Table of Contents

Market Insight: Flat Enameled Wire

Market Analysis: Winding Wire Demand for Transformers

Industrial demand for flat enameled wire, specifically rectangular cross-section magnet wire, remains robust and strategically critical within the global transformer manufacturing sector. This demand is primarily driven by the relentless expansion of electrical infrastructure, particularly in renewable energy integration, urbanization projects, and grid modernization initiatives worldwide. Key growth vectors include the proliferation of distribution transformers for smart grids, high-efficiency power transformers for renewable energy substations (solar and wind), and specialized units for industrial motor drives and traction applications. Stringent international energy efficiency standards, such as IE4 and IE5 for motors and comparable regulations for transformers (e.g., DOE 2016 in the US, Ecodesign Lot 20 in the EU), necessitate superior core and winding materials. Flat enameled wire, with its optimized space utilization in windings compared to round wire, directly contributes to achieving these higher efficiency classes by enabling denser coil packing and reduced copper or aluminum losses. The shift towards aluminum as a core conductor material, driven by significant cost and weight advantages (approximately 35-40% lower raw material cost versus copper), further intensifies demand for high-performance aluminum flat enameled wire solutions meeting exacting electrical and mechanical specifications.

The paramount importance of wire quality cannot be overstated, as it directly dictates transformer reliability, lifespan, and operational safety. Substandard enameled wire introduces critical failure points. Inadequate enamel insulation integrity, characterized by pinholes, thin spots, or poor adhesion, compromises dielectric strength. This significantly increases the risk of inter-turn or turn-to-ground short circuits under operational voltage stresses, particularly during transient events like switching surges or lightning strikes. Such faults often initiate catastrophic cascade failures within the transformer core and windings. Furthermore, poor thermal stability of the enamel system—failing to meet required thermal classes (e.g., Class 180, 200, 220 per IEC 60317)—leads to accelerated insulation degradation at elevated operating temperatures. This degradation manifests as reduced mechanical strength, increased brittleness, and ultimately, thermal runaway. Consistent conductor dimensional tolerances and surface smoothness are equally vital; variations cause uneven winding tension, localized hotspots, and reduced thermal conductivity between turns, undermining the efficiency gains targeted by modern designs. Partial discharge inception voltage (PDIV) is a critical quality metric; low PDIV indicates micro-voids or impurities within the enamel, initiating damaging partial discharges that erode insulation over time, even below nominal operating voltages.

For transformer manufacturers, sourcing flat enameled wire is not a commodity decision but a fundamental risk management and performance optimization strategy. Inferior wire necessitates costly over-engineering of the transformer design to compensate for reliability uncertainties or leads directly to field failures with severe financial and reputational consequences. High-purity aluminum conductors with precisely controlled metallurgical properties, combined with advanced multi-layer enamel systems exhibiting exceptional thermal endurance, dielectric strength, flexibility, and chemical resistance, are non-negotiable for meeting modern transformer lifecycle expectations. The premium paid for certified, consistently high-quality flat enameled wire translates directly into reduced warranty claims, extended service life exceeding 30 years, lower total cost of ownership, and compliance with the most rigorous global safety and performance standards. In this context, supplier expertise in metallurgical process control and enamel formulation is as critical as the raw material specifications themselves. Quality is the cornerstone of transformer reliability, demanding rigorous supplier qualification and stringent incoming inspection protocols focused on both material composition and finished wire performance characteristics. The sourcing decision carries a significant reliability premium.

Technical Specs: Flat Enameled Wire

Technical Specifications for Flat Enameled Wire

Flat enameled wire, also known as rectangular magnet wire, is a precision-engineered conductor primarily used in high-efficiency electrical windings for transformers, inductors, motors, and generators. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and manufacturing expertise, our flat enameled wire is produced to meet stringent international standards, ensuring optimal performance under demanding thermal and electrical conditions. The technical specifications governing this product are critical to its reliability and integration into advanced electromagnetic systems. Key parameters include insulation breakdown voltage, elongation, and thermal class, all of which are rigorously controlled during production.

Insulation breakdown voltage is a fundamental indicator of the dielectric strength of the enamel coating. This parameter determines the maximum electric field the insulation can withstand before electrical failure occurs. For flat enameled wire, a high breakdown voltage ensures operational safety and long-term insulation integrity, particularly in high-voltage applications. Our manufacturing process employs multi-layer polymer coatings—typically polyurethane, polyester-imide, or polyamide-imide—applied with precision to achieve consistent thickness and defect-free coverage. The breakdown voltage is measured per unit thickness and is directly influenced by coating uniformity and substrate surface preparation.

Elongation, expressed as a percentage, reflects the mechanical ductility of the conductor. It is a measure of how much the wire can stretch before fracture under tensile stress. High elongation values are essential for winding processes, especially in tight-radius applications where mechanical deformation is inevitable. Aluminum-based flat enameled wire typically exhibits elongation values ranging from 1.5% to 6%, depending on alloy composition and temper. Our proprietary annealing techniques enhance ductility while maintaining adequate tensile strength, allowing for smooth, crack-free winding without compromising structural integrity.

Thermal class defines the maximum continuous operating temperature the wire can endure without significant degradation of electrical or mechanical properties. Our flat enameled wire series covers thermal classes from 130°C to 220°C, enabling application-specific selection based on thermal environment. Higher thermal classes utilize advanced insulation systems such as triple-layer coatings (e.g., PEI/PAI) to resist thermal aging, chemical exposure, and thermal shock. These materials are tested per IEC 60317 and ASTM D2343 standards to validate thermal endurance and thermal shock resistance.

The following table outlines the typical technical parameters for our flat enameled aluminum wire products:

| Parameter | Test Method | Typical Value Range | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60172, ASTM D437 | 3,000 – 8,000 V (rms) | Measured at 90% coating thickness |

| Elongation | ASTM E8/E8M | 1.5% – 6.0% | Depends on temper and alloy grade |

| Thermal Class | IEC 60172, UL 1446 | 130°C, 155°C, 180°C, 200°C, 220°C | Based on insulation system |

| Conductor Material | GB/T 3954 | Aluminum 1350, 8030 | High purity, low oxygen content |

| Dimensional Tolerance | IEC 60121 | ±0.02 mm (thickness), ±0.03 mm (width) | Precision rolled and ground profiles |

These specifications are validated through in-house quality control systems, including continuous monitoring during drawing, annealing, and coating processes. All batches undergo rigorous electrical, mechanical, and thermal testing to ensure compliance with customer and industry requirements.

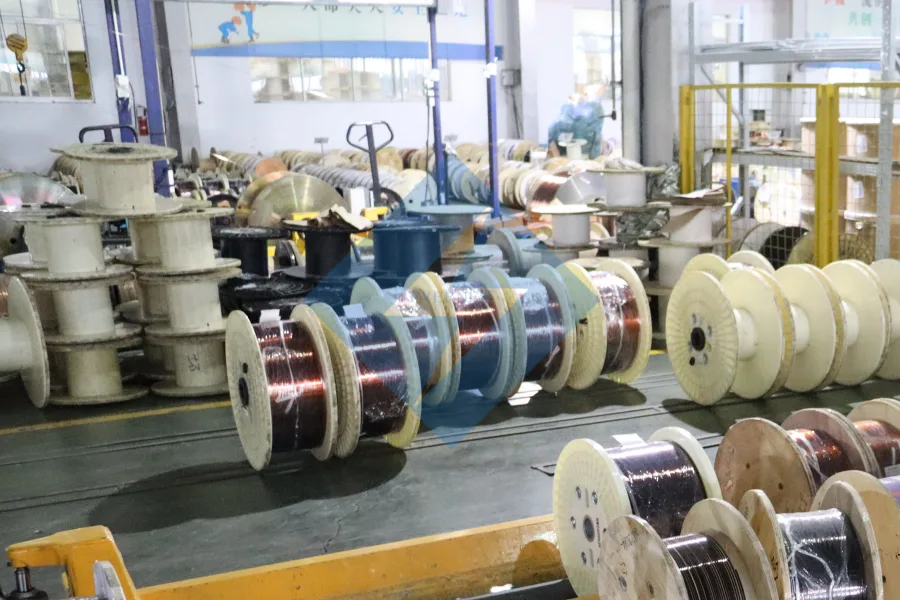

Factory Tour: Manufacturing

Manufacturing Process for Flat Enameled Aluminum Wire

Luoyang Xinzhaohe Aluminum Co., Ltd employs a rigorously controlled sequence to produce high-performance flat enameled aluminum winding wire, leveraging 20+ years of metallurgical expertise. The process begins with high-purity aluminum rod (GB/T 3954 Grade A, ≥99.7% Al), subjected to precision rod drawing. This stage utilizes multi-die continuous drawing blocks with computerized tension control to achieve the target rectangular cross-section. Critical parameters include die geometry calibration, lubricant chemistry (synthetic aqueous emulsions), and incremental reduction ratios (typically 15–20% per pass) to prevent surface defects and internal stress buildup. In-process diameter verification occurs via laser micrometers at 5-meter intervals, ensuring dimensional tolerance adherence within ±0.01 mm.

Subsequent annealing occurs in a continuous nitrogen-purged furnace system operating at 200–300°C. This recrystallization step eliminates work hardening from drawing, restoring optimal electrical conductivity (≥61% IACS) and ductility for winding. Precise residence time control (±2 seconds) and oxygen content <10 ppm prevent oxide inclusion formation, which could compromise enamel adhesion. Post-annealing, the wire undergoes ultrasonic cleaning in deionized water to remove residual lubricants and particulates, followed by immediate drying at 80°C to avoid surface recontamination.

The enameling phase applies multiple polymer layers via precision die coating. A base coat of modified polyesterimide ensures adhesion to aluminum, followed by functional topcoats (e.g., polyamide-imide for thermal class 200°C). Each layer is cured in-stage at 450–550°C under controlled oxygen levels to achieve complete cross-linking without thermal degradation. Film thickness is maintained at 30–120 μm per side through real-time viscometer feedback and optical micrometer monitoring.

Inline testing validates performance at production speed (up to 120 m/min). Critical checks include:

| Test Parameter | Standard Requirement | Xinzhaohe Control Limit | Method |

|---|---|---|---|

| Dielectric Strength | ≥1800 V (IEC 60317) | ≥2200 V | 100% spark testing |

| Elongation | ≥8% | ≥10% | Tensile testing |

| Adhesion (Pin Test) | Pass (IEC 60851-5) | Zero flaking | Mandrel wrap |

| Continuity | 0 breaks/km | 0 breaks/10 km | Electrical monitoring |

Final quality control integrates destructive testing on 1% of production lots: thermal shock (200°C/30 min), solderability (280°C/3 sec), and accelerated aging per IEC 60172. All process data is traceable via batch-specific digital logs, enabling root-cause analysis for continuous improvement. This integrated approach ensures consistent delivery of enameled wire meeting IEC 60317 and customer-specific specifications for demanding motor and transformer applications.

Packaging & Logistics

Export Packaging for Flat Enameled Aluminum Winding Wire

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in enameled aluminum winding wire, we maintain stringent standards for export packaging to ensure product integrity during international transit. Given the hygroscopic nature of enameled insulation and the dimensional sensitivity of flat wire profiles, our packaging system is engineered to mitigate mechanical stress, moisture ingress, and environmental degradation—particularly critical during prolonged sea freight operations.

All flat enameled wire reels are mounted on precision-machined, kiln-dried wooden pallets that comply with ISPM 15 regulations for international wood packaging. These pallets provide structural stability, distribute load weight evenly, and are compatible with standard container handling equipment. Each reel is securely fastened to prevent axial or radial movement during vessel roll, pitch, and vibration conditions common in maritime transport. The use of solid hardwood components ensures resistance to compression and splintering, even under multi-tier stacking within shipping containers.

Immediately following spooling and final inspection, each wound reel is hermetically sealed using multi-layer moisture-proof composite film. This vapor barrier film consists of aluminum foil laminates with low water vapor transmission rates (WVTR < 0.5 g/m²/day), effectively isolating the enameled wire from ambient humidity. Desiccant packs are strategically placed within the sealed envelope to absorb residual moisture and buffer against condensation risks during temperature fluctuations across climatic zones.

The sealed unit is then overwrapped with high-density polyethylene (HDPE) outer sheathing to provide abrasion resistance and additional protection against salt-laden atmospheres encountered in marine environments. Critical handling labels, including “Do Not Stack,” “Protect from Moisture,” and “This Side Up,” are affixed to all four sides of the pallet to guide proper stowage and handling.

For containerized shipments, we recommend the use of 20-foot or 40-foot dry van containers with controlled ventilation settings when possible. Pallets are arranged to minimize void spaces, reducing the potential for shifting. Optional container desiccants (e.g., ClimaDry or Absorpole systems) can be deployed to actively regulate internal humidity over voyages exceeding 30 days.

Our packaging protocol has been validated across major trade routes—including Asia to Europe, North America, and Southeast Asia—with zero reported incidents of moisture-related insulation failure or mechanical deformation. This reliability stems from rigorous internal testing, including simulated salt spray, drop, and vibration trials per ASTM D4169 and ISTA 3A standards.

By integrating robust wooden palletization with advanced moisture barrier technology, Luoyang Xinzhaohe ensures that flat enameled aluminum winding wire arrives at destination facilities in optimal condition, ready for immediate processing in motor, transformer, and inductor manufacturing lines.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Flat Enameled Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and industrial manufacturing expertise to deliver high-performance flat enameled aluminum winding wire. Our vertically integrated facility, purpose-built for aluminum conductor production, provides unparalleled control over the critical parameters defining wire reliability in demanding electromagnetic applications. We understand that sourcing flat enameled wire requires assurance beyond basic specifications; it demands a partner with deep process mastery and a commitment to consistent, traceable quality.

Our core strength resides in advanced aluminum metallurgy and precision wire processing. We utilize 99.99% purity aluminum ingot, subjected to rigorous in-house chemical analysis and proprietary melting/casting protocols to minimize impurities and ensure optimal electrical conductivity. This foundational control is essential for achieving the target resistivity required in aluminum enameled wire designs. The flat wire drawing process employs computer-controlled multi-die blocks with laser micrometers for real-time dimensional verification, guaranteeing tight tolerances on width, thickness, and edge profile critical for efficient coil winding density and thermal management. Surface integrity is paramount; our continuous annealing and cleaning lines operate under strict inert atmosphere control to prevent oxidation prior to enameling.

The enameling application represents a critical value-add where our engineering focus delivers tangible performance benefits. We deploy state-of-the-art multi-layer coating systems with precise viscosity and temperature regulation for uniform film build. Our formulations, developed in collaboration with leading resin suppliers, offer superior thermal class performance (up to 220°C), exceptional dielectric strength, and robust mechanical properties including scratch resistance and flexibility essential for high-speed winding operations. Every batch undergoes stringent in-process and final electrical testing per IEC 60317 standards, including breakdown voltage, continuity, and thermal endurance verification. Full material traceability from ingot to finished spool is maintained through our integrated ERP system.

Our supply chain infrastructure is engineered for industrial reliability. With an annual production capacity exceeding 10,000 metric tons of flat aluminum wire, we maintain strategic raw material buffers and flexible scheduling to meet demanding project timelines. Dedicated logistics protocols ensure moisture-sensitive enameled wire is handled and shipped in climate-controlled containers with desiccant, preventing hydrolysis during transit. We hold ISO 9001 certification, with documented quality management systems audited by major transformer and motor OEMs.

Partnering with Luoyang Xinzhaohe means accessing not just a supplier, but a metallurgical and process engineering resource committed to solving your specific winding challenges. We collaborate closely with design and procurement teams to optimize wire specifications for performance, manufacturability, and cost-efficiency within your unique application constraints.

Technical Specifications Overview

| Parameter | Capability Range | Control Standard |

|---|---|---|

| Conductor Material | AL 1350 / AL 1370 | ASTM B233, GB/T 3954 |

| Width | 1.00 mm – 10.00 mm | ±0.02 mm |

| Thickness | 0.50 mm – 3.00 mm | ±0.01 mm |

| Enamel Thermal Class | 180 (H) to 220 (C) | IEC 60317 |

| Min. Breakdown Volt | 3000 V AC (1 min) | IEC 60851-5 |

| Min. Elongation | 1.5% | ASTM B233 |

For detailed technical consultation or to discuss your specific flat enameled wire requirements, contact our engineering team directly. Cathy Zhang provides dedicated B2B support for global sourcing partners. Reach out to initiate a technical dialogue: cathy@transformerstrip.com.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing flat enameled wire directly from China.