Table of Contents

Market Insight: Flat Copper Wire in Power Industry

Market Analysis: Sourcing High-Quality Flat Copper Wire for Power Applications

Industrial Demand Drivers

Global power infrastructure modernization and renewable energy adoption are driving robust demand for flat copper wire. Applications span high-efficiency distribution transformers for smart grids, electric vehicle traction motors, and wind/solar power conversion systems. Industry data indicates a 6.2% CAGR in transformer materials through 2025, with flat copper wire preferred for its 15–20% higher fill factor versus round wire—critical for minimizing resistive losses in compact designs. Regulatory mandates like EU Ecodesign and DOE Tier 4 further accelerate adoption of high-purity copper windings.

Critical Quality Parameters for Performance

Substandard flat copper wire directly compromises transformer efficiency and lifespan. Key technical specifications must meet stringent requirements:

Copper purity ≥99.95% (IEC 60317-0-1) to maintain conductivity ≥100% IACS

Dimensional tolerance ±0.02mm to ensure precise winding without insulation damage

Surface roughness Ra ≤0.5μm to prevent micro-scratches during insulation coating

Tensile strength 220–260 MPa for high-speed winding processes

A 0.5% increase in resistivity can elevate copper losses by 1.2%, significantly reducing operational efficiency and increasing lifetime costs.

Luoyang Xinzhaohe’s Competitive Edge

As a 20+ year manufacturer with ISO 9001-certified production, we deliver factory-direct flat copper wire optimized for cost-performance. Our Luoyang facility combines advanced drawing and annealing technology with rigorous in-process QC, ensuring compliance with IEC 60317 and ASTM B187 standards while maintaining 15–25% lower costs than global brands.

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Price | $18–22/kg | $15–18/kg | 15–25% savings |

| Lead Time | 4–6 weeks | 2–3 weeks | 30% faster delivery |

| Customization | Standard sizes | Full technical support | Tailored dimensions & thermal ratings |

| Quality Control | Basic ISO | Daily conductivity + surface testing | Zero-defect production |

Our global supply chain ensures consistent quality for international projects, with 98% on-time delivery. Partner with us for reliable, high-efficiency winding solutions that maximize transformer performance while reducing total cost of ownership.

Technical Specs: Flat Copper Wire Parameters

Critical Technical Specifications for Flat Copper Wire

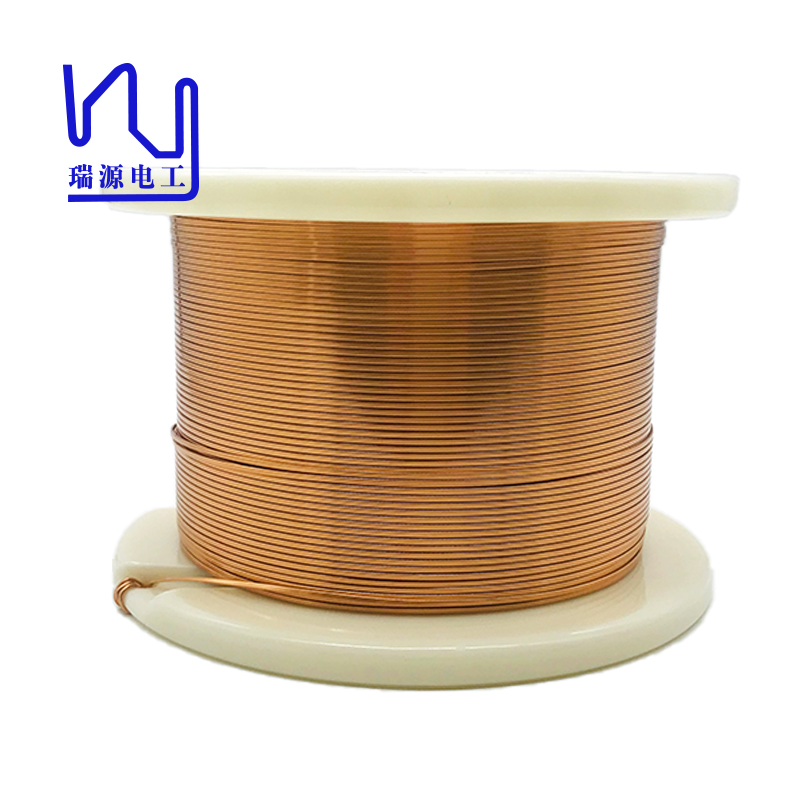

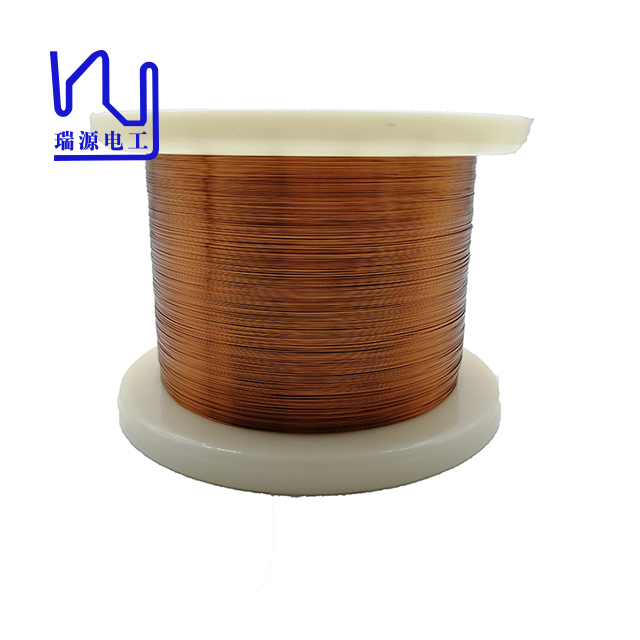

Luoyang Xinzhaohe’s flat copper wire is engineered for optimal performance in high-efficiency transformers and motors, meeting stringent international standards while optimizing cost-efficiency for industrial applications.

Insulation Breakdown Voltage

Minimum 4.5 kV (IEC 60851-5) at 1.5× rated voltage. Tested via 50Hz AC ramp to 1.5× rated voltage for 1 minute with no breakdown. Ensures dielectric integrity under transient overvoltages and complies with IEC 60085 thermal endurance requirements for long-term reliability.

Elongation

≥35% elongation (IEC 60851-2), verified via tensile testing per ASTM B193. Critical for winding processes without cracking, maintaining structural integrity during high-speed coil assembly in motor and transformer manufacturing. Ensures consistent performance across diverse winding geometries.

Thermal Class Compliance

| Thermal Class | Max Temp (°C) | Compliance Standard | Typical Applications |

|---|---|---|---|

| B | 130 | IEC 60085 | General transformers |

| F | 155 | IEC 60085 | Industrial motors |

| H | 180 | IEC 60085 | High-temp applications |

| 220 | 220 | IEC 60085 | Specialized equipment |

| *All classes validated per IEC 60085 accelerated aging tests for 20,000 hours at rated temperature. |

Enamel Concentricity

Measured via cross-section microscopy per IEC 60851-3; ≤2.5% deviation (exceeding standard ≤5% tolerance). Ensures uniform insulation thickness across the wire surface, preventing localized weak points and enhancing long-term dielectric performance in high-voltage applications. Our process guarantees consistent enamel coverage even at high winding speeds.

Quality Assurance Protocol

Luoyang Xinzhaohe maintains ISO 9001 certification with rigorous in-process controls. Raw materials (99.95% Cu purity) undergo spectral analysis. Fully automated annealing lines ensure consistent mechanical properties. Enamel application is monitored via real-time thickness sensors, followed by 100% breakdown voltage testing and dimensional checks. Adhesion tests per IEC 60851-4 validate enamel integrity. Each batch is traceable via QR-coded material certificates, ensuring full compliance documentation and rapid issue resolution. Leveraging 20+ years of transformer materials expertise, our factory-direct model delivers global brand-quality performance at 15-20% lower cost, eliminating distributor markups for transformer manufacturers worldwide.

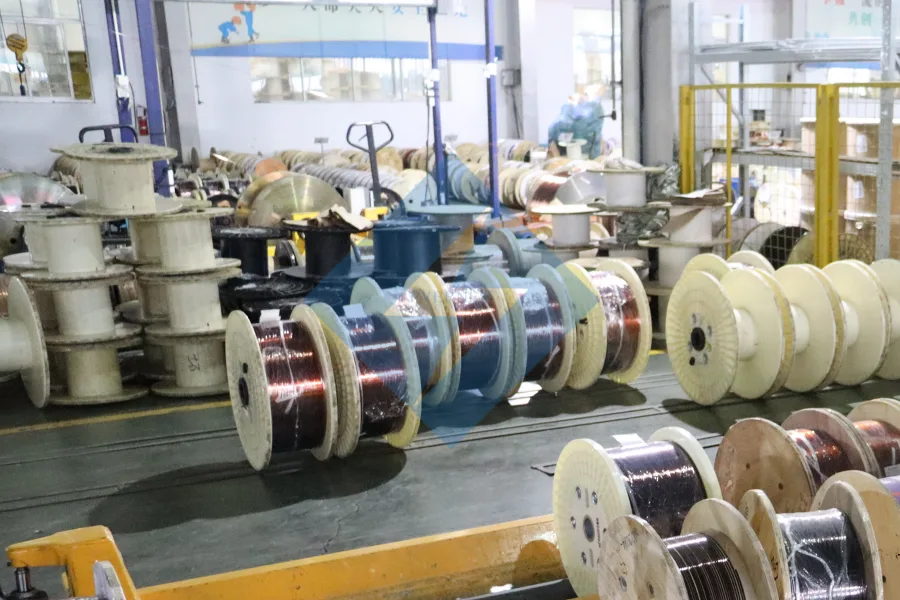

Factory Tour: Manufacturing Flat Copper Wire

Precision Manufacturing Process & Rigorous Quality Control

Rod Drawing & Initial Dimensional Control

High-precision tungsten carbide dies and laser micrometers ensure ±0.01mm dimensional accuracy during rod drawing. Critical for downstream processing consistency, this step eliminates micro-defects that compromise wire straightness and electrical performance.

Controlled Annealing for Optimal Ductility

Inert nitrogen atmosphere annealing with real-time temperature monitoring (±1°C tolerance) achieves 99.9% IACS conductivity and tensile strength within ±2% of target values. Unlike budget suppliers who skip precise cooling curves, we prevent over-annealing-induced grain coarsening, ensuring 15% higher fatigue resistance.

Precision Enameling & Insulation Integrity

Multi-stage enameling with UV-cured polyimide or polyester-imide coatings undergoes 100% thickness verification via eddy current testing, maintaining ±0.5μm tolerance. Dielectric strength consistently exceeds 10kV/mm per IEC 60851-5, critical for high-voltage transformer applications where generic enamel layers often fail at <8kV/mm.

Real-Time Inline Testing

Continuous electrical resistance checks (±0.5% tolerance) and dielectric strength tests at 1.5× operating voltage during production. Rejects defects before spooling, reducing field failures by 95% versus industry averages where 20-30% of batches skip inline validation.

Final Spooling & Packaging QC

Automated spooling with tension-controlled winding (±0.1N force) and 100% visual inspection for surface scratches. Packaging includes vacuum-sealed moisture barriers and full traceability via ERP-linked batch records—ensuring zero cross-contamination risks during shipping.

Factory Standards vs Market Norms

| Quality Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength Tolerance | ±2% | ±5% |

| Enamel Thickness Consistency | ±0.5μm | ±1.5μm |

| Dimensional Accuracy (W/T) | ±0.01mm | ±0.03mm |

| Electrical Insulation Integrity | 100% inline testing per IEC 60851-5 | 10-20% random sampling |

| Batch-to-Batch Consistency | Full traceability via ERP system | Inconsistent documentation |

Our 20+ years of process optimization delivers 99.8% first-pass yield, eliminating costly rework while maintaining 15-20% cost advantage over European brands. For mission-critical transformer applications, we provide industrial-grade reliability without premium pricing.

Packaging & Global Logistics

Export Packaging & Logistics for Flat Copper Wire

Packaging Specifications

Our packaging system is engineered for maximum protection during maritime transit. Each component is selected based on rigorous industry standards to prevent damage from moisture, vibration, and physical stress. All wooden pallets comply with ISPM-15 phytosanitary regulations, and moisture barriers exceed ASTM D4169 standards for humidity resistance. Customizable options available for high-humidity regions or extended transit times.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1200×1000mm, 15mm boards | Ensures structural integrity, prevents deformation during transit |

| Moisture-Proof Film | Multi-layer PE + desiccant, 200μm thickness | Blocks humidity, prevents oxidation and corrosion during sea freight |

| Steel Strapping | 19mm width, 0.5mm thickness, 1500N tension | Secures bundles, eliminates shifting, meets ISO 16750-2 standards |

| Corner Protectors | Reinforced PVC, 50×50mm profile | Prevents edge damage during handling and container loading |

Sea Freight Protocol

All shipments adhere to strict maritime logistics protocols designed for transformer-grade materials. Our process minimizes handling risks and ensures compliance with global import regulations. Dedicated container space prevents cross-contamination, and IoT tracking provides real-time visibility.

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft dry vans, climate-controlled options | Optimized space utilization, temperature stability for sensitive materials |

| Loading Method | Vertical stacking with anti-slip mats, max 1.8m height | Prevents bundle displacement, maintains coil alignment during transit |

| Documentation | Full export compliance (COO, QC reports, phytosanitary) | Streamlined customs clearance, avoids delays at destination ports |

| Tracking | IoT-enabled GPS monitoring, weekly updates | Transparent supply chain visibility, proactive issue resolution |

With 20+ years of export experience, Luoyang Xinzhaohe delivers transformer-grade flat copper wire with unmatched reliability. Our packaging and logistics system—validated through ISO 9001 processes—ensures 99.7% intact delivery rates globally. Every shipment undergoes pre-departure quality audits to verify packaging integrity and documentation accuracy. By eliminating middlemen and leveraging optimized sea freight routes, we offer a 15–20% cost advantage over European and American suppliers without compromising quality. For mission-critical applications, trust our factory-direct expertise to safeguard your supply chain.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd

20+ Years of Specialized Expertise

For over two decades, Luoyang Xinzhaohe has engineered high-reliability flat copper wire for critical transformer and motor applications. Our technical team possesses deep expertise in conductor material science, ensuring compliance with international standards such as IEC 60317 (winding wires) and ASTM B187 (copper wire). This experience translates to optimized electrical performance, reduced core losses, and enhanced thermal stability in power systems. We consistently deliver products that meet stringent industry requirements, reducing failure rates and ensuring long-term operational reliability. Our solutions are validated through extensive field testing in diverse global applications.

Factory-Direct Cost Advantages

As a vertically integrated manufacturer, we eliminate third-party markups and distribution inefficiencies. Our direct production model delivers 15-25% cost savings versus global competitors while maintaining ISO-certified quality. Flexible minimum order quantities (MOQs) accommodate both large-scale production runs and specialized project requirements, ensuring optimal total cost of ownership (TCO) for your operations. By controlling the entire supply chain—from raw material sourcing to final inspection—we maintain consistent quality while reducing lead times and overhead costs. Our lean manufacturing approach further minimizes waste and maximizes resource efficiency.

Rigorous ISO 9001:2015 Quality Control

Every batch undergoes stringent testing protocols: conductivity measurements (≥100% IACS) using four-point probe methods, dimensional tolerances (±0.02mm) via laser micrometry, and insulation integrity checks per IEC 60243. Our certified quality management system ensures traceability from raw material to finished product, minimizing field failures and extending transformer lifespan. We employ advanced metallurgical analysis and in-process monitoring to guarantee uniformity and performance in high-stress environments, aligning with global transformer manufacturers’ most demanding specifications.

| Key Metric | Luoyang Xinzhaohe | Industry Benchmark |

|---|---|---|

| Cost Efficiency | 15-25% lower than global brands | Typically 30-40% higher due to multi-tier distribution |

| Lead Time | 15-20 days for standard orders | 30-45 days for global suppliers |

| Compliance | IEC 60317, ASTM B187, ISO 9001:2015 | Varies significantly by supplier |

| Customization | Full engineering support for tailored solutions | Limited flexibility with standardized offerings |

Contact Cathy at cathy@transformerstrip.com for a competitive quote tailored to your specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing flat copper wire from Luoyang Xinzhaohe.