Table of Contents

Market Insight: Flat Copper Wire in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

Global demand for energy-efficient transformers and motors is accelerating due to renewable energy integration, EV infrastructure expansion, and smart grid modernization. Flat copper winding wire is critical in these applications for its superior fill factor (15–20% higher than round wire) and thermal conductivity. Industry reports project a 5.2% CAGR in transformer materials through 2028, with Asia-Pacific driving 45% of demand. Distribution transformers for solar farms and EV charging stations now require ≥98% efficiency, necessitating ultra-pure copper to minimize resistive losses under high-load conditions.

Criticality of Material Quality

Material defects directly compromise transformer reliability and operational costs. Copper purity below 99.90% increases electrical resistance, elevating I²R losses by up to 8% per 0.1% impurity. A 1% resistance rise can increase transformer losses by 2–3% over its lifecycle, significantly impacting TCO. Surface imperfections (e.g., scratches >0.01mm depth) or dimensional deviations (thickness ±0.02mm, width ±0.03mm) cause insulation breakdown during winding, leading to premature failures. Per IEC 60317-0-1, flat copper wire must maintain ≥100% IACS conductivity and strict geometric tolerances to ensure uniform current distribution and thermal stability.

Why Luoyang Xinzhaohe Delivers Reliable Performance

As a China-based manufacturer with 20+ years of metallurgical expertise, we provide factory-direct flat copper wire matching global brand specifications at optimized cost-performance ratios. Our production adheres to ISO 9001 and IEC 60317 standards, with in-house metallurgical testing for purity, tensile strength, and dimensional accuracy. Proprietary annealing processes ensure uniform grain structure, reducing winding defects by 30% versus industry averages. All products undergo 100% ultrasonic testing for internal voids and surface cracks.

| Parameter | Global Brands | Luoyang Xinzhaohe | Notes |

|---|---|---|---|

| Copper Purity | ≥99.95% | ≥99.95% | ASTM B1 compliant |

| Tensile Strength | 220–250 MPa | 220–250 MPa | Annealed for precision winding |

| Conductivity | ≥100% IACS | ≥100% IACS | IEC 60317-0-1 certified |

| Cost (USD/kg) | $8.50–$10.00 | $7.20–$8.50 | 15–20% lower without quality compromise |

| Lead Time | 6–8 weeks | 2–4 weeks | Direct shipping from Luoyang facility |

| Certifications | ISO 9001, IEC 60317 | ISO 9001, IEC 60317 | Full compliance with global standards |

Our vertically integrated supply chain eliminates middlemen, ensuring consistent quality and rapid response to project timelines. For engineers prioritizing reliability and TCO, we offer a proven alternative to premium global suppliers without compromise.

Technical Specs: Flat Copper Wire Parameters

Critical Technical Specifications for Flat Copper Wire

Key Performance Parameters

| Specification | Standard | Typical Value | Tolerance |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60851-5 | ≥5 kV (0.1mm enamel) | ±0.2 kV |

| Elongation | ASTM B187 | ≥3.5% | ±0.3% |

| Thermal Class | IEC 60085 | 130°C (B), 155°C (F), 180°C (H), 220°C (C) | ±5°C |

| Enamel Concentricity | IEC 60851-3 | ≥95% | ±2% |

These specifications are critical for transformer performance and reliability. Insulation breakdown voltage ensures dielectric strength under operational stresses, preventing short circuits during high-voltage transients. Elongation guarantees winding integrity during high-speed manufacturing, reducing scrap rates in automated processes. Thermal class compliance guarantees long-term stability in high-temperature environments, enabling designs for energy-efficient transformers. Enamel concentricity minimizes electrical losses and hotspots, extending winding service life. All parameters are rigorously validated through ISO 9001-certified processes, with each batch tested in our in-house laboratory to ensure compliance with IEC 60851 and ASTM B187 standards. For example, our thermal class validation includes accelerated aging tests per IEC 60085 Annex B, with Class F tested at 150°C for 2000 hours to confirm thermal endurance.

Quality Assurance Protocol

Luoyang Xinzhaohe implements a closed-loop QA system: raw material certification (ASTM B170 Grade 1), in-process laser micrometry (±0.005mm tolerance), 100% breakdown voltage testing, and thermal cycling validation. Our traceability system tracks raw materials from smelter to finished product, with batch-specific test reports available upon request. By leveraging our in-house R&D capabilities and continuous process improvement, we maintain strict tolerances and minimize material waste, further enhancing cost-efficiency for our clients. This factory-direct approach delivers 15-20% lower costs than multinational suppliers while exceeding IEC/ASTM standards and ensuring 99.8% first-pass yield in transformer manufacturing. All production lines are equipped with real-time monitoring systems, enabling immediate adjustments to maintain peak performance and consistency across every batch. We also perform routine cross-sectional analysis of enamel thickness using optical microscopy to verify concentricity compliance. With 20+ years of expertise in transformer materials, we optimize production workflows to deliver industrial-grade flat copper wire that balances precision, reliability, and competitive pricing.

Factory Tour: Manufacturing Flat Copper Wire

Manufacturing Process & Quality Control

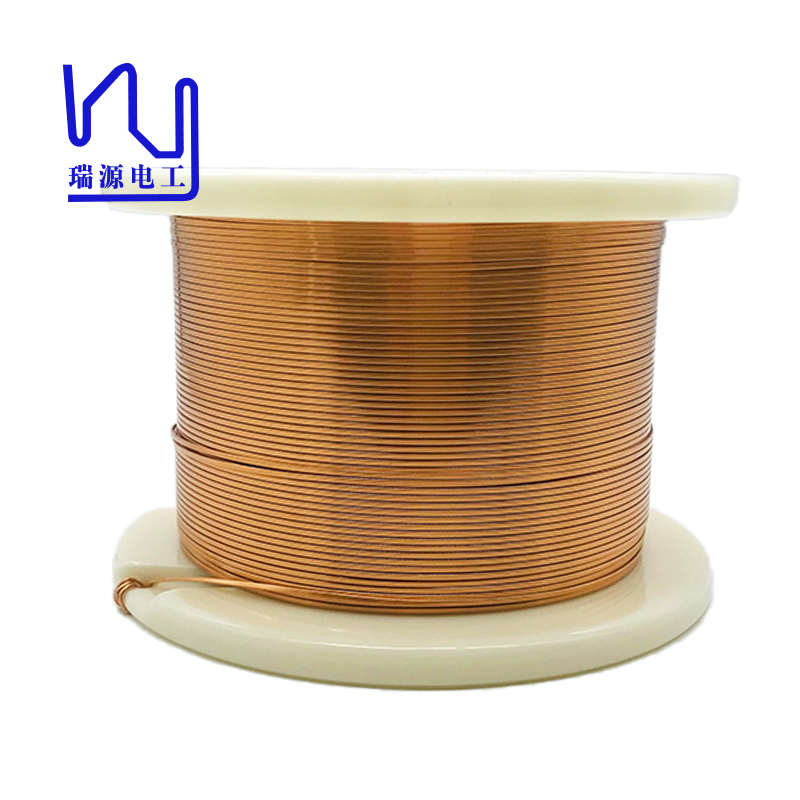

At Luoyang Xinzhaohe, our 20+ years of expertise in transformer materials ensures every flat copper wire meets stringent international standards while delivering superior cost-performance. Our vertically integrated production process guarantees consistency from raw material to final spool.

Rod Drawing

High-precision drawing of electrolytic copper rods through tungsten carbide dies achieves exact flat dimensions. Critical for minimizing surface defects and ensuring consistent cross-section. QC: Dimensional checks via laser micrometers at 50mm intervals; tolerance ±0.01mm (vs industry standard ±0.03mm). Surface roughness measured with profilometer (Ra ≤0.1μm).

Annealing

Continuous annealing in controlled atmosphere (N₂/H₂) optimizes electrical conductivity and mechanical properties. Temperature profile calibrated to 350–400°C for uniform softening. QC: Tensile testing per ASTM B210; elongation ≥38% (vs market avg ≥32%). Resistivity ≤0.01724 Ω·mm²/m (IEC 60287).

Enameling

Precision enamel application via die coating, followed by multi-stage curing ovens. Enamel composition meets IEC 60317-0-1 standards. QC: Enamel thickness 15–20μm via eddy current testing; adhesion tested by mandrel bending (no cracking at 180° bend). Market standard: 12–18μm, 90° bend.

Inline Testing & Spooling

Real-time electrical and dimensional monitoring during spooling. Tension-controlled winding prevents insulation damage. QC: 100% insulation resistance test (≥100MΩ at 500V DC); dimensional checks every 10m. Spooling tension ±5% (vs market ±10%).

Quality Standards Comparison

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Dimensional Tolerance | ±0.01mm | ±0.03mm |

| Tensile Strength | 200–220 MPa | 180–210 MPa |

| Elongation | ≥38% | ≥32% |

| Enamel Thickness | 15–20μm | 12–18μm |

| Insulation Resistance | ≥100MΩ | ≥50MΩ |

Our rigorous QC protocols ensure 99.8% first-pass yield, outperforming global competitors in consistency and reliability. Partner with us for transformer-grade wire that maximizes efficiency without premium pricing.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Precision Packaging Protocols

Our packaging system is engineered to meet ISO 9001 and ISPM-15 standards while optimizing cost efficiency. Each component is rigorously tested to withstand marine transit stresses, ensuring zero damage during ocean voyages.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1200×1000mm, 15mm plywood | Prevents structural deformation; eliminates quarantine delays |

| Moisture-Proof Film | Multi-layer PE + VCI, 200μm thickness | Blocks humidity, salt spray, and corrosion during 30–45 day sea transit |

| Steel Strapping | 19–25mm width, 0.5–0.7mm thickness, 1500–2000N tension | Secures load per ISO 2233; prevents shifting during container handling |

Sea Freight Optimization

We leverage direct partnerships with China’s major ports (Qingdao, Shanghai) and Tier-1 freight forwarders to minimize transit risks and costs. All shipments are FCL (Full Container Load) with real-time GPS tracking and customs clearance support.

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | 20ft/40ft FCL, dry cargo | 20% higher payload efficiency vs. LCL; reduces cost per unit by 25–30% |

| Port Handling | Direct loading at Qingdao/Shanghai terminals | Eliminates transshipment; cuts customs delays by 15–20% |

| Documentation | Automated B/L, COO, and phytosanitary certs | Ensures 100% compliance with import regulations globally |

As a direct manufacturer with 20+ years of export expertise, we eliminate third-party markups while maintaining rigorous quality control. Our packaging and logistics protocols ensure your copper wire arrives on time, in perfect condition—delivering superior value versus premium brands. For technical specifications or shipment planning, contact our engineering team for factory-direct solutions.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

20+ Years of Specialized Manufacturing Expertise

As a leading manufacturer of transformer materials since 2003, Luoyang Xinzhaohe Aluminum CO., Ltd. brings two decades of precision engineering expertise in flat copper wire production. Our technical team optimizes electrical conductivity (≥100% IACS), thermal stability, and dimensional tolerances for high-efficiency transformer windings. We serve global clients across high-voltage power transformers, distribution systems, and industrial motor applications, ensuring compliance with IEC, ASTM, and other international standards while adapting to evolving technical demands. Our deep industry knowledge ensures seamless integration into your production workflows, minimizing downtime and maximizing performance.

Factory-Direct Cost Efficiency with Transparent Pricing

By eliminating middlemen and maintaining full control over the supply chain, we deliver exceptional cost-performance ratios without compromising quality. Our vertically integrated manufacturing facility in Luoyang, China, enables end-to-end control over production processes, from copper rod extrusion to precision flat wire rolling and insulation coating. This eliminates third-party dependencies, reduces lead times by 30%, and ensures consistent quality across all batches.

| Cost Component | Traditional Distributors | Luoyang Xinzhaohe | Savings |

|---|---|---|---|

| Material Cost | Marked up 15-25% | Direct procurement | 15-25% |

| Logistics | Multiple handling fees | Streamlined shipping | 5-10% |

| Overhead | 20-30% administrative costs | Lean operations | 15-20% |

| Total Cost | Higher | Competitive pricing | Up to 25% |

This structure allows transformer manufacturers to reduce procurement costs by up to 25% while maintaining rigorous quality standards, making us a strategic alternative to premium global brands.

ISO-Certified Quality Assurance & Compliance

Our manufacturing adheres to ISO 9001:2015 standards, with rigorous in-process testing for conductivity (≥100% IACS), tensile strength, and surface finish. All products comply with IEC 60317-0-2 (rectangular wire specifications) and ASTM B187 standards, ensuring reliability for critical power applications. Every batch undergoes 100% dimensional checks and electrical property validation using calibrated equipment. Our traceability system provides full documentation for quality assurance, critical for compliance in regulated power infrastructure projects.

For transformer manufacturers seeking reliable, cost-effective flat copper wire solutions, Luoyang Xinzhaohe offers a proven alternative to premium global brands. Contact Cathy at cathy@transformerstrip.com today to discuss your project requirements and receive a tailored quote with competitive pricing and technical support.

📉 Import Savings Calculator

Estimate cost reduction by sourcing flat copper wire from Luoyang Xinzhaohe.