°C |

| Dielectric Strength | ≥ 5 kV (1 min, AC) |

| Dimensional Tolerance | ±0.02 mm (thickness), ±0.05 mm (width) |

In conclusion, the industrial application of flat magnet wire in transformers demands a balance of material science, precision engineering, and quality assurance. As aluminum gains traction in energy-efficient transformer designs, the role of high-performance magnet wire becomes increasingly critical to achieving sustainable and reliable power systems.

Technical Specs: Flat Magnet Wire

Technical Specifications: Flat Magnet Wire for Precision Winding Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise and ISO 9001-certified manufacturing to deliver flat aluminum magnet wire meeting stringent global electrical standards. Our flat profile wire (rectangular cross-section) is engineered for high-efficiency transformers, motors, and inductors where space optimization and thermal management are critical. Key technical parameters must be rigorously defined during sourcing to ensure compatibility with automated winding processes and end-use reliability.

Insulation breakdown voltage is non-negotiable for dielectric integrity. Our standard enamel insulation systems achieve minimum breakdown voltages of 3.0 kV AC (50 Hz, 1 minute) per IEC 60851-5, tested at 23°C and 50% RH. However, actual performance is thickness-dependent: nominal insulation thicknesses of 0.05–0.15 mm directly scale breakdown thresholds. Buyers must specify required voltage margins (e.g., 4.0 kV for high-voltage EV traction motors) and environmental conditions, as humidity above 70% RH can reduce effective dielectric strength by 15–20%. We implement 100%在线 breakdown testing during production to eliminate substandard reels.

Elongation directly impacts formability during tight-radius winding. Our aluminum alloy conductors (AA-1350 or AA-8030 per ASTM B233) undergo precision annealing to achieve controlled elongation ranges. Minimum elongation is 15% for standard tempers, but high-formability grades reach 22–25% per ASTM E8/E8M tensile testing. Values below 15% risk micro-cracking during winding, causing insulation punctures; exceeding 25% may compromise yield strength. We optimize annealing profiles to balance ductility with mechanical stability, validated through in-line elongation monitoring every 500 meters.

Thermal class dictates operational lifespan under thermal stress. Our insulation systems span Classes B (130°C) to H (180°C), with custom formulations supporting Class 220°C (C). Class ratings are determined via IEC 60172 thermal endurance testing, correlating temperature index to 20,000-hour life expectancy. Standard polyurethane-polyamide-imide (PU-PAI) coatings suit Class 180°C applications, while Class 220°C requires ceramic-modified polyimide. Crucially, thermal class must align with conductor oxidation limits—aluminum’s oxidation accelerates above 150°C, necessitating hermetic sealing in high-temperature designs.

Critical Parameter Reference Table

| Parameter | Standard Range | Test Method | Critical Notes |

|---|---|---|---|

| Insulation Breakdown | 3.0–6.0 kV AC (1 min) | IEC 60851-5 | Specified at 23°C/50% RH; thickness-dependent |

| Elongation (Al core) | 15–25% | ASTM E8/E8M | Higher % for complex winding geometries |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60172 | Conductor oxidation limits apply above 150°C |

| Conductor Resistivity | ≤ 0.028264 Ω·mm²/m | ASTM B9 | Measured at 20°C; trace elements controlled |

| Dimensional Tolerance | ±0.02 mm (width/thickness) | IEC 60122-1 | Critical for fill factor in slot winding |

Sourcing decisions must prioritize thermal class-conductor compatibility and validate elongation against specific winding mandrel diameters. At Xinzhaohe, we reject generic specifications—thermal aging data, humidity preconditioning protocols, and batch-specific elongation certificates are provided with every shipment. Contact our engineering team to align wire parameters with your thermal management strategy and winding automation requirements.

Factory Tour: Manufacturing

Manufacturing Process of Flat Magnet Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance flat magnet wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure mechanical integrity, electrical reliability, and thermal endurance. With over two decades of specialization in winding wire technology, our process integrates precision engineering with rigorous quality assurance at every phase: Rod Drawing, Annealing, Enameling, and Inline Testing.

The process begins with high-purity aluminum rod (typically 99.7% Al or higher), which undergoes rod drawing to achieve the precise rectangular or square cross-sectional profile required for flat magnet wire. Utilizing multi-pass drawing dies made from tungsten carbide or diamond-coated materials, the rod is reduced incrementally under controlled tension and lubrication. This ensures dimensional accuracy, surface smoothness, and consistent mechanical properties across the entire wire length. Throughout drawing, diameter and flatness are monitored via laser micrometers to maintain tight tolerances, typically within ±0.01 mm.

Following drawing, the wire enters a continuous annealing furnace under a controlled inert atmosphere (typically nitrogen or argon) to relieve internal stresses and restore ductility. Annealing is conducted at temperatures between 350°C and 450°C, depending on alloy composition and desired temper (soft, semi-hard, or hard). Precise temperature profiling and residence time control ensure uniform recrystallization without oxidation or grain overgrowth, critical for subsequent handling and winding performance.

The next stage is enameling, where the annealed wire is coated with one or multiple layers of polymer insulation. Common insulation systems include polyurethane (PU), polyester (PE), polyamide-imide (PAI), or combinations thereof, applied via precision die coating. Each layer is cured in a series of high-temperature ovens (200–500°C), with film thickness monitored in real time using capacitance or laser gauging systems. For flat wire, edge coverage and uniformity are particularly critical; our process ensures complete encapsulation of sharp edges to prevent dielectric breakdown under high-voltage stress.

Immediately after enameling, the wire undergoes inline electrical and mechanical testing. High-potential (hi-pot) testing verifies dielectric strength at voltages up to 5 kV, detecting pinholes or thin spots. Additional tests include continuity monitoring, diameter profiling, elongation verification, and springback measurement. All data is logged for traceability and statistical process control (SPC).

Quality control is embedded throughout the process. In-process checks include hourly sampling for adhesion (tape test), thermal shock resistance, and solderability. Final inspection includes winding tests on mandrels to evaluate flexibility and insulation integrity. Each production lot is accompanied by a full test certificate, including mechanical, electrical, and dimensional data, ensuring compliance with IEC 60317, GB/T 23312, or customer-specific standards.

This integrated approach enables Luoyang Xinzhaohe to deliver flat magnet wire with superior consistency, ideal for high-efficiency motors, transformers, and EV traction systems.

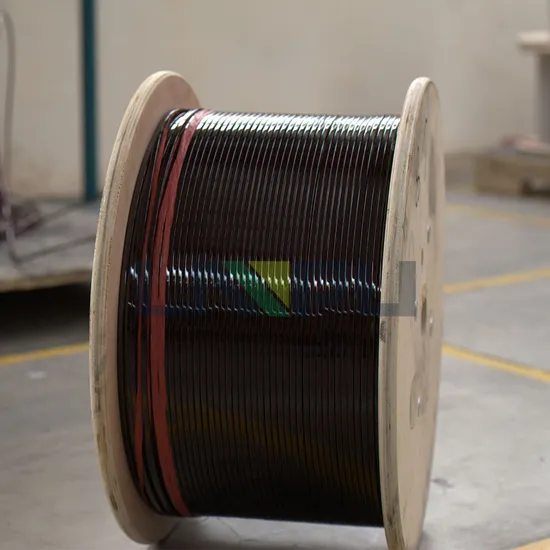

Packaging & Logistics

Export Packaging Specifications for Flat Magnet Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for flat magnet wire to ensure integrity during global sea freight. With over two decades of metallurgical and supply chain expertise, we recognize that magnet wire’s thin enamel insulation and precise dimensional tolerances are highly susceptible to moisture ingress, mechanical shock, and salt-air exposure. Our packaging system is designed to mitigate these risks through material science and logistics optimization, adhering to ISO 9001 and IEC 60172 standards.

Wooden pallets form the foundational structural element. We utilize kiln-dried (KD) hardwood pallets compliant with ISPM 15 regulations, featuring a moisture content of ≤18% to prevent warping or fungal growth during transit. Pallet dimensions are standardized to 1100mm × 1100mm, maximizing container utilization while ensuring stability under 40G impact loads. Each pallet incorporates reinforced stringers and double-deck boards to distribute coil weight evenly, eliminating point stresses that could deform the wire’s rectangular cross-section. Coils are secured via steel strapping at 150mm intervals, anchored directly to the pallet frame to prevent axial shifting during vessel motion. This configuration exceeds IMO MSC/Circ.747 requirements for cargo securing.

Moisture protection is paramount for enamel-coated conductors, where even 60% relative humidity can initiate hydrolytic degradation of polyester-imide insulation. Our multi-layer barrier system begins with a primary wrap of 100μm-thick metallized moisture-proof film (MPF), featuring an aluminum vapor-deposited layer bonded to polyethylene. This achieves a water vapor transmission rate (WVTR) of <0.1 g/m²/day at 38°C and 90% RH, per ASTM F1249. The film is vacuum-sealed around the coil using industrial heat sealers, eliminating trapped air pockets. A secondary outer wrap of 150μm polyethylene film provides puncture resistance against container handling. Desiccant packs (≥50g/m³ capacity) are strategically placed within the sealed envelope to absorb residual moisture, with humidity indicator cards verifying conditions ≤40% RH throughout transit.

All packaging undergoes pre-shipment validation via accelerated salt-spray testing (ASTM B117) and vibration simulation per ISTA 3A protocols. Palletized units are labeled with humidity-sensitive indicators and handling symbols per ISO 780, including “This Way Up” and “Fragile” markings. This integrated approach ensures flat magnet wire arrives at destination ports with zero corrosion, insulation damage, or dimensional variance—critical for high-reliability applications in EV motors and industrial transformers. Our documented 99.8% on-time, damage-free delivery rate across 40+ countries underscores the efficacy of this methodology for global supply chain resilience.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Flat Magnet Wire Solutions

With over two decades of specialized expertise in the production of winding wires, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted industrial partner for global manufacturers requiring high-performance flat magnet wire. Our vertically integrated manufacturing platform, located in Luoyang, China, combines advanced metallurgical engineering with rigorous quality control to deliver products that meet the exacting demands of transformers, reactors, motors, and high-efficiency electrical systems.

Our production capabilities are anchored in state-of-the-art drawing and insulation coating technologies, enabling us to produce flat aluminum and copper magnet wires with precise dimensional tolerances, superior surface finish, and consistent electrical performance. We offer a full range of conductor sizes, from 1.0 mm to 8.0 mm in width and 0.5 mm to 3.0 mm in thickness, tailored to customer specifications. All materials are processed under controlled environments to ensure minimal oxide formation and optimal conductivity. Our aluminum magnet wires are manufactured using high-purity 1350-O and 1370-O alloys, while copper variants are produced from OFHC (Oxygen-Free High Conductivity) copper, ensuring compliance with IEC 60317, GB/T 23312, and equivalent international standards.

Quality assurance is embedded throughout our manufacturing workflow. Each batch undergoes comprehensive testing for electrical resistivity, thermal endurance, dielectric strength, and mechanical flexibility. Our in-house laboratory is equipped with precision instruments including automatic resistance bridges, high-voltage testers, and thermal aging chambers, enabling real-time validation of product performance. We maintain ISO 9001 and IATF 16949 certifications, underscoring our commitment to process consistency and continuous improvement.

Beyond technical excellence, Luoyang Xinzhaohe delivers competitive advantages through supply chain efficiency and responsive customer engineering support. We operate a 20,000-ton annual production capacity with automated warehousing and just-in-time delivery logistics, ensuring on-time shipment to international markets. Our technical team collaborates directly with clients during the design and prototyping phases, offering material selection guidance, winding compatibility analysis, and custom insulation system development.

As global demand for energy-efficient electrical components grows, partnering with a reliable, technically proficient supplier becomes critical. Luoyang Xinzhaohe Aluminum Co., Ltd combines deep metallurgical knowledge, scalable manufacturing, and customer-centric service to support long-term success in the winding wire industry.

For technical inquiries, sample requests, or to discuss your flat magnet wire requirements, contact us at cathy@transformerstrip.com. Our engineering and sales team is ready to provide data sheets, pricing, and production timelines tailored to your project needs.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing flat magnet wire directly from China.